Professional Documents

Culture Documents

Vibration Monitoring System For Steam Turbine

Uploaded by

diksha surekaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vibration Monitoring System For Steam Turbine

Uploaded by

diksha surekaCopyright:

Available Formats

INNOVATION INVESTIGATION

USING THE INDUSTRIAL INTERNET OF

THINGS TO TRANSFORM HUMAN SAFETY

AND ENERGY CONSUMPTION IN THE

MINING INDUSTRY

NTT INNOVATION INSTITUTE, INC.

TRANSFORMING IDEAS INTO MARKETPLACE REALITIES

Unanswered Challenges in the World of Heavy

Industry and Mining

Within the worlds of Heavy Industry and Energy/Natural Resources

“

(ENR), mining is a business that is decades behind in terms of the use of

technology, protocols, and systems that can have a positive impact on

people, society and profitability.

Overall, Heavy Industry faces big challenges brought about by a long

history of low risk attitudes, closed systems, and the technological The mining industry is

immaturity of entrenched legacy equipment. At the same time, they are

starved for what only innovative approaches can provide: new ways in desperate need of a

to increase asset efficiency, decrease costs, insure worker safety and technology intervention.

productivity, and deliver more competitive products in the market.

-

Mining is a perfect test bed for innovation in the world of Heavy Industry. Dr. John R. Spear, Professor of Civil and

It is a business that has lived on nothing but small incremental change, Environmental Engineering, Colorado School

steadfastly avoiding much that might disrupt the status quo. Additionally, of Mines

if a technology can provide hardiness and success in its uniquely tough

and gritty environment, there are many other business environments

waiting that face similar challenges, but with far less daunting

surroundings.

Mining also provides challenges where both economic and quality of life

issues can be addressed simultaneously. That’s a dual challenge worthy

of attention.

© NTT Innovation Institute, Inc. | www.ntti3.com 1

Can Technology Replace the Proverbial Canary in the

Coal Mine?

The mining industry is in desperate need of a technology intervention.

The manner in which the industry currently monitors the quality of air and

dangerous gas-related safety for miners is not all that far removed from

the days of “canaries in the coal mines.”

In many underground mines today, a person is sent out every hour to NTT i3 Looks for Big Unique

traverse the mine, manually read sensors, and document the status of

oxygen levels, dangerous gases, and escape routes. This is recorded

Challenges in IIoT

on physical boards at a central location. A mine manager performs

NTT i3 looks to identify those “dark

a standard analysis on the data in order to make decisions on how

areas” that exist within the “industrial

to regulate oxygen levels inside the mine. This ancient methodology

environments” of sensors, networks

does not allow for any real-time monitoring and automated response to

and data – and then explore the ways

changes in conditions, and it also requires an individual to be placed in a

that hidden data can be brought into

potentially hazardous situation.

the light to make a difference. Always

While the mines may have sensors, many are not connected to intelligent in our consideration is the use of

networks that could supply safer real-time recommendations. And the technology to improve the quality

networks that do exist have largely dated “homegrown” software. of human life, as well as provide

economic benefits to enterprise

So in thinking about this current state and the need for technological companies.

intervention, the industry question should become:

We seek important challenges that

“Can we automate air and dangerous gas monitoring and generate extend beyond a single narrow

related alerts and ventilation on demand? And could we do it in industry. While we may develop

a way that makes the mines safer for workers as well as brings a prototype in a specific business

economic benefits to the operators?” segment, we strive to define and

deploy the technology against

IoT

a broader context into adjacent

businesses.

Because of our belief in the dynamic

nature of organizations, we seek to

maximize technology interoperability

and flexibility. We fight against the

closed historic and single-vendor

approaches that plague many

industries.

© NTT Innovation Institute, Inc. | www.ntti3.com 2

Full Lifecycle Innovation

Innovation starts with the ambitious and once hidden idea, but it doesn’t stop there. True innovation is about both

thinking and doing – taking an idea and an opportunity and shaping it into something real with the capacity to

address significant human and business problems.

Full Lifecycle Innovation is what we call our four-phase approach to innovation. It is a practical approach to one of

the most creative and essential practices in business today – transforming ideas into marketplace realities.

Open Innovation is where we scout for those In the Applied R&D phase, we use the baseline

initial ideas and real world insights that may spark that we built with our initial ideas and early prototype

an innovation opportunity and fuel an early stage feedback, and dig in more deeply with collaborative

exploration through prototypes. We seek a balance pilots with actual customers in real business situations.

between casting a wide net for ideas and looking for We look for and work with partners that have the guts,

ways that we can leverage the strength of our core ambition, patience, and willingness to champion a

competencies, the powerful assets of our partner project that may well upend their own status quo.

operating companies, and relationships with startups

and researchers.

In this mining investigation, we focused on the two early phases of Open

Innovation and Applied R&D, with activities such as:

DESIGN THINKING IDEA DISCOVERY MARKET INSIGHTS

RESOURCE, PARTNER,

PILOT

AND FIRST CUSTOMER INITIAL PROTOTYPES

IDENTIFICATION IMPLEMENTATION

© NTT Innovation Institute, Inc. | www.ntti3.com 3

Innovation Discovery and Development

Between Sept 2015 and March 2016, a team of engineers and industry

experts from NTT i3, the Colorado School of Mines, and the Edgar Mine

focused on field insights, design thinking, prototype iteration, and an

initial deployment test.

Identify and

expand into

additional

industry

opportunities

Analyze

results

Partner and Pilot

Opportunity

Colorado School of

Mines and Edgar Mine

Mining

Decades behind in

using technology

to solve important

human, Deploy and test

environmental, Edgar Mine

and business

problems

Expert and Customer

Field Research

and Insights through Open

Forums. Define biggest

problems and what

technology can impact

Opportunity in

Heavy Industry Prototype and iterate

Interest in IIoT

and ENR to reference design

Leverage expertise

in Networks and

the Cloud Human Need, Problem

Selection, and

Hypothesis

Development

“Ventilation on demand” to

increase human safety and

decrease energy costs Identification of critical

resources and

technology partners

“

For our first prototype I was inspired to use HomeGenie in

the prototype as a result of some experimentation for my

own home automation system

-

NTT i3 team member

© NTT Innovation Institute, Inc. | www.ntti3.com 4

The Prototype added to gather data points in real-time about gas

levels, airflow direction, and doorway status.

Rapid prototype development and iteration begins in • These sensors are connected via gateways to a

the Open Innovation phase. The focus is on architecting self-propagating intelligent network that can be

an approach to the problem that supports the initial automatically expanded and managed.

divergence of ideas, while being flexible and vendor- • The network enables the data to be stored locally

agnostic. In the Applied R&D phase, technology or in the cloud.

solutions begin to converge as the prototype is shaped • Data is analyzed against policies that address

into a deployable model for pilot testing with a partner. the question “Do changes in the data indicate a

The prototype used and monitored in the pilot then problem in the mine?”

provides the team with the opportunity to: • The data, analytics, and KPIs are viewed in

dashboards by human operators (either local or

• Validate and/or iterate on their hypothesis. at HQ) who can then send commands back to the

• Begin to identify future potential partners in new appropriate machines to change conditions in the

industries facing a common need. mine.

• Note the opportunities to create product from the • A gateway enables commands to travel back

prototype. through the network and change the state of

relevant infrastructure in the mine such as fans and

The working prototype currently deployed in the doorways.

Colorado School of Mines’ Edgar Mine demonstrates • Aggregated data in the cloud enables the

important communications capabilities needed in IIoT generation of analytics and visualizations for long-

including: machine to cloud, machine to machine, and term planning and forecasting.

machine to human. • In the near future, this architecture could

incorporate machine learning, leading to the

• Legacy sensors were upgraded and connected to automation of certain parameters of change in the

a network, while new more intelligent sensors were mining environment as a result of the data.

Fans ESE

Motor Control ESI

Controlled

Environments Cloud

ta

Da

Data Command

Command

Data Sensors Networking Data

Data Local Network

Sensors Interface Device

Cognito Server

Gases Raspberry Pi ESE

Hardware

Air Flow ESI

HomeGenie

Doors Cognito Software

Software

To concept, build, test and deploy the prototype over a period of a few months, the team

of engineers and mining experts used a variety of hardware and software technology from

startups, the Open Source Community, and NTT i3’s own platform and intellectual property.

© NTT Innovation Institute, Inc. | www.ntti3.com 5

Pilot Results and Moving into the Near Future About NTT Innovation

Institute, Inc.

By adding intelligence to the existing network and sensors in the Edgar

Mine, we have successfully implemented our prototype for ‘ventilation on NTT Innovation Institute, Inc. (NTT i3)

demand.’ Efficiency was added not only through intelligent monitoring of is the Silicon Valley-based innovation

environmental status, but also by enabling variable control of equipment center for NTT Group, one of the

such as fans. This evolved systems from operating in a simple binary world’s largest ICT companies. NTT

on-off mode, to more nuanced levels of control responding dynamically i3 works with established enterprise

to conditions in the closed environment. As a result, we observed 10% companies interested in investigating

energy savings in just the first 2 weeks of the pilot program along with new approaches to evolving into

a projected 120 man hours saved per year. For mid-sized mines that technology-first, digitally-driven

are not currently attempting to optimize the air flow dynamics in their businesses. Likewise, NTT i3 partners

enclosed environments, we would expect to see 30% in energy savings. with early stage digitally-native

businesses looking to expand their

As we continue this investigation into the impact of “ventilation on

presence and challenger advantage.

demand in close environments,” we will not only look for additional mines

for pilot test beds, but also investigate opportunities for deployments in NTT i3 embraces a unique full lifecycle

adjacent heavy industries and enclosed industrial spaces. These might approach to innovation combining

include the food and beverage industry, underground construction, and best practices of open innovation

clean rooms. research, applied R&D expertise,

and agile product development.

In the near future, we can see this technology architecture evolving to Collaborative open innovation

embrace the “sensing revolution” of the Industrial Internet of Things with elevates and expands enterprise

“nanoized sensors” being deployed remotely on demand in mines and companies’ internal conversations

other environments via drones. Could we then have a world in which no and explorations around digital

human life is risked below ground, environmental quality is maximized, innovation opportunities. Applied

and the economic costs are minimized? R&D expertise then brings focus and

practical application by translating

Those are worthy challenges for our teams and for the industry.

those ambitious ideas into the

“

development of new technology

platforms, products, and practices.

To accelerate the movement of

The challenge of using IoT to provide innovation from initial idea to

‘ventilation on demand’ at CSM’s Edgar marketplace implementation,

NTT i3 combines its access to the

Experimental Mine was initially daunting but significant global infrastructure

ultimately a ‘breeze’ – and worthy because it resources, investment fund, research

knowledge, and trusted long-

addresses both issues of economic benefit and standing customer relationships of

increased human safety in an industry that has NTT Global with its own software

startup expertise and deep enterprise

often been slow to embrace changes to the relationships.

status quo.

-

Contact Us

Dr. Priscilla P. Nelson, Professor and Head, Department of Mining Engineering, NTT Innovation Institute, Inc.

Colorado School of Mines 1950 University Avenue, Suite 600

East Palo Alto, CA 94303

info@ntti3.com

© NTT Innovation Institute, Inc. | www.ntti3.com 6

You might also like

- Power Plant BrochureDocument12 pagesPower Plant Brochurediksha surekaNo ratings yet

- Improving Downtime Energy Efficiency Iot Connected BriefDocument4 pagesImproving Downtime Energy Efficiency Iot Connected BriefKishore KNo ratings yet

- IoT & Compressed Air Management SystemsDocument42 pagesIoT & Compressed Air Management Systemsdiksha surekaNo ratings yet

- Ad 19 NPSHDocument14 pagesAd 19 NPSHdiksha surekaNo ratings yet

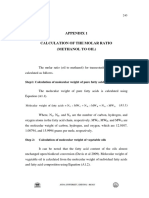

- Appendix 1: Step1: Calculation of Molecular Weight of Pure Fatty AcidsDocument6 pagesAppendix 1: Step1: Calculation of Molecular Weight of Pure Fatty Acidsdiksha surekaNo ratings yet

- Volume 21 12 Dec2010 PDFDocument68 pagesVolume 21 12 Dec2010 PDFdiksha surekaNo ratings yet

- Mass Flow Meter Analysis For Reliable Measuring: Tihomir KupanovacDocument6 pagesMass Flow Meter Analysis For Reliable Measuring: Tihomir Kupanovacdiksha surekaNo ratings yet

- Centrifugal pump data sheet detailsDocument1 pageCentrifugal pump data sheet detailsdiksha surekaNo ratings yet

- Mit PDFDocument93 pagesMit PDFdiksha surekaNo ratings yet

- Fuels and CombustionDocument26 pagesFuels and CombustionEjaz AhmedNo ratings yet

- Biodiesel 36244Document110 pagesBiodiesel 36244api-3802837100% (1)

- Toolbox 2 Energy Auditing in Industry: Step-By-Step Guide To Carrying Out An Energy AuditDocument23 pagesToolbox 2 Energy Auditing in Industry: Step-By-Step Guide To Carrying Out An Energy AuditRamesh AnanthanarayananNo ratings yet

- Molecules: High-Quality Biodiesel Production From Buriti (Mauritia Flexuosa) Oil SoapstockDocument9 pagesMolecules: High-Quality Biodiesel Production From Buriti (Mauritia Flexuosa) Oil Soapstockdiksha surekaNo ratings yet

- P&IDDocument18 pagesP&IDhectornicolauNo ratings yet

- Project number pressure transmitter datasheetDocument2 pagesProject number pressure transmitter datasheetdiksha surekaNo ratings yet

- Energy Audit Main Doc SpecDocument8 pagesEnergy Audit Main Doc Specdiksha surekaNo ratings yet

- Packed Bed Colunm Experiment ProcedureDocument25 pagesPacked Bed Colunm Experiment ProcedureNikhil Kumar ChennuriNo ratings yet

- Bailey's Industrial Oil and Fat Products, 6 Volume SetDocument3,688 pagesBailey's Industrial Oil and Fat Products, 6 Volume Setender arslan100% (4)

- Degumming & Refining TechnologiesDocument44 pagesDegumming & Refining Technologiessimonatics08No ratings yet

- HanSun Pipe FittingsDocument35 pagesHanSun Pipe Fittingspurav_patel20079232No ratings yet

- Biodiesel Handbook PDFDocument70 pagesBiodiesel Handbook PDFdiksha surekaNo ratings yet

- Biomass Thermal ConversionDocument334 pagesBiomass Thermal ConversionalenocitoNo ratings yet

- 3949-Jos-ee-Instr - S108 - 07 P&ID Isa Symbols and Loop DiagramsDocument3 pages3949-Jos-ee-Instr - S108 - 07 P&ID Isa Symbols and Loop Diagramsdiksha surekaNo ratings yet

- Feedstocks For BiofuelsDocument26 pagesFeedstocks For Biofuelsdiksha surekaNo ratings yet

- Metallurgical Extractions - SL - LLDocument37 pagesMetallurgical Extractions - SL - LLRoger RumbuNo ratings yet

- Appendix 1: Step1: Calculation of Molecular Weight of Pure Fatty AcidsDocument6 pagesAppendix 1: Step1: Calculation of Molecular Weight of Pure Fatty Acidsdiksha surekaNo ratings yet

- 02 Script ExtractionDocument2 pages02 Script Extractiondiksha surekaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BU53U01A01-01E - 012 Yokogawa LNG Supply ChainDocument9 pagesBU53U01A01-01E - 012 Yokogawa LNG Supply ChainosmondmanurungNo ratings yet

- VRV HSDocument17 pagesVRV HSAnthony WoenarwanNo ratings yet

- Bandi Saneswari: Email Phone NumberDocument4 pagesBandi Saneswari: Email Phone NumberShafiNo ratings yet

- Solidworks PDM: Take Control of Your Data To Enhance Collaboration and InnovationDocument4 pagesSolidworks PDM: Take Control of Your Data To Enhance Collaboration and InnovationEnijad ArnautNo ratings yet

- Modern Automated Control Systems in The Oil and Gas Industry Example On Installation of Preliminary Gas Preparation KumliDocument5 pagesModern Automated Control Systems in The Oil and Gas Industry Example On Installation of Preliminary Gas Preparation KumliFernandoNo ratings yet

- S120 Basic Positioner OverviewDocument36 pagesS120 Basic Positioner OverviewInslley RoberthNo ratings yet

- Smart Grid 1187 2707 1 SMDocument11 pagesSmart Grid 1187 2707 1 SMmanjusingNo ratings yet

- Filtro Marco y PlatosDocument5 pagesFiltro Marco y PlatosCesar LapaNo ratings yet

- Billing and Collection: Initiatives by Bangalore Water Supply and Sewerage Board. Documented by - Rohit NadkarniDocument24 pagesBilling and Collection: Initiatives by Bangalore Water Supply and Sewerage Board. Documented by - Rohit Nadkarnirohitplanning0% (1)

- Direct Epi Uorescent Filter TechniqueDocument12 pagesDirect Epi Uorescent Filter TechniqueGabyta CabreraNo ratings yet

- PLC Manual - 1803096 - Mayank Shahabadee - FINALDocument72 pagesPLC Manual - 1803096 - Mayank Shahabadee - FINALMayank Shahabadee67% (3)

- Healthcare IT Revenue Cycle in United States Resume Brad BriskenDocument2 pagesHealthcare IT Revenue Cycle in United States Resume Brad BriskenBradBriskenNo ratings yet

- Control Philosophy - Rev 5Document113 pagesControl Philosophy - Rev 5Rakesh Karan SinghNo ratings yet

- Be Open and Independent: SIMATIC S7-1500 Software ControllerDocument8 pagesBe Open and Independent: SIMATIC S7-1500 Software ControllerLuis CortezNo ratings yet

- Chapter # 1: Introduction To Robotics Mechanics & ControlDocument51 pagesChapter # 1: Introduction To Robotics Mechanics & ControlAli AliNo ratings yet

- Assignment 1Document5 pagesAssignment 1hussainNo ratings yet

- Exstream03Content01Doc PDFDocument108 pagesExstream03Content01Doc PDFAymen EL ARBI100% (3)

- Broshure Heavy Industry enDocument24 pagesBroshure Heavy Industry enMahendra Donizar100% (1)

- Brochure SIMARIS Software ToolsDocument8 pagesBrochure SIMARIS Software ToolsDavid LovatoNo ratings yet

- Project Report On Automated Test EquipmentDocument46 pagesProject Report On Automated Test EquipmentGaurav PooniyaNo ratings yet

- Acc SVN25C en - 02082011Document68 pagesAcc SVN25C en - 02082011Mark Izsm AmersonNo ratings yet

- Carta Psicrometrica PDFDocument1 pageCarta Psicrometrica PDFFederico Ferreira LopezNo ratings yet

- Robotics and HumanityDocument24 pagesRobotics and HumanityJohn Francis MatutinaNo ratings yet

- PDT126ATAG3 - 250 kVA: ModelDocument2 pagesPDT126ATAG3 - 250 kVA: ModeldachinicuNo ratings yet

- 3BSE078160 en I System 800xa 6.0.3 Product CatalogDocument120 pages3BSE078160 en I System 800xa 6.0.3 Product CatalogJose Mella0% (1)

- 05 DP DP CouplerDocument15 pages05 DP DP CouplerIsai AnguianoNo ratings yet

- Bida20-008 FBI AssignmentDocument9 pagesBida20-008 FBI AssignmentBafenyi KopongNo ratings yet

- Instrument Functional DiagramsDocument29 pagesInstrument Functional DiagramsNino NievesNo ratings yet

- The Future of Model Coordination Is More Than Clash Detection!Document13 pagesThe Future of Model Coordination Is More Than Clash Detection!Nadia Dyorota Magdalena AdyamcyzkovnaNo ratings yet

- Product Catalog Split System Air Conditioners OdysseyDocument144 pagesProduct Catalog Split System Air Conditioners OdysseyRobin DittoNo ratings yet