Professional Documents

Culture Documents

The Rhodium: Structure

Uploaded by

Waskito BudiawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Rhodium: Structure

Uploaded by

Waskito BudiawanCopyright:

Available Formats

The Structure of Rhodium

By E. S. Bale, A.I.M.

This note, a communication from the Johnson Matthey Research Labora-

tories, records an investigation into the crystal structure of high-purity

rhodium carried out in an attempt to understand why this metal should

present such dificulties i n working

It is well known that rhodium, although intermediate anneals to sheet 0.060 inch in

having a face-centred cubic crystal structure, thickness, from which a tensile specimen was

is much more difficult to work than most other prepared.

metals of similar structure such as copper, This specimen was annealed in high vacuum

silver, gold, platinum or palladium. It has and tested using an extensometer capable of

been suggested that this difficulty might be measuring to O.OOOOI inch. The applied load

due to the presence of impurities, while was increased and no elastic region was

another suggestion which has been put for- observed, the stress-strain diagram being a

ward is that a transformation takes place to smooth curve from the origin. The mech-

some other crystal form (I, 2 ) . anical properties obtained from this test are

The present investigation was therefore shown in the table.

undertaken into the behaviour of pure

rhodium towards external stresses and into Mechanical Properties of Pure

the possibility of a transformation taking Rhodium

place.

To obviate any anomalous behaviour due Proof stress (0.01:h), tons per sq.

to the presence of foreign elements a specially inch .. .. .. .. 3.8

prepared batch of chloropentammine rhodium Proof stress (0.1 yo),tons per sq. inch 4.6

dichloride was taken and after several recrystal- Ultimate tensile strength, tons

lisations a sample of rhodium oxide was per sq. inch . . . . .. 30.6

obtained which gave the spectrographic Elongation, per cent, on 2 in. , . 6.5

analysis shown below. Modulus of elasticity, pounds per

Element Per cent sq. inch .. .. .. .. 4 1 . 2 ~loB

cu 0.0002 Vickers hardness .. .. I10

Fe 0.0001

M g 0.0001

Si 0.oOoI

Ca 0.0002 Another sample of the pure rhodium was

K 0.OooI used to obtain a work hardening curve, which

Na 0.0002

showed that the hardness increased to over

The following elements were not detected: 300 VPN with about 15 per cent reduction by

Ag, Al, As, Au, Ba, Cd, Co, Cr, Ir, Li, Mn,

Mo, Os, Pb, Pd, Pt, Rb, Ru, Sb, Sn, Sr, Te, rolling. It was apparent from these tests that

Ti, V, W, Zn, Zr. pure annealed rhodium is initially very soft,

By reduction of this oxide, rhodium con- but that its rate of work-hardening is very

taining less than 10 parts per million of rapid at room temperature.

metallic impurities was produced. As mentioned earlier, there seemed no

A sample of this metal was pressed, sintered reason why pure rhodium should behave in

in oxygen-free hydrogen and cold rolled with this manner as it has a face-centred cubic

Platinum Metals Rev., 1958, 2 , (21, 61-63 61

3 900

0 4

I 3 000

lx

W

3 060

I

<

LL

2 3840

W

5u

-I

3 820

Fig. 1 Bffert of temnpera-

ture o n the lattice para-

3 aoo meter of rhodium

500 1000 1500

TEMPERATURE OC

structure, but its behaviour towards mechani- high temperature electrical conductivity

cal working seemed like that of a material measurements were made during heating to

with a more complex structure. 1450°C and cooling to room temperature.

In order to investigate the possibility that Fig. 2 shows the curve obtained from these

an allotropic transformation occurred with measurements and it can be seen that no

increasing temperature, an apparatus was significant change of shape or hysteresis

constructed by which high temperature occurs. These two experiments provided sub-

X-ray diffraction photographs could be stantial evidence that the crystal structure of

obtained and examples of the crystal structure rhodium is face-centred cubic between room

of rhodium were determined at temperatures temperature and say 15ooOC.

up to 1600°C. Fig. I shows the relationship It follows, therefore, that either rhodium is

between the diffraction spacing and tempera- susceptible to the presence of impurity atoms

ture, and as this relationship is a straight line of an order unknown in any other face-centred

it can be concluded that rhodium has a face- cubic metal, or that the mechanism of its

centred cubic crystal structure over the range plastic behaviour is unlike that of metals with

from room temperature to 1600'C. a similar crystal structure.

To confirm this result and to ensure that It appears most likely, therefore, from the

the atomic packing was consistently perfect, present work that pure rhodium has an intrin-

Fig. 2 Effect of tempera-

ture on the electrical re-

sistivity of rhodium

ELECTRICAL RESISTIVITY - MICROHMS PER C M CUBE

Platinum Metals Rev., 1958, 2 , (21, 62

sically high rate of work-hardening and that based on a study of slip line formation com-

this is due to a different mechanism of slip bined with a suitable X-ray diffraction tech-

processes than occur in other face-centred nique would be necessary to define the opera-

cubic metals. Further experimental work tive slip system.

References

I F. M. Jaeger and J. E. Zanstra . . Proc. K . Akad. Wet. Amsterdam, 1931, 34, 15

2 A. A. Rudnitsky, R. S. Polyakova and Izvest. Sekt. Platiny (Akad. Nauk SSSR), 1955, 29,

I. L. Tyurin . . .. .. . . 185-189; 190-196

Vacuum Casting Uranium Reactor Fuel Elements

TEMPERATURE CONTROL WITH PLATINUM THERMOCOUPLES

Among the final operations at the Spring- group of high-frequency vacuum furnaces.

fields Works of the United Kingdom Atomic These are of the stationary-crucible, bottom-

Energy Authority is the vacuum casting of pouring type, the base of the crucible being

high-purity uranium into rods for use as pierced by a pouring hole, closed during

reactor fuel elements. melting by a graphite or alumina bung.

The Springfields Works undertakes the For successful casting the pouring tempera-

preparation of almost all the uranium refined ture is critical, and is controlled by means of

in Britain, starting from the ore. After a platinum : rhodium-platinum thermocouples

series of chemical treatments, uranium tetra- led in through the top of each furnace.

fluoride is reduced with metallic calcium by When correct pouring temperature has been

firing in a reduction mould. attained, the bung is removed by means of a

T o produce the reactor fuel elements in graphite rod and a system of bell cranks, push

the required shape and size, and also to rods and levers, and the molten uranium runs

remove metallic and non-metallic impurities, through a launder into the moulds stationed

the uranium is then melted and cast in a in the lower part of the furnace.

A battery of three high-

frequency vacuum cast-

ing furnaces for the

production of uranium

reuctor fuel elements at

the Springjelds F’orks

of the Atomic Energy

;4uthority. Tempera-

ture control during melt-

ing and casting the

uranium is effected by

means of platinum:

rhodium-pl utinum

thermocouples

Platinum Metals Rev., 1958, 2 , (21, 63-63 63

You might also like

- Precipitation Hardening in 350 Grade Maraging SteelDocument14 pagesPrecipitation Hardening in 350 Grade Maraging SteelAriel NemcoNo ratings yet

- Materials Chemistry and Physics, 14 (1986) 259-261: in The NetherlandsDocument9 pagesMaterials Chemistry and Physics, 14 (1986) 259-261: in The NetherlandsDTMM Anggit DriasadityaNo ratings yet

- J. Krudtaa Central Institute For Industrial Research, Blindern, Oslo (Norway)Document9 pagesJ. Krudtaa Central Institute For Industrial Research, Blindern, Oslo (Norway)Milla GomesNo ratings yet

- Magnetic Conductive Outer Layer in Oxygen-Deficient Tio Single CrystalsDocument7 pagesMagnetic Conductive Outer Layer in Oxygen-Deficient Tio Single CrystalsSahil AkramNo ratings yet

- Transmutation of Iodine: Results of The EFTTRA-T1 Irradiation TestDocument6 pagesTransmutation of Iodine: Results of The EFTTRA-T1 Irradiation TestWalid BadrNo ratings yet

- Characteristics of Martensitic Stainless Steel Nitrided in A Low-Pressure RFDocument6 pagesCharacteristics of Martensitic Stainless Steel Nitrided in A Low-Pressure RFPramod MishraNo ratings yet

- Diamagnetism of Copper.: by Dr. S. P, Aniachandra Ra0Document11 pagesDiamagnetism of Copper.: by Dr. S. P, Aniachandra Ra0Muhammad MujtabaNo ratings yet

- Oxidation of Rhodium-PlatinumDocument8 pagesOxidation of Rhodium-PlatinumDaniele SabbatoNo ratings yet

- Rheology and Metal Forming of Fire-Refined CopperDocument6 pagesRheology and Metal Forming of Fire-Refined CoppervitordeleteNo ratings yet

- Uncorrected Proofs: Stability of Precipitates Under Electropulsing in 316L Stainless SteelDocument6 pagesUncorrected Proofs: Stability of Precipitates Under Electropulsing in 316L Stainless SteelDebabrata BhuyanNo ratings yet

- 001 Microstructures andDocument7 pages001 Microstructures andPraew ClikNo ratings yet

- Gold Electrowinning From Diluted Cyanide Liquors PDFDocument12 pagesGold Electrowinning From Diluted Cyanide Liquors PDFAlguienNo ratings yet

- Evolution of Carbide Precipitates in 2.25Cr-1Mo Steel During Long-Term Service in A Power PlantDocument7 pagesEvolution of Carbide Precipitates in 2.25Cr-1Mo Steel During Long-Term Service in A Power PlantRogger Asmat VasquezNo ratings yet

- Hydrogen Reduction Cobalt-Chromium Spinel Oxides. Stoichiometric Cobalt ChromiteDocument6 pagesHydrogen Reduction Cobalt-Chromium Spinel Oxides. Stoichiometric Cobalt ChromiteDuongNo ratings yet

- Development of C12 ADocument11 pagesDevelopment of C12 AVasu RajaNo ratings yet

- Based Noble: Electrodes MetalsDocument10 pagesBased Noble: Electrodes MetalsSumedh WaradeNo ratings yet

- Corrosion Behavior of Copper at Elevated Temperature: Int. J. Electrochem. Sci., 7 (2012) 7902 - 7914Document13 pagesCorrosion Behavior of Copper at Elevated Temperature: Int. J. Electrochem. Sci., 7 (2012) 7902 - 7914idanfriNo ratings yet

- The Effect of Alloying and of The Structure On Active-Passive Transition Potential Range of 17% Chromium Ferritic Stainless SteelsDocument6 pagesThe Effect of Alloying and of The Structure On Active-Passive Transition Potential Range of 17% Chromium Ferritic Stainless SteelsBANUNo ratings yet

- Keywords: Transmutation, Technetium, Iodine, Fission Product, TargetDocument8 pagesKeywords: Transmutation, Technetium, Iodine, Fission Product, TargetWalid BadrNo ratings yet

- Welding Research: Stress Corrosion Characteristics of Maraging Steel Weldments in Air and PentaboraneDocument8 pagesWelding Research: Stress Corrosion Characteristics of Maraging Steel Weldments in Air and PentaboraneHagen_of_TronjeNo ratings yet

- Xiao2013 Article MicrostructureAndPropertiesOfCDocument6 pagesXiao2013 Article MicrostructureAndPropertiesOfCShivansh MishraNo ratings yet

- Hot and Cold Rolling of High Nitrogen Cr-Ni and CR-MN Austenitic Stainless SteelsDocument6 pagesHot and Cold Rolling of High Nitrogen Cr-Ni and CR-MN Austenitic Stainless SteelsLuana CarolineNo ratings yet

- Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yuDocument2 pagesPhase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yuSinhrooNo ratings yet

- Heat-Treatment o F UraniumDocument7 pagesHeat-Treatment o F UraniumOmar VillanuevaNo ratings yet

- BF00587656Document2 pagesBF00587656prabathnilanNo ratings yet

- Thermodynamics of Titanium and Oxygen Dissolved in Liquid Iron Equilibrated With Titanium OxidesDocument10 pagesThermodynamics of Titanium and Oxygen Dissolved in Liquid Iron Equilibrated With Titanium Oxidesarchivossubidos_No ratings yet

- Chemical Degradation MechanismDocument7 pagesChemical Degradation MechanismDR. JunioNo ratings yet

- Influence of Apparatus Geometry and Deposition Conditions On The Structure and Topography of Thick Sputtered CoatingsDocument6 pagesInfluence of Apparatus Geometry and Deposition Conditions On The Structure and Topography of Thick Sputtered CoatingsJonathan DeomampoNo ratings yet

- Effect of Intergranular Precipitation On The Internal Oxidation Behavior of CR - MN-N Austenitic Stainless SteelsDocument8 pagesEffect of Intergranular Precipitation On The Internal Oxidation Behavior of CR - MN-N Austenitic Stainless SteelsDomingo FernándezNo ratings yet

- (Advances in Materials Science) Assessment of Fitness For Service of Cr-Mo Steel Tubes in Catalytic Reforming Charge HeatersDocument10 pages(Advances in Materials Science) Assessment of Fitness For Service of Cr-Mo Steel Tubes in Catalytic Reforming Charge HeatersM ANo ratings yet

- Iridium Platinum AlloysDocument9 pagesIridium Platinum Alloysnguyen9si9nguyenNo ratings yet

- Ruthenium Dioxide As A Hydrogen-Evolving Cathode: Brown Boveri Research Center, CH-5405 Baden, SwitzerlandDocument2 pagesRuthenium Dioxide As A Hydrogen-Evolving Cathode: Brown Boveri Research Center, CH-5405 Baden, SwitzerlandOussama IkhlefNo ratings yet

- 5optimization of Microstructure and Properties of As-Cast Various Si Containing Cu-Cr-Zr Alloy by Experiments and First-Principles CalculationDocument10 pages5optimization of Microstructure and Properties of As-Cast Various Si Containing Cu-Cr-Zr Alloy by Experiments and First-Principles Calculation波唐No ratings yet

- Less-Common Metals Elsevier Sequoia S.A., Lausanne - Printed in The NetherlandsDocument11 pagesLess-Common Metals Elsevier Sequoia S.A., Lausanne - Printed in The NetherlandsInaamNo ratings yet

- Carburization of Austenitic and Ferritic Stainless Steels in Liquid SodiumDocument24 pagesCarburization of Austenitic and Ferritic Stainless Steels in Liquid Sodium鄭勝元No ratings yet

- Ijems 22 (3) 283-287Document5 pagesIjems 22 (3) 283-287Ankur gaurNo ratings yet

- Magnetic Roasting of Some Egyptian FerruDocument10 pagesMagnetic Roasting of Some Egyptian FerruravibelavadiNo ratings yet

- Trab. CongreDocument11 pagesTrab. CongreNathanael Wagner MetalNo ratings yet

- Aging of A Heat Resistant Alloy: Universidad Aut6noma Del Estadode Morelos, Zacatecas, MexicoDocument7 pagesAging of A Heat Resistant Alloy: Universidad Aut6noma Del Estadode Morelos, Zacatecas, MexicoEzequiel RuggieroNo ratings yet

- Phase Diagram Study of Alloys in Iron Carbon Chromium Mo-NiDocument13 pagesPhase Diagram Study of Alloys in Iron Carbon Chromium Mo-NiRavichandran JayaprakashNo ratings yet

- Space: Station ResistojetsDocument9 pagesSpace: Station ResistojetsAbhishek DadhwalNo ratings yet

- Electrical Sliding Wear Property of Al2O3 Particle Reinforced Cu CR ZR Matrix CompositeDocument5 pagesElectrical Sliding Wear Property of Al2O3 Particle Reinforced Cu CR ZR Matrix Compositemohamed aliNo ratings yet

- Practical 6Document7 pagesPractical 6Farid FazamyNo ratings yet

- Exposed Slag Eye Formation Air and ArgonDocument10 pagesExposed Slag Eye Formation Air and ArgonEstéfano Aparecido VieiraNo ratings yet

- On Structural, Optical and Dielectric Properties of Zinc Aluminate NanoparticlesDocument9 pagesOn Structural, Optical and Dielectric Properties of Zinc Aluminate NanoparticlesbudhladaNo ratings yet

- Syifa Luthfiyah - Paper - ISAIME PDFDocument9 pagesSyifa Luthfiyah - Paper - ISAIME PDFSyifa LuthfiyahNo ratings yet

- Effect of Phase Transformation On Corrosion Behaviour of Zn-22Al AlloysDocument10 pagesEffect of Phase Transformation On Corrosion Behaviour of Zn-22Al AlloysAlex GarciaNo ratings yet

- Thermit Welding of Chromium Vanadium RailsteelDocument8 pagesThermit Welding of Chromium Vanadium Railsteelsantu_23No ratings yet

- Fundamental Studies of Copper Anode Passivation During Electrorefining: Part III. The Effect of ThioureaDocument7 pagesFundamental Studies of Copper Anode Passivation During Electrorefining: Part III. The Effect of ThioureaLeandro GuzmánNo ratings yet

- Eagar 034Document11 pagesEagar 034saransh guptaNo ratings yet

- Journal of Alloys and Compounds: Raghavendra Sagar, R.L. RaibagkarDocument7 pagesJournal of Alloys and Compounds: Raghavendra Sagar, R.L. RaibagkarRachna SelvamaniNo ratings yet

- Synthesis and Characterization of Nanocrystalline Powders For Partially Stabilized Zirconia CeramicsDocument5 pagesSynthesis and Characterization of Nanocrystalline Powders For Partially Stabilized Zirconia Ceramicsamirlove206No ratings yet

- A Study On Zirconium Rich Uranium-Zirconium Alloys PDFDocument8 pagesA Study On Zirconium Rich Uranium-Zirconium Alloys PDFOmar VillanuevaNo ratings yet

- 1 s2.0 S0921452607003730 MainDocument6 pages1 s2.0 S0921452607003730 MainBhabaniNo ratings yet

- Electrodeposited Gold Composites: Particle-Hardened Gold For Enhanced Wear Resistance in Sliding Contact ApplicationsDocument4 pagesElectrodeposited Gold Composites: Particle-Hardened Gold For Enhanced Wear Resistance in Sliding Contact ApplicationsCicero Gomes de SouzaNo ratings yet

- Silver Recovery From Photographic FilmDocument9 pagesSilver Recovery From Photographic FilmMohammad YoussefiNo ratings yet

- Shigematsu 1992Document3 pagesShigematsu 1992ewrNo ratings yet

- Sugiura 2014Document5 pagesSugiura 2014Stefany Alejandra Fonseca MoralesNo ratings yet

- Mechanical Properties of Cu-Cr System Alloys With and Without ZR and AgDocument7 pagesMechanical Properties of Cu-Cr System Alloys With and Without ZR and AgShivansh MishraNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusNo ratings yet

- Palluna 468: Palladium-Nickel ElectrolyteDocument2 pagesPalluna 468: Palladium-Nickel ElectrolyteWaskito BudiawanNo ratings yet

- Intrusion Related Gold Deposits Morrison GDocument20 pagesIntrusion Related Gold Deposits Morrison GWaskito BudiawanNo ratings yet

- New Hydrometallurgical Process For Gold RecoveryDocument6 pagesNew Hydrometallurgical Process For Gold RecoveryWaskito BudiawanNo ratings yet

- 1199 Leaching Platinum Group Metals in A Sulfuric Acidchloride Solutionae22Document4 pages1199 Leaching Platinum Group Metals in A Sulfuric Acidchloride Solutionae22Waskito BudiawanNo ratings yet

- FireAssayLecture CompatibilityModeDocument71 pagesFireAssayLecture CompatibilityModeWaskito BudiawanNo ratings yet

- ARGONZA, Christian Gil D - Reaction Paper 4 - ME193-2Document2 pagesARGONZA, Christian Gil D - Reaction Paper 4 - ME193-2Christian ArgonzaNo ratings yet

- Jaeger Column InternalsDocument15 pagesJaeger Column Internalslazy5No ratings yet

- Dep Trai Loi Tai AiDocument192 pagesDep Trai Loi Tai AiHoàng Hồng DươngNo ratings yet

- BarometerDocument13 pagesBarometerjanr123456No ratings yet

- Brazing Filler Metal Selector Chart: NicrobrazDocument2 pagesBrazing Filler Metal Selector Chart: NicrobrazathulpcucekNo ratings yet

- Ch111lec AdasDocument4 pagesCh111lec AdasMark Cliffton BadlonNo ratings yet

- ChatGPT Thermal LoadsDocument2 pagesChatGPT Thermal LoadsPanos PanagiotopoulosNo ratings yet

- Sources and Remedies of High Freq Piping Vibration N Noise PDFDocument24 pagesSources and Remedies of High Freq Piping Vibration N Noise PDFSmith780512No ratings yet

- Staad Output FileDocument8 pagesStaad Output FilePriyanshi DixitNo ratings yet

- Gaseous StateDocument14 pagesGaseous StatemayankNo ratings yet

- Capstone Project Report 18705 18713 18715 18718 18722Document31 pagesCapstone Project Report 18705 18713 18715 18718 18722Ibaad KaziNo ratings yet

- The Limit Deposit Velocity Model, A New Approach: Sape A. Miedema, Robert C. RamsdellDocument14 pagesThe Limit Deposit Velocity Model, A New Approach: Sape A. Miedema, Robert C. RamsdellZhadyra BerdauletovaNo ratings yet

- Rav Series Data Sheet: "H" VersionDocument2 pagesRav Series Data Sheet: "H" VersionCapacitacion TodocatNo ratings yet

- P9736 (1) (1) 000000000000000000000000Document29 pagesP9736 (1) (1) 000000000000000000000000WASEM ANWARNo ratings yet

- 2016 - 10 Girth Welding of API 5L X70 and X80 Sour Service PipesDocument8 pages2016 - 10 Girth Welding of API 5L X70 and X80 Sour Service PipesAnonymous GhPzn1xNo ratings yet

- Problem Set 2Document7 pagesProblem Set 2Capi PaucarNo ratings yet

- 19c Latent Heat of FusionDocument3 pages19c Latent Heat of FusionAndrae Tennant100% (1)

- Condensation HMTDocument22 pagesCondensation HMTbalakalees100% (1)

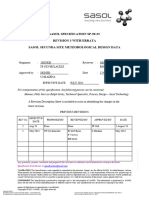

- SP-90-33 Rev 3 - Secunda Site Meteorological Design DataDocument23 pagesSP-90-33 Rev 3 - Secunda Site Meteorological Design DataJacquesBritsNo ratings yet

- Technical Note: Underwater Welding - Present Status and Future ScopeDocument11 pagesTechnical Note: Underwater Welding - Present Status and Future ScopeJohn RajNo ratings yet

- Compressor FoundationDocument4 pagesCompressor FoundationnvnagarajuNo ratings yet

- A2 - Waves AnsDocument20 pagesA2 - Waves AnsNight Mist7No ratings yet

- فلترDocument41 pagesفلترمروان الشباليNo ratings yet

- Chap 1 Introduction To Physical ChemistryDocument43 pagesChap 1 Introduction To Physical ChemistryFarajNo ratings yet

- Comparative Response Assessment of Steel Frames With Different Bracing PDFDocument14 pagesComparative Response Assessment of Steel Frames With Different Bracing PDFaxl_calin82No ratings yet

- Pu Sealant Mccoy Soudal Soudaflex 611 Pu SealantDocument2 pagesPu Sealant Mccoy Soudal Soudaflex 611 Pu SealantsasidharkanthetiNo ratings yet

- Buckling Performance of Cable Systems 9aDocument14 pagesBuckling Performance of Cable Systems 9aSivakumar NatarajanNo ratings yet

- 2 Aakash Test NeetDocument15 pages2 Aakash Test Neethardik cheema100% (1)

- Maintenance and Repair of Pressure VesselsDocument81 pagesMaintenance and Repair of Pressure Vesselsjishnunelliparambil100% (3)

- Upward and Downward ContinuationDocument7 pagesUpward and Downward ContinuationFauzanulNo ratings yet