0% found this document useful (0 votes)

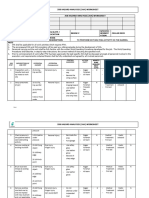

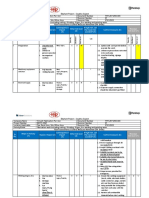

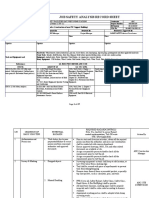

547 views1 pageSafety Check For Lube Oil Flushing: SI. No. Description Observation Yes/No/NA Remarks

The document outlines a 14-point safety checklist for lube oil flushing that includes verifying the circulation loop is identified, leak tests are completed, permits and housekeeping are in order, equipment is greased and guarded, entry is restricted with warnings, lighting and access are sufficient, communication through tool box talks occurred, fire equipment is available, SIMOPS are stopped, emergency stops are provided, temporary connections are integrity checked, and lines are tagged. The checklist is to be signed off by both the site engineer and HSE engineer.

Uploaded by

Rísês ÃfrözCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

547 views1 pageSafety Check For Lube Oil Flushing: SI. No. Description Observation Yes/No/NA Remarks

The document outlines a 14-point safety checklist for lube oil flushing that includes verifying the circulation loop is identified, leak tests are completed, permits and housekeeping are in order, equipment is greased and guarded, entry is restricted with warnings, lighting and access are sufficient, communication through tool box talks occurred, fire equipment is available, SIMOPS are stopped, emergency stops are provided, temporary connections are integrity checked, and lines are tagged. The checklist is to be signed off by both the site engineer and HSE engineer.

Uploaded by

Rísês ÃfrözCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd