Professional Documents

Culture Documents

SWZ 222 Ionl 2222794

SWZ 222 Ionl 2222794

Uploaded by

Enrique Murgia0 ratings0% found this document useful (0 votes)

2 views4 pagesDETROIT SWITCH

Original Title

swz-222-ionl-2222794

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDETROIT SWITCH

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views4 pagesSWZ 222 Ionl 2222794

SWZ 222 Ionl 2222794

Uploaded by

Enrique MurgiaDETROIT SWITCH

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

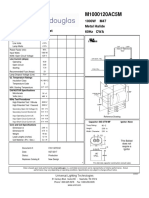

DETROIT SWITCH, INC.

Form 1871-D

Snstructions

No. 222-10

CONTROL SWITCHES

DESIGNED TO MEET THE REQUIREMENTS AND

WITHSTAND THE TEST FOR GRADE A CLASS 1

TYPE B OF NAVAL SEA SYSTEMS COMMAND

MILITARY SPECIFICATIONS MIL-S-901 FOR HI-

SHOCK, MIL-C-2212 FOR A.C. AND D.C. SWITCH-

ING DEVICES, MIL-E-2036 FOR WATERTIGHT AND

MIL-R-16743 FOR REFRIGERATION EQUIPMENT.

ENCLOSURE: WATERTIGHT

SERVICE: NAVY A

SHOCK: CLASS HI

‘The 222-10 Controls incorporate a seamless

metallic bellows power element which, when

actuated by pressure or temperature, operates the

switch mechanism to open or close an electrical

circuit, A permanent magnet in the switch

iechanismn provides a positive snap-action on both

the opening and closing cycles. This snap-action

prevents excessive arcing at the contacts.

ALARM PANEL (MIL-A-17196)

The switch may be used on vessels having an

annunciator panel (Spec. MIL-A-17196) with a

supervisory cireuit continuously indicating

whether ship's wiring between the panel and the

alarm switch is in working order. To provide for

this feature a Navy approved type resistor is

connected across the switch terminal screws. This

resistor is easily removed when switch is used on

panels without this supervisory circuit,

INSTALLATION

Do not attach a pressure or direct connection

temperature control by turning the case. Use a

wrench on the power element hex.

Prossure Controls

Pressure controls may be installed directly at the

point where the pressure is to be controlled, or

mounted remotely and connected with standard

pipe and fittings.

NOTE: On steam pressures over 15 pounds, a

siphon (water seal) must be used to prevent

damage to the control

‘Temperature Controls, Direct Connection

Direct connection temperature controls must be

installed with the thermal bulb in a free circulation

of the medium to be controlled. Do not place the

bulb in a dead end of pipe or any other location

where it will not encounter the average tempera-

ture of the medium. Make certain there is suffi-

Gent room for the bulb in order that it will not be

damaged by coming in contact with the bottom or

side of the opening

‘Temperature Controls, Remote Connection

Remote connection temperature controls are

furnished with flexible tubing between the control

and the thermal bulb. This permits mounting the

control on a wall or any other convenient support.

Model NL (solid) thermal bulb must be installed

within 75 Deg, of vertical pointing downward (with

flexible tube coming out of upper end of bulb).

Model NN (large coil) bulb must be installed within

75 Deg. of vertical upward (with flexible tube

coming out of lower end of bulb).

NOTE: See below for standard temperature bulb

iustrated mounting position

The thermal bulb must be located in a free

circulation of the liquid or other substance to be

controlled. Do not place the bulb in a dead end of

pipe or any other place where it will not meet the

average temperature of the liquid or substance to

be controlled

Care should be taken not to put sharp bends in

the flexible tube or damage the bulb by trying to

install it where there is insufficient room.

Do not twist the flexible tube. When installing a

control with a demountable union, assemble the

union on the tubing, leaving it loose enough to

turn freely on the tubing. After the bulh has bee:

inserted to the desired position and the union has

been screwed into place, tighten packing to pre-

vent leakage. Be careful not to damage the tubing

when tightening the union packing.

SETTING

The adjusting screw for setting the differential

operating point, if adjustable differential is

specified, is located inside the case and is exposed

when the watertight cover is removed. Range

adjustments may be made without removing the

cover. This control is available with either screw

driver or knob range adjustment, located on the

end of the case.

RANGE ADJUSTMENT: Screwdriver or knob

justment establishes the point at which the

switch will close. Range on screwdriver adjustment

models is adjustable over the entire range of the

control, while only one third of the range is

normally adjustable on knob adjustment models.

If itis desired to ad-

just the knob adjust-

ment models over the .

full range of the ele-

ment, loosen range ad

justing knob lock

Screw #A", Fig. 2. Re- °

move screw *B*, Fig. 2

and pull the knob out

until the stop clears

the locking clamp.

Turn the stop on the

knob past the clamp and replace the knob. Three

full turns of the knob cover the entire range of the

element.

DIFFERENTIAL ADJUSTMENT (single pole,

single throw only): Governs the point at which the

switch opens, but does not affect the point at which

the switch closes. The differential will vary with

changes in range adjustment on temperature types

but will remain constant on pressure types.

SWITCHES WHICH OPEN THE CIRCUTT WITH

INCREASING TEMPERATURE OR PRESSURE ARE

ADJUSTED AS FOLLOWS.

To Set: Turn differential screw counter-clockwise

against stop for minimum differential. Bring

temperature or pressure to point where circuit is 0

close. If contacts are open, turn range screw slowly

clockwise until contacts just close. If contacts are

already closed, turn range screw eounter-clockwise

until contacts open; then turn slowly clockwise

until contacts just lose. This fixes the closing

point. Differential screw, which governs the point

at which the contacts open, may be turned

clockwise to widen the differential slightly.

SWITCHES WHICH CLOSE THE CIRCUIT WITH

INCREASING TEMPERATURE OR PRESSURE ARE

ADJUSTED AS FOLLOWS:

To Set: Tarn differential screw counter-clockwise

igainst stop for minimum differential. Bring

{emperature or pressure to point where circuit isto

dlowe: If contac are open, turn range screw slowly

counter-clockwise until contacts just close. If

contacts are already closed, turn range screw

dockwise until contacts open; then turn slowly

counter-clockwise until contacts just close. This

fixes the closing point.

Differential screw which governs the point at

which the contacts open, may be turned clockwise

to widen the differential slightly

‘Types other than single pole - single throw are

adjusted for opening or closing setting as described,

above but the differential is factory set and should

not be adjusted in the field.

NOTES: When adjusting temperature switches,

all types, allow several minutes for thermal bulb to

acquire proper temperature before making set-

tings.

After adjusting all switches, cheek adjustments

by observing an operating eyele

‘When adjusting double throw switches all refer

ences to “contacts opening” or “contacts closing”

reler to the UPPER CONTACTS ONLY.

ELECTRICAL RATINGS IN AMPS

‘SPST SPOT” - DUAL SPST - DUAL CONTACT OPST™

TNOUGTIVE LOCKED ROTOR,

OUTAGE

Ae. De. AG. De.

We 160 28 960 | 960

= 0 wo | 40

400 40 28 zo | 20

«0 22 20 sz | 20

* Lower Gontset rated att amp D.G. and 16 amps AC. a 115 W

‘Upper Gomzact 6 capaie of erect coal of motte up 61 HP

(esgned for votages fom 1510 650 AC. and OC

PRESSURE OPERATED

MOUNTING POSITION

‘TEMPERATURE OPERATED (STANDARD BULBS)

Mount bulbs within 75° of position shown

fo

Terese

les

Models NAct

NEct and NB-8

= | pew tL

wean oa eae

cette lotta NES

*T-

oat WOK

‘Moxie! NN Mode! NH-1

1:2 Bulb tip must be horizontal or below

DETROIT SWITCH, INC.

1025.33 BEAVER AVENUE

PITTSBURGH, PA. 15233

Phone 412/322-9144

Technical Data | NSN 5930-01-177-8943

Characteristic

STYLE DESIGNATOR

OVERALL LENGTH

OVERALL HEIGHT

OVERALL WIDTH

BODY HEIGHT

NONPILE-UP CONTACT

ARRANGEMENT

CONTACT ACTION STIMULUS

CONTACT ADJUSTABILITY

CONTACT ADJUSTMENT RANGE

CONTACT ADJUSTMENT TYPE

CONTACT VOLTAGE RATING IN

VOLTS

CONTACT LOAD CURRENT

RATING,

MEDIA FOR WHICH DESIGNED

TEMP SENSING ELEMENT TYPE

CAPILLARY TUBE LENGTH

BULB LENGTH

Specifications

73 RECTANGULAR

5.188 INCHES NOMINAL

5.687 INCHES NOMINAL

2.812 INCHES NOMINAL

2.750 INCHES NOMINAL

4 POLE, DOUBLE THROW, ONE.

POSITION MOMENTARY

INCREASE

ACTUATION POINT ADJUSTABLE

-10.00 TO 60.00 ACTUATION POINT

DEGREES FAHRENHEIT

EXTERNAL ACTUATION POINT

SCREW

115.0 AC AT SEA LEVEL FIRST.

VOLTAGE 550.0 AC AT SEA LEVEL

SECOND VOLTAGE 115.0 DC AT SEA

LEVEL THIRD VOLTAGE 550.0 DC AT

SEA LEVEL FOURTH VOLTAGE,

16.0 AMPERES INDUCTIVE LOAD

FIRST VOLTAGE 3.2 AMPERES

INDUCTIVE LOAD SECOND.

VOLTAGE 9.6 AMPERES INDUCTIVE

LOAD THIRD VOLTAGE 2.0

AMPERES INDUCTIVE LOAD

FOURTH VOLTAGE

LiquiD

CAPILLARY TUBE-BULB

240.0 INCHES NOMINAL

3.000 INCHES NOMINAL

Characteristic

BULB DIAMETER

TERMINAL TYPE

MOUNTING METHOD

UNTHREADED MOUNTING HOLE

DIAMETER,

MOUNTING FACILITY PATTERN

LONGEST HORIZONTAL

DISTANCE BETWEEN MOUNTING

CENTERS

SHORTEST HORIZONTAL

DISTANCE BETWEEN MOUNTING

CENTERS

LONGEST VERTICAL DISTANCE

BETWEEN MOUNTING CENTERS

FEATURES PROVIDED

Il HAZARDOUS

LOCATIONS/ENVIRONMENTAL

PROTECTION

Il PRECIOUS MATERIAL

Ill PRECIOUS MATERIAL AND.

LOCATION

Specifications

0.375 INCHES NOMINAL

SCREW

BRACKET AND UNTHREADED HOLE

0.281 INCHES NOMINAL

ISOSCELES TRIANGLE

2.406 INCHES NOMINAL,

0.656 INCHES NOMINAL,

3.281 INCHES NOMINAL

ELECTRICAL ACCESS PORT

WATERTIGHT AND DUSTPROOF

SILVER

CONTACTS SILVER

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Partsprice PDFDocument602 pagesPartsprice PDFEnrique Murgia50% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- CMDDocument61 pagesCMDEnrique MurgiaNo ratings yet

- NITROGENDocument8 pagesNITROGENEnrique MurgiaNo ratings yet

- EFA-56 KnochensaegeDocument10 pagesEFA-56 KnochensaegeEnrique MurgiaNo ratings yet

- BA DL Brustbeinsaege EFA 57 en 02.2020Document34 pagesBA DL Brustbeinsaege EFA 57 en 02.2020Enrique MurgiaNo ratings yet

- M1000120AC5MDocument1 pageM1000120AC5MEnrique MurgiaNo ratings yet

- SS Cnpulse 12132018Document2 pagesSS Cnpulse 12132018Enrique MurgiaNo ratings yet

- Itsupply: Hardware ManualDocument131 pagesItsupply: Hardware ManualEnrique MurgiaNo ratings yet

- Gear Pump Shhark Low NoiseDocument2 pagesGear Pump Shhark Low NoiseEnrique MurgiaNo ratings yet

- Sauer Danfoss Hydraulic Gear Pump Group 4Document23 pagesSauer Danfoss Hydraulic Gear Pump Group 4Enrique MurgiaNo ratings yet

- Port Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestDocument3 pagesPort Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestEnrique MurgiaNo ratings yet

- Sauer Danfoss Hydraulic Gear Pump Group 3Document33 pagesSauer Danfoss Hydraulic Gear Pump Group 3Enrique Murgia100% (1)

- Elektro Oliepot EloDocument1 pageElektro Oliepot EloEnrique MurgiaNo ratings yet

- Mini Squirt Hot Melt Adhesive ApplicatorDocument2 pagesMini Squirt Hot Melt Adhesive ApplicatorEnrique MurgiaNo ratings yet

- Sandvik DTH Drilling Tools: RH550r HammerDocument1 pageSandvik DTH Drilling Tools: RH550r HammerEnrique MurgiaNo ratings yet

- Universal Bugomatic Bro 3 19Document4 pagesUniversal Bugomatic Bro 3 19Enrique MurgiaNo ratings yet

- RiktningsVäljarventiler HYSPCSEDocument46 pagesRiktningsVäljarventiler HYSPCSEEnrique MurgiaNo ratings yet

- Danroll Drum MotorDocument112 pagesDanroll Drum MotorEnrique MurgiaNo ratings yet

- YyyyygyDocument2 pagesYyyyygyJohann Piñón SalgadoNo ratings yet

- X55-600 BrochureDocument9 pagesX55-600 BrochureEnrique MurgiaNo ratings yet

- Robotic Shotcrete Applications For Mining and Tunneling: A History of Robotic ApplicatorsDocument6 pagesRobotic Shotcrete Applications For Mining and Tunneling: A History of Robotic ApplicatorsEnrique MurgiaNo ratings yet

- 962 Stager Manual Rev BDocument18 pages962 Stager Manual Rev BEnrique MurgiaNo ratings yet

- TFP1511 09 2015Document8 pagesTFP1511 09 2015Enrique MurgiaNo ratings yet

- AC Motors Asynchronous Servomotors: Operating InstructionsDocument56 pagesAC Motors Asynchronous Servomotors: Operating InstructionsEnrique MurgiaNo ratings yet

- LS 2001 BaseCoat OkDocument4 pagesLS 2001 BaseCoat OkEnrique MurgiaNo ratings yet