Professional Documents

Culture Documents

Oil Water Separator Iapp12

Uploaded by

Andres SanchezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Water Separator Iapp12

Uploaded by

Andres SanchezCopyright:

Available Formats

APPLICATIONS

April 1998 volume 12

SIC CODE 49

OIL / WATER SEPARATOR FEED

Modern power plants often Centrifugal and gear ability to reduce

utilize huge turbine pumps greatly emulsify the emulsification resulted in

generators to produce product reducing the the Blackmer MLX4 being

electricity. Often these effectiveness of the installed.

generators are washed separators. Running at

down for cleaning. The 68 RPM and driven by a These pumps have been

residue, from this process 5 H.P. motor, the MLX4 is running for 3 years without

can be a water and oil providing the required problems.

mixture. 60 GPM at 5-10 PSI

discharge pressure to feed

To properly dispose of this the separators.

material it must be fed to a Competition

separator where the oil is Competitively priced with

separated from the water. other pumping options, the

• Gear pumps

superior lift capability, the • Centrifugal pumps

To accomplish this “feed” high efficiency and the

the Blackmer MLX4 pumps

have been successfully

applied. The “wash down”

is collected in basins or

sumps. To draw from the

basins and feed the

separators requires as

much as 4 feet of lift. The

MLX4 was applied

because of its capability to

handle this condition.

Emulsification, the mixing

of the water and oil,

prohibits the separators

from operating efficiently.

Therefore, the emulsifying

must be reduced as much

as possible. The Blackmer

vane technology proves to

be the answer.

CHECKLIST

1. Lift conditions

2. Confirm all specifications

3. Available site utilities

4. Frequency of operation

OIL / WATER SEPARATOR FEED

SIC CODES

49 491 4911

ELECTRIC, GAS ELECTRIC ELECTRIC

SERVICES SERVICES SERVICES

1809 Century Avenue, Grand Rapids, Michigan 49509-1595, U.S.A.

Telephone: (616) 241-1611 • Fax: (616) 241-3752

E-Mail: blackmer@blackmer.com • Internet: www.blackmer.com

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Millmax Pumps: KrebsDocument8 pagesMillmax Pumps: Krebshanz aeNo ratings yet

- Blackmer Cat PDFDocument16 pagesBlackmer Cat PDFsladjandjordjevicNo ratings yet

- BLACKMER PD PumpsDocument8 pagesBLACKMER PD PumpsrasottoNo ratings yet

- ONGA BrosurDocument10 pagesONGA BrosurBebebhnya NitaNo ratings yet

- Blackmer Vane PumpDocument12 pagesBlackmer Vane PumpforuzzNo ratings yet

- Diesel Pumpset Selection HandbookDocument44 pagesDiesel Pumpset Selection Handbookahmedomar_953724702No ratings yet

- Fuel FiltersDocument1 pageFuel FiltersalpanakaurNo ratings yet

- August 2011 IssueDocument40 pagesAugust 2011 IssueGas, Oil & Mining Contractor MagazineNo ratings yet

- Blackmer Positive Displacement Pump For Liquefied Gas ApplicationsDocument20 pagesBlackmer Positive Displacement Pump For Liquefied Gas ApplicationsDaniel Leal Pintor100% (1)

- Vertical Roller Pre Grinding Mill by AMCLMachinery Limited@ Mangalam CementsDocument16 pagesVertical Roller Pre Grinding Mill by AMCLMachinery Limited@ Mangalam CementsRahul RoyNo ratings yet

- MFC - Microseparator Fuel CoalescerDocument2 pagesMFC - Microseparator Fuel Coalescerhg66No ratings yet

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsDocument4 pagesKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniNo ratings yet

- Dominion Motors CaseDocument12 pagesDominion Motors CaseAgrimGargNo ratings yet

- Water Systems Catalog 06-12 WEBDocument36 pagesWater Systems Catalog 06-12 WEBUmar MajeedNo ratings yet

- KREBS millMAX Slurry Pump BrochureDocument12 pagesKREBS millMAX Slurry Pump BrochureEloize OliveiraNo ratings yet

- SS Pumps - Ce SeriesDocument3 pagesSS Pumps - Ce Seriesshashank ovhalNo ratings yet

- White Star Quatro BrochureDocument3 pagesWhite Star Quatro Brochurechau nguyenNo ratings yet

- Boletín 2004 de Especificaciones Serie C-Max McCormickDocument15 pagesBoletín 2004 de Especificaciones Serie C-Max McCormickJosé Inés Bazán MotaNo ratings yet

- MANUALE BLACK DEVIL AGGIORNATO Novembre 2021 4Document17 pagesMANUALE BLACK DEVIL AGGIORNATO Novembre 2021 4JuanSilvaNo ratings yet

- Estandar Instuctor de Motoniveladoras Carlos Hernan Rodriguez BedoyaDocument105 pagesEstandar Instuctor de Motoniveladoras Carlos Hernan Rodriguez BedoyaJorgeAMoralesNo ratings yet

- Alco Loco WDG3A (Modification)Document44 pagesAlco Loco WDG3A (Modification)PrateekSinghBaghel100% (2)

- Bomba Submersa FE - Petro STPDocument6 pagesBomba Submersa FE - Petro STProbsonlagambaNo ratings yet

- CROPTON GREAVES Domestic Pumps PDFDocument16 pagesCROPTON GREAVES Domestic Pumps PDFAjay YashNo ratings yet

- LPG Blackmer PumpsDocument16 pagesLPG Blackmer Pumpssizweh100% (1)

- Bombas CornellDocument12 pagesBombas CornellGabo Cabezas NaranjoNo ratings yet

- Training Overview: Presented by Akash KarpeDocument22 pagesTraining Overview: Presented by Akash KarpeMukesh Kumar VaishnavNo ratings yet

- Anchor Electric Pump-OverviewDocument2 pagesAnchor Electric Pump-Overviewhaha234No ratings yet

- WSP Series Self Priming PumpsDocument1 pageWSP Series Self Priming PumpsabmopalhvacNo ratings yet

- Filtros Motores CumminsDocument4 pagesFiltros Motores Cumminsangel acuñaNo ratings yet

- Internship ReportDocument6 pagesInternship Reportdarshan randiveNo ratings yet

- Cornell BR Mine DewateringDocument8 pagesCornell BR Mine Dewateringtan_dat2003No ratings yet

- 490 24,2 KWM at 1500 RPMDocument1 page490 24,2 KWM at 1500 RPMautokrautuvasNo ratings yet

- Mission Centrifugal PumpsDocument60 pagesMission Centrifugal PumpsWell Site Ranger100% (2)

- Rotary PumpsDocument31 pagesRotary PumpsalbertNo ratings yet

- DT190CBROCDocument4 pagesDT190CBROCJhonny RodriguezNo ratings yet

- Palmer CAR-Series Sand Reclamation SystemsDocument2 pagesPalmer CAR-Series Sand Reclamation SystemsJORGE RUBENNo ratings yet

- The Final Mill ReportDocument31 pagesThe Final Mill ReportAnil Dhaniya100% (1)

- ATS - Catalogo Compañia AirmaticDocument24 pagesATS - Catalogo Compañia AirmaticJORGE VELAZQUEZNo ratings yet

- Mill MAX8 PG EmailversionDocument5 pagesMill MAX8 PG EmailversionPrimitivo GonzálezNo ratings yet

- Oberdorfer N301MDocument2 pagesOberdorfer N301MJavier GarciaNo ratings yet

- Mobilair M50: 185 CFM at 100 PsigDocument2 pagesMobilair M50: 185 CFM at 100 PsigDjNo ratings yet

- Reclaimer/Mixer: Machine Shown May Have Optional EquipmentDocument12 pagesReclaimer/Mixer: Machine Shown May Have Optional EquipmentBakat Setiya Hadi100% (1)

- 18M3 Attachment Guide - V2Document63 pages18M3 Attachment Guide - V2Luis Jose LlobanNo ratings yet

- Submersible Pumping SystemsDocument58 pagesSubmersible Pumping SystemsMiroslavCrnogoracNo ratings yet

- The Complete Programme For High Pressure TechnologyDocument28 pagesThe Complete Programme For High Pressure TechnologyRafael EspinosaNo ratings yet

- SuperchargerDocument13 pagesSuperchargerJose Alberto Luna ValladaresNo ratings yet

- Blackmer LPG Training ManualDocument74 pagesBlackmer LPG Training ManualEjaz Ahmed Rana100% (2)

- Semi Automatic A/C Machine: Quality Shop EquipmentDocument1 pageSemi Automatic A/C Machine: Quality Shop EquipmentzayerirezaNo ratings yet

- WH2009 WaterHorseCatalogDocument132 pagesWH2009 WaterHorseCatalogAiko FeroNo ratings yet

- Roto Rainer 2011Document8 pagesRoto Rainer 2011sunilbholNo ratings yet

- Wash and Clean: by Michael Rasmussen, Industry Application Team, Grundfos, DenmarkDocument9 pagesWash and Clean: by Michael Rasmussen, Industry Application Team, Grundfos, DenmarkAlpesh PatelNo ratings yet

- Dominion MotorsDocument26 pagesDominion MotorsNikhil BhadNo ratings yet

- DM-45 Sales BrochureDocument4 pagesDM-45 Sales Brochurejuancaf773557100% (1)

- NP Pumps BlackmerDocument4 pagesNP Pumps BlackmerrasottoNo ratings yet

- Positive Displacement Pumps and Oil-Free Gas Compressors: For Liquefied Gas ApplicationsDocument20 pagesPositive Displacement Pumps and Oil-Free Gas Compressors: For Liquefied Gas ApplicationscajacaNo ratings yet

- GM 8.1L Engine Control Module MEFI4Document267 pagesGM 8.1L Engine Control Module MEFI4Andres SanchezNo ratings yet

- Breve Catálogo de Productos - MASON IndustriesDocument4 pagesBreve Catálogo de Productos - MASON IndustriesAndres SanchezNo ratings yet

- GM 008 02Document4 pagesGM 008 02Hugo Narvaez FuentesNo ratings yet

- 7 Responsibilities of Leaders - B Tracy PDFDocument7 pages7 Responsibilities of Leaders - B Tracy PDFAndres SanchezNo ratings yet

- Lista de Partes Cover de Entrada AD5 232540799 - en PDFDocument3 pagesLista de Partes Cover de Entrada AD5 232540799 - en PDFAndres Sanchez100% (1)

- Forum Baker SPDDocument61 pagesForum Baker SPDAndres SanchezNo ratings yet

- Abs Certificado BombaDocument2 pagesAbs Certificado BombaAndres SanchezNo ratings yet

- Inst Ope Main ML - 185 - SDocument20 pagesInst Ope Main ML - 185 - SAndres SanchezNo ratings yet

- Training Manual: Sliding Vane Process PumpsDocument90 pagesTraining Manual: Sliding Vane Process PumpsAndres SanchezNo ratings yet

- Parts List: Mlx4B, Mlx4B-Cs: Cast Steel Head Cast Steel Jacketed HeadDocument7 pagesParts List: Mlx4B, Mlx4B-Cs: Cast Steel Head Cast Steel Jacketed HeadAndres SanchezNo ratings yet

- Curves MLX-MLN 106-021Document2 pagesCurves MLX-MLN 106-021Andres SanchezNo ratings yet

- GM 008 02Document4 pagesGM 008 02Hugo Narvaez FuentesNo ratings yet

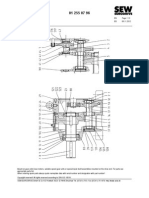

- Parts List 01 255 07 96: Helical Gear Unit R107Document3 pagesParts List 01 255 07 96: Helical Gear Unit R107Parmasamy Subramani50% (2)

- Como Leer Las Listas de Partes SEW Instructions PDFDocument1 pageComo Leer Las Listas de Partes SEW Instructions PDFAndres SanchezNo ratings yet

- Training Manual: Sliding Vane Process PumpsDocument90 pagesTraining Manual: Sliding Vane Process PumpsAndres SanchezNo ratings yet

- The Relationship Between Law and MoralityDocument12 pagesThe Relationship Between Law and MoralityAnthony JosephNo ratings yet

- AP Online Quiz KEY Chapter 8: Estimating With ConfidenceDocument6 pagesAP Online Quiz KEY Chapter 8: Estimating With ConfidenceSaleha IftikharNo ratings yet

- 2.1BSA-CY2 - REVERAL, ANGELA R. - EXERCISE#1 - Management ScienceDocument3 pages2.1BSA-CY2 - REVERAL, ANGELA R. - EXERCISE#1 - Management ScienceAngela Ricaplaza ReveralNo ratings yet

- Sap Successfactors Training Materials Guide: April 2020Document4 pagesSap Successfactors Training Materials Guide: April 2020pablo picassoNo ratings yet

- Write A Program in C To Check Whether A Entered Number Is Positive, Negative or ZeroDocument10 pagesWrite A Program in C To Check Whether A Entered Number Is Positive, Negative or ZeroSabin kandelNo ratings yet

- Introduction To Communication Systems: James Flynn Sharlene KatzDocument15 pagesIntroduction To Communication Systems: James Flynn Sharlene KatzAnisari MeiNo ratings yet

- Citibank Vs Hon ChuaDocument12 pagesCitibank Vs Hon ChuaJA BedrioNo ratings yet

- 47 Vocabulary Worksheets, Answers at End - Higher GradesDocument51 pages47 Vocabulary Worksheets, Answers at End - Higher GradesAya Osman 7KNo ratings yet

- Tropical Design Reviewer (With Answers)Document2 pagesTropical Design Reviewer (With Answers)Sheena Lou Sangalang100% (4)

- Social Studies 5th Grade Georgia StandardsDocument6 pagesSocial Studies 5th Grade Georgia Standardsapi-366462849No ratings yet

- Pentagram Business PlanDocument13 pagesPentagram Business PlantroubledsoulNo ratings yet

- Block-1 Communication IGNOUDocument81 pagesBlock-1 Communication IGNOUr kumarNo ratings yet

- Khenpo Tsultrim Gyamtso Rinpoche - Meditation On EmptinessDocument206 pagesKhenpo Tsultrim Gyamtso Rinpoche - Meditation On Emptinessdorje@blueyonder.co.uk100% (1)

- Assignment 1: Microeconomics - Group 10Document13 pagesAssignment 1: Microeconomics - Group 10Hải LêNo ratings yet

- Goldilocks and The Three BearsDocument2 pagesGoldilocks and The Three Bearsstepanus delpiNo ratings yet

- Money Habits - Saddleback ChurchDocument80 pagesMoney Habits - Saddleback ChurchAndriamihaja MichelNo ratings yet

- Planificare 3 FairylandDocument6 pagesPlanificare 3 FairylandBulf Adela MihaelaNo ratings yet

- Before The Hon'Ble High Court of Tapovast: 10 Rgnul National Moot Court Competition, 2022Document41 pagesBefore The Hon'Ble High Court of Tapovast: 10 Rgnul National Moot Court Competition, 2022sagar jainNo ratings yet

- Right To Information: National Law University AND Judicial Academy, AssamDocument20 pagesRight To Information: National Law University AND Judicial Academy, Assamsonu peterNo ratings yet

- Basic Elements of Rural DevelopmentDocument7 pagesBasic Elements of Rural DevelopmentShivam KumarNo ratings yet

- Bekic (Ed) - Submerged Heritage 6 Web Final PDFDocument76 pagesBekic (Ed) - Submerged Heritage 6 Web Final PDFutvrdaNo ratings yet

- PT3 Liste PDFDocument2 pagesPT3 Liste PDFSiti KamalNo ratings yet

- SyerynDocument2 pagesSyerynHzlannNo ratings yet

- Checklist of Requirements of Special Land Use PermitDocument1 pageChecklist of Requirements of Special Land Use PermitAnghelita ManaloNo ratings yet

- Bba 2ND Year Business Communication NotesDocument11 pagesBba 2ND Year Business Communication NotesDivya MishraNo ratings yet

- Pr1 m4 Identifying The Inquiry and Stating The ProblemDocument61 pagesPr1 m4 Identifying The Inquiry and Stating The ProblemaachecheutautautaNo ratings yet

- Due Date: 29-12-2021: Fall 2021 MTH104: Sets and Logic Assignment No. 1 (Lectures # 16 To 18) Total Marks: 10Document3 pagesDue Date: 29-12-2021: Fall 2021 MTH104: Sets and Logic Assignment No. 1 (Lectures # 16 To 18) Total Marks: 10manzoor ahmadNo ratings yet

- Sjögren's SyndromeDocument18 pagesSjögren's Syndromezakaria dbanNo ratings yet

- Makalah Soal Soal UtbkDocument15 pagesMakalah Soal Soal UtbkAndidwiyuniarti100% (1)

- Co-Publisher AgreementDocument1 pageCo-Publisher AgreementMarcinNo ratings yet