Professional Documents

Culture Documents

Gantner Shaft Winch 2016 06

Uploaded by

freddyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gantner Shaft Winch 2016 06

Uploaded by

freddyCopyright:

Available Formats

COMPANY PROFILE

Tailor made winches

for deep mining

Winches and hoists play a pivotal role in many mines and mining projects around the world.

For underground constructions and deep mining, winches and drives are essential for

efficient and safe operations, writes Gilbert Domig, the technical director and MD of Gantner

Seilbahnbau GmbH. Such winches and drives are specifically fabricated, for the needs of each

site and purpose of operation, by very specialised engineering and manufacturing companies.

This article presents the usage of shaft winches, taking as an example the electro-hydraulic

rope winch which was specifically designed as the emergency egress shaft winch for the

Roseberry mine in Tasmania.

antner Seilbahnbau GmbH, founded purposes when replacement material is brought in via the

G

in 1948, has been developing and shaft; when manpower is lowered to complete maintenance

constructing winches that are employed works; and for rescue purposes. This latter application is

in a wide variety of applications. Today, one of Gantner’s specialties, and one in which it has a wide

Gantner is established as a full service, range of experience fabricating winches with the highest

winch manufacturing company that of safety features thereby permitting the transportation of

offers a complete service from the personnel.

development to the eventual start-up of the winch, including

every intermediate production step. CASE STUDY: RESCUE SHAFT WINCH, TASMANIA

During 2014, Gantner received an order from a mine operator

SHAFT WINCHES in Tasmania for the complete development and construction

Shaft winches are one of the major winch-categories upon of a deep mining shaft winch, with the additional criteria that

which Gantner focuses. Such winches are essential in it be suitable for rescue purposes. As such the facility was

deep mining, as well as in the hydro-power industry at dam designed to lift and lower (in the shortest time possible) a

penstocks, where drift shafts with an inclined grade, are rescue capsule up-down a 500m vertical mine shaft.

common. Winches can be used in many instances from

vertical to inclined shafts, and of course they are used for The work was undertaken on behalf of the Mancala Group,

many different purposes: material handling, when mined a mine planning company from Melbourne, Australia. The

material needs to be brought to the surface; for service winch needed to fulfill several strict criteria to comply with

24 Coal International • May June 2016

COMPANY PROFILE

Australia’s safety standards regarding its construction,

functionality and integrated control system.

It took a year from project launch to the installation and

commissioning of this 100% Ganter winch.

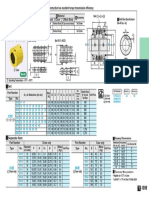

TECHNICAL FEATURES

The rope drum has a diameter of 865mm and its width is

820mm. The line pull is a constant 30kN, the rope is 565m in

length and the line speed reaches 1m/sec. The drive capacity

is 37kW and the brake power amounts to 2.2kW.

The haul rope diameter is 16mm with a minimum breaking

strength of 210kN.

The winch consists of a massive base frame with integrated

attachment points for the housing of high-quality SKF

bearings. These bearings carry the drum unit with the main design. Hence – in the unlikely case of component failure –

shaft being powered by a hydraulic drive. a second valve will take over that role. The same principle

applies to all other control components.

The drum unit consists of a drum with screwed on half shells

provided by Lebus, which results in a perfect winding result. CONTROL SYSTEM

The design of the winch was carried out by experienced in- The design and programming of the control system, as

house technicians. well as the electrical and electronic wiring is done in-

house. Only quality components which are approved by the

Line pull, rope length, rope layers and drum width have to majority of countries are used, however, special attention is

seamlessly mesh with each other. Massive drum flanges made to adhere to local regulations and customer needs.

absorb the lateral forces of the rope layers; the rope One special requirement, was the interface regulation with

movement is horizontal. the customer’s existing control system and the evaluation

of signals.

The rope winch is designed according to “Supply Functional

Specification,” as well as the principles of the MDG33 and THE STRUCTURE OF THE WINCH

the MDG2005. The winch is constructed for use between a The machine itself consists of the winch unit’s drive

temperature range of 0° to +45°C. assembly and the operating panel. The drive assembly

consists of a basic sub-structure with an enclosure in which

SAFETY FEATURES the drive motors, hydraulic pumps and control facilities are

Understandably, this shaft winch project is in line with built. The winch unit consists of a base frame on which

Australian standards. In addition, different international the rope drum with drum axis and drive motor is fastened.

standards and directives, such as exerts of the Ropeway The drive motor is supported over a torque bracket with

Directive, have been applied. a load measuring device within the base frame. Four disk

brakes, which carry the force over the brake flange onto

All components have been designed and

calculated by Gantner with the calculations

verified by an independent civil engineer.

During production, strict quality management

ensured the proper execution of all aspects of

the work from design, electrical planning and

manufacturing through to assembly, thereby

ensuring the perfect the construction and

performance of the finished winch.

Essential safety features of this winch are two

disc brakes which individually are able to provide

the necessary power for the braking process.

Each disc has two hydraulically controlled

brakes produced by Svendborg.

A large number of rope-end terminations secures

the rope of the winch, so any unintentional release

or slide is impossible.

Another safety feature is the redundant valve

Coal International • May June 2016 25

COMPANY PROFILE

the rope drum directly, are controlled by means of two separate circuits. The

connection between drive assembly and winch unit occurs via a supply pipe in

which hydraulic hoses and control wires are conducted. The operating console

allows full control and monitoring of the machine.

QUALITY & SAFETY – A CLOSE RELATION FOR SHAFT WINCHES

The quality of the winch - its functionality, materials employed, method of

manufacture and (of course) the control system itself, are all essential for the

overall safety rating. The whole development and fabrication process followed

the ISO 9001 and OHSAS 18001 standards. Accurate and quality testing of

every single part and process, as well as a focused material inspection regime

(including material certification) were part of the project.

The mine planning company, who were responsible for the correct installation and

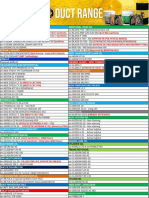

MINING WINCHES

functionality of the rescue winch, was GANTNER is a specialist in the

present at the first start-up and testing design, development and manufac-

phase at Gantner’s production turing of winches. Founded in 1948,

facility. This ensured that the GANTER disposes of a great expe-

required level of quality could rience and know-how and expertise

be approved well before the for all kind of winches.

mine installation. This close Winches are safe and reliable

cooperation between the machines that enable the handling

producing company and the of material in challenging situations.

customer was fundamental Quality, safety and highest standards

for the success of this complex in all aspects are fundamental and

project. necessary.

GANTNER is specialized on a

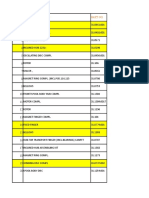

TECHNICAL DETAILS

focused development and construc-

Drum diameter 865mm tion for the winch and its purpose,

designing tailor-made winches that

Drum width 820mm meet the customer’s requirements

Line pull (empty drum) 30kN at 100%.

Line pull (full drum) 30kN The portfolio includes various kinds

of winches, including rescue winches,

Rope diameter 16mm shaft winches and service winches

Minimum break load 210kN for material handling as well as for

personnel transportation in mining

Power 37kW

and the construction industry.

Braker power 2.2kW

GANTNER is certified in

» Quality - ISO 9001:2015

Winch unit

» Safety - OHSAS 18001:2007

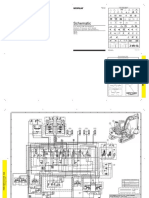

The drive of the machine consists of the following components:

» Environment - ISO 14001:2015

• Rope drum (1) • Rope drum support (6)

• Brake block (2) • Torque arm (7) GANTNER Seilbahnbau GmbH

• Thrust stop (3) • Hydraulic motor (8) Industriestrasse 8

• Base frame (4) • Force measuring rod (9) 6832 Sulz

• Pin clamping set (5) Austria

Tel: +43 5522 32483

WWW.GANTNER-WINCHES.COM

Gilbert Domig is the technical director and MD of

Gantner Seilbahnbau GmbH, the winch technologies

specialist, based in Sulz, Austria. Having gained

considerable experience in engineering and

mechanical construction in a variety of fields and

sectors, Domig has more than 20 years’ experience

designing and creating high-performing winches in

engineering with wire rope systems. Domig aims to

find the most creative ideas and to convert these

into high performance winches.

26 Coal International • May June 2016

You might also like

- Some Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentFrom EverandSome Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentRating: 3.5 out of 5 stars3.5/5 (2)

- Turbo-Generator Solutions For Power and Heat Co-Generation: Systems and Mechanical Drive ApplicationsDocument4 pagesTurbo-Generator Solutions For Power and Heat Co-Generation: Systems and Mechanical Drive ApplicationsManoj SinghNo ratings yet

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Turbo-Generator Solutions For Power and Heat Co-Generation: Systems and Mechanical Drive ApplicationsDocument4 pagesTurbo-Generator Solutions For Power and Heat Co-Generation: Systems and Mechanical Drive ApplicationsManoj SinghNo ratings yet

- EPM Valve Automation TechnologiesDocument8 pagesEPM Valve Automation TechnologiesWahyu YuliadiNo ratings yet

- Wheel Loader 992KDocument24 pagesWheel Loader 992KRonald Mario Kupa AnticonaNo ratings yet

- Rexroth D&C For Wind TurbinesDocument16 pagesRexroth D&C For Wind TurbinesxxshNo ratings yet

- Accumulators and Coolers For Wind PowerDocument8 pagesAccumulators and Coolers For Wind PowerMiguel Angel LopezNo ratings yet

- 40K Catalog CompleteDocument141 pages40K Catalog CompleteJuliyanto ST100% (1)

- Valve Automation BrochureDocument8 pagesValve Automation BrochuresalemNo ratings yet

- Konecranes Brochure Waste To Energy en 2013Document12 pagesKonecranes Brochure Waste To Energy en 2013abcNo ratings yet

- Belt Conveyors, Stackers and Reclaimers and ReclaimersDocument34 pagesBelt Conveyors, Stackers and Reclaimers and ReclaimersAndreNunesNo ratings yet

- Technoroll BrosureDocument13 pagesTechnoroll BrosurephitokrioNo ratings yet

- Engine Roof - Support - SystemsDocument8 pagesEngine Roof - Support - SystemsAustinNo ratings yet

- Bermingham Lead BrochureDocument8 pagesBermingham Lead BrochureDemian LeivaNo ratings yet

- Saf T Gard ActuatorsDocument14 pagesSaf T Gard ActuatorsoghaleNo ratings yet

- FPU Brochure - For Web - Lowres - Original - 88353Document12 pagesFPU Brochure - For Web - Lowres - Original - 88353JonNo ratings yet

- Tel Fax: Cumhuriyet Mah. Nurol Sokak No:31 100. Yil Bulvari 1230 Sk. No:2Document40 pagesTel Fax: Cumhuriyet Mah. Nurol Sokak No:31 100. Yil Bulvari 1230 Sk. No:2Malkhaz Bregadze100% (1)

- Corporate BrochureDocument20 pagesCorporate BrochuresaritasohamNo ratings yet

- Heavy Wall Reactors Pressure VesselsDocument7 pagesHeavy Wall Reactors Pressure VesselsSambanthan VenkatesanNo ratings yet

- Aexq1170 01Document34 pagesAexq1170 01Jose FerreiraNo ratings yet

- Build Beyond Imagination: Eik Engineering SDN BHDDocument20 pagesBuild Beyond Imagination: Eik Engineering SDN BHDdanangNo ratings yet

- EQ-011 Multielement WavemakerDocument4 pagesEQ-011 Multielement WavemakerFahmy ArdhiansyahNo ratings yet

- Vem Morors MarineDocument36 pagesVem Morors MarineembasianNo ratings yet

- Steel Industry Solutions: Intelligent Lifting For Competitive SteelDocument12 pagesSteel Industry Solutions: Intelligent Lifting For Competitive Steeljuanmata26No ratings yet

- Mixer CifaDocument12 pagesMixer Cifapablopela100% (1)

- 20K Catalog - Complete PDFDocument213 pages20K Catalog - Complete PDFVíctor Hugo Morales CurayNo ratings yet

- 20K Catalog CompleteDocument213 pages20K Catalog CompleteVara PrasadNo ratings yet

- Screens On Screen: Crushing & ScreeningDocument3 pagesScreens On Screen: Crushing & ScreeningJHON ANGEL VARGAS HUAHUASONCCONo ratings yet

- Brochure WeldersDocument16 pagesBrochure WeldersNeel ShahNo ratings yet

- Raise BorerDocument2 pagesRaise BorerL Joseline Avila CondoriNo ratings yet

- Cargadores de Ruedas Cat Specalog 992k Wheel Loader PDFDocument20 pagesCargadores de Ruedas Cat Specalog 992k Wheel Loader PDFpercyNo ratings yet

- PES Wind 1 17 Moventas Talking Point 1Document4 pagesPES Wind 1 17 Moventas Talking Point 1Karthik VaidhyanathanNo ratings yet

- 993K Specalog Aehq5922 PDFDocument32 pages993K Specalog Aehq5922 PDFpercyNo ratings yet

- Lehe2027-00 G20CM34Document4 pagesLehe2027-00 G20CM34mario_r3604466No ratings yet

- 1831 e Cr421 en Voith Turbo Safeset Torque Limiting CouplingsDocument32 pages1831 e Cr421 en Voith Turbo Safeset Torque Limiting CouplingsEfrain Sisa SNo ratings yet

- Mechanical Cementation ProductsDocument20 pagesMechanical Cementation Productstafhim rashidNo ratings yet

- MAAG Gear KA and KB BrochureDocument5 pagesMAAG Gear KA and KB BrochureZahir KhiraNo ratings yet

- Wavemakers For Physical Models: EquipmentDocument10 pagesWavemakers For Physical Models: Equipmentesmaeil013No ratings yet

- Oceans of Opportunities.Document14 pagesOceans of Opportunities.Uhrin ImreNo ratings yet

- Renold Cement Bucket ElevatorDocument23 pagesRenold Cement Bucket ElevatorLutfi IsmailNo ratings yet

- 15 Line Boring EquipmentDocument12 pages15 Line Boring EquipmentWeldingSupply.com.au100% (1)

- Jetstream Pump FE Brochure.7 2016Document12 pagesJetstream Pump FE Brochure.7 2016Phit Nguyen VietNo ratings yet

- Bucket Wheel Stacker/ReclaimerDocument2 pagesBucket Wheel Stacker/ReclaimerJavier TorresNo ratings yet

- BM SA ROPE ATTACHMENTS HRDocument4 pagesBM SA ROPE ATTACHMENTS HRTheo van der BergNo ratings yet

- Mokveld Brochure Angle Choke ValveDocument16 pagesMokveld Brochure Angle Choke ValvekglorstadNo ratings yet

- Planetary Plug-In Gearboxes by LiebherrDocument12 pagesPlanetary Plug-In Gearboxes by LiebherrRachid Smaili100% (1)

- Flyercavotec Mining and Construction Reels18112021ld - 4Document16 pagesFlyercavotec Mining and Construction Reels18112021ld - 4iemch2908No ratings yet

- CEEM 460K AHWU - Technical Specification - Rev 2014Document38 pagesCEEM 460K AHWU - Technical Specification - Rev 2014Son DDarrell100% (1)

- NTB A900C-A904C - enGB - 14-05Document28 pagesNTB A900C-A904C - enGB - 14-05Juanjo Condori Sucasaire0% (1)

- Plenty Side Entrytechnical ManualDocument26 pagesPlenty Side Entrytechnical Manualaqeelkhan7942No ratings yet

- 6.04. Wüst MDocument8 pages6.04. Wüst MAnonymous NUn6MESxNo ratings yet

- PDR BearingDocument11 pagesPDR BearingcristinelbNo ratings yet

- Conveyor Idler and PulleyDocument1 pageConveyor Idler and PulleymkpqNo ratings yet

- Onshore Equipment Catalogue: Crc-EvansDocument106 pagesOnshore Equipment Catalogue: Crc-EvansEmmanuel LawrenceNo ratings yet

- AgitatingDocument24 pagesAgitatingBánh Cuốn Tôm ThịtNo ratings yet

- Demag Aircraft Process CranesDocument20 pagesDemag Aircraft Process CranesAnand TornekarNo ratings yet

- Plenty Side Entry MixersDocument26 pagesPlenty Side Entry MixersMarina Fernández MirandaNo ratings yet

- 5 - GrenCo - Company PresentationDocument34 pages5 - GrenCo - Company PresentationCluis KeNo ratings yet

- 16M Motor Grader-Maintenance IntervalsDocument62 pages16M Motor Grader-Maintenance IntervalsJuan Amanqui Garcia100% (3)

- 2300 Perkins PDFDocument1 page2300 Perkins PDFluisferNo ratings yet

- Principle of Esp: Understeer & Oversteer ControlDocument3 pagesPrinciple of Esp: Understeer & Oversteer ControllequangthongNo ratings yet

- Motor GeneratorsDocument15 pagesMotor GeneratorsAnonymous OuY6oAMggxNo ratings yet

- Suzuki 150Document4 pagesSuzuki 150Betty BentonNo ratings yet

- Parts RequestDocument4 pagesParts RequestMansoor KhanaliNo ratings yet

- Parts Manual Fisher & Paykell "Smart Drive" Electronic Washing MachineDocument21 pagesParts Manual Fisher & Paykell "Smart Drive" Electronic Washing MachineEric ApperleyNo ratings yet

- NEF45AM1A.S500 Exploded Views (D50IST)Document17 pagesNEF45AM1A.S500 Exploded Views (D50IST)Daniel MuratallaNo ratings yet

- HD Job Time Codes Manual 2003Document224 pagesHD Job Time Codes Manual 2003Brian Cook100% (4)

- Series 4000: Generator/Pump Power Packages For The Oil & Gas Industry - Constant SpeedDocument2 pagesSeries 4000: Generator/Pump Power Packages For The Oil & Gas Industry - Constant Speedavinash_1229No ratings yet

- Brunsviga: Olympia Werke Ag - WilhemshavenDocument9 pagesBrunsviga: Olympia Werke Ag - WilhemshavenAnonymous HGOomkn69No ratings yet

- 966H Buletin PreliminaryDocument52 pages966H Buletin PreliminaryGrober Campos CalixtoNo ratings yet

- Embraco Aftermarket Product Line Catalog With Wiring Diagrams 85x112021Document28 pagesEmbraco Aftermarket Product Line Catalog With Wiring Diagrams 85x112021Pradeep JhaNo ratings yet

- Bajai Qute SpacifiDocument79 pagesBajai Qute Spacifimekonenabdisa3No ratings yet

- TF1254 F463F4K PDFDocument292 pagesTF1254 F463F4K PDFHarold Gerardo100% (1)

- Eni Product Range 2021Document1 pageEni Product Range 2021ranjanguptNo ratings yet

- Exercise 1: Pressing Cheeses: Cheese ProductionDocument8 pagesExercise 1: Pressing Cheeses: Cheese ProductionAhmed HusseinNo ratings yet

- Hl760-9 Error CodeDocument57 pagesHl760-9 Error CodevolvoNo ratings yet

- Controls, Start-Up, Operation, Service and Troubleshooting: 30XA080-500 Air-Cooled Liquid Chillers 60 HZDocument126 pagesControls, Start-Up, Operation, Service and Troubleshooting: 30XA080-500 Air-Cooled Liquid Chillers 60 HZHasib Khan100% (1)

- Mesys ManualDocument285 pagesMesys Manual王念社No ratings yet

- Detroit Diesel Series 53 Operators ManualDocument538 pagesDetroit Diesel Series 53 Operators ManualDennis Klineman100% (6)

- Contact!: Revmaster's Breakthrough R-2300 Engine Offers More Horsepower at A Lower Cruise RPM That Previous VersionsDocument8 pagesContact!: Revmaster's Breakthrough R-2300 Engine Offers More Horsepower at A Lower Cruise RPM That Previous VersionsGustavo CalixtoNo ratings yet

- 312 BL Diagrama HidraulicoDocument2 pages312 BL Diagrama Hidraulicoesmeralda67% (3)

- Chai Couplig Catalogue PDFDocument1 pageChai Couplig Catalogue PDFMinh AnhNo ratings yet

- pp10233-03 - TurbochargerDocument2 pagespp10233-03 - TurbochargerBoBoMilovanovicNo ratings yet

- Craftsman MODEL NUMBER 917.250520 Owners ManualDocument64 pagesCraftsman MODEL NUMBER 917.250520 Owners Manualbullwinkle1054776No ratings yet

- Type 1035/El-O-Matic Rack-and-Pinion Rotary ActuatorDocument24 pagesType 1035/El-O-Matic Rack-and-Pinion Rotary ActuatorRollyDuqueCampoverdeNo ratings yet

- MoM ManualDocument79 pagesMoM ManualHamid CheemaNo ratings yet

- Electric Bypass Valve Counteracting Turbo Lag With New Technology 51631Document2 pagesElectric Bypass Valve Counteracting Turbo Lag With New Technology 51631supljinaNo ratings yet

- SV 5C 1Document3 pagesSV 5C 1FredNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Offshore Projects and Engineering ManagementFrom EverandOffshore Projects and Engineering ManagementRating: 5 out of 5 stars5/5 (2)

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbFrom EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationFrom EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationRating: 4.5 out of 5 stars4.5/5 (2)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Structural Analysis: In Theory and PracticeFrom EverandStructural Analysis: In Theory and PracticeRating: 4.5 out of 5 stars4.5/5 (24)

- The Engineer's Guide to Plant Layout and Piping Design for the Oil and Gas IndustriesFrom EverandThe Engineer's Guide to Plant Layout and Piping Design for the Oil and Gas IndustriesRating: 4 out of 5 stars4/5 (16)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- Oil: An Overview of the Petroleum IndustryFrom EverandOil: An Overview of the Petroleum IndustryRating: 4.5 out of 5 stars4.5/5 (3)

- Construction Process Planning and Management: An Owner's Guide to Successful ProjectsFrom EverandConstruction Process Planning and Management: An Owner's Guide to Successful ProjectsRating: 4 out of 5 stars4/5 (13)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Piping Engineering Leadership for Process Plant ProjectsFrom EverandPiping Engineering Leadership for Process Plant ProjectsRating: 5 out of 5 stars5/5 (1)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesFrom EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesRating: 4.5 out of 5 stars4.5/5 (13)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesFrom EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesRating: 5 out of 5 stars5/5 (7)

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsFrom EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsRating: 5 out of 5 stars5/5 (3)