Professional Documents

Culture Documents

Exercise No: 02 AN-201 (PR) : Determination of Moisture Content in Feed/feed Ingredients

Exercise No: 02 AN-201 (PR) : Determination of Moisture Content in Feed/feed Ingredients

Uploaded by

Docter Syco0 ratings0% found this document useful (0 votes)

6 views2 pagesThe document discusses the determination of moisture content in feed and feed ingredients. It explains that moisture content is the percentage of water in a solid sample, and its determination is important for labeling, quality, stability and preventing economic losses. The process involves weighing a sample before and after drying in a hot air oven, then using a formula to calculate the percentage moisture based on the weight differences. Key equipment used includes a hot air oven, desiccator, weighing balance and sample containers.

Original Description:

animal nutrition

Original Title

Moisture Determinaton

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the determination of moisture content in feed and feed ingredients. It explains that moisture content is the percentage of water in a solid sample, and its determination is important for labeling, quality, stability and preventing economic losses. The process involves weighing a sample before and after drying in a hot air oven, then using a formula to calculate the percentage moisture based on the weight differences. Key equipment used includes a hot air oven, desiccator, weighing balance and sample containers.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesExercise No: 02 AN-201 (PR) : Determination of Moisture Content in Feed/feed Ingredients

Exercise No: 02 AN-201 (PR) : Determination of Moisture Content in Feed/feed Ingredients

Uploaded by

Docter SycoThe document discusses the determination of moisture content in feed and feed ingredients. It explains that moisture content is the percentage of water in a solid sample, and its determination is important for labeling, quality, stability and preventing economic losses. The process involves weighing a sample before and after drying in a hot air oven, then using a formula to calculate the percentage moisture based on the weight differences. Key equipment used includes a hot air oven, desiccator, weighing balance and sample containers.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

EXERCISE NO: 02 AN-201(Pr)

Determination of moisture content in feed/feed ingredients

Moisture

After drying, the loss of weight in a feed/ ingredient is called as moisture

The percentage (%) of water (liquid) percent in a solid sample

Important of moisture determination

Determination of moisture is important for number of different reasons like labeling,

texture, taste, appearance, quality, stability and weight loss.

The weight above the normal range may cause the loss in weight and also leads to

economical losses.

Furthermore, high moisture (%) decreases the stability of the ingredient or feed due

to high risk of fungal diseases and toxicity.

Equipments and glasswares used in moisture determination

Hot air oven

Desiccator

Electric weighing balance

Pertri dishes/ Crucible cups

Spatula

Grinded sample

Process:

Take a petri dish or crucible cup and weight on weighing electronic balance and note

the reading as W1

Add upto 3-5 gram of grinded sample in weighed Petri dish and again note the

reading as W2

Keep the Petri dish with sample in hot air oven at 1050C for 2-3 hrs until the all

moisture is removed.

Remove the Petri dish from hot air oven and place in a desiccator for 10-15 minutes

to cool the sample.

After cooling weight, again the Petri dish with sample and note the reading as W3

Now calculate moisture content with the help of given formula.

Calculations: Moisture (%)= W2-W3 x 100

W1-W2

Example M (%)= 49.443-48.292 =1.151 x 100= 10.21

38.175-49.443 =11.268

Note:

W1- Empty weight of Pertri dish/cruicible cup =38.175

W2 – Weight of Petri dish + Sample weight (Before drying) =49.443

W3- Weight of Petri dish + Sample weight (After drying) =48.292

You might also like

- Analyses For Milk PowderDocument9 pagesAnalyses For Milk PowderEtta Jenee100% (1)

- Solar Grain Dryer Dr. George OwinoDocument11 pagesSolar Grain Dryer Dr. George OwinoGeorge OparNo ratings yet

- Grain Drying and Dryers: Agricultural Mechanization For Sustainable Farming System Course 2004Document71 pagesGrain Drying and Dryers: Agricultural Mechanization For Sustainable Farming System Course 2004RamilArtates100% (2)

- SOP Water AnalysisDocument114 pagesSOP Water AnalysisYogesh Dhekale100% (1)

- Experiment No. 6 - Bitumen Extraction Test: ObjectiveDocument4 pagesExperiment No. 6 - Bitumen Extraction Test: ObjectiveKanishka Sarkar88% (8)

- Determination of Moisture ContentDocument8 pagesDetermination of Moisture ContentLaksilu Viduraga Peiris100% (13)

- Determination of Moisture ContentDocument7 pagesDetermination of Moisture ContentLaksilu Viduraga Peiris71% (7)

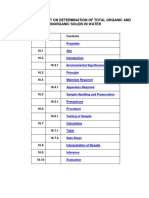

- 16.0 Experiment On Determination of Total Organic and Inorganic Solids in WaterDocument13 pages16.0 Experiment On Determination of Total Organic and Inorganic Solids in WaterVishnu NandakumarNo ratings yet

- (Lab Report Operation Unit) Experiment 5: INTRODUCTION TO DRYING PROCESS: DRYING A SOLIDDocument9 pages(Lab Report Operation Unit) Experiment 5: INTRODUCTION TO DRYING PROCESS: DRYING A SOLIDFazsroul84% (19)

- MoistureDocument13 pagesMoistureAsif AnwarNo ratings yet

- Study of Spray DryingDocument18 pagesStudy of Spray DryingMahe Rukh100% (2)

- Lab Report 1Document8 pagesLab Report 1nikhil reddyNo ratings yet

- Report01 (Dileepa)Document10 pagesReport01 (Dileepa)Dileepa NeranjanaNo ratings yet

- Group 1 Soil Lab Report PDFDocument28 pagesGroup 1 Soil Lab Report PDFMUHAMMAD IMAN ASYRAF AHMAD NIZANo ratings yet

- ATT-15/96, MOISTURE CONTENT, Oven Method, Soil and Gravel 1.0 ScopeDocument3 pagesATT-15/96, MOISTURE CONTENT, Oven Method, Soil and Gravel 1.0 ScopeAndita Tri BudiantoNo ratings yet

- Food Analysis ManualDocument23 pagesFood Analysis ManualLavan GaddamNo ratings yet

- Department of Textile Engineering: Lab ReportDocument6 pagesDepartment of Textile Engineering: Lab ReportMd Ifta Khairul AlamNo ratings yet

- 2017 CH 414Document38 pages2017 CH 414Mian GulshadNo ratings yet

- Experiment Title: Titration AnalysisDocument3 pagesExperiment Title: Titration AnalysisHarwinder SinghNo ratings yet

- Moisture Content ReportDocument7 pagesMoisture Content ReportchukwuokemosesNo ratings yet

- 1 Determination of Apparent Porosity: The Evacuation MethodDocument5 pages1 Determination of Apparent Porosity: The Evacuation MethodMohammed Salah FahimNo ratings yet

- 1586333153Document6 pages1586333153Sar OyaNo ratings yet

- DRYINGDocument85 pagesDRYINGdivakarNo ratings yet

- Aashto T 84Document4 pagesAashto T 84Muhammad HasifNo ratings yet

- Group 3-Laboratory 2Document8 pagesGroup 3-Laboratory 2Lenoj OlarNo ratings yet

- $rif4foj (2017 - 11 - 27 15 - 16 - 35 Utc)Document4 pages$rif4foj (2017 - 11 - 27 15 - 16 - 35 Utc)Rob DamhuisNo ratings yet

- Experiment On: Extrusion Cooking AIMDocument8 pagesExperiment On: Extrusion Cooking AIMShobikaNo ratings yet

- Northbrook CollegeDocument10 pagesNorthbrook CollegeDaniyal AsifNo ratings yet

- Determination of Moisture Content: ObjectiveDocument3 pagesDetermination of Moisture Content: ObjectiveDiendo Boquiren MahlyNo ratings yet

- Chemical AnalysisDocument8 pagesChemical AnalysisSBNo ratings yet

- Aeng 95 Exer No. 3 Calibration of A Grain Moisture MeterDocument10 pagesAeng 95 Exer No. 3 Calibration of A Grain Moisture MeterRufina RiveraNo ratings yet

- Determination of Moisture: NG Mui CHNGDocument3 pagesDetermination of Moisture: NG Mui CHNGApostolos PatsiasNo ratings yet

- الوزن النوعي ووحدة الوزن والمحتوى المائيDocument7 pagesالوزن النوعي ووحدة الوزن والمحتوى المائيMarean AljNo ratings yet

- Group No.: - Date Conducted: - Group MembersDocument3 pagesGroup No.: - Date Conducted: - Group MembersMaricar DimasNo ratings yet

- Practical Manual - Processing of Spices and Plantation CropsDocument26 pagesPractical Manual - Processing of Spices and Plantation CropsDhaya VNo ratings yet

- WI 3 SG & Absortion of Aggregates Issue 2-1Document3 pagesWI 3 SG & Absortion of Aggregates Issue 2-1Raja VarshneyNo ratings yet

- Mapúa University: Experiment No. - 2Document15 pagesMapúa University: Experiment No. - 2Mark PulongbaritNo ratings yet

- Laboratory Activity No. 1Document4 pagesLaboratory Activity No. 1Christopher Andrei Salonga LimNo ratings yet

- Moisture ContentDocument6 pagesMoisture ContentJM BoylesNo ratings yet

- Lab 2Document6 pagesLab 2Lenoj OlarNo ratings yet

- Q 535 Q 5Document23 pagesQ 535 Q 5JAN JERICHO MENTOYNo ratings yet

- Super-Clean PET Flake ProcessDocument5 pagesSuper-Clean PET Flake ProcessViktorNo ratings yet

- Phsophonate Content Solid ContentDocument1 pagePhsophonate Content Solid ContentGovindanayagi PattabiramanNo ratings yet

- Experiment 1 Evt637Document5 pagesExperiment 1 Evt637Azmi AslamNo ratings yet

- Lab Report Food AnalysisDocument2 pagesLab Report Food AnalysisAlimah Azeli100% (1)

- Drying Chamber: Hot AirDocument8 pagesDrying Chamber: Hot AirAbhinav ShankarNo ratings yet

- Experiment 2 Tray DryerDocument5 pagesExperiment 2 Tray DryerHajra AamirNo ratings yet

- Labarotary Report 1Document7 pagesLabarotary Report 1Nor FazilahNo ratings yet

- Hara HapDocument6 pagesHara HapMonyet...No ratings yet

- Total Moisture Content of Aggregate by Drying Aashto T 255: ScopeDocument3 pagesTotal Moisture Content of Aggregate by Drying Aashto T 255: ScopeMd Imtiazul AlamNo ratings yet

- Experiment 5 - 3DDocument20 pagesExperiment 5 - 3DPoh Ching HongNo ratings yet

- ACT 9 Filter Grp1Document8 pagesACT 9 Filter Grp1Junn Edgar LibotNo ratings yet

- Pressure Filtration PracticalDocument15 pagesPressure Filtration PracticalServeshan Naidoo33% (3)

- PGDBST 03Document61 pagesPGDBST 03UJJWAL RAJ SINGHNo ratings yet

- Exp - No - 6Document7 pagesExp - No - 6LAURILLA ANTONETTE MAE L.No ratings yet

- Mahin - 193003051 (TTQC Lab8)Document5 pagesMahin - 193003051 (TTQC Lab8)MahinNo ratings yet

- Drying, Grading & Fruit HarvestersDocument9 pagesDrying, Grading & Fruit HarvestersJanardhan RaoNo ratings yet

- Tray DryerDocument15 pagesTray Dryerfaez94No ratings yet

- 06 DryersDocument6 pages06 DryersEdwin TorilloNo ratings yet

- New XNTDocument1 pageNew XNTDocter SycoNo ratings yet

- PharmaDocument7 pagesPharmaDocter SycoNo ratings yet

- Ideology of PakistanDocument3 pagesIdeology of PakistanDocter SycoNo ratings yet

- Determination of Acid Insoluble Ash (Sand of Silica)Document2 pagesDetermination of Acid Insoluble Ash (Sand of Silica)Docter SycoNo ratings yet