Professional Documents

Culture Documents

Welding at C1-1

Uploaded by

mohanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding at C1-1

Uploaded by

mohanCopyright:

Available Formats

CHECK FOR WELD CAPACITY BETWEEN COLUMN WEB AND FLANGE

AT BASE OF C1-1

The weld size is to be checked for the horizontal shear force between the column flange and the web.

For our rigid frame, external shear is maximum at the base (Resting on Concrete column)

And the column size at this location is BU-I-300x5(W) +200x10(O.F) +200x10(I.F)

The horizontal shear stress at any point in the cross-section is:

V I.a.t. y

Where:

V = external vertical shear on column

I = moment of inertia of whole section

t = thickness of section at plane where stress is desired

a = area of section beyond plane where stress is desired

y = distance of center of gravity of area to neutral axis of entire section

Location: Based on the computer output already submitted the max. Shear force is 43.63kN (at

col. base)

V= 43.63/1.15 = 37.94 kN (1.15 factored load)

a = 20x1 = 20 cm2

y = 15.5cm

I = 10738.3 cm4

t = 0.5cm

The horizontal shear stress at any point in the cross-section:

37.94 x 20 x15.5

V .a . y

I .t 2.19kN / cm2

10738.3 x0.5

Horizontal shear force = 2.19 x 0.5 = 1.1kN/cm

Weld provided between column flanges to web is

Single side 5mm fillet weld (Submerged Arc Weld)

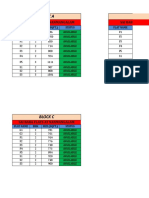

CROSS SECTION AT BASE COLUMN.

Weld capacity per cm length = 1.0 x 0.5 x 0.33 x 70 (ksi) x 0.6894

= 7.97kN/cm

The weld capacity (7.97 KN/cm) is greater than the actual horizontal force (1.1kN/cm)

From the above calculation, it is very clear that single side weld is sufficient.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rigging and Lifting Handbook SampleDocument26 pagesRigging and Lifting Handbook Samplemohan100% (1)

- Lesson 1 Egyptian CartoucheDocument4 pagesLesson 1 Egyptian CartouchemohanNo ratings yet

- Welded Built-Up Columns, April 1966: Lehigh PreserveDocument95 pagesWelded Built-Up Columns, April 1966: Lehigh PreservemohanNo ratings yet

- Block A Block B: Sai Baba Flats at Nanmangalam Sai Baba Flats at NanmangalamDocument2 pagesBlock A Block B: Sai Baba Flats at Nanmangalam Sai Baba Flats at NanmangalammohanNo ratings yet

- 03 Eurocodes Steel Workshop KUHLMANNDocument2 pages03 Eurocodes Steel Workshop KUHLMANNmohanNo ratings yet

- Asme Metric Material Secletion SheetDocument2 pagesAsme Metric Material Secletion SheetmohanNo ratings yet

- Elegant Structures: Diagrids Take To The Sky: Terri Meyer BoakeDocument13 pagesElegant Structures: Diagrids Take To The Sky: Terri Meyer BoakemohanNo ratings yet

- ?B %?C?D E Ÿ G Hiÿ J ?Ÿ K Lmÿ #HN N ?C Ÿ) Op?LDocument1 page?B %?C?D E Ÿ G Hiÿ J ?Ÿ K Lmÿ #HN N ?C Ÿ) Op?LmohanNo ratings yet

- Architects in PondicherryDocument3 pagesArchitects in PondicherrymohanNo ratings yet

- Horizontal Lifeline Systems GuidelineDocument4 pagesHorizontal Lifeline Systems GuidelinemohanNo ratings yet

- MSC Dissertation Project Guidelines - CE - 2014-15Document17 pagesMSC Dissertation Project Guidelines - CE - 2014-15mohanNo ratings yet