Professional Documents

Culture Documents

Steel

Steel

Uploaded by

M Roy0 ratings0% found this document useful (0 votes)

38 views22 pagesQuestion

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentQuestion

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views22 pagesSteel

Steel

Uploaded by

M RoyQuestion

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 22

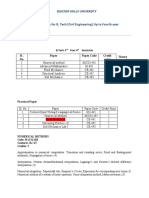

4AT2 caper? Simple Connections

&

eo Et

aie

FIGURE 7.194

Detemine he maximum eves ead that can be appli fhe tv oa ode and

‘tis 20 Investigate al Lit sas. Al sutra sol A36 and the weld te

‘sie filet weld wit £70 lets, Note that the estan member e 2 dbl

‘ogni often ood eam ee

Sime ae

Seas |so% 8

eee

HO

FIGURE 7.112

ke

we

temine the maximum service lsd, thatcan be applied if thie ldo dead

ond to 2.5 Each component ina PL'4x 7 of A247 tel. The weld sa ciach

fil weit E7Ociestede.

1, Use LRPD.

b. Use ASD.

SSS,

oune P7119

@

Probiens 473

‘A tension member spice is made with cinch B70 filet wel as shown in

Figure P7114. Each side ofthe splice is welded s shown. Te inex member i

PL 6 andeach outer members PL. ie 3. All sel i ANG Determine the

‘muimum sevice load, that can be appliad th iv lot dead and ato 3.9.

1. UseLRFD,

Use ASD,

Pitti

GuRE Pr:

Design a weld connection. The given tad re rie loads. Use = $0 ke for

‘eagle tension mentor and Fy =36 ki for he gset plat. Show you reason

seth, complete wid dimensions

2. Ure LRFD.

Ure ASD.

sa

ASS

pam

FIQURE P1158

Design swell conection forthe conditions of Problem 7.43, Show your result

‘ona setch, complete with dimensions.

2 Use LRED.

Use SD,

4

ATA copie? Simple Comestons

7447 _Design welded conection for am MC9 239 of AS72 Grae 50 steel connected

14 inchick ust pae, Te gute eis AG ste Show your aul on

sketch, complete wih dimensions.

2 Use LRFD.

Use ASD,

tons

oun Pr

(318) Use LRFD and design a welded connection to rest the arabe strength of the

tention member in gure 7.118 Al sels A36, Show your results ona stich,

complete with dimensions

ven

—

_

Floune Pra

7A¥9 Use ASD w sole duble-agle sion member and design 8 welded conection

‘hat wil esis» deal oad of 2 kipe aa live load of 36 kip. The member wil be

12 fet long ad wl be cones a neh hick guse pee. Use AN6 tel for

tah the tension memter andthe gusset ple. Show your resus ona sketch, com

plete with dimensions,

mo PLASTIC

OO B21 —— ELnsric Provame 873

8.2.2 The bolt group shown in Figure P8.2-2 consists of s-nch-diametes, Group A slip-

“rls alia Asse te beg eg int ono

‘limo Erm elon

4 The moc ares od hat cone pe ER ee

8 Thema evi dt an pid ASD rd

© 00 0 O—lbe

pve a

oooo00

femened

Gl

Figure 823, Ucar i sad cote if mma ahr rs

ee

oO oe

Sate Sy bes

82-4 The fistenesin the conection of igre P8.2-4areplced atthe usual gage distance

(Gee Figur 3 24). What ditional force is expences comeguene of her

‘ees not being on the enol ai of the member?

fryafrac®

578

Chapter eentie Connections

a28

‘Group A bal ar used inthe conecton in Figure P69 Uso an ast nays and

cleemie the roqued sie isis permite. The IDs ond consis of kis

of sevice ded lod and 75 kp of serie liv lod All strstr ston A36

oun

EU ye

t T

°

L-re °°

t

wot Now

rauneraze

A plates connected tothe web of une a shown ia Figure 82-10.

‘Use an htc naps nd compte the maximus bol res.

®, Usette ales mPar Yo he Manual tn the maxi ol force byte uh

‘mate sueath meio (Not tha the cult Cex be erp athe ra

tel conection load a mesimum fstenr free) What the pres i

‘ence om he vale obi by te lati only

ot

Solve Problem 82.2 by ihe inate rng method asthe tables in Fat 7 of he

Maal

“The bolt group shown in Fue P2-12 conse of incite, Group A

‘beaig- pe bls in single shen. The bearing strength i adeqete. Use LRED sod

{he aber n Part 7 ofthe Manual deere the flowing

18. The maximum penmsible factored la.

1b. The equied numberof bok pe verte row ithe etre oad 15 kip

x

Net section strength: =

Ac = AyU= 2,50(0.9671) = 2.418 in?

P= Fad = 65(2.418) = 157.2 kips

2 ;

Fa 1512 « 73.6kipe

co

Rearmesen -armamiess 37a |

1, 0(0.6)F:

Fea ABB a sassepin, — Bocermalal = LCE NE

= 8.1%)

Base metal shear strength of the plate:

OSs . 0600139) 5 srpuin>

SEL «OSS 5. iin» 1856 isin

Nt")

Re

a

Yield

apore: Ae = YEE - LESBO) «« sstipsin > L856 tpn

‘Base metal shear strength ofthe tension member:

vtings Bp = ‘se = 2.15040 17 «3.5 pain > 5 iin,

Rupture; & = aoe aes — - 179) 3, 491 kipsin, > 1.856) ‘kips‘in.

Tevelddebisenerbantetwemsisin. 9's x3Lx Se

)

P= 48. akips f

Z

C/

otal weld strength = 1.856(13 + 13) = 48.26 kips

Weld strength controls overall: P, = 48.26 kips.

@

Fe = 0.90F 4, = 0,90(36)5.12) = 165.9 kins GS

poor A

( Netseion: U=1= $= 1 =

Ae = Agld = $.120.8342)

GP. = 0.75F Ae = 0.75(58)(4.271) = 185.8

Weld: FOR GACH 1" LONG

#R, =

(0. 7070(0.€F sxx)] = 0.75(0.707)(3/16)(0.6 x 70) = 4. 176 kipsin, e—

(Altemate: 6Ry = 1,392.3 sixteonths = 4. 176 kpsin)

Forte strength of the coanection, investigate the two options given in AISC 12.4(0).

1. Use the basic weld strength fr both the longitudinal and transverse welds.

I6(S +5 +5) = 62. 64 kips (for one engley — \WVE/_D

2. Use 0.85 times the basic weld strength forthe longitudinal welds and 1S times the

basic weld strength forthe transverse weld. “4 TENSION

aoe

9R. (4. 176MS +5) + 1.564. 176) S2kips (forone angley C) R WELD

‘The larger value may be used. For two angles, the total weld strength is

(66.82 x2 = 133. 6kips

ee [alp sTUFF

Che ik sear onus pain is of nse met sear seg] © a

16 Iyt

Ay = Aus = (8) 22 = 3.75002 I LI

pol

= 36) = Lariat

Ay 3G) = 1.875

From AISC Equation 4,

Ry = 0.6F Aw + Une vam a

.6(58)(3.750) + 1.0(58)(1.875) = 239.3 kips

with an upper limit of

0.6F Ap, + UsF vAny = 0.6(36)(3. 750) + 1,0(58)(1.875) = 189. 8 kips

[7-55] y

Block shear design strength = Ry = 0.75(189.8) = 142.4 ips

Weld shear controls, and P, = 133.6kips. Let

1.2D + 1.6(2D) = 133.6, Solution is: {D = 30. 36)

P = D4+L =30,36+2(30.36) = 91.1 kips P= 91.1 ips

= 3615.12)

34512) A104 hips

Fase Ag 058)4.271) = 83. 9kips

p.7071(0.6F ew) Lo 7079(316)(0.6 x70)

7184 kis /

ybnate: Be 0.97% 3 sees 2.784)

‘For the | women ine the two options given i AISC J2.4(c).

{eld stength for both thy “ongitainal and transys welds

1 Coe the bas

/

Be Areas +5 +5) = a1. 16hips orone angle)

/

2, Use4485 timesihe basic as forthe nga welds and 5 timeye

(verse weld,

basi-veld strength forthe tr

R

‘The larger valuc may Me used. For two: sang total allowable welg/rength =

44,542 = 89. Lips

Cees staronte suerte oftne meal steyanagh Fotis /

(7-56)

jos

= 153 ‘ie J

QPL HpxS

640 kipsin,

= 64, Sets ony a P= 65.0 kips

/

(@) LRED solution. Gross ction: For the outer member,

Az = (SIN6)(3) x 2 = 1.875 in?

For the inner member,

3.0in? 4

Outer member contol: 6,P, = 0.90%; = 0.90(36)1.875) = 60.7Skips GS}

Net section: de = Ay

P= 0.75FyAe = 0.75(58)(1.875)

Ay = W2K6)

1.56 ips MSR

Weld: §Ry = 1,392 3 sixteenths =4. 176 kipslin

1. Basie weld strength for both the longitudinal and transverse welds:

Re

176(3 +3 +3)2 = 75. 17 kips

2. 0.85 times the basic weld strength forthe longitudinal welds and 1.5 times the basie

weld strength for the transverse weld

#Re

0.85(4, 176)(3 +3) + 1.5(4. 176)(3)] «2 = 80.18 kips

Use the larger value of 80.18 kips

Check block shear on the inner member in leu of base metal shear strength

158 Y

02cm li oye aed rd el romain cbc ce nem

Ag = Aw = 4G) x2 © 3.0in2

40) =15in.

Au = 40) =1.5

From AISC Equation 34-5,

Ry = O.GF Am + UF

6(58)(3.0) + 1.0(58)(1.5) = 191.4 ips

with an upper limit of

0.6F Ay. + UssFvAus ~ 0.6(36)(3.0) + 1.0(58)(1.5) = 151. 8 ips

Block shear design strength = + = 0.75(151.8) = 113.9 kips

Gross section tensile strength controls, and Py = 60.75 kips. Let

1.2D + 1.6(3D) = 60.15, Solution is: {D = 10.13}

P= D+3L = 10.13+3(00, 13) = 40, Skips P= 40.5 kips

(©) ASD solution

a 36(1.875) _

Gr C575). ~ 40,4 kips

Net section:

Fxde « 58(1898) _

Be Fale = Slag = 544k

Wel Ae «092793 sites =2.784 isn

nd transverse welds

|. Basic weld strength for both the longitudinal

z

t

2. 0.85 times the basic weld strength forthe longitudinal welds and 1.5 times the basic

weld strength for the transverse weld

T8S(3 #3 +3) <2 = 50.11 Rips

Be

Ra. = (0.85(2, 784)(3 +3) + 1.5(2, 784)(3)] <2 = 53.45 kips

Use the larger value of 53.45 kips

Ib

‘Check block shear on the gusset plate in lieu of base metal shear strength. From the

(7-59)

LLRFD solution, the rominal block shear strength is

Ry = 151.8 kips

‘The allowable block shear strength is

Re 1SLB

Ay = SLB = 75. okips

Gross section tensile strength controls:

From AISC Table 32

thickness). Maxi

‘Thyeld strength of 5.568 kipsi

wi be used, To determine the

the longitudinal and transverde welds,

total required length of weld = 085

V

(7-60)

leat ofnghuinal welds = JBSE=$. = 6,4

Forthe second apt, te sengh of the longi wel

0.856 58) = 4.759 isin

snd the stent ofthe ranevere wel i

1 (S56) = 8.35 kin,

‘The load to be carted by the longitudinal welds is

104~ 5(8.352) = 62.24 kips

0 the required length of the longitudinal welds is

B24. 6 57515

2(4.733), 6875

‘The first option requires shorter longitudinal welds. Try a S-inch transverse weld and

{so 7-inch longitudinal welds. Check the block shear strength ofthe gusset plate,

Ayn DEO 525m dy EG) = LATS

Ry = O.6F Aas + UssF Aw = 0.6(58)(5.28) + 1.0(58)(1.875) = 2091.5 hips

with an upper limit of

0.6F Ap + UnFvdm = 0,6(36)(5.25) + 1.0(58)(1.875)

‘= 222. 2kips (controls)

‘The design strength is

OR

75(222.2) = 167 kips > 104 kip (OK)

Use Yin fillet welds as shown,

2/

(7-1)

(©) ASD solution Py =D +L = 20 +50 = 70kips

Tryw sing RAR 0.929 intents 3.71 isin,

Bee el she senh (gut ple cont) The allowable she yl srengh i

- (2) =5.4kipsin.

oar = 0.406)(3) ~5.4ip

andi alovablsna pure sreaghis

0.3Fy

(2

1150() = 6 25 ipin

The weld strength of 3712 kipslin. governs. Both longitudinal and transverse welds

willbe used. To determine the required length ofthe longitudinal welds, investigate

{he two options specified in AISC12.4¢). First, assuming the same strength for both

the longitudinal and iensverse welds,

total required lengih of weld = 70> = 18, 86 in,

372

length of longitudinal welds = 1EAB=5. — 6,03 in

For the second option, the strength of the longitudinal welds is

0.85(3.712) = 3.155 kipwin,

and the strength of the transverse weld is

,

won »f

7-62)

2 ety Ati ae ob ae dd pda sc inn wpa

1.5@.712)

Forthe second opin the strength ofthe longitainal weds is

0.85(4, 640) =3.944 kipstin

andthe strength of he transverse weld is

1.5(4.640) = 6.96 kipsfin

‘The load tobe card by the longitena weds is

140 -9(6.96

17.36 kips

$0 the required lengih of the longitudinal welds is

= TL36_ ~ 0,807 in

313.944)

‘The second option requires shorter longitudinal welds. Try a9-inch transverse weld

and two 10-inch longitudinal welds. Check the lock shear strength ofthe gusset plat,

From the LRFD solution, Ry = 357. 8 kips, and the allowable strength is

Ry. 357.8

Ae - B78 «179 ips > 140) (0K)

Use 5!16-in. fillet welds, witha 9-n. transverse weld and two 10-in. longitudinal welds

®

‘Tension member gross section: $,P, = 0.90F,4, = 0.90(36)(1.93)

For the net section, assume U = 0.80: A, = ApU~ 1.93(0,80) = 1, $44 in? \

Py = 0.75F dc = 0.1558)(1.544) = 67.16 ips. «use Py = 62.53 kins SR

62. 53 kips

Fort = 1/4 in, min. w = 1/8 in, and max w = 1/41/16 = 3/16;in. __

‘Tey two Hongituding £70 fillet welds, and W minimize he lenglt oF the connection, ry

inch, —

Ry = 1.392 x3 sitoenths = 4.176 kipsin, ——

pe Ie bowel

Wi

[7-68]

‘The base metal shear yield strength (angle controls) is

ouch = 0.660)(4.) = 54k

Shear npturesenghis 0.451 = 0.4505 (4) = 6.525 pin

‘The wed strength of 4.176 kips/n. governs.

uired length = $2.53 in.

Required length = $2:53. = 14, 97

‘Check essumed value of U :

—1gS = 0.865 >assumed vaeaf 080 (OK)

70 fillet welds as shows.

jn

L

A19

Pa = 12436 = 48 kps or 48/2 = 24 kips/angle

dd, = gee = PA tin?

Reads = 9k = Toca ~ 1 iM

Yd Ae = hie = 24 2 0.828 in?

Reddte= 55, 5s = 98

in, r = abe ~ 121020

Min. = 305° = “300

48 in

‘Try 224 %24% 4, Ag = 1.19 in2 (forone angle) >1.11 in? (OK)

From the properties table forthe double-angle seston, rn, =0.764 in.>048 OK) f

7-69]

= i 2.30270.18

Pm” Seley 556

p= bigs = LEBAO — omapeipe=

= 7.942 107P hips +

Tipe = 0.08667 + 7.942 « 107P = 0,166P hips

Ley = 0.057 +

p= {Spa's an = (CATO DIP = 0.27827 kips

Slip-eritial strength will control over shear. Assuming Class A surfaces,

(1733P = 0.2233P ips |

y= wDahyan, = 0,30(1-13)1.0N28)(1) = 8.482 kipolt

(0) Re = 1.019.492) = 9.492 ipso

Let P= Py and 0.27820, = 9.492 Pan 34.1 hips

Be = 242 = 6 s28 ipetot

Let P= Pp, and 0.27127, = 6.328 = Pam 34.1 ips

Direct shear component: po = $5» 13.0 ips |

Determine location of centroid with respect to lower let bot:

eats, p= 222-345

eens 6, = 4266-18 =9.2in

M = 65(9.2) = 598.0 in-kips

Dest +97) = (1.72) +B - 1.8) + 6.472) +G.4-3)" + (7-342)

0.0in?

Top rightboltisertica, x= 3-1.8=1.2in, y=344-3.4=3.6in, 16/

62)

mca ai Ane nel pa ral ph acne op

= = 528G.9) 35, 98 ips»

Poo ™ Seay ~ Sg = 35.88

p= sy = SEED = 36

35.83 kips* Spy ~ 13 + 11.96 = 24.96 kips |

p= [Spat Sey = (SPECT = 43.71 kips

p= 83.7 kips

824

Direct shear components pa = Jf = 15.0 ips

‘M=75(1-58) = 118.5 in

Dat ty?) = (1.25)(2) + 2.599) = 15.68 in?

Pur bls = UESGD «89st

p= {Sp Lay = (ULOF FORTH ~ 26.17 kips

Without considering eccentricity, p = pa = 15.0kips

Difference =26,17 = 15 = 9. 17kips (61%) Difference =9.17 kips

f

1

ws /

(8.2 -2 Probhom deg

ey) G-44)

Use Table 7-8, Angle 307. n= Sands = 3in. = tn30"

a | fobs

—— | oo

x= 10tan30° + 35. — 8, 524 in.

ah

Catena sto

‘Slip-critical

Ra = ADabyTam, ~ 0.30(1.13)(1.0)(28)(1) = 9,492 kipsfbot PER BOLT

Ferthe connection, Ry = CRq.= 4.756(9.492) = 45.14 kips

—FoRr | BOLT

(@) LRFD sation FoR CONNECTION

Pam BBn = 0.75(85.14) = 33.86 hips 2. =33.9 ips

(®) ASD solution

Ap = St = 2 sri Pa =22.6hips

8212

Use Table 7-13, Angle = 30°, ne 3ands = 3in,

ee 44442—31mn30°

(C= 5.687 (by interpolation) 7

268 in.

(#13)

‘cog tenyAt eve ons tr dd pede en erp

et ssteremae nm [aso]

|

YTABLE 31

Minimum Bott Pretension, kips!

ema Gag con

sorsinin | waraitencey oar tooty

ek feo) 5

ES | ‘s

TABLE J3.1M

Minimum Bolt Pretension, kN'!

‘The snh ainda te RCSC Spat ole ihe 8

code oer an sgt sl blest ented one decg dvinge (Set

‘Tle. fr minim bt peson comers Signed pre.

se reper)

‘Une Nts Tat ao pan maton eso aie Fr

supa Ys Bas dae hve ben pte! we pert rapist

‘neces pci probe on Geen deren

ce] Destcxconstoerarionsrorsotts | DEIGNTARL

Table 7-8 (continued)

Coefficients C for Eccentrically Loaded Bolt Groups Coettic

= Angle=30° CG =4,7%

‘aie sera ot abt ran, | asx

rr Rrascaernnes wr, | P= ike ce, Pot Pi (oe Fh

‘eal seg ra ps

tcxetiy of Puan rene“ fe

‘wearin in +

frotibiee,nayte

| Giernedorcemer oe

c= hal canner ae. A

| sateen Cmne ge

|G = come tteseon E

Tambor of Bln oe Vert Row

in ; ania

1[?[*/* eye 7 ,* /*/[nie

T | va0| 200] a7] ee) oes] 07 | var | wr | ver | wr] mo | me 7

3 | vos 2ar| 1a] se] a6] ‘sas| 119 | i39 | seo | 120 | ato | 223 3

4 | ose | ata] a5e| Sao} 712] 90d] s10 | 90] a2 | aaa | 92 | 212 4

5 | aa0| 140] ze) 476/ 646) azo] to2 | r22 | 142 | 103 | 10a | ane 5

© | ar | teo| 26i| 429] 96) rer] ‘945] 14 | 194 | ta | 174 | tos §

-1| 086 | 133] 263| 30] sae] 70) ars) 106 | 125 | 145 | 165 | 106 7

fas | 133| 240] sar/-tap) bso] Geel ‘bee| 13 tor | ist | tee 8

rs. | oss | 128] 220) 320{ 436) oo] 750] a2 111 | 129 | 49 | 158 8

ele us | 138} 2as| 308] E36) sei] 709) 972] 104 | s22 | 143 | 160 y |e

42 | aaa | ine] 47s] 26s] a72| sa] 62s) 773] ‘ea vio | 2a | 48 R

1 | os7 | 090] 15s] 234] a2o| 37] 55a] 655) a3) 993] ine | 133, rm

1s | 038 | oan] 132] 200| 205] 350] Sos) S25) 75] 900] 108 | 122 6

te | 030 | a7z| 42s] 40] Zor] 355] tsr) 570) 6s] a27} 520] 2 8

x | o2r| oas| saa] 173) 20a[ 32s] | 520) 635] 202] aas) toa »

24 | 023 | oss] 096] 145) 207] 277] 37] 47] Sa] ese] 72) 300 a

x | oz | o4s| ass| s2r| 179] zai] a1] soo] 47a) 575] 97a] 721 8

42 | ote | aaa azs| 132] 18] 212] 276] 34s] 25] Sn] soul 700 2

o_| ove | 03s] cos} too) so] iai| 27] 310] 35i]_asa]_ seal 62 %

Zp iwy aa] sss] 735] oe] tia Pose [tse Pra [as PHS | Bo 7

3 | 10s | 250] 431] és] or] sno | asa | tsa | azs | 391 5

4 | ose | 256) 450] @s3| os0| tao | 127 | 47 | ies | te ‘

§ | oan | 220] 13] ero] si4| in2| 123 | 143 | tee | sea 3

& | ar | 200] 20] Sea| 220) \a7s] 118 | 139 | 180 | 180 5

7 | ost | 19] ssi] sar] 727) sao} ass | sa4 | 155 | 128 7

8 | ose | 174] 325] 435 | 626) sao] tos | 120 | 150 | 121 a

® | oss | a1] 302] )

CVEN 446 cuss numaer “Sate _ J—/— race Ly

,

>

aS dik |

Jz oe Ae 2 y

alten)

@ =

J= tx Ty 22/0

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Syllabus: MX ROAD Total Duration: 64hrs Theory:2hrs/DayDocument4 pagesSyllabus: MX ROAD Total Duration: 64hrs Theory:2hrs/DayM RoyNo ratings yet

- 8th SemDocument6 pages8th SemM RoyNo ratings yet

- Seacom Skills University: B.Tech4 Year7 Semester Theory Paper SL - No. Paper Paper Code Credit PointDocument12 pagesSeacom Skills University: B.Tech4 Year7 Semester Theory Paper SL - No. Paper Paper Code Credit PointM RoyNo ratings yet

- DistrictWiseList324 PDFDocument2 pagesDistrictWiseList324 PDFM RoyNo ratings yet

- Outcome1 T1 PDFDocument12 pagesOutcome1 T1 PDFM RoyNo ratings yet

- A Paper On:-Implementation of 4-Lane Cable Stayed ROB at Barddhaman - Future Fast Track Model For New ROB Over Busy YardDocument16 pagesA Paper On:-Implementation of 4-Lane Cable Stayed ROB at Barddhaman - Future Fast Track Model For New ROB Over Busy YardM RoyNo ratings yet

- Seacom Skills University: B.Tech 2 Year 3 Semester Theory Paper Sl. No. Paper Paper Code Credit PointDocument12 pagesSeacom Skills University: B.Tech 2 Year 3 Semester Theory Paper Sl. No. Paper Paper Code Credit PointM RoyNo ratings yet

- 1a-Corner Restoration BookDocument20 pages1a-Corner Restoration BookM RoyNo ratings yet

- Seacom Skills University Syllabus For B. Tech (Civil Engineering) Up To Fourth YearDocument9 pagesSeacom Skills University Syllabus For B. Tech (Civil Engineering) Up To Fourth YearM RoyNo ratings yet

- Seacom Skills University: B.Tech 2 Year 4 Semester Theory Paper Sl. No. Paper Paper Code Credit PointDocument11 pagesSeacom Skills University: B.Tech 2 Year 4 Semester Theory Paper Sl. No. Paper Paper Code Credit PointM RoyNo ratings yet

- 03 Stress Complete PDFDocument56 pages03 Stress Complete PDFM RoyNo ratings yet

- The University of Trinidad & Tobago Alternate Final Examinations December 2013Document8 pagesThe University of Trinidad & Tobago Alternate Final Examinations December 2013M RoyNo ratings yet

- Seacom Skills University: B.Tech3 Year5 Semester Theory PaperDocument9 pagesSeacom Skills University: B.Tech3 Year5 Semester Theory PaperM RoyNo ratings yet

- Experiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineDocument2 pagesExperiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineM RoyNo ratings yet

- RCD Assignment 1Document5 pagesRCD Assignment 1M RoyNo ratings yet

- Curri Cul Um For ST Aad. Pro: Cetpa Infotech Pvt. LTDDocument4 pagesCurri Cul Um For ST Aad. Pro: Cetpa Infotech Pvt. LTDM RoyNo ratings yet

- Free-Body Diagrams, Equations of Equilibrium & Constraints For A Rigid BodyDocument19 pagesFree-Body Diagrams, Equations of Equilibrium & Constraints For A Rigid BodyM RoyNo ratings yet

- NoticeDocument1 pageNoticeM RoyNo ratings yet

- Internal Combustion Engines4 PDFDocument34 pagesInternal Combustion Engines4 PDFM RoyNo ratings yet