Professional Documents

Culture Documents

Steam Jacket Details PDF

Uploaded by

icetesterOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steam Jacket Details PDF

Uploaded by

icetesterCopyright:

Available Formats

3 RODS EQUALLY SPACED-WITH 120 LONG

NOTES

(SEE TABLE) 1- ALL THICKNESS VALUES AND DIMENSIONS ARE IN mm.

SEE NOTE 8 SEE DETAIL " G " OR "D" 2- JACKET FITTING TO BE SPLIT FOR ASSEMBLY OF PROCESS

STEAM INLET STEAM JACKET

PROCESS

LINE LINE & JACKET.

LINE

3- LENGTH OF LINE BETWEEN FLANGES OR RINGS TO BE

SEE NOTE 5 TACK WELD

150 DETERMINED BY STRESS ANALYSIS BUT SHALL NEVER

S.O. FLG. (TYP.) EXCEED 12000.

SEE DET. "B" 4- STEEL PIPE TO BE SAME SIZE AS STEAM INLET LINE AS

(TYP.) CALLED FOR ON P&ID.

5- JACKETS MAY BE CONNECTED IN SERIES UP TO MAXIMUM

30 LENGTH OF 20000.

30

6- ROD DIA. BASED ON JACKETING PIPE ASTM A53 Gr.B WITH

SLIP-ON RED. FLG.

SCH. STD. UP TO 8"(DN200) & SCH.30 FOR 10"(DN250)

& LARGER.

STEAM CONNECTION

7- ALL WELDINGS SHALL CORRESPOND TO PROJECT WELDING

SPACERS SEE DETAIL "C" FOR ORIENTATION OF COUPLING

JACKETED VALVE PROCEDURE.

SEE SPOOL DWG. SECTION "S"-"S"

ROD TABLE 8- STEAM PIPE SIZE TO BE SAME AS CONNECTION SIZE.

JACKETED PIPE TABLE "S" LINE SIZE 9- PROVIDE BREACK FLANGE IF IT IS NECESSARY.

MAX.

LINE SIZE JACKET SIZE ROD STEAM ROD

STEAM, COND. & DRAIN 100 PROCESS LINE PROCESS ROD 10-IN PROCESS AREA A NEW STEAM SHALL BE SUPPLIED

JACKET DIA. AT EVERY 12 METERS MAX. WHICH IS MAXIMUM LENGTH

CONNECTION SIZE 90°ELL.45°ELL. CONC. 150 JACKET LINE SPACING

PROCESS STEAM JACKET DN NPS DN NPS

RED.. OF JACKET PIPE AND OUTSIDE THE PROCESS AREA A

15 1/2" 50 2" 13 2500

DN NPS DN NPS DN NPS NPS NPS NPS TO TRAP

PROCESS TACK WELD NEW STEAM SHALL BE SUPPLIED AT EVERY 24 METERS

20 3/4" 50 2" 7 3000

MAX. WHICH IS MAXIMUM LENGTH OF JACKET PIPE,

15 1/2" 50 2" 20 3/4" 2" 2" - 25 1" 50 2" 7 3500

STEEL ROD SPACER 1 ANY HOW EVERY 12 METERS JACKET PIPE SHALL BE

STEAM INLET 40 1/2" 80 3" 14 4000

20 3/4" 50 2" 20 3/4" 2" 2" -

50 80 8 5200

TRAPPED.

JACKETED VALVE 2" 3"

25 1" 50 2" 20 3/4" 2" 2" - STEAM JACKET 80 3" 100 4" 6 6400 11-IMPINGEMENT PLATE FOR PROTECTING PROCESS LINE

40 1 1/2" 80 3" 20 3/4" 3" 3" - W.N. FLG. 100 4" 150 6" 19 7200 AGAINST CRROSION.

ROD SPACING 150 6" 200 8" 17 8300

SEE DET. "E" 150 100 150 12-"X" SHALL BE AS FOLLOWS:

50 2" 80 3" 20 3/4" 3" 3" - 200 8" 250 10" 18 9400

(TYP.)

(MIN.) 12000 250 300 16 10500

t < 6 X=t

80 3" 100 4" 20 3/4" 4" 4" - 10" 12"

"S"

(MAXIMUM) 300 12" 350 14" 5 10900 t > 6 X=6

100 4" 150 6" 20 3/4" 6" 6" -

350 14" 400 16" 15 11100 WHERE "t" IS THE PIPE WALL THICKNESS.

BREAK FLANGE

150 6" 200 8" 25 1" 8" 8" -

13-WELDING LOACTION OF PROCESS ELBOW WILL DIFFER

200 250 25 RESPECT TO THE JACKETED ELBOW BASED ON ELBOWS

DETAIL " C "

8" 10" 1" 12" 10" 12"x10"

250 300 25

DETAIL " B " DIMENSION.

10" 12" 1" 14" 12" 14"x12"

300 12" 350 14" 25 1" 16" 14" 16"x14" 14-Ø IS BASED ON SCH.40 THICKNESS FOR JACKETING.

350 14" 400 16" 25 1" 18" 16" 18"x16"

DETAIL " A "

TRANSITION RING SEE DET. "H" W.NECK FLG.

STEAM CONNECTION FOR ORIENTATION

SEE NOTE 13 ROD LOCATION OF COUPLING SEE SPOOL DWG.

STEAM JACKET TEE

AT BENDS TABLE STEAM JACKET TEE

L OF ROD

SEE NOTE 2 SEE NOTE 2

.

ROD LINE SIZE ST

90 S.R. ELL. IN

"L" DIM. OR

C

DN NPS

CH N

90 L.R. ELL. 45° S.R. ELL.

15 1/2" 1000 AN TIO

BR EC

3/4" NN

SEE NOTE 2 20 1000 CO RIN

G

25 1" 1000 N PROCESS TACK WELD

IO "

SIT "H

STEAM JACKET 40 1 1/2" 1500 AN AIL STEEL ROD SPACER

TR DE

T

LINE 50 2" 1500 E

SE

PROCESS 80 3" 1500

STEAM JACKET

TYPICAL

MIN. "L"

LINE MIN. "L" 100 4" 1800

45° L.R. ELL.

ROD TYPICAL 150 6" 2000 S.W HALF CPLG. 150 100 130 50

C

L OF ROD 200 8" 2500 DRAIN

250 10" 3000 PROCESS LINE STUB-IN

PROCESS LINE BRANCH CONNECTION

300 12" 3000

350 14" 3000

TYP. DETAIL AT BENDS TYP. DETAIL AT 45° ELBOW TYP. BRANCH CONN. DETAIL DETAIL "D" DETAIL "E"

FOR 3/4"(DN20) TO 6"(DN150) PIPE FOR 3/4"(DN20) TO 14"(DN350) PIPE

SEE NOTE 9

SEE NOTE 13

L OF ROD

90 S.R. ELL.

STEAM INLET 37° 30' ± 2° 30'

C

S.W. HALF COUPLING STEAM OUTLET

90 L.R. ELL.

SEE NOTE 2

MIN.

50x30x6mm.

SEE NOTE 11

TRANSITION RING TABLE

STEAM JACKET LINE SIZE

LINE TRANSITION RING

PROCESS STEAM JACKET

PROCESS DN NPS DN NPS 0 C 0 D 0 E F

LINE

SEE NOTE 14

MIN. "L" 15 1/2" 23.3 C

PROCESS LINE

JACKET LINE

TYPICAL B

ØC

20 3/4" 28.7

ØE

PROCESS LINE A

ØD

50 2" 60.3 55.7 10

25 1" 35.4 REV. DESCRIPTION DATE

ROD 1

SEE DETAIL "C" 40 1/2" 50.3

50 2" 80 3" 88.9 81.1 62.0 15 IRANIAN PETROLEUM STANDARDS

80 3" 100 4" 114.3 107.0 90.7 15

NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION

X 100 4" 150 6" 168.3 158.9 116.1 20

SEE NOTE 12

150 6" 200 8" 219.1 207.5 170.7 20

150 100 130 100 130 150

STEAM JACKET DETAILS

200 8" 250 10" 273.1 259.3 221.5 20

JACKET LINE TRANSITION RING

TYP. DETAIL AT BENDS S.W. HALF COUPLING TRANSITION RING

F

ASTM A515 Gr.70 250 10" 300 12" 323.9 308.0 276.4 25

DRAIN TO CONDENSATE SEE DETAIL "H" 300 12" 350 14" 355.6 338.1 327.2 25

FOR 8"(DN200) TO 14"(DN350) PIPE RECOVERY STATION

DETAIL " H "

DETAIL " G "

350 14" 400 16" 406.4 385.8 359.2 25

DATE DRAWING No. SHEET REV.

SEE NOTE 10

IPS-D-PI-127

1

1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Guide to Designing Jacketed Piping SystemsDocument11 pagesGuide to Designing Jacketed Piping SystemsDhirendra Singh Rathore100% (7)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 30 Reasons For Universalplantviewer: Free and Easy Viewer For The Plant IndustryDocument8 pages30 Reasons For Universalplantviewer: Free and Easy Viewer For The Plant IndustryicetesterNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Clash Detection or Clash AvoidanceDocument28 pagesClash Detection or Clash AvoidanceicetesterNo ratings yet

- FBE Coating PDFDocument12 pagesFBE Coating PDFthadikkaran100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Propane and Propane Tank SafetyDocument10 pagesPropane and Propane Tank SafetyicetesterNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Torsional Vibration Case Study Highlights Design ConsiderationsDocument8 pagesTorsional Vibration Case Study Highlights Design ConsiderationsicetesterNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Isogen LessonDocument40 pagesIsogen LessonDxtr Medina50% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 7 Interface Management PlanDocument18 pages7 Interface Management PlanFerry Triwahyudi100% (2)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The First Modularisation of A LNG Plant PDFDocument15 pagesThe First Modularisation of A LNG Plant PDFGustavo Gonzalez ServaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Excel Power Pivot TutorialDocument24 pagesExcel Power Pivot TutorialicetesterNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Si Oshem Fpls Design ManualDocument49 pagesSi Oshem Fpls Design ManualicetesterNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Modularization Critical Success Factors and Project PDFDocument261 pagesModularization Critical Success Factors and Project PDFicetesterNo ratings yet

- Torsional Vibration Case Study Highlights Design ConsiderationsDocument8 pagesTorsional Vibration Case Study Highlights Design ConsiderationsicetesterNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- OptionSwitchesUpdate PDFDocument348 pagesOptionSwitchesUpdate PDFJorge Santos RomeroNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Torque PDFDocument3 pagesTorque PDFicetesterNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Modularization Critical Success Factors and Project PDFDocument261 pagesModularization Critical Success Factors and Project PDFicetesterNo ratings yet

- SpectableBlinds Catalog SingleBlindsSpacers PDFDocument10 pagesSpectableBlinds Catalog SingleBlindsSpacers PDFicetesterNo ratings yet

- SHAW ModularizacionDocument64 pagesSHAW ModularizacionicetesterNo ratings yet

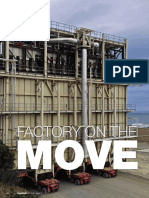

- Factory On The MoveDocument4 pagesFactory On The MoveicetesterNo ratings yet

- Schoenborn JM T 2012Document162 pagesSchoenborn JM T 2012Yoseph BirruNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PDFDocument12 pagesPDFMustafa ElfatihNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Secure Energy For Europe Chapter 7Document18 pagesSecure Energy For Europe Chapter 7Krishna KusumaNo ratings yet

- GAPS Plant LayoutDocument11 pagesGAPS Plant Layoutvb_pol@yahooNo ratings yet

- A05 Gas SweeteningDocument2 pagesA05 Gas SweeteningicetesterNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- A Review and Analysis of Modular Construction PracticesDocument164 pagesA Review and Analysis of Modular Construction PracticesSabrina ShukriNo ratings yet

- OTAP Command LineDocument5 pagesOTAP Command LineicetesterNo ratings yet

- 3D Model ReviewDocument12 pages3D Model ReviewDana GuerreroNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- p2c2 ProgressmeasurementDocument19 pagesp2c2 ProgressmeasurementicetesterNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)