Professional Documents

Culture Documents

The Reinforcement of Steel Columns PDF

The Reinforcement of Steel Columns PDF

Uploaded by

clam2014Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Reinforcement of Steel Columns PDF

The Reinforcement of Steel Columns PDF

Uploaded by

clam2014Copyright:

Available Formats

The Reinforcement of Steel Columns

LAMBERT TALL

There may be a need for a steel column to have load- stress magnitude and distribution. Residual stresses are those

carrying capacity additional to that planned in the original internal stresses set up in a member due to plastic

design. Columns may be reinforced by the addition of deformations such as those due to cooling after welding.2,3

material in the form of cover plates, or by changing the Since the residual stresses exist in the cross section before

residual stress distribution to a more favorable one by the the application of load, their effect is to reduce the load-

laying of a weld, or by a method that combines both of these carrying capacity from that which it would have been

effects. For columns carrying design loads, their otherwise.1,2,3,4 Equilibrium requires the existence of both

reinforcement is possible and safe. The strength of reinforced tensile and compressive residual stresses in the cross section

columns is identical for the conditions of reinforced under (Fig. 3), yet it is only the compressive residual stresses that

load and reinforced under no load. The maximum effect of contribute to the reduction of compressive strength. The

reinforcement is obtained when the reinforcing weld is as magnitude and distribution of residual stresses in a structural

close as possible to the edge of the flange of the base shape. shape is normally of academic interest only; however, it may

be possible and desirable to ensure that the residual stress

distribution is modified to a more "favorable" one, where the

INTRODUCTION term "favorable" means that the loss of compressive strength

is a minimum. (Note that a favorable residual stress

There may be a need for a steel column to have load- distribution reduces the negative effects of residual stress, it

carrying capacity additional to that planned in the original cannot increase basic strength above what it would be if no

design. The column may be already in place and the

reinforcement may need to be carried out under load or with

the load temporarily relieved.

Columns may be reinforced by the addition of material in

the form of cover plates, or by changing the residual stress

distribution to a more favorable one, or by a method that

combines both of these effects. The effect of the addition of

material is obvious, and warrants no further consideration

here. This paper is concerned with those cases where welding

is used for the reinforcement, either alone or with cover

plates. The discussion is limited to rolled wide-flange shapes

as the shapes to be reinforced, and the loads are restricted to

static loads.

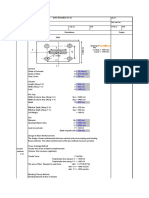

Reinforcement is usually understood to be the welding of Fig. 1. Reinforcement by Cover Plates

cover plates to the flange of the shape (Fig. 1). Figure 2

indicates the reinforcement of a shape by the laying of a weld

bead on the flange tip, which may be the only option

available in some conditions and which improves column

strength by changing the residual stress distribution.

COLUMN STRENGTH

The strength of a steel compression member is a function

of a number of parameters, such as the yield point, effective

length, eccentricity of load, and residual stress magnitude and

distribution.1,2,3,4 While all of these parameters are important,

those that come into play in this discussion are the residual

Lambert Tall is professor of civil engineering at Florida

International University, Miami, FL. Fig. 2. Reinforcement by Welding

FIRST QUARTER / 1989 33

residual stresses were present. The presence of residual

stresses always reduces strength.) The simplest way to

change the residual stresses into a more favorable

distribution is through the application of heat, either by

welding or by flame-cutting. Both welding and flame-cutting

have a concentrated source of heat input which produces a

highly non-uniform temperature distribution and thus residual

stresses with a relatively high magnitude—the residual

stresses will be at the yield point in tension at the weld or at

the flame-cut edge (Fig. 4).5 A favorable residual stress

distribution may be defined as one where tensile residual

stresses are positioned so that the critical portions of the

cross section will remain elastic under a compressive load. Fig. 4. Residual Stresses in Flame-Cut Plate

The laying of a weld bead onto a column's flange tips

(Fig. 2), changes the residual stresses there from the usual

compressive value into tension at the yield point. This more should be noted that the actual absolute increase in strength

favorable residual stress distribution results in a marked would be considerably higher, since the non-dimensionalized

improvement in column strength (Fig,. 5).6 (No additional strength in Fig. 7 is defined with respect to the yield strength

material is involved in the reinforcement, that of the weld of the total cross section which differs before and after

bead being neglected in strength considerations.) reinforcement.

The term "reinforcement" normally describes the welding Additional information on the effect of a favorable

of cover plates to the flanges of a shape (Fig. 1). The residual stress distribution is obtained also when a

increase in strength resulting is substantially greater than for comparison is made between the strength of welded shapes

welding alone because of the combined effect of the built up from UM plates and built up from FC plates.1,5 Thus,

additional material of the cover plates and the more favorable Fig. 8 shows the residual stress distribution of such shapes,8

residual stress distribution. Figure 6 shows the residual and Fig. 9 shows the comparison of column strength, both

stresses in a rolled shape of A7 steel (W8 × 31 shape with a theoretical and experimental.3 While the welding process

yield point of 37 ksi) and in the reinforced shape after a 7 × does reduce the magnitude of the original high tensile

3/8 in. plate has been welded to the flange tips. Figure 7 residual stresses at the flange tips which had been flame-cut,

indicates test results for the same shape, L/r = 48, showing a nevertheless the final residual stresses there are tensile (or

10% relative increase in strength after reinforcement.7 It occasionally very low compressive, depending on the welding

Fig. 3. Residual Stresses in Rolled Shape Fig. 5. Strength of Columns Reinforced by Welding

34 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Fig. 6. Residual Stresses in Reinforced Shape: Before and After Fig. 8. Residual Stresses in Welded Shapes

parameters and geometry of the shape) such that the final Curve 2, although only for rolled shapes of light and medium

residual stress distribution is favorable since the material size with a weld bead placed on the flange tips. However, a

remaining elastic under load is furthest from the buckling weld bead placed on the flange tips of a welded shape built

axis. Normally, FC plates are used for the fabrication of up from flame-cut plates or on the flange tips of a heavy

welded shapes as a convenience—the use of UM plates is rolled shape would not improve strength significantly, so that

discouraged as they result in a less favorable residual stress no change in column curve would be expected.

distribution in the shape. (Actually, UM plates are not

normally used for fabrication because the edges are not

perfectly straight due to the rolling process, and need to be REINFORCEMENT UNDER LOAD

flame cut for straightness.) Although many columns can be reinforced while carrying

The concept of "Multiple Column Curves" has been load without creating an unsafe condition, this is not

under consideration.1,2 It is of interest that the order of advisable as a general rule, and if it is carried out, then it

magnitude of the improvement in column strength by using a should be only after an analysis for safety.

more favorable residual stress distribution is such that Clearly, transverse welding must never be carried out on

Column Curve 1 could be used for design instead of Column any column under load, since the complete cross section will

Fig. 7. Strength of Column Reinforced by Cover Plates Fig. 9. Strength of Welded Shapes

FIRST QUARTER / 1989 35

be affected by the temperature rise. Thus, it is critical that

only one flange of the column be welded longitudinally at a

time so that only one flange tip of the cross section will be

plastic at any one time. The amount of plastification of the

flange tip during welding depends on the heat input from the

welding, and thus on the welding parameters such as speed of

welding and weld size.9, 10 For a ½ in. thick plate, 4 in. wide,

welded at an edge, the approximate temperature distribution

curves are shown in Fig. 10.9 Noting that the yield point is a

function of temperature,9,10 and that, for A36 steel, the value

Fig. 11. Reinforcement Not Recommended

of the yield point has dropped to about 22 ksi at 1000°F, then

it may be concluded from Fig. 10 that the maximum distance

of flange material of a welded edge that will have a column of A7 steel (37 ksi yield point, L/r of 48) loaded to a

temperature above 1000°F and hence have its yield point compressive stress of 25 ksi. It was concluded that: "The

lowered to 22 ksi is no more than 1 in. from the edge. influence of welding is confined to a very small area in the

Flanges thicker and wider than 8 × ½ in. would show an even vicinity of the weld. The material properties in the major

lesser effect of lowered yield point since the weld bead would portion of the section are not affected enough to reduce the

remain the same in size even for a heavier flange. strength of the section." Since the cross-sectional area

From the above discussion, it may be concluded that, if plastified by the weld bead becomes relatively smaller as the

the working load currently on the column corresponds to an size of the column cross section increases, it appears that

allowable stress that is no more than about 22 ksi for A36 columns heavier than a W8 × 31 may be welded

steel, then the column may be welded safely without longitudinally under load without distress—however, a

removing the load. If the current working load on the column definitive statement on this must await the results of further

corresponds to an allowable stress above 22 ksi for A36 study.

steel, then a buckling analysis should be conducted assuming It is of interest that the residual stresses in the reinforced

that a one-inch width of one flange tip has yielded and is thus shape of Fig. 6 are identical for both cases of reinforcement

lost to the buckling resistance. This latter case implies an under load or reinforcement under no load.7 Further, in Fig.

eccentric load on an unsymmetric cross section, that is, 7, the test results for the reinforced shape are identical for

biaxial bending of a beam-column, which is complex for both cases of reinforced under load or reinforced under no

cases other than short columns.2 load.7

While a detailed buckling analysis is recommended in the

latter case, it is of interest to note than an experimental study

of the reinforcement of columns under load7 showed that the SOME PRACTICAL CONSIDERATIONS

welding process had no discernible effect on a W8 × 31

The width of cover plates used to reinforce shapes has a

lower limit in size, but effectively no upper limit, if the

intention is to secure a favorable residual stress distribution.

The width of the cover plate should be no narrower than the

width of the flange less a sufficient space for the weld to be

deposited—this ensures that the weld is as close as possible

to the edge of the flange to be effective in changing the

residual stress there to tension. When the cover plate is wider

than the flange, the width depends only on the usual design

considerations of width-thickness limitation.

While any location of additional steel by welding is

possible in the reinforcement of columns, the maximum effect

is obtained only when the weld is as close as possible to the

edge of the flange of the base shape, as noted above. Thus, a

location close to the juncture of flange and web would create

additional tensile residual stresses there with accompanying

addition of compressive stresses at the flange tips—thus, a

lowering of strength from the residual stress effect which

Fig. 10. Theoretical Temperature Distribution Curves would tend to negate the increase obtained from the

36 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

additional material. Examples of existing reinforcing practice and web does not contribute additional strength since the

which actually contribute little if any additional strength are residual stress effect tends to cancel the additional

shown in Fig. 11. (The situation in Fig. 11b could represent a material effect.

net increase in strength if the inside welds were placed first, 9. The use of intermittent welds for reinforcing is not

followed by the outside ones.) recommended.

Flame-cut plates are normally used as cover plates.

While this is not a critical requirement for cover plates of a

size similar to that of the flange since the welding process ACKNOWLEDGMENTS

affects both simultaneously, it becomes very important for

relatively wide cover plates for the cases shown in Fig. 1b Special thanks are given to John Springfield, Carruthers

and 1c. In these cases, the favorable residual stress and Wallace Limited, Toronto, on whose suggestion this

distribution results from the flame-cut edge of the cover paper was prepared, and who read the manuscript with care,

plates, and the weld contributes very little, if anything, to made a number of valuable suggestions, and discussed the

improving column strength. topic in general. His encouragement is greatly appreciated.

The use of intermittent welds is not recommended. While

they are prohibited in fatigue situations, their use in the REFERENCES

reinforcement of building columns is counterproductive at the

flange tips and only marginally useful at the juncture of 1. Tall, L., "Centrally Compressed Members." In Stability

flange and web (such as in Fig. 11) as far as residual stress and Strength of Structures, edited by R. Narayanan.

formation is concerned. London: Elsevier, 1982

2. Johnston, B. G., Editor, "Guide to Stability Design

Criteria for Metal Structures," 3rd Edition, Wiley, 1976

CONCLUSIONS 3. Tall, L., "Structural Steel Design," 2nd Edition,

Ronald/Wiley, 1974

1. The reinforcement of steel columns by cover plates 4. Beedle, L. S., and L. Tall, "Basic Column Strength,

welded to the flanges normally improves column strength ASCE.," Paper 2555, Vol. 68 (ST7), July 1960

because of the combined effect of additional material and 5. McFalls, R. K., and L. Tall, "A Study of Welded

the creation of a favorable residual stress distribution. Columns Manufactured From Flame-Cut Plates,"

2. The deposit of a weld bead onto a column's flange tips Welding Journal, Vol. 48, April 1969

introduces a more favorable residual stress distribution 6. Fujita, Y., "Ultimate Strength of Columns with Residual

resulting in a marked improvement in column strength. Stresses," Journal, Society of Naval Architects, Japan,

3. The reinforcement of a column may result in the column January 1960

being assigned a higher column curve, if the concept of 7. Nagaraja Rao, N. R., and L. Tall, "Columns Reinforced

multiple column curves is considered. Under Load," Welding Journal, Vol. 42, April 1963

4. Flame-cut plates, rather than UM plates, are normally 8. Tebedge, N. and L. Tall, "Contraintes Résiduelles dans

used for the reinforcement of columns. les Profiles en Acier—Synthése des Valeurs Mesurées,"

5. For columns carrying design loads, their reinforcement Construction Métallique, Paris, June 1974 ('Residual

under load is possible and is safe—the loads and the Stresses in Structural Steel Shapes A Summary of

design should be checked to ensure that code Measured Values, Fritz Lab. Report 337.34, Lehigh

requirements are met. University, February 1973)

6. The maximum effect of reinforcement is obtained when 9. Tall, L., "Residual Stresses in Welded Plates, a

the reinforcing weld is as close as possible to the edge of Theoretical Study," Welding Journal, Vol. 43, January

the flange of the base shape. 1964

7. The strength of reinforced columns is identical for the 10. Tall, L., "The Calculation of Residual Stresses—in

conditions of reinforced under load and reinforced under Perspective," Trans., International Conference on

no load. Residual Stresses in Welded Construction, London, The

8. The welding of rods or plates to the juncture of flange Welding Institute, November 1977

FIRST QUARTER / 1989 37

Annual Index

Volume 25, 1988

First Quarter 1-44 Third Quarter 85-125

Second Quarter 45-84 Fourth Quarter 129-168

SUBJECT INDEX

BRACING FRAMES

Design of Diagonal Cross-Bracings Part 2: Experimental A Practical P-Delta Analysis Method for Type FR and

Study - Picard and Beaulieu .....................................156 PR Frames - Lui..........................................................85

Connection Flexibility and Beam Design in Non-sway

BRIDGES Frames - Nethercot, Buick and Kirby ..........................99

A Conceptual Approach to Prevent Crack-related Failure

of Steel Bridges - Verma, and McNamara ...................17 GIRDERS

Plastic Collapse Load of Continuous Composite Plate

BUCKLING Girders - Kubo and Galambos .................................... 145

Flexural-torsional Buckling for Pairs of Angles Used as

Columns - Brandt........................................................39 LOAD AND RESISTANCE FACTOR DESIGN

Effect of Connector Spacing and Flexural-torsional LRFD and the Structural Engineering Curriculum -

Buckling on Double-angle Compressive Strength - Zahn Geschwinder...............................................................79

and Haaijer ..............................................................109 Understanding Composite Beam Design Methods Using

LRFD - Lorenz ...........................................................35

COLUMNS Design of Partially or Fully Composite Beams, with

Columns from Theory to Practice - Bjorhovde ................21 Ribbed Metal Deck, Using LRFD Specification -

Reinforcing Loaded Steel Compression Members - Vinnakota, Foley and Vinnakota.................................60

Brown .......................................................................161

OPTIMIZATION

COMPOSITE DESIGN Preliminary Minimum Weight Design of Moment Frames

Plastic Collapse Load of Continuous Composite Plate for Lateral Loading - Grigorian and Grigorian ......... 129

Girders - Kubo and Galambos...................................145 Optimal Design of Cantilever-suspended Girders -

Understanding Composite Beam Design Methods Using Gurfinkel ....................................................................54

LRFD - Lorenz............................................................35

Design of Partially or Fully Composite Beams, with PARKING GARAGES

Ribbed Metal Deck, Using LRFD Specification - Parking Structure with a Post-tensioned Deck -

Vinnakota, Foley and Vinnakota .................................60 Bakota ...................................................................... 119

CONNECTIONS TRUSSES

Design of 8-bolt Stiffened End Plates - Murray and Secondary Stresses in Trusses - Nair ............................144

Kukreti........................................................................45

Discussion: Griffiths and Wooten ................................52 VIBRATION

Connection Flexibility and Beam Design in Non-sway A New Approach to Floor Vibration Analysis -

Frames - Nethercot, Buick and Kirby ..........................99 Tolaymat .................................................................. 137

END-PLATES WELDING

Design of 8-bolt Stiffened End Plates - Murray and Reinforcing Loaded Steel Compression Members -

Kukreti........................................................................45 Brown....................................................................... 161

Discussion: Griffiths and Wooten ................................52 Field Welding to Existing Structures - Ricker ...................1

38 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

AUTHOR INDEX

Bakota, John F. Lorenz, Robert F.

Parking Structure with a Post-tensioned Deck..............119 Understanding Composite Beam Design Methods Using

LRFD .........................................................................35

Beaulieu, D. (see Picard A.)

Lui, Eric M.

Bjorhovde, Reidar A Practical P-Delta Analysis Method for Type FR and PR

Columns From Theory to Practice .................................21 Frames........................................................................85

Brandt, G. Donald McNamara, Michael P. (see Verma, Krishna K.)

Flexural-torsional Buckling for Pairs of Angles Used as

Columns ....................................................................39 Murray, Thomas M. and Anant R. Kukreti

Design of 8-bolt Stiffened End Plates .............................45

Brown, J. H.

Reinforcing Loaded Steel Compression Members ........161 Nair, R. Shankar

Secondary Stresses in Trusses ...................................... 144

Davison, J. Buick (see Nethercot, David A.)

Nethercot, David A., J. Buick Davison and Patrick A. Kirby

Foley, Christopher M. (see Vinnalota, Sriramula)

Connection Flexibility and Beam Design in Non-sway

Frames........................................................................99

Galambos, Theodore V. (see Kubo, Masahiro)

Picard, A. and D. Beaulieu

Geschwinder, Louis F.

Design of Diagonal Cross-bracings Part 2:

LRFD and the Structural Engineering Curriculum ...........79

Experimental Study ................................................... 156

Griffiths, John D. and James Wooten

Ricker, David T.

Disscusion on Simplified Design of 8-bolt Stiffened

Field Welding to Existing Steel Structures........................1

Moment End Plates......................................................52

Tolaymat, Raed A.

Grigorian, Carl (see Grigorian, Mark)

A New Approach to Floor Vibration Analysis............... 137

Grigorian, Mark and Carl Grigorian

Verma, Krishna K. and Michael P. McNamara

Preliminary Minimum Weight Design of Moment Frames

A Conceptual Approach to Prevent Crack-related Failure

for Lateral Loading ...................................................129

of Steel Bridges...........................................................17

Gurfinkel, German

Vinnakota, Murthy R. (see Vinnakota, Sriramula)

Optimal Design of Cantilever-suspended Girders ............54

Vinnakota, Sriramula, Christopher M. Foley and Murthy R.

Haaijer, Geerhard (see Zahn, C. J.)

Vinnakota

Design of Partially or Fully Composite Beams, with

Kirby, Patrick A. (see Nethercot, David A.)

Ribbed Metal Deck, Using LRFD Specifications .........60

Kubo, Masahiro and Theodore V. Galambos

Wooten, James (see Griffiths, John D.)

Plastic Collapse Load of Continuous Composite Plate

Girders......................................................................145

Zahn, C. J. and Geerhard Haaijer

Effect of Connector Spacing and Flexural-torsional

Kukreti, Anant R. (see Murray, Thomas M.) Buckling on Double-angle Compressive Strength....... 109

FIRST QUARTER / 1989 39

You might also like

- Shear Transfer at Top Plate, Drag Strut DesignDocument4 pagesShear Transfer at Top Plate, Drag Strut DesignVarga Zoran100% (1)

- Aisc TearoutsDocument11 pagesAisc Tearoutsclam2014No ratings yet

- A Model Specification For Stability Design by Direct AnalysisDocument10 pagesA Model Specification For Stability Design by Direct Analysisalexmolina3No ratings yet

- Don't Put Welds in BendingDocument2 pagesDon't Put Welds in BendingRune OveraasNo ratings yet

- Twisting Moments Two Way Slabs Concrete InternationalDocument6 pagesTwisting Moments Two Way Slabs Concrete InternationalamarradoNo ratings yet

- Ns23.1 Final Handout 2 Slides PerDocument54 pagesNs23.1 Final Handout 2 Slides PerÇağatay TahaoğluNo ratings yet

- Fundamentals of Beam BracingDocument16 pagesFundamentals of Beam BracinghungNo ratings yet

- Structure Mag - 2018-08 - Anchorage of Wood Structural WallsDocument3 pagesStructure Mag - 2018-08 - Anchorage of Wood Structural WallstdegrobertNo ratings yet

- Pakyaw RatesDocument36 pagesPakyaw RatesKesMercado100% (5)

- Engineering Journal - 4th Quarter 2010 - Design of Structural Steel Pipe RacksDocument8 pagesEngineering Journal - 4th Quarter 2010 - Design of Structural Steel Pipe Racksger80No ratings yet

- Riverside Bid SetDocument106 pagesRiverside Bid Setsajid yaqoobNo ratings yet

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNo ratings yet

- Wind Loading Non-Building StructuresDocument57 pagesWind Loading Non-Building Structuressdutta2591100% (1)

- Design of Brick Diaphragm WallsDocument43 pagesDesign of Brick Diaphragm WallsDa WongNo ratings yet

- Ansi Asabe Ep378.4 - 2010-06Document3 pagesAnsi Asabe Ep378.4 - 2010-06StephanNo ratings yet

- AISC Effect of Compound Buckling On Compression Strength of Built-Up MembersDocument8 pagesAISC Effect of Compound Buckling On Compression Strength of Built-Up Memberssebastian9033No ratings yet

- Gusset Plate Stability Using Variable Stress TrajectoriesDocument6 pagesGusset Plate Stability Using Variable Stress TrajectoriestmaNo ratings yet

- ACI 435R-95 - Control of Deflection in Concrete StructuresDocument77 pagesACI 435R-95 - Control of Deflection in Concrete StructuresGabriel Jordán Pozo100% (1)

- Portals and Trussed Frame StructuresDocument5 pagesPortals and Trussed Frame StructuresMichael SandersNo ratings yet

- Applications of Pretensioned Anchor Rods in Industrial FacilitiesDocument10 pagesApplications of Pretensioned Anchor Rods in Industrial FacilitiescharlesroberNo ratings yet

- IEEE693 Tutorial3-2007c (Compatibility Mode) PDFDocument145 pagesIEEE693 Tutorial3-2007c (Compatibility Mode) PDFjinjin0205No ratings yet

- Behavior and Design of Double Tees With Web OpeningsDocument17 pagesBehavior and Design of Double Tees With Web Openingsunix0123100% (1)

- Recommendations For Shear Lag Factors For Longitudinally Welded Tension MembersDocument22 pagesRecommendations For Shear Lag Factors For Longitudinally Welded Tension MembersSergioAlcantaraNo ratings yet

- FYP 2k15 DesigningDocument51 pagesFYP 2k15 DesigningMuhammad Dawood Khokhar100% (1)

- Bumper Sizing Codes and CalculationsDocument4 pagesBumper Sizing Codes and CalculationsravindranathanneNo ratings yet

- Metal Building and Roofing SystemDocument22 pagesMetal Building and Roofing SystemConstro FacilitatorNo ratings yet

- Steelwise PDFDocument3 pagesSteelwise PDFrohalestat100% (1)

- Seismic Guidelines For CranesDocument28 pagesSeismic Guidelines For CranesCathe PacNo ratings yet

- Method Statement For Static Load Test For Micro PilesDocument5 pagesMethod Statement For Static Load Test For Micro PilesAndy Lian100% (1)

- A New Formula To Calculate Crack Spacing For Concrete PlatesDocument11 pagesA New Formula To Calculate Crack Spacing For Concrete PlatesphamminhquangNo ratings yet

- 1960 Specification For The Design of Light Gage Cold-Formed Steel Stru PDFDocument41 pages1960 Specification For The Design of Light Gage Cold-Formed Steel Stru PDFTimbo6808No ratings yet

- Bolts and NutsDocument2 pagesBolts and NutsBalaji SampathNo ratings yet

- Aci 355.3Document129 pagesAci 355.3billybob801No ratings yet

- 5 PilecapDocument6 pages5 PilecapMaheshNo ratings yet

- Design of Crane Runway Beams With Channel Cap PDFDocument9 pagesDesign of Crane Runway Beams With Channel Cap PDFNguyen Duc CuongNo ratings yet

- Engineering For Steel ConstructionDocument2 pagesEngineering For Steel ConstructionBiju Muttathukatil0% (1)

- RUDDY - Ponding of Concrete Deck FloorsDocument9 pagesRUDDY - Ponding of Concrete Deck FloorsmarinamoviaNo ratings yet

- Elastic Stability of Circular Cylindrical ShellsFrom EverandElastic Stability of Circular Cylindrical ShellsRating: 5 out of 5 stars5/5 (1)

- Blodgett's TreasuresDocument3 pagesBlodgett's Treasuresfzhou100% (1)

- Design of Box Girder BridgesDocument31 pagesDesign of Box Girder BridgesAnonymous Gd0PTUQNo ratings yet

- SDI Technical Note No 10Document7 pagesSDI Technical Note No 10phil brownNo ratings yet

- Concrete Reinforcement Degradation and Rehabilitation Damages, CorrosionDocument176 pagesConcrete Reinforcement Degradation and Rehabilitation Damages, CorrosionWilmer PradoNo ratings yet

- Evolution of ACI 562 Code Part 3Document7 pagesEvolution of ACI 562 Code Part 3Ziad BorjiNo ratings yet

- Direct Analysis and Design Using Amplified First-Order AnalysisDocument18 pagesDirect Analysis and Design Using Amplified First-Order Analysisอภิรักษ์ มานะกิจศิริสุทธิNo ratings yet

- HILTI ExBar Rebar Design Soft WareDocument30 pagesHILTI ExBar Rebar Design Soft WareRodrigo Fuente GarcíaNo ratings yet

- 500plus Reidbar Design ManualDocument42 pages500plus Reidbar Design ManualChristopher GarciaNo ratings yet

- Suspended Ceiling - BOQDocument32 pagesSuspended Ceiling - BOQAvdija HamzićNo ratings yet

- Lewis - Structural Questionaire With AnswersDocument87 pagesLewis - Structural Questionaire With AnswerslewisphilipjonNo ratings yet

- Design of Steel and Composite Beams With Web OpeningsDocument19 pagesDesign of Steel and Composite Beams With Web OpeningsAngelica Gamiz ArciniegaNo ratings yet

- Direct Method Obtaining Plate Buckling Coefficient Double-Coped BeamDocument2 pagesDirect Method Obtaining Plate Buckling Coefficient Double-Coped Beamclam2014No ratings yet

- Researchpaper Design Model of Built Up Stiffened Column Base Under Large Eccentric LoadDocument10 pagesResearchpaper Design Model of Built Up Stiffened Column Base Under Large Eccentric LoadNishant GaurNo ratings yet

- Discussion - The Importance of Tension Chord BracingDocument2 pagesDiscussion - The Importance of Tension Chord BracingKeaten ClaneyNo ratings yet

- Geschwindner-A Practical Look at Frame Analysis, Stability and Leaning Columns, AISC PDFDocument15 pagesGeschwindner-A Practical Look at Frame Analysis, Stability and Leaning Columns, AISC PDFRicardo GómezNo ratings yet

- Thornton 1990 BQ 4Document2 pagesThornton 1990 BQ 4Wheni Candra Dewi AsmaralisaNo ratings yet

- Aircraft Wheel LoadsDocument60 pagesAircraft Wheel LoadsCatherine Mohanji GeraNo ratings yet

- SteelwiseDocument5 pagesSteelwiseΈνκινουαν Κόγκ ΑδάμουNo ratings yet

- Anchor 201 - Evaluation of Factors That Affect Bond StressDocument27 pagesAnchor 201 - Evaluation of Factors That Affect Bond StressPatrice AudetNo ratings yet

- Quality Assurance For Structural Engineering Firms: Clifford SchwingerDocument21 pagesQuality Assurance For Structural Engineering Firms: Clifford Schwingerash_hanamant4143No ratings yet

- One Way SlabDocument69 pagesOne Way Slabforlogin018No ratings yet

- Design Method For The Bolts in Bearing-Type Connections With FillersDocument7 pagesDesign Method For The Bolts in Bearing-Type Connections With FillersAnonymous 7MdZQn1No ratings yet

- Cross Bracing Design PDFDocument5 pagesCross Bracing Design PDFVictor Miranda AcuñaNo ratings yet

- PCA Design of Deep GirderDocument12 pagesPCA Design of Deep GirderWasin WaiyasusriNo ratings yet

- Steelwise Strength and EngagementDocument3 pagesSteelwise Strength and EngagementGiri DharanNo ratings yet

- Steelwise Nov-2014 PDFDocument5 pagesSteelwise Nov-2014 PDFJatinTankNo ratings yet

- SEI - ASCE - 7-16 - Snow Loads - DRAFT - FrontDocument12 pagesSEI - ASCE - 7-16 - Snow Loads - DRAFT - FrontrcNo ratings yet

- RISA GuideDocument120 pagesRISA GuideGary J. Davis, P. E.No ratings yet

- Miami Pedestrian Bridge Collapse Computational Forensic AnalysisDocument17 pagesMiami Pedestrian Bridge Collapse Computational Forensic AnalysisAmmarNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Pile Driving Effects On Nearby BuildingDocument5 pagesPile Driving Effects On Nearby BuildingRanga KalharaNo ratings yet

- Repair Method For Corroded Steel Girder Ends Using CFRP SheetDocument7 pagesRepair Method For Corroded Steel Girder Ends Using CFRP SheetRanga KalharaNo ratings yet

- Environmental PhysicsDocument9 pagesEnvironmental PhysicsRanga KalharaNo ratings yet

- Sewer Defect CodesDocument6 pagesSewer Defect CodesRanga KalharaNo ratings yet

- The Effect of Water Table On Bearing Capacity: Er. Nishant Raj Kapoor, Er. SumitshringiDocument5 pagesThe Effect of Water Table On Bearing Capacity: Er. Nishant Raj Kapoor, Er. SumitshringiRanga KalharaNo ratings yet

- Brick Work in SrilankaDocument10 pagesBrick Work in SrilankaRanga KalharaNo ratings yet

- Building Cracks - Causes and RemediesDocument5 pagesBuilding Cracks - Causes and RemediesRanga KalharaNo ratings yet

- BOI Guidelines For Factory Building PDFDocument16 pagesBOI Guidelines For Factory Building PDFRanga KalharaNo ratings yet

- Chapter 2Document18 pagesChapter 2Ranga KalharaNo ratings yet

- Accepted Manuscript: 10.1016/j.watres.2014.08.048Document40 pagesAccepted Manuscript: 10.1016/j.watres.2014.08.048Ranga KalharaNo ratings yet

- Catalog Mecanice DIPOLpdf PDFDocument7 pagesCatalog Mecanice DIPOLpdf PDFMihai ConstantinescuNo ratings yet

- Copper Slag As Sand Replacement For HighDocument6 pagesCopper Slag As Sand Replacement For HighANURAG CHAUHANNo ratings yet

- Concrete Construction ArticleCoping With Formwork SpecificationsDocument5 pagesConcrete Construction ArticleCoping With Formwork SpecificationscrdavalosNo ratings yet

- Structure of The Rennovated Clement's Church, St. Panteleymon - Plaoshnik - OhridDocument7 pagesStructure of The Rennovated Clement's Church, St. Panteleymon - Plaoshnik - OhridTaulantKarriqiNo ratings yet

- Concrete Design To AS 3600-2018 Amendment 2: Capacity Reduction FactorDocument4 pagesConcrete Design To AS 3600-2018 Amendment 2: Capacity Reduction FactorTai NguyenNo ratings yet

- Sas4 Mee 098Document12 pagesSas4 Mee 098Mark MaglangitNo ratings yet

- Stainless Steel As Reinforcement: BY-Bhrugesh Patel SD-1210Document30 pagesStainless Steel As Reinforcement: BY-Bhrugesh Patel SD-1210Jay KushwahaNo ratings yet

- Fracture and Fatigue (ME514) : 1 IIT Ropar, PunjabDocument9 pagesFracture and Fatigue (ME514) : 1 IIT Ropar, PunjabgidlavinayNo ratings yet

- Reconciliation Sheet For RA-09-container Yard DevelopmentDocument60 pagesReconciliation Sheet For RA-09-container Yard DevelopmentVara PrasadNo ratings yet

- Design Steps of One Way Slab RCCDocument7 pagesDesign Steps of One Way Slab RCCKosygin LeishangthemNo ratings yet

- Design of PilecapsDocument3 pagesDesign of PilecapsShyamali LiyanageNo ratings yet

- CE323 Structural Analysis I: N/M N/M NDocument2 pagesCE323 Structural Analysis I: N/M N/M Nعبدالله عبدالحكيم عامرNo ratings yet

- 1978 Effect of Sequence of Construction in Analysis of Multistoreyed Building - S.C.chakrabarti G. C. Nayak and S.K. AgarwalaDocument6 pages1978 Effect of Sequence of Construction in Analysis of Multistoreyed Building - S.C.chakrabarti G. C. Nayak and S.K. AgarwalaAnonymous UXWnUJqhNo ratings yet

- Composite Shear Connection Training - MoCDocument81 pagesComposite Shear Connection Training - MoCAbdifatah HassanNo ratings yet

- Student Number: 2015-01127 - Name: Robles, Mariecor Elsie, B. - Adviser: Engr. Maricel DC. AquinoDocument8 pagesStudent Number: 2015-01127 - Name: Robles, Mariecor Elsie, B. - Adviser: Engr. Maricel DC. AquinoMariecor Elsie RoblesNo ratings yet

- Advanced Concrete Structures: B.E. (Civil Engineering) Semester Seventh (C.B.S.)Document4 pagesAdvanced Concrete Structures: B.E. (Civil Engineering) Semester Seventh (C.B.S.)ENGINEERING FORUMNo ratings yet

- Reinforced Concrete Culvert PipesDocument3 pagesReinforced Concrete Culvert PipesAbdurezak AbdurehimNo ratings yet

- Basic Civil FondationDocument22 pagesBasic Civil FondationGokul KannanNo ratings yet

- Monopitch Roof Steel Truss (Ware House) 12345Document5 pagesMonopitch Roof Steel Truss (Ware House) 12345FatihNo ratings yet

- Development of Geopolymer ConcreteDocument13 pagesDevelopment of Geopolymer Concreteपाँशुल जम्वाल राजपूतNo ratings yet