Professional Documents

Culture Documents

Delavan 110

Uploaded by

anghello buendia0 ratings0% found this document useful (0 votes)

9 views4 pagesinstrumetnos

Original Title

Delavan110

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinstrumetnos

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views4 pagesDelavan 110

Uploaded by

anghello buendiainstrumetnos

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

SONAC?® 110

MEFUNCTION

Single Point Switch for on-off control of liquids

METYPICAL USES

High Level Alarm or Control

Pump Control or Inlot Starvation Alarm

FlowiNo Flow Indication

Low Level Alarm or Control

MEPRIMARY AREAS OF APPLICATION

‘he Sonac® 110 provides the most reliable overtiow

alarm or control available

Where liquids to be sensed constantly change physical

or electrical properties. The Sonac® 110 principle of

measurement is used with extremely small vossels or

pipes and whan litle or no intrusion into the process is

required,

Non-dedicated vessels - liquids

The device senses virtually any liquid and does

not need adjustment when the density or dielectric

constants are changed,

High temperature, High pressure service

‘he welded, all stainless steel sensor body is designed

for service at temperatures to 20°F (+104°C) and

pressures to 2,000 psig.

Fluids with foam blankets

The control ignores foam to indicate the true liquid level

DELAVAN

Process Instrumentation

eyes

aCe

MEFEATURES

+ Auto test self-checking

The unique selt-checking feedback loop constantly

proves" that the control is working properly and offers,

superior reliabily in critical applications.

Really Fail-safe

The Sonac® 110 is designed so that any electrical or

mechanical failure of sensor or component will cause

a change of state to the Fail Mode. Redundant circuit

components are used in critical locations,

Stable, dependable performance

This sensing technique provides a wetidry ratio of

100:1 to provide dependable performance year in and

ut, without periodic adjustment.

No false trips due to surge or splashing liquids

Compact

The electronic amplifier is located in an integral explo-

sion proof housing threaded to the rear of the sensor.

Versatile power supply

‘The standard units are designed to accept 118 Volts

AC, 230 Vells AC or low voltage DC input power

Non-intrusive

‘The sensor need not extend into the vessel beyond 1/4

This feature minimizes the possibilty of product bridging.

Rugged

The all stainless steel, heavy duty sensor resists

damage from product abrasion of corrosion. No

J

TS

DELAVAN

Process Instrumentation

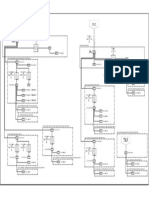

MEPRINCIPLE OF OPERATION

‘The sensors a magnetostrictive device consisting ofa diaphragm,

nickel tube, magnet, dive coll and pickup col. (See sensor typical

ross section),

When 40 kHz energy is applied to the dive col it causes the

phragm to vibrate ata frequency determined by the mechanical

resonant systom ofthe sensor. Electcal energy is transiorrd to

the pickup coll when the diaphragm is free to move in gas. When

the ciaphragm motion is loaded by a process material ess energy.

is transferred to the pickup col

“The pickup ool ofthe sansar is connected tothe input f an ampl-

fier and the output ofthe ampliier tothe dive col to form a fee

back loop cult. Any energy appearing in the output ofthe sensor

ul be fed to the amplifier, amplified and retumed tothe input of

the sensor. This causes vibrations at 40 kHz to occurin the

este

‘nh standard sensors

DELAVAM >? :0c0ss Instrumentation

an L&J TECHNOLOGIES Company

"Sor! Butter Road

Hilde, 1. 60162

Ph: (708) 236-6000

Fax: (708) 235-8006

Emailsales technologies com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- E 0FE02 0248674 215102420 HBC 1Document1 pageE 0FE02 0248674 215102420 HBC 1anghello buendiaNo ratings yet

- Certificado de Calidad: #N° Factura: Cliente: FechaDocument1 pageCertificado de Calidad: #N° Factura: Cliente: Fechaanghello buendiaNo ratings yet

- PCI Medical Catalog DOCS 500Document1 pagePCI Medical Catalog DOCS 500anghello buendiaNo ratings yet

- PCI Medical Catalog DOCS 500Document1 pagePCI Medical Catalog DOCS 500anghello buendiaNo ratings yet

- Diagrama de BloquesDocument1 pageDiagrama de Bloquesanghello buendiaNo ratings yet

- Catalogo de ProductosDocument24 pagesCatalogo de Productosanghello buendiaNo ratings yet

- Se 150 Kva Construido BNDocument1 pageSe 150 Kva Construido BNanghello buendiaNo ratings yet

- Gabinetes AutosoportadosDocument12 pagesGabinetes Autosoportadosanghello buendiaNo ratings yet

- HS - Sika Rep-500Document5 pagesHS - Sika Rep-500PercyCabezasArmellonNo ratings yet

- Ampliación MollendoDocument1 pageAmpliación Mollendoanghello buendiaNo ratings yet