Professional Documents

Culture Documents

PVC Cement Medium Body/Gray: General Description

Uploaded by

Marcos ArrueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PVC Cement Medium Body/Gray: General Description

Uploaded by

Marcos ArrueCopyright:

Available Formats

206 PVC CEMENT

LOW

MEDIUM BODY/GRAY VOC

GENERAL DESCRIPTION:

E-Z Weld 206 Medium Body Gray is a medium set PVC Solvent Cement. It is

formulated to provide good gap filling properties needed to join large

diameter pipes and fittings

APPLICATION:

This cement is good for joining Schedule 40 & 80 PVC pipes and fittings up

to 8” diameter interference fit. It is approved for cold water pressure

applications. It may also be used for non-pressure application such as drain,

waste, vent, sewer, gas, conduit etc. up to 10” diameter interference fit. For

superior joints use with E-Z Weld Primer, Purple (No.212) or Clear (No.

211). Never add thinner or additive. Never use the cement if it is stringy,

lumpy or jelly like. Always follow instructions on the label.

Application temperature: 32˚F to 110˚F

Storage temperature: 40˚F to 100 ˚F

CERTIFICATION:

This product is tested, certified and approved by the NSF

International for use on potable (drinking) water drain, waste and vent system. It is also listed by the

International Association of Plumbing & Mechanical Officials (IAPMO). It carries the Uniform Plumbing

Code (UPC) seal. This cement meets ASTM Standard D 2564.

R

PW, DWV, SW

QUALITY ASSURANCE:

Every batch of cement is carefully checked and monitored to assure consistently high quality standards. Records of

every batch are kept. A sample of every batch is taken and kept at least one year. All ingredients are purchased from

approved suppliers. This cement has passed the following test (performed in accordance with ASTM Std. D 2564)

Lap Shear: 250 psi after 2 hours cure time, 500 psi after 16 hours cure time, 900 psi after 72 hours cure time

Hydrostatic Burst: 400 psi after 2 hours cure time

PHYSICAL PROPERTIIES:

Color: Gray Body: Medium Set: Medium Shelf life: 3 years (Unopened can)

Viscosity: Min 500 cps @ 73˚F Specific Gravity: 7.698

LOW VOC (VOLITILE ORGANIC COMPOUND) Maximum VOC per SCAQMD 1168/316A: 510 g/l

CURE TIME GUIDE:

The ASTM has developed the following schedule and may be used as a guide (for relative humidity 60% or less. Sch.

40 size pipe.) eg. a 2” pipe size joint made at 55 degrees F, 50% Relative Humidity and a test pressure of 100 psi

would require a cure time of 4 hrs.

Temperature Pipe Size Pipe Size Pipe Size

Range (˚F) ½” to 1 ¼” 1 ½” to 3” 3” to 6”

Up to 181 psi Up to 181 psi Up to 181 psi to

180 psi to 370 psi 180 psi to 315 psi 180 psi 315 psi

60 to 100 1 Hr 6 Hrs 2 Hrs 12 Hrs 6 Hrs 24 Hrs

40 to 60 2 Hrs 12 Hrs 4 Hrs 24 Hrs 12 Hrs 48 Hrs

10 to 40 8 Hrs 12 Hrs 16 Hrs 96 Hrs 48 Hrs 8 Days

206 PVC CEMENT

®

LOW

MEDIUM BODY/GRAY VOC

AVAILABILITY:

Size Part No. Regular (UPC No.)

1/4pt 20601 892996002225

1/2pt 20602 892996002232

¼ pt., ½ pt., Pt. And Qt. cans

are supplied with dauber inside

Pt 20603 892996002249

cap. Gallon sizes supplied with

Qt 20604 892996002256 plain cap only.

Gal 20605 892996002263

PACKAGING:

Size ¼ Pt ½ Pt Pt Qt Gal

Fluid oz 4 8 16 32 128

Liters 0.12 0.24 0.49 0.95 3.79

Units per case 24 24 12 12 6

Weight per case - Lb. 8 15 14 27 49

Weight per case - Kg 3.63 6.81 6.36 12.26 22.70

Cubic feet per case 0.28 0.42 0.43 0.73 1.12

Cubic meter per case 0.008 0.012 0.012 0.021 0.032

Cases per pallet 240 140 144 100 45

SAFETY PRECAUTIONS:

Ensure adequate ventilation to avoid vapor build up which may cause flash fire. Vapor build up may also cause

dizziness, headaches or eye watering. If symptoms are experienced use respiratory protection (NOISH/MSHA TC 23 c

or equivalent) or leave are and provide more fresh air. Avoid contact with eyes, skin and clothing by use of safety

glasses and gloves. Professionals should consult ASTM Standard F 402-93 Safe Handling of Solvent Cements,

Primers and Cleaners Used for Joining Thermoplastic Pipe and Fittings. Professional users should also read the

Material Safety Data Sheet for the product.

Inhalation: If breathing is difficult vacate to fresh air. If breathing problems persist seek immediate medical attention.

Eyes: Flush eyes thoroughly with water for 15 minutes. Get immediate medical attention.

Internal: If swallowed give 1 or 2 glasses of water immediately, call physician, hospital or poison control immedi-

ately. DO NOT INDUCE VOMITING.

SHIPPING / TRANSPORTATION:

Material packaged in less than a liter size is exempted under “Limited Quantity Rules” by DOT. These packages may

be shipped with the description ORM - D Consumer Commodity. Packages shipped under this description are not

subject to shipping paper requirements for flammable materials.

For a liter and larger sizes (gallon and above container):

Proper shipping name: Adhesive Flammable Class 3 UN No: UN 1133 Packing group: PG II

Tel: 561-844-0241 • Fax: 561-848-8958 • www.e-zweld.com

MEDIUM GRAY

PVC SOLVENT CEMENT

Page 1 of 2

TECHNICAL SPECIFICATION: Oatey Medium Gray PVC Solvent Cement is recommended for solvent welding all classes and

schedules of PVC pipe and fittings up to 6” with interference fit. Medium Gray PVC Solvent Cement can be used for potable

water, sewer and drain, waste and vent systems. This product is compliant with California South Coast Air Quality Management

District (SCAQMD) Rule 1168 and Ozone Transport Commission (OTC) regulations for Volatile Organic Compound emission

levels. Note: This product is not for use in a system using or being tested by compressed air or gases.

INGREDIENTS (CAS Number)

Acetone (67-64-1)

Amorphous Silica (112945-52-5)

Cyclohexanone (108-94-4)

Gray Colorant (N/A)

Methyl Ethyl Ketone (78-93-3)

PVC Resin (9002-86-2)

Tetrahydrofuran (109-99-9)

LISTINGS

PHYSICAL/CHEMICAL PROPERTIES

Appearance Gray Liquid NSF Standard 61 IAPMO Listed

Viscosity min. 500 cps @ 73° F ± 2° F for PW, DWV, SEWER

Density 7.74 ± 0.2 lbs/gallon

Lap Shear Strength (minimum per ASTM Standards) Meets ASTM Standard D 2564

2 hours 250 psi

16 hours 500 psi

72 hours 900 psi

Set Up Time

30° F to 50° F 5 – 6 minutes

50° F to 70° F 3 – 4 minutes

70° F to 90° F 1 – 2 minutes

Shelf Life 3 years from manufacture date

Maximum VOC per SCAQMD 1168/316A or BAAQMD

Method 40: 510 g/L

PRODUCT NUMBER SIZE PACK CARTON WEIGHT

30883 4 oz. 24 9 lbs.

30884 8 oz. 24 15 lbs.

30885 16 oz. 24 29 lbs.

30886 32 oz. 12 28 lbs.

30887 Gallon 6 50 lbs.

Visit www.oatey.com for updates 1/2010

MEDIUM GRAY

PVC SOLVENT CEMENT

Page 2 of 2

DIRECTIONS FOR USE PRECAUTIONS

Read all directions carefully before using this product. Read all information carefully before using this product.

• Do not breathe vapors. Use only in well ventilated area.

If forced air ventilation is used, be sure it does not cause DANGER: EXTREMELY FLAMMABLE. VAPORS MAY

a fire hazard from solvent vapors. If adequate ventilation CAUSE FLASH FIRES. MAY IRRITATE EYES AND

cannot be provided, wear a NIOSH-approved respirator SKIN. VAPOR HARMFUL. MAY IRRITATE

for organic solvents. • Do not use or store near heat, RESPIRATORY TRACT AND CAUSE CENTRAL

sparks, or flames. Do not smoke, eat or drink when NERVOUS SYSTEM DEPRESSION. HARMFUL OR

using. Do not take internally. Vapors may accumulate in FATAL IF SWALLOWED.

low places and may ignite explosively. • Store and use at

temperatures between 40ºF and 110ºF. At temperatures May cause irritation to eyes, skin, and nose, throat, and

outside of this range, special care must be taken to respiratory tract. May cause coughing, sore throat,

prepare good joints and prevent exposures to solvents. difficulty breathing, headache, dizziness, nausea. Long

• Stir or shake before using; if jelly-like, don’t use. Keep term repeated overexposures to solvents may cause

container closed when not in use. • Avoid eye and skin damage to the brain, nervous system, reproductive system,

contact - wear safety glasses with side shields and wear respiratory system, mucous membranes, liver, and kidneys.

rubber gloves. • Do not thin. KEEP OUT OF REACH OF CHILDREN.

1. Square pipe ends and remove all burrs and dirt. FIRST AID: If swallowed, DO NOT INDUCE

2. Check dry fit of pipe and fitting. Pipe should easily VOMITING. Drink water and call a doctor or poison

go 1/3 of the way into the fitting. If the pipe control center immediately. This product may be aspirated

bottoms, it should be snug. into the lungs and cause chemical pneumonitis, a

3. Use a suitable applicator at least 1/2 the size of the potentially fatal condition. If contact with eyes, flush with

pipe diameter. For larger size pipe systems use a water for 15 minutes and seek medical attention if irritation

natural bristle brush or roller. persists. If contact with skin, flush with water and then use

4. Clean pipe and fitting with a listed primer. baby oil or Oatey Hand Cleaner to remove residue. If

5. Apply liberal coat of cement to pipe to the depth of inhaled and ill feelings develop, get fresh air and obtain

the socket; leave no uncoated surface. medical attention if ill feelings persist. FOR EMERGENCY

6. Apply a thin coat of cement to inside of fitting; avoid FIRST AID INSTRUCTIONS CALL 1-877-740-5015.

puddling of cement. Puddling can cause weakening FIRE: Use dry chemical, foam, or carbon dioxide

and premature failure of pipe or fitting. Apply a extinguisher. Water spray may be applied to reduce

second coat of cement to the pipe. potential vapors or for cooling. Burning liquid extinguished

7. Assemble parts QUICKLY. Cement must be fluid. If with water will float and may re-ignite on surface of water.

cement surface has dried, recoat both parts. SPILLS: Remove all sources of ignition and ventilate area.

8. Push pipe FULLY into fitting using a 1/4 turning Personnel cleaning up the spill should wear appropriate

motion until pipe bottoms. personal protective equipment, including respirators if

9. Hold pipe and fitting together for 30 seconds to vapor concentrations are high. Soak up spill with absorbent

prevent pipe push-out – longer at low temperatures. material. Put absorbent material in covered, labeled metal

Wipe off excess. containers. Dispose of in accordance with local regulations.

10. Allow 15 minutes for good handling strength and 2

A fire or explosion may result if dry granular calcium

hours cure time at temperatures above 60ºF before

hypochlorite is used to disinfect plastic piping systems and

hydrostatic pressure testing up to 180 psi. Longer

is exposed to organic vapors found in solvent cements,

cure times may be required at temperatures below cleaners or primers. Do not disinfect piping system with

60ºF or with pipe diameters over 3”. DO NOT TEST dry granules. Do not store dry granular calcium

WITH AIR. hypochlorite near solvent cements, cleaners or primers.

DO NOT REUSE EMPTY CONTAINER. KEEP OUT OF REACH

This product is not for use with caustic or acidic chemical OF CHILDREN.

solutions. Consult Oatey Technical Department for more

information. Refer to material safety data sheet for more information.

Before purchase and use of a product, review the product application and be

certain the product, installation and use will be in compliance with any applicable codes and regulations.

Visit www.oatey.com for updates 1/2010

PLASTI-WELD™

403 SERIES MEDIUM GRAY

United Elchem Industries

PH: 1-800-321-9532 PVC SOLVENT CEMENT

FAX: 1-800-321-9535 Page 1 of 2

TECHNICAL SUBMITTAL

TECHNICAL SPECIFICATION: Plasti-Weld 403 Series Medium Gray PVC Solvent Cement is recommended for solvent welding all schedules

and classes of PVC pipe and fittings up to 6” with interference fit. Medium Gray PVC Solvent Cement can be used for potable water, sewer

and drain, waste and vent systems. This product is compliant with California South Coast Air Quality Management District (SCAQMD) Rule

1168 and Ozone Transport Commission (OTC) regulations for Volatile Organic Compound emission levels. Note: This product is not for use

in a system using or being tested by compressed air or gases.

INGREDIENTS (CAS Number)

Acetone (67-64-1)

Amorphous Silica (112945-52-5)

Cyclohexanone (108-94-4)

Gray Colorant (N/A)

Methyl Ethyl Ketone (78-93-3)

PVC Resin (9002-86-2)

Tetrahydrofuran (109-99-9)

LISTINGS

PHYSICAL/CHEMICAL PROPERTIES

Appearance Gray Liquid NSF Standard 61 IAPMO Listed

Viscosity minimum 500 cps @ 73° F ± 2° F for PW, DWV, SEWER

Density 7.74 ± 0.2 lbs/gallon

Lap Shear Strength (minimum per ASTM Standards) Meets ASTM Standard D 2564

2 hours 250 psi

16 hours 500 psi

72 hours 900 psi

Set Up Time

30° F to 50° F 5 – 6 minutes

50° F to 70° F 3 – 4 minutes

70° F to 90° F 1 – 2 minutes

Shelf Life 3 years from manufacture date

Maximum VOC per SCAQMD 1168/316A or BAAQMD

Method 40: 510 g/L

PRODUCT NUMBER SIZE PACK CARTON WEIGHT

40366S 4 fl. oz. 24 9 lbs.

40356S 8 fl. oz 24 16 lbs.

40346S 16 fl. oz. 24 27 lbs.

40336S 32 fl. oz. 12 26 lbs.

40324 Gallon 6 52 lbs.

Visit www.elchem.com for updates 1/2010

PLASTI-WELD™

403 SERIES MEDIUM GRAY

United Elchem Industries

PH: 1-800-321-9532 PVC SOLVENT CEMENT

FAX: 1-800-321-9535 Page 2 of 2

TECHNICAL SUBMITTAL

DIRECTIONS FOR USE PRECAUTIONS

Read all directions carefully before using this product. Read all information carefully before using this product.

• Do not breathe vapors. Use only in well ventilated area. If

forced air ventilation is used, be sure it does not cause a fire DANGER: EXTREMELY FLAMMABLE. VAPORS MAY CAUSE

hazard from solvent vapors. If adequate ventilation cannot be FLASH FIRES. MAY IRRITATE EYES AND SKIN. VAPOR

provided, wear a NIOSH-approved respirator for organic HARMFUL. MAY IRRITATE RESPIRATORY TRACT AND CAUSE

solvents. • Do not use or store near heat, sparks, or flames. CENTRAL NERVOUS SYSTEM DEPRESSION. HARMFUL OR FATAL

Do not smoke, eat or drink when using. Do not take internally. IF SWALLOWED.

Vapors may accumulate in low places and may ignite

explosively. • Store and use at temperatures between 40ºF May cause irritation to eyes, skin, and nose, throat, and

and 110ºF. At temperatures outside of this range, special care respiratory tract. May cause coughing, sore throat, difficulty

must be taken to prepare good joints and prevent exposures breathing, headache, dizziness, nausea. Long term repeated

to solvents. • Stir or shake before using; if jelly-like, don’t use. overexposures to solvents may cause damage to the brain,

Keep container closed when not in use. • Avoid eye and skin nervous system, reproductive system, respiratory system,

contact - wear safety glasses with side shields and wear mucous membranes, liver, and kidneys. KEEP OUT OF REACH OF

rubber gloves. • Do not thin. CHILDREN.

1. Square pipe ends and remove all burrs and dirt. FIRST AID: If swallowed, DO NOT INDUCE VOMITING. Drink

2. Check dry fit of pipe and fitting. Pipe should easily go 1/3 water and call a doctor or poison control center immediately.

of the way into the fitting. If the pipe bottoms, it should This product may be aspirated into the lungs and cause chemical

be snug. pneumonitis, a potentially fatal condition. If contact with eyes,

3. Use a suitable applicator at least 1/2 the size of the pipe flush with water for 15 minutes and seek medical attention if

diameter. For larger size pipe systems use a natural irritation persists. If contact with skin, flush with water and then

bristle brush or roller. use baby oil or hand cleaner to remove residue. If inhaled and ill

4. Clean pipe and fitting with a listed primer. feelings develop, get fresh air and obtain medical attention if ill

5. Apply liberal coat of cement to pipe to the depth of the feelings persist. FOR EMERGENCY FIRST AID INSTRUCTIONS

socket; leave no uncoated surface. CALL 1-877-740-5015.

6. Apply a thin coat of cement to inside of fitting; avoid FIRE: Use dry chemical, foam, or carbon dioxide extinguisher.

puddling of cement. Puddling can cause weakening and Water spray may be applied to reduce potential vapors or for

premature failure of pipe or fitting. Apply a second coat cooling. Burning liquid extinguished with water will float and

of cement to the pipe. may re-ignite on surface of water.

7. Assemble parts QUICKLY. Cement must be fluid. If SPILLS: Remove all sources of ignition and ventilate area.

cement surface has dried, recoat both parts. Personnel cleaning up the spill should wear appropriate personal

8. Push pipe FULLY into fitting using a 1/4 turning motion protective equipment, including respirators if vapor

until pipe bottoms. concentrations are high. Soak up spill with absorbent material.

9. Hold pipe and fitting together for 30 seconds to prevent Put absorbent material in covered, labeled metal containers.

pipe push-out – longer at low temperatures. Wipe off Dispose of in accordance with local regulations.

excess.

10. Allow 15 minutes for good handling strength and 2 hours A fire or explosion may result if dry granular calcium

hypochlorite is used to disinfect plastic piping systems and is

cure time at temperatures above 60ºF before hydrostatic

exposed to organic vapors found in solvent cements, cleaners or

pressure testing up to 180 psi. Longer cure times may be

primers. Do not disinfect piping system with dry granules. Do

required at temperatures below 60ºF or with pipe not store dry granular calcium hypochlorite near solvent

diameters over 3”. DO NOT TEST WITH AIR. cements, cleaners or primers. DO NOT REUSE EMPTY

CONTAINER. KEEP OUT OF REACH OF CHILDREN.

This product is not for use with caustic or acidic chemical

solutions. Consult Technical Department for more Refer to material safety data sheet for more information.

information.

Before purchase and use of a product, review the product application and be

certain the product, installation and use will be in compliance with any applicable codes and regulations.

Visit www.elchem.com for updates 1/2010

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mobile Tower and Mobile Phone Radiation Hazards - Prof Girish Kumar - June 2013Document50 pagesMobile Tower and Mobile Phone Radiation Hazards - Prof Girish Kumar - June 2013Neha Kumar100% (1)

- Science Culminating Task RubricDocument2 pagesScience Culminating Task Rubricapi-311644452No ratings yet

- Ret Ro Gam Er Iss Ue 168 2017Document116 pagesRet Ro Gam Er Iss Ue 168 2017Albanidis X. Kostas100% (1)

- PM Speed Adjusting Motor For PSGDocument2 pagesPM Speed Adjusting Motor For PSGFathima Regin100% (2)

- PMP Lite Mock Exam 2 QuestionsDocument16 pagesPMP Lite Mock Exam 2 QuestionsJobin John100% (1)

- MRCPCH Part 1 Questions With Individual Subject Summaries 4eDocument52 pagesMRCPCH Part 1 Questions With Individual Subject Summaries 4ePasTestBooks88% (25)

- Technology Vs TechniquesDocument5 pagesTechnology Vs TechniquesPRATIK DARBHE100% (1)

- STM - Merck Case AnswersDocument2 pagesSTM - Merck Case AnswersreetayanNo ratings yet

- Li Fi TechnologyDocument15 pagesLi Fi TechnologyParmeshprasad Rout100% (1)

- AMR130 Datasheet-1.1eDocument2 pagesAMR130 Datasheet-1.1eMarcos ArrueNo ratings yet

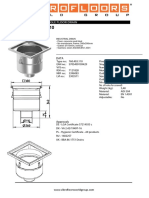

- Product 760.403.110: Product Sheet - Single Floor DrainDocument4 pagesProduct 760.403.110: Product Sheet - Single Floor DrainMarcos ArrueNo ratings yet

- Sistema de Filtrado y Purificacion de AguaDocument16 pagesSistema de Filtrado y Purificacion de AguaMarcos ArrueNo ratings yet

- Filtros de Sistema de Purificacion de Agua PDFDocument20 pagesFiltros de Sistema de Purificacion de Agua PDFMarcos ArrueNo ratings yet

- E-Solutions With Grundfos E-PumpsDocument16 pagesE-Solutions With Grundfos E-PumpsMarcos ArrueNo ratings yet

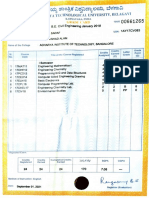

- UG190239 - Avaneesh NatarajaDocument21 pagesUG190239 - Avaneesh NatarajaAvaneesh NatarajaNo ratings yet

- Harold Bloom'S Psychoanalysis in Peri Sandi Huizhce'S Puisi EsaiDocument5 pagesHarold Bloom'S Psychoanalysis in Peri Sandi Huizhce'S Puisi EsaiAhmadNo ratings yet

- PRP ConsentDocument4 pagesPRP ConsentEking InNo ratings yet

- RIZALDocument6 pagesRIZALElaine Key MarasiganNo ratings yet

- Electrical Submersible Pumps and Motors: Pleuger Water-Filled Design Byron Jackson Oil-Filled DesignDocument8 pagesElectrical Submersible Pumps and Motors: Pleuger Water-Filled Design Byron Jackson Oil-Filled DesignGunjanNo ratings yet

- Unit 7 Assessment Guidance 2021-2022Document13 pagesUnit 7 Assessment Guidance 2021-2022JonasNo ratings yet

- User Manual For e-MRODocument2 pagesUser Manual For e-MROABHISHEK SHARMANo ratings yet

- Descriptive Statistics I Theory Questions (1997-2016)Document9 pagesDescriptive Statistics I Theory Questions (1997-2016)Satyaki GhosalNo ratings yet

- Quick Guide System 1200 - Monitoring Using Sets of AnglesDocument3 pagesQuick Guide System 1200 - Monitoring Using Sets of AnglesariyarathneNo ratings yet

- WWW - Universityquestions.in: Question BankDocument11 pagesWWW - Universityquestions.in: Question BankgokulchandruNo ratings yet

- Christmas Book 2004Document98 pagesChristmas Book 2004Ron BarnettNo ratings yet

- Simcnc Python Scripts Guide enDocument53 pagesSimcnc Python Scripts Guide enÁron SzárazNo ratings yet

- Teachers Beliefs About Multilingualism and A Multilingual Pedagogical ApproachDocument19 pagesTeachers Beliefs About Multilingualism and A Multilingual Pedagogical ApproachKhalid S. H, Ph.DNo ratings yet

- Catalogo PDFGeneratorDocument3 pagesCatalogo PDFGeneratoredwraulNo ratings yet

- UMG 512 ProDocument12 pagesUMG 512 Propuikmutnb2No ratings yet

- Technology,: OF Credits EarnedDocument8 pagesTechnology,: OF Credits EarnedAATISH KUMARNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Faculty AdsNo ratings yet

- How Could Auto Manufacturer Use Transportation To Increase The Efficiency of Supply Chain?Document25 pagesHow Could Auto Manufacturer Use Transportation To Increase The Efficiency of Supply Chain?guddianushaNo ratings yet

- The Use of Salicylaldehyde Phenylhydrazone As An Indicator For The Titration of Organometallic ReagentsDocument2 pagesThe Use of Salicylaldehyde Phenylhydrazone As An Indicator For The Titration of Organometallic ReagentsLuca PeregoNo ratings yet

- 01-Thermal Integrity Profiler PDI USF TIPDocument2 pages01-Thermal Integrity Profiler PDI USF TIPAlexandru PoenaruNo ratings yet

- Word As "BUNDLES" of MeaningDocument19 pagesWord As "BUNDLES" of MeaningDzakiaNo ratings yet