Professional Documents

Culture Documents

Transmission Installation Guide Quick Reference

Uploaded by

iriana2009Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transmission Installation Guide Quick Reference

Uploaded by

iriana2009Copyright:

Available Formats

A T T E N T I O N

YOUR WARRANTY DEPENDS ON YOUR ADHERENCE TO THESE GUIDELINES

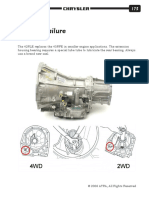

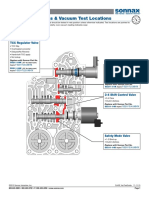

62TE INSTALLATION GUIDE

Chrysler Automatic Transmission

CHECKLIST

• Compare replacement transmission and torque convertor to original before installation.

• Scan original vehicle computer, record any codes for later review and resolve all codes.

• Transmission cooler and lines must be hot flushed or replaced.

• The drain back valve in the cooler line must be removed or replaced to prevent a cooler restriction that will cause

transmission failure.

• Inspect flex plate closely and completely for cracks or any damage.

• Inspect all engine and transmission mounts for wear and damage.

• Be sure both dowel pins are clean, installed properly, and are in good condition.

• Seat the torque converter completely in the transmission prior to installation in the vehicle.

• Verify that the engine block and bell housing surfaces are clean and free of paint, grease, oil and corrosion.

• Air tools should NOT be used to force the transmission against the engine block; this may damage or break the

transmission case.

• Torque converter bolts stretch with use. Be sure to check length before installation or replace them to prevent

torque converter damage.

• Clean the driveshaft yoke or transfer case input shaft prior to installation to prevent transmission output seal

damage.

• Inspect driveshafts and u-joints for wear, binding, and damage.

• Test all sensors and switches that have been transferred from the original transmission for correct operation.

• Using the purchased synthetic or ATF+4, add 5 qts of fluid and start the engine. Continue adding fluid until full, as

indicated on dipstick. For applications without dipsticks, see Fluid Check Procedure on the next page.

• Check fluid level in NEUTRAL with the transmission at operating temperature. The transmission vent is located on

the pump and will allow fluid to leak if it is overfilled.

• Confirm that the transmission has a good ground connection; reattach all ground straps to the correct location free

of paint, grease, oil and corrosion.

• Verify that the engine block and bell housing surfaces are clean and free of paint, grease, oil and corrosion.

• Adjust gearshift linkage after installation.

• Adjust throttle valve cable or reset throttle valve actuator to prevent improper shift timing and transmission damage.

Revision 8.15.14 62TE Installation Guide Page 1 of 2

62TE INSTALLATION GUIDE

Chrysler Automatic Transmission

QUICK LEARN PROCEDURE

The installing facility should verify they have the proper tools and that the scan tool they have is capable of perform-

ing the necessary procedures. As an option, the vehicle may be towed to a dealership to perform these functions at the

installing facility’s expense.

Operating the vehicle in any manner without performing the procedures described above can cause immediate

damage to the transmission.

To perform the Quick Learn Procedure, the following conditions must be met:

• The brakes must be applied

• The engine speed must be above 500 rpm

• The throttle angle (TPS) must be less than 3 degrees

• The shift lever position must stay until prompted to shift to overdrive

• The shift lever position must stay in overdrive after the Shift to Overdrive prompt until the DRB III indicates the

procedure is complete.

• The calculated oil temperature must be above 60°F and below 200°F

1. Plug the DRB III scan tool into the diagnostic connector. The connector is located under the instrument panel.

2. Go to the Transmission > Miscellaneous > Quick Learn Procedure screen.

3. Follow the instructions of the DRB III to perform the Quick Learn Procedure.

FLUID CHECK PROCEDURE

If your transmission does not come with a dipstick, follow these instructions. To ensure proper fluid level, use Miller

special tool 9336A

1. Verify that the vehicle is parked on a level surface.

2. Remove the dipstick tube cap.

3. Actuate the service brake. Start engine and let it run at

idle speed in selector lever position “P”.

4. Shift through the transmission modes several times with

the vehicle stationary and the engine idling.

5. Warm up the transmission, wait at least 2 minutes

and check the oil level with the engine running.

Push the Oil Dipstick 9336 into transmission fill

tube until the dipstick tip contacts the oil pan and

pull out again, read off oil level, repeat if necessary.

NOTE: When inserting dipstick special tool 9336, excess force may cause

the dipstick to slip past the stop on the bracket in the transmission oil

pan. The dipstick should be inserted into the fill tube approximately 16.7”.

The dipstick will protrude from the fill tube when installed.

6. Check transmission oil temperature using the appropriate

scan tool.

7. The transmission Oil Dipstick 9336 has indicator marks every 10 mm. Determine the height of the oil level on the

dipstick and using the height, the transmission temperature, and the following graph, determine if the transmission oil

level is correct.

8. Add or remove oil as necessary and recheck the oil level.

9. Once the oil level is correct, install the dipstick tube cap.

Revision 8.15.14 62TE Installation Guide Page 2 of 2

You might also like

- 2008 - 7 - 4 4L30E PumpDocument4 pages2008 - 7 - 4 4L30E PumpJon Rodriguez100% (1)

- Transmission NoteDocument6 pagesTransmission Notesyariza ismailNo ratings yet

- 41TE Accumulator PositionDocument10 pages41TE Accumulator PositionLula MarquesNo ratings yet

- G4a El FallasDocument8 pagesG4a El FallasLogam Lopez100% (1)

- User Guide TOKI0B5CLToolkit 0B5 Third EditionDocument22 pagesUser Guide TOKI0B5CLToolkit 0B5 Third Editiontalleres Llanos del campo100% (1)

- Portals Raybestos Files PM 1340 TCCcatalog 040715Document32 pagesPortals Raybestos Files PM 1340 TCCcatalog 040715robertoperez525No ratings yet

- Transmission Control Module (TCM) Adaptation - 8HP45 / 845RE / 8HP50 / 8HP70 / 8HP75 / 8HP90Document6 pagesTransmission Control Module (TCM) Adaptation - 8HP45 / 845RE / 8HP50 / 8HP70 / 8HP75 / 8HP90jorge almaraz0% (1)

- 345S Operators Manual: 511bailey Ave PO Box 324 New Hampton, IA 50659 Fax: 1-641-394-6224Document9 pages345S Operators Manual: 511bailey Ave PO Box 324 New Hampton, IA 50659 Fax: 1-641-394-6224valangelofNo ratings yet

- Atb209 Isuzu 4l80-E ...... High or Low PressureDocument3 pagesAtb209 Isuzu 4l80-E ...... High or Low PressureAleNo ratings yet

- 2006 Seminar Sonnax PDFDocument18 pages2006 Seminar Sonnax PDFHumberto LojanNo ratings yet

- GM 5L40E Automatic Diagrams and ListDocument9 pagesGM 5L40E Automatic Diagrams and ListBrayan Aragon diego100% (1)

- ZF 9hpDocument3 pagesZF 9hpNilay Srivastava0% (1)

- 5HP-19-PR: I.D. The Valve Body First!Document1 page5HP-19-PR: I.D. The Valve Body First!Esther KoltermanNo ratings yet

- 09D-TG AtsgDocument75 pages09D-TG AtsgValdir Gomiero100% (1)

- 616048547-Solenoid-10R80Document48 pages616048547-Solenoid-10R80XaiNo ratings yet

- Thectsc Mechatronic ReplacementDocument22 pagesThectsc Mechatronic Replacementros56100% (1)

- 4HP20Document140 pages4HP20suattosun100% (2)

- CUTIE DSG 2 TOURAN 1.6 DIESEL - PDF Versiunea 1 PDFDocument403 pagesCUTIE DSG 2 TOURAN 1.6 DIESEL - PDF Versiunea 1 PDFMarinel TerisNo ratings yet

- Ford Fnr5 TCC SlipDocument2 pagesFord Fnr5 TCC SlipAlex Maceira Graterol100% (2)

- Trans 722.9 TransTec PDFDocument4 pagesTrans 722.9 TransTec PDFMarcos MontesNo ratings yet

- 6F35 - 6F55 Installation Guide: Read This Entire Document Before Installing Your TransmissionDocument8 pages6F35 - 6F55 Installation Guide: Read This Entire Document Before Installing Your TransmissionPedro Isai Vega100% (2)

- Transfer Case MP 3023Document103 pagesTransfer Case MP 3023jackson vivasNo ratings yet

- Torque Converter NotesDocument5 pagesTorque Converter NotesGhostrider1No ratings yet

- Aa80e EngDocument772 pagesAa80e EngMarco MeloncelliNo ratings yet

- Sonnax 77701-076-InDocument2 pagesSonnax 77701-076-InmiguelNo ratings yet

- Technical Bulletin Listing: Transmission # # Pages SubjectDocument17 pagesTechnical Bulletin Listing: Transmission # # Pages SubjectAleNo ratings yet

- A43Document126 pagesA43Василий ДимовNo ratings yet

- 1.users Manual Dipstick Mercedes 722.6 722.7 722.8 Professional ToolsDocument2 pages1.users Manual Dipstick Mercedes 722.6 722.7 722.8 Professional ToolsLeonardo SouttoNo ratings yet

- Workshop Manual Checking Fluid Level PDKDocument11 pagesWorkshop Manual Checking Fluid Level PDKEderson BJJNo ratings yet

- TF-80SC VBL InteractiveDocument1 pageTF-80SC VBL InteractiveMauricio Exequiel ChavezNo ratings yet

- VW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFDocument68 pagesVW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFlucafelicianioanNo ratings yet

- MPS6 Wpistons PDFDocument1 pageMPS6 Wpistons PDFCambio Automático do Brasil100% (1)

- 2006 174 PDFDocument14 pages2006 174 PDFSantiago EscobarNo ratings yet

- 722.6 TruthTable 2Document2 pages722.6 TruthTable 2Jack CarlNo ratings yet

- 845RE Introduction: Presented By: Bill Brayton ATRA Senior Research TechnicianDocument42 pages845RE Introduction: Presented By: Bill Brayton ATRA Senior Research Techniciantejonmx0% (1)

- 4f27e Parte 1Document5 pages4f27e Parte 1libertyplusNo ratings yet

- AWTF80-81SC Huyndai VeracruzDocument6 pagesAWTF80-81SC Huyndai VeracruzRafael H Juliao Bolaño100% (1)

- Cmax 4a PDFDocument13 pagesCmax 4a PDFAlberto Morillas PueblaNo ratings yet

- Mechatronik SealDocument3 pagesMechatronik SealMihai Serban OlariuNo ratings yet

- ATDocument164 pagesATjacor96100% (1)

- 5L40E VacTestGuide InteractiveDocument7 pages5L40E VacTestGuide Interactivevmv68No ratings yet

- AW450 43elDocument9 pagesAW450 43elAlan Borges Da SilvaNo ratings yet

- SSP 390 7 Speed Double Clutch Gearbox 0AMDocument76 pagesSSP 390 7 Speed Double Clutch Gearbox 0AMEdgar Oswaldo Hinojosa Mayoral100% (1)

- Atra GM 6l45!50!80-90 BulletinDocument2 pagesAtra GM 6l45!50!80-90 BulletinAndrés Caleb Blanco GuzmanNo ratings yet

- AL4 Pressure Regulation FaultDocument3 pagesAL4 Pressure Regulation Faultsirajmy100% (1)

- Technical Service Information: BMW ZF-5HP-18Document2 pagesTechnical Service Information: BMW ZF-5HP-18Alejandro RoldanNo ratings yet

- Mercedes 722.0 To 722.6 5 Speed Chassis Ending 177-123 - 4 Bolt Pan Chassis Ending 123-126 - 6 Bolt Pan 3-4 SPEEDDocument6 pagesMercedes 722.0 To 722.6 5 Speed Chassis Ending 177-123 - 4 Bolt Pan Chassis Ending 123-126 - 6 Bolt Pan 3-4 SPEEDTransmisiones Automáticas Chepe0% (1)

- NAG 1/W5A580 Auto Transmission Diagnosis and RepairDocument42 pagesNAG 1/W5A580 Auto Transmission Diagnosis and RepairKamerom CunninghamNo ratings yet

- 6T40 Gen2 Zip in PDFDocument10 pages6T40 Gen2 Zip in PDFnurdinzai100% (1)

- At Re5r05aDocument70 pagesAt Re5r05aManuel ManriqueNo ratings yet

- 722.9, 7G-Tronic NAG2 Uncomfortable Shift QualityDocument3 pages722.9, 7G-Tronic NAG2 Uncomfortable Shift QualityИгорь НаумовNo ratings yet

- 62TEDocument4 pages62TEFSR140780% (5)

- DACCODocument333 pagesDACCOestebangm100% (2)

- Ac Tech Form - Re5r05aDocument4 pagesAc Tech Form - Re5r05aossoskiNo ratings yet

- 2005 KJ Transmission DSLDocument244 pages2005 KJ Transmission DSLmock_er100% (2)

- Fluid Check Ig Cd4eDocument5 pagesFluid Check Ig Cd4enameNo ratings yet

- Attention: FamiliesDocument4 pagesAttention: FamiliesthuggbondedNo ratings yet

- Attention: 6R140 Installation GuideDocument4 pagesAttention: 6R140 Installation GuideAlex Maceira GraterolNo ratings yet

- Install 6l80Document4 pagesInstall 6l80oliver lealNo ratings yet

- 206-00 Brake System General - General Procedures - Brake Disc MachiningDocument4 pages206-00 Brake System General - General Procedures - Brake Disc MachiningCARLOS LIMADANo ratings yet

- Computer Event AdvertDocument5 pagesComputer Event AdvertJAMES WARURUNo ratings yet

- Service Manual for Compact Disc Stereo Cassette ReceiverDocument35 pagesService Manual for Compact Disc Stereo Cassette ReceiverRodrigo NegrelliNo ratings yet

- Eaton Automated Transmissions TRIG0020: Installation GuideDocument140 pagesEaton Automated Transmissions TRIG0020: Installation GuideLuis MedinaNo ratings yet

- Reference Guide To Mining Machine ApplicationsDocument54 pagesReference Guide To Mining Machine ApplicationsYohanes WibowoNo ratings yet

- Network Cabling Design Best PracticesDocument40 pagesNetwork Cabling Design Best PracticesThomas Or0% (1)

- AISG Cable - Connector Installation GuidelinesDocument2 pagesAISG Cable - Connector Installation GuidelinesRubic SantosNo ratings yet

- Product data sheet mini circuit breaker A9F74206Document2 pagesProduct data sheet mini circuit breaker A9F74206Rasek ResolfNo ratings yet

- A Solenoid Engine: Students of Group 10 IEC College of Engineering & TechnologyDocument14 pagesA Solenoid Engine: Students of Group 10 IEC College of Engineering & TechnologyArvind Kumar100% (4)

- Zenit Steel Series Electric Submersible Pumps enDocument2 pagesZenit Steel Series Electric Submersible Pumps enedekovacsNo ratings yet

- Computer - An Introduction: Computer, Machine That Performs Tasks, Such As Mathematical Calculations or ElectronicDocument14 pagesComputer - An Introduction: Computer, Machine That Performs Tasks, Such As Mathematical Calculations or ElectronicprakashkumarvermaNo ratings yet

- Tailoring NC II Multiple Choice PracticeDocument13 pagesTailoring NC II Multiple Choice PracticeJe-ann H. GonzalesNo ratings yet

- Electrical and Electronic Engineering Rectifier GuideDocument38 pagesElectrical and Electronic Engineering Rectifier GuideDenifer DeepNo ratings yet

- Main Engine 6m26.2 Spare Parts CatalogueDocument96 pagesMain Engine 6m26.2 Spare Parts Cataloguehany mohamed75% (4)

- TA30 Tier3 8591Document370 pagesTA30 Tier3 8591Yeison RamirezNo ratings yet

- Easy Altivar 310 - ATV310H037N4EDocument6 pagesEasy Altivar 310 - ATV310H037N4ESundeep Bandi100% (1)

- 1998 Ford Mustang Brakes - Service Mustang and GT Models Cobra ModelDocument3 pages1998 Ford Mustang Brakes - Service Mustang and GT Models Cobra Modelatlanticblue98No ratings yet

- C4 Corvette Courtesy Lights Dimmer Module RepairDocument13 pagesC4 Corvette Courtesy Lights Dimmer Module RepairSjoling8211No ratings yet

- Electrical ReviewerDocument16 pagesElectrical ReviewerPrincess Diana ArrojadoNo ratings yet

- Delta6rc FinalDocument2 pagesDelta6rc FinalsarvottamNo ratings yet

- Coduri MandqwdqwDocument59 pagesCoduri MandqwdqwRazvanSandolacheNo ratings yet

- What Is The Difference Between MCB, MCCB, ELCB, and RCCBDocument7 pagesWhat Is The Difference Between MCB, MCCB, ELCB, and RCCBrod8silvaNo ratings yet

- STM32 Microcontroller General Oct2012Document69 pagesSTM32 Microcontroller General Oct2012dcesentherNo ratings yet

- Specification Sheet NGRDocument5 pagesSpecification Sheet NGRAghniaNurAnNisaNo ratings yet

- Test Report: Newage CablesDocument4 pagesTest Report: Newage CablesMuhammad Shabbir AwanNo ratings yet

- InstallationDocument170 pagesInstallationSteve Alain Onana DangNo ratings yet

- L100 (0a)Document1 pageL100 (0a)jonodo89No ratings yet

- Mechanical Equipment List for Oxide Leach Area ProjectDocument3 pagesMechanical Equipment List for Oxide Leach Area ProjectNelson Cuevas AvendanoNo ratings yet

- ARDU-5351mini English ManualDocument15 pagesARDU-5351mini English ManualPalade LiviuNo ratings yet

- TES-2360 LCR Multimeter Testing Auto-Ranging FunctionsDocument2 pagesTES-2360 LCR Multimeter Testing Auto-Ranging FunctionsMuadzhim RedzuanNo ratings yet