0% found this document useful (0 votes)

269 views5 pagesEnvironmental Audit of Kumbhi Kasari Distillery

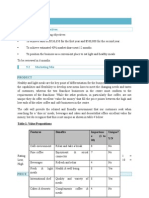

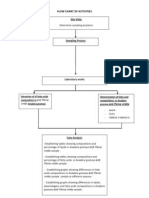

This document summarizes an environmental audit of a distillery factory located near Kolhapur, Maharashtra, India. The audit identified the factory's various waste streams and treatment processes. The distillery produces alcohol from molasses and generates spent wash wastewater. The factory has implemented an anaerobic digestion system to treat the spent wash, which reduces the organic load and yields biogas. The environmental audit aims to evaluate the distillery's environmental performance and identify opportunities to improve waste minimization and treatment.

Uploaded by

Fazreen DzulkafliCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

269 views5 pagesEnvironmental Audit of Kumbhi Kasari Distillery

This document summarizes an environmental audit of a distillery factory located near Kolhapur, Maharashtra, India. The audit identified the factory's various waste streams and treatment processes. The distillery produces alcohol from molasses and generates spent wash wastewater. The factory has implemented an anaerobic digestion system to treat the spent wash, which reduces the organic load and yields biogas. The environmental audit aims to evaluate the distillery's environmental performance and identify opportunities to improve waste minimization and treatment.

Uploaded by

Fazreen DzulkafliCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd