Professional Documents

Culture Documents

How To Solder Mask Pcbs

How To Solder Mask Pcbs

Uploaded by

Imam BysOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Solder Mask Pcbs

How To Solder Mask Pcbs

Uploaded by

Imam BysCopyright:

Available Formats

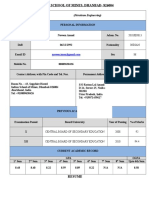

How To Solder Mask PCBs

Created by Ruiz Brothers

Last updated on 2018-08-22 04:03:56 PM UTC

Guide Contents

Guide Contents 2

Overview 3

Rusty PCBs? 3

Mechanic's Solder Mask 3

Solder Mask 5

Making A Solder Mask Template 5

DIY Sharpie Solder Mask 5

Eagle CAD 5

Tweak Artwork 6

Printing on Transparency Film 6

Print Settings 6

Prep Film 6

Double-Mask 7

Applying Resin 8

Clean PCB 8

Apply Resin 8

Spread Resin 8

Squeegee Resin 9

Place Mask 9

Expose UV Resin 10

Peel Film 10

Clean & Cure 11

Post Processing 11

Rub, Wash and Rinse 11

Through Holes 12

Final Cure 12

Solder Components 13

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 2 of 13

Overview

Rusty PCBs?

Wether you're etching or CNC milling your own PCBs,

the copper layer on the substrate will eventually begin

to oxidize and rust. The best way to prolong the life of

your PCBs is to give them a protective coating. This is

where PCB Solder Masks come into play.

Solder masks resist solder and act as a protective layer that rests on top of the copper traces. It's the green stuff found

on most common PCBs. Solder masks can take high temperates, so it can handle the intense heat from the tip of a

soldering iron.

Mechanic's Solder Mask

UV curable solder mask is a special type of resin that

hardens when exposed to ultraviolet light. It comes

different colors in a syringe type tube. You can find it

online or purchase it from your local electronics hobby

shop.

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 3 of 13

There's a few household items and supplies that can

help assist the procedure. Most important parts needed

is the UV resin and transparency film.

UV Curable Solder Mask Resin

Transparency Film

Isopropyl alcohol

Nitrile gloves

Paper towels

Topperware tray

X-acto knife

Ruler / T-square

Silicone mat

Cutting mat

1 x Mechanic UV Curable Solder Mask

Type: LY-UVH900

BUY NOW

1 x Transparency Film

Quick Dry type for InkJet Printers

BUY NOW

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 4 of 13

Solder Mask

Making A Solder Mask Template

The first thing I need to do was to make a solder mask

template. This is basically a transparent film that has

artwork of the pads and vias in your PCB design.

DIY Sharpie Solder Mask

If your PCB design is simple, you could DIY your own

solder mask template with a sharpie. Overlay a piece of

transparency film over the PCB and mark in the pads

and vias using a fine tipped sharpie. You'll want to

double up on transparency film to make the pads more

darker, which will be helpful to block out the UV light

when exposing the solder mask resin.

Eagle CAD

For more complex designs, I suggest making a custom

template with the help of your CAD software. In

Autodesk Eagle, it's as easy as isolating the pads and

vias layer. I also suggest showing the mounting holes

and board outline, which is helpful for obtaining good

alignment. You can use the "Print" feature to save out a

PDF.

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 5 of 13

Tweak Artwork

You may find it useful to tweak the pads and outlines

using a vector graphics editing software (such as Adobe

Illustrator or Inkscape) – I found it necessary to fill in the

holes in the pads so the resin doesn't harden when

exposed. You can also add vector graphics for getting

DIY silkscreen graphics.

You'll want to layout multiple copies of the PCB so that

they can be doubled up. I did this by copying and

pasting the vectors in Adobe Illustrator and tried to

maintain even padding/margin space between them.

Printing on Transparency Film

Getting the solder mask artwork onto a transparency

film can be done with either laser toner printer or an

inkjet printer. The inkjet printers are more common and

require a special "Quick-Dry" type transparency

paper. One side has a coarse texture which is the side

we’ll need to print on. The rough surface allows the ink

to dry so it sticks and it doesn’t wipe off.

Print Settings

Using the print dialog, I changed the paper type to the glossy paper and cranked up to the highest quality print setting

– This will ensure the ink sticks to the transparency film.

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 6 of 13

Prep Film

Using an x-acto knife, cut out the artwork and make

sure to leave padding around the edges so it’s easier to

handle the film. You'll need to double up the artwork

because the ink just isn’t dark enough to fully block out

the UV light.

Double-Mask

To stick them together, I added drops of superglue

along the edges. You’ll want to make sure not to get

this on the ink, so make sure there’s plenty of blank

space. Perfect alignment is very important, so you may

want to tack the artwork down so it stays in place. Blank

pieces film can be used to spread the resin, so make

sure you have a few.

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 7 of 13

Applying Resin

Clean PCB

Before applying the resin, you'll want to make sure the

PCB is cleaned and free of any rust. Since mine were

CNC milled, I used a scotch brite pad to lightly buff out

the burrs and was even able to remove a small amount

of oxidization.

Apply Resin

Once cleaned, place the PCB down on a piece of blank

film. Remove the protective cap from the tube and press

your finger against the plunger to dispense the resin

onto the PCB. It’s easy to dispense onto the PCB but

how much to use will depend on the size of the PCB.

Use your best judgement to determine how much resin

can cover the entire PCB.

Spread Resin

Grab a second piece of blank transparency film and lay

it over the glob of resin. This will help spread the resin

across the surface of the PCB. Lightly press down on the

piece of film and let the resin spread. A piece of glass or

acrylic can then be placed on top of the blank film to

further evenly distribute the resin.

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 8 of 13

Squeegee Resin

You can use a squeegee to further spread the resin,

especially to the corners and any hard to reach areas.

Don't press too hard or you may get thin spots. Avoid

causing any air bubbles – slowly move the squeegee

across the surface of the PCB. Any excess resin can be

scrapped off the edges of the PCB. It's a little tricky to

get perfect, so take your time!

Place Mask

Once you're happy with the resin application, place the

solder mask film over the PCB and line up the artwork.

Alignment is super important here, so you may want to

take your time finessing the placement. To give the film

a bit more "grip", I added a drop of alcohol to the back

of the mask so that it would stick to the blank film better.

Expose UV Resin

Now it's time to expose the resin! To do this, I used a

100LED UV flashlight. You can use a lamp too, just make

sure the light source is large enough to cover the whole

PCB. To properly expose the resin, you’ll need to find

the right balance of exposure time. In my project, I

exposed the resin for about 10 seconds with the

flashlight about 2-3 inches away from the PCB.

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 9 of 13

Peel Film

When I first tried this, I started to peel away the film and

quickly knew I didn’t expose it evenly enough. The

some of resin stuck to the PCB but a big chuck tore

off. The size of the PCB, amount of resin and the

distance of light source all matters so you’ll need to do a

few tests to get it right. After a few trials and tribulations,

I found 10 seconds works well with the right amount of

resin. Any longer can result in over exposed solder

mask.

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 10 of 13

Clean & Cure

Post Processing

Now it's time to get rid of all the uncured resin. I suggest

submerging the PCB in a container with isopropyl

alcohol. That will help loosen up the unexposed resins

and any excess globs. You'll want to agitate the PCB by

shaking it back and forth in the container.

Rub, Wash and Rinse

Then, use a paper towel to scrub away any remaining

resin. The copper pads should be exposed, along with

any extra artwork. If not, the resin may have been

overexposed (too much time under the UV light).

Through Holes

If your PCB features any through hole components or

mounting holes, you'll want to use a tool to poke out any

resin that may be clogging the holes. A needle, fine

tipped tweezers or similar tool can be used.

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 11 of 13

Final Cure

Once all of the under exposed resin has been removed

and PCB cleaned, it's time to fully cure the resin. Using

the UV light, expose the PCB again, this time for about a

minute. This will ensure all of the resin is hardened and

fully cured.

Solder Components

Now it's time to add the components to your PCB! So,

How well does the solder mask actually work? Welp,

pretty good. It resists solder and looks pretty clean after

soldering. It actually flows onto the pads much better

than bare copper, which is pretty nice.

© Adafruit Industries https://learn.adafruit.com/how-to-solder-mask-pcbs Page 12 of 13

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Poetry RecitationDocument17 pagesPoetry RecitationSHarliza Ramli0% (1)

- Concept MapDocument3 pagesConcept Mapapi-416613415No ratings yet

- Native American Weaving,: Sanatujut: Pride in Women's Work - Copper and Caribou Inuit Clothing ..Document7 pagesNative American Weaving,: Sanatujut: Pride in Women's Work - Copper and Caribou Inuit Clothing ..Monette DelaramaNo ratings yet

- Hammer Tactical IndustriesDocument6 pagesHammer Tactical IndustriesChris BaktisNo ratings yet

- EMCEE SCRIPT LITERARY Cultural Contest 2019Document5 pagesEMCEE SCRIPT LITERARY Cultural Contest 2019Ej MagallanesNo ratings yet

- Language Focus: Unit 2 Test: StandardDocument5 pagesLanguage Focus: Unit 2 Test: StandardGuSD Pelotero0% (1)

- Ferm FHB-940 Wood LatheDocument26 pagesFerm FHB-940 Wood LatheLuke McNeilageNo ratings yet

- Backgroundfile 124144 PDFDocument40 pagesBackgroundfile 124144 PDFkldasdsadNo ratings yet

- VanladyloveDocument17 pagesVanladyloveapi-301944749No ratings yet

- Good Thesis Statement Their Eyes Were Watching GodDocument5 pagesGood Thesis Statement Their Eyes Were Watching Goddivyawatsonstamford100% (2)

- Michigan State University PKG 101 Quiz 3Document6 pagesMichigan State University PKG 101 Quiz 3uknowgaryNo ratings yet

- Way of The Iron Fist: Relentless PursuitDocument2 pagesWay of The Iron Fist: Relentless PursuitJoão Vitor Ferrari CampassiNo ratings yet

- 0311 Romantic Era TechniquesDocument27 pages0311 Romantic Era TechniquesAmir FallahNo ratings yet

- La Mode Design and Suitability of Dress - Marie Eugenie Jobin - 1920Document726 pagesLa Mode Design and Suitability of Dress - Marie Eugenie Jobin - 1920Kassandra M Journalist100% (1)

- Naveen Anand - CV (2010JE0813)Document2 pagesNaveen Anand - CV (2010JE0813)Priyanka PanigrahiNo ratings yet

- Narrative (Story) WritingDocument14 pagesNarrative (Story) WritingTest a QuizNo ratings yet

- Death-Leprosy Bass Tab BookDocument44 pagesDeath-Leprosy Bass Tab BookmanuNo ratings yet

- Peiods of English and American LiteratureDocument7 pagesPeiods of English and American LiteratureJochannicmav Chan RemobarezNo ratings yet

- Soul and SpaceDocument2 pagesSoul and SpaceAngelica AycochoNo ratings yet

- Tufted Carpet Miss AtiyyahDocument14 pagesTufted Carpet Miss Atiyyahjannah0808No ratings yet

- Lied Der DelphineDocument1 pageLied Der DelphineJulesNo ratings yet

- 2ND Quarter Examination in Arts 8Document2 pages2ND Quarter Examination in Arts 8Merry Rose RubioNo ratings yet

- Osensei Disciples Chart 2018Document1 pageOsensei Disciples Chart 2018Iago Feijoo BlancoNo ratings yet

- Art and Politics in The Former "Portuguese Colonial Empire". The Monument To Mouzinho de Albuquerque in Lourenço MarquesDocument29 pagesArt and Politics in The Former "Portuguese Colonial Empire". The Monument To Mouzinho de Albuquerque in Lourenço MarquesLisboa24No ratings yet

- ART 1ui3 Course OutlineDocument6 pagesART 1ui3 Course OutlineAlyNo ratings yet

- Orion - Plato Versus The PoetDocument2 pagesOrion - Plato Versus The PoetLaonikos Psimikakis-ChalkokondylisNo ratings yet

- B. Choose The Letter (A, B, C or D) Next To The Word Whose Main Stress Is Placed Differently From Others. (0.5 Point)Document5 pagesB. Choose The Letter (A, B, C or D) Next To The Word Whose Main Stress Is Placed Differently From Others. (0.5 Point)Khôi Nguyên ĐặngNo ratings yet

- SAS-5 and 6-Week 4-SOCSCI 104Document4 pagesSAS-5 and 6-Week 4-SOCSCI 104Bench RodriguezNo ratings yet

- Genigraphics Poster Template Sidebar 36x48Document1 pageGenigraphics Poster Template Sidebar 36x48Fahad MateenNo ratings yet

- Color AssociationsDocument31 pagesColor AssociationsAlina MusatNo ratings yet