Professional Documents

Culture Documents

Machine Screws 24 External Threads PDF

Uploaded by

Saif UllahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Screws 24 External Threads PDF

Uploaded by

Saif UllahCopyright:

Available Formats

Machine Screws Thread Dimensions

L L

Basic

major

diameter

Basic

pitch

diameter

Minor

diameter

Axis of screw thread

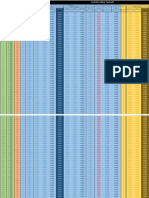

2A External Threads for Machine Screws and SEMS ASME B 1.1 (2002)

Major Diameter Pitch Diameter Tensile Strength,a

Nominal Size & Series Stress Area,

Allowance lb., min. (STEEL

Threads per Inch Designation Max Min Max Min Tolerance in2

screws only)

0-80 0.060 UNF .0005 .0595 .0563 .0514 .0496 .001762 0.00180 -

1-64 0.073 UNC .0006 .0724 .0686 .0623 .0603 .001970 0.00263 -

1-72 0.073 UNF .0006 .0724 .0689 .0634 .0615 .001899 0.00278 -

2-56 0.086 UNC .0006 .0854 .0813 .0738 .0717 .002127 0.00370 -

2-64 0.086 UNF .0006 .0854 .0816 .0753 .0733 .002040 0.00394 -

3-48 0.099 UNC .0007 .0983 .0938 .0848 .0825 .002302 0.00487 -

3-56 0.099 UNF .0007 .0983 .0942 .0867 .0845 .002191 0.00523 -

4-40 0.112 UNC .0008 .1112 .1061 .0950 .0925 .002507 0.00604 360

4-48 0.112 UNF .0007 .1113 .1068 .0978 .0954 .002361 0.00661 396

5-40 0.125 UNC .0008 .1242 .1191 .1080 .1054 .002562 0.00796 470

5-44 0.125 UNF .0007 .1243 .1195 .1095 .1070 .002484 0.00830 498

6-32 0.138 UNC .0008 .1372 .1312 .1169 .1141 .002820 0.00909 550

6-40 0.138 UNF .0008 .1372 .1321 .1210 .1184 .002614 0.01015 609

8-32 0.164 UNC .0009 .1631 .1571 .1428 .1399 .002916 0.0140 850

8-36 0.164 UNF .0008 .1632 .1577 .1452 .1424 .002804 0.01474 884

10-24 0.190 UNC .0010 .1890 .1818 .1619 .1586 .003319 0.0175 1050

10-32 0.190 UNF .0009 .1891 .1831 .1688 .1658 .003004 0.0200 1200

12-24 0.216 UNC .0010 .2150 .2078 .1879 .1845 .003400 0.0242 1450

12-28 0.216 UNF .0010 .2150 .2085 .1918 .1886 .003224 0.0258 1548

1/4-20 0.250 UNC .0011 .2489 .2408 .2164 .2127 .003731 0.0318 1900

1/4-28 0.250 UNF .0010 .2490 .2425 .2258 .2225 .003322 0.0364 2200

5/16-18 0.3125 UNC .0012 .3113 .3026 .2752 .2712 .004041 0.0524 3150

5/16-24 0.3125 UNF .0011 .3114 .3042 .2843 .2806 .003660 0.0580 3480

3/8-16 0.375 UNC .0013 .3737 .3643 .3331 .3287 .004363 0.0775 4650

3/8-24 0.375 UNF .0011 .3739 .3667 .3468 .3430 .003804 0.0878 5268

1/2-13 0.500 UNC .0015 .4985 .4876 .4485 .4435 .004965 0.1419 8500

1/2-20 0.500 UNF .0013 .4987 .4906 .4662 .4619 .004288 0.1599 9594

Tolerance on Nominal Nominal Screw Length

Length Screw Size Up to 1/2 in., incl. Over 1/2 to 1 in., incl. Over 1 to 2 in., incl. Over 2 in.

0 thru 12 -0.02 -0.03 -0.06 -0.09

L

1/4 thru 3/4 -0.03 -0.03 -0.06 -0.09

a

Tensile strength values are based on 60,000 psi. and apply to carbon steel screws and SEMS only. Hex and Hex Washer head machine screws

of sufficient length may be wedge tensile tested. Other head styles may be axial tensile tested.

78 This page prints with a watermark

Steel & Mechanical & Performance

Machine Screws

Stainless Requirements

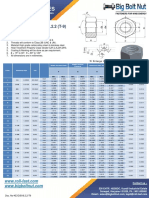

Description A straight shank fastener with external threads designed to go through a hole or nut that is pre-tapped to form a mating thread for the screw.

Machine screws form a fastening superior in strength to spaced thread screws.

Steel Stainless Aluminum

18-8 Stainless steel machine screws are used in applications which

In some applications, aluminum

Steel Zinc is the most common require general atmospheric corrosion resistance, in food processing

machine screws can be a less

Applications/ and most popular variety of steel machinery and refrigeration equipment. Stainless is also superior to steel

expensive alternative to stainless

Advantages machine screws in withstanding some elevation in application operating temperature while

screws because of their resistance

Steel Zinc yellow screws are maintaining its strength.

to corrosion and high rate of

popular in electronics applications. 316 Stainless steel offers superior corrosion resistance to 18-8 and is

conductivity. Aluminum machine

Steel Zinc Black and Black Oxide superior at maintaining its strength at high temperatures.

screws should be fastened with

screws are used to blend in with 410 Stainless steel is recommended in applications where greater

aluminum nuts to minimize the

black-colored components. tensile strength is needed such as control mechanisms or valves under

chance of galvanic corrosion.

high stress. 410 is not as corrosion resistant as are 18-8 or 316 stainless

AISI 1006 - 1022 or equivalent

Material steel.

SAE 18-8 stainless steel 316 stainless steel 410 stainless steel 2024-T4 alloy

Rockwell B85 - B95 Rockwell B85 - B95 Rockwell C34

Hardness Rockwell B70 - B100.

(approximate)* (approximate)* (approximate)

-

80,000 psi. minimum

60,000 psi. minimum. (100,000 psi after cold 85,000 - 140,000 psi. 180,000 psi. 62,000 psi. minimum

working)*

Tensile Steel machine screws which have a nominal diameter smaller than #4 are not subject to tensile testing. No. 4 and No. 5 machine screws which are

shorter than 1/2” are not subject to tensile testing. Steel machine screws of diameters No. 6 to 1/2” inclusive, which are shorter than either 1/2” or 3D

Strength (where D is the nominal screw size in inches) are not subject to tensile testing. Such steel machine screws of a size to be tested shall meet the tensile

load requirements listed above.

Tensile strength values for stainless screws are offered as approximations only; there is no single standard for the performance requirements of

stainless machine screws.

See Appendix-A for information Aluminum machine screws are

Stainless machine screws are usually supplied plain or with a black oxide

Plating on the plating of steel machine

finish.

usually supplied without any

screws additional finish.

*Hardness and tensile strength standards are offered as guides only for stainless machine screws. There is currently no national standard for these performance requirements for stainless machine

screws.

This page prints with a watermark 79

You might also like

- Optimum Pipe Size - Liquid Flow: CROSS-SECTIONAL AREA (SF)Document1 pageOptimum Pipe Size - Liquid Flow: CROSS-SECTIONAL AREA (SF)genergiaNo ratings yet

- Fastener Size Tables - MechaniCalcDocument14 pagesFastener Size Tables - MechaniCalcperdhana2000No ratings yet

- Unifai Screw INCHDocument21 pagesUnifai Screw INCHAnonymous RgGtg29No ratings yet

- Thread Pitch ChartDocument2 pagesThread Pitch ChartGeorgeMtyNo ratings yet

- External Threads For Machine Screws and SEMSDocument2 pagesExternal Threads For Machine Screws and SEMSez1010No ratings yet

- Key elevation of bow string girderDocument1 pageKey elevation of bow string girdergoutammand100% (1)

- Thread Pitch Chart PDFDocument2 pagesThread Pitch Chart PDFDarkvaderNo ratings yet

- CadcamDocument45 pagesCadcamManar Abu ShadyNo ratings yet

- Section 2 - Thread - BasicsDocument27 pagesSection 2 - Thread - BasicsChris MedeirosNo ratings yet

- Pavilion MareDocument16 pagesPavilion MarenicnicnicNo ratings yet

- Leaching PPT 2022Document20 pagesLeaching PPT 2022gautham GAUTHAMNo ratings yet

- Collapsible Core Injection MoldingDocument11 pagesCollapsible Core Injection MoldingagniflameNo ratings yet

- Influence Lines in Continuous BeamsDocument10 pagesInfluence Lines in Continuous BeamsRudranath BhattacharyaNo ratings yet

- Secant Pile ReinforcementDocument8 pagesSecant Pile ReinforcementghansaNo ratings yet

- Ansi 70Document2 pagesAnsi 70Omar Reinoso TigreNo ratings yet

- Kyodo Pipe Producs SpecificationDocument3 pagesKyodo Pipe Producs SpecificationTengku MunzirNo ratings yet

- Application Notes Welding (English)Document8 pagesApplication Notes Welding (English)metallurgist100% (6)

- Thread DataDocument17 pagesThread DatabassNo ratings yet

- Unifai Screw INCH PDFDocument21 pagesUnifai Screw INCH PDFAnonymous HI6BetNo ratings yet

- Class 2B Internal Threads PDFDocument2 pagesClass 2B Internal Threads PDFLaural MarshallNo ratings yet

- Class 2B Internal ThreadsDocument2 pagesClass 2B Internal ThreadsRanjeet DongreNo ratings yet

- Internal Threads Class 2B Dimensions and TolerancesDocument2 pagesInternal Threads Class 2B Dimensions and TolerancesLaural MarshallNo ratings yet

- Nuts ThreadsDocument2 pagesNuts ThreadsP S Lakshmi KanthanNo ratings yet

- NutsthreadsDocument2 pagesNutsthreadsXerxes YuudaiNo ratings yet

- Technical Data: Diameter - Pitch Combinations For Class of FitDocument1 pageTechnical Data: Diameter - Pitch Combinations For Class of FitecavalinNo ratings yet

- Standard of Depth of Cut for External ThreadingDocument3 pagesStandard of Depth of Cut for External ThreadingNaren SomaruNo ratings yet

- External Internal Thread Dimensions For UNF Screw Thread 2016Document1 pageExternal Internal Thread Dimensions For UNF Screw Thread 2016Satnam Rachna FastenersNo ratings yet

- External & Internal Thread Dimensions UNF Screw ThreadsDocument1 pageExternal & Internal Thread Dimensions UNF Screw ThreadsRanjeet DongreNo ratings yet

- Hexagon Head Bolts/Screws Dimensions and SpecsDocument2 pagesHexagon Head Bolts/Screws Dimensions and SpecsKathy MejíaNo ratings yet

- Carbon, Alloy and Stainless Steel Pipes Dimensions and SpecificationsDocument4 pagesCarbon, Alloy and Stainless Steel Pipes Dimensions and SpecificationsstvirtueNo ratings yet

- Drill Pipe Data API Ex VAMDocument2 pagesDrill Pipe Data API Ex VAMShane_d980No ratings yet

- 1 Core Copper Xlpe Armoured & Unarmoured Power CablesDocument1 page1 Core Copper Xlpe Armoured & Unarmoured Power CablesSikandar MirzaNo ratings yet

- DrillchartDocument5 pagesDrillchartcc6689No ratings yet

- 1.1 KV 4 Core Alluminium Copper PVC Armoured Unarmoured Power CablesDocument1 page1.1 KV 4 Core Alluminium Copper PVC Armoured Unarmoured Power CablesManali PrajapatiNo ratings yet

- General Tolerances - DIN - IsO - 2768Document1 pageGeneral Tolerances - DIN - IsO - 2768Luis Eduardo García MaltosNo ratings yet

- Internal Threads - Class 2BDocument13 pagesInternal Threads - Class 2BCraig SwensonNo ratings yet

- NAS1102 Series Specifications: Screw, Machine Flat 100° Head Full Thread, Torq-SetDocument1 pageNAS1102 Series Specifications: Screw, Machine Flat 100° Head Full Thread, Torq-SetIliaNo ratings yet

- Metric Copper Tubing: Straight Tubes Soft Pancake CoilsDocument1 pageMetric Copper Tubing: Straight Tubes Soft Pancake CoilssobheysaidNo ratings yet

- TATA Apron Feeder Main Frame TADocument14 pagesTATA Apron Feeder Main Frame TAMohammad AdilNo ratings yet

- Thread TablesDocument22 pagesThread TablesMuthukumar VeerappanNo ratings yet

- REFERENCE TapDrillSizes Oct1217Document1 pageREFERENCE TapDrillSizes Oct1217Denis MartinNo ratings yet

- Features: Hand Crimp Tool Specification Sheet Order No. 63819-1300Document9 pagesFeatures: Hand Crimp Tool Specification Sheet Order No. 63819-1300Jose Antonio Huitron NuñezNo ratings yet

- ISO 9001 Certified Fastener Supplier Offers Wind Energy Hexagon NutsDocument1 pageISO 9001 Certified Fastener Supplier Offers Wind Energy Hexagon NutsANo ratings yet

- Hypress Ficha Tecnica Mang R1 PDFDocument1 pageHypress Ficha Tecnica Mang R1 PDFManuel ArangoNo ratings yet

- External Threads - Class 2A: Machine ScrewsDocument11 pagesExternal Threads - Class 2A: Machine ScrewsCraig SwensonNo ratings yet

- Bulong-Vit Ren AnhDocument103 pagesBulong-Vit Ren AnhtaoamanNo ratings yet

- Rosca Americana Fina Unf TecemDocument1 pageRosca Americana Fina Unf TecemPauloPaixãoNo ratings yet

- MU07 Rosca Americana Fina Unf Tecem PDFDocument1 pageMU07 Rosca Americana Fina Unf Tecem PDFmarcosNo ratings yet

- ELEKTRISOLA SbCuWire IEC Datasheet EngDocument1 pageELEKTRISOLA SbCuWire IEC Datasheet EngMarco PoloNo ratings yet

- Dimensione Tubos From TEMA - Standards - of - The - Tubular - Exchanger - Ed2019Document2 pagesDimensione Tubos From TEMA - Standards - of - The - Tubular - Exchanger - Ed2019María Pardo IbáñezNo ratings yet

- Chimney Design Code BS4076:1989 Plate Grades and LoadsDocument7 pagesChimney Design Code BS4076:1989 Plate Grades and LoadsRufus D SNo ratings yet

- Sr. No Parameter Damper Size Blade Size Frame Side Frame Top & Bottom Angle Width 40 MM Partition W 166 MMDocument1 pageSr. No Parameter Damper Size Blade Size Frame Side Frame Top & Bottom Angle Width 40 MM Partition W 166 MMsabir hussainNo ratings yet

- Machshop ManualDocument14 pagesMachshop ManualAnthony BoydNo ratings yet

- Dodge Oversize Twinsert HC943 Rev4Document12 pagesDodge Oversize Twinsert HC943 Rev4BarNo ratings yet

- Screw Bolt and NutDocument7 pagesScrew Bolt and NutsutarnoNo ratings yet

- asset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document42 pagesasset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Axel DominiqueNo ratings yet

- Technical Data Sheet Product CatalogueDocument16 pagesTechnical Data Sheet Product CatalogueKamalNo ratings yet

- Scew Thread IndexDocument3 pagesScew Thread IndexRyszardZNo ratings yet

- InputgDocument31 pagesInputgSilvio DiazNo ratings yet

- Moment Distribution MethodDocument101 pagesMoment Distribution MethodLourdesNo ratings yet

- Eye Bolt StandardsDocument5 pagesEye Bolt Standardsnilesh tadhaNo ratings yet

- Bang Tra Ren He Inch PDFDocument14 pagesBang Tra Ren He Inch PDFNg HiếuNo ratings yet

- 3.5 Core Cu ArmdDocument1 page3.5 Core Cu ArmdJitendra KumarNo ratings yet

- Trabajo de SismosDocument2,630 pagesTrabajo de SismosArturo SuarezNo ratings yet

- Internal Thread Dimensions For UNC Screw Thread 2016Document1 pageInternal Thread Dimensions For UNC Screw Thread 2016J. Fabián MenaNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Tabel Elektroda LasDocument162 pagesTabel Elektroda LasNaufal Dzaky M ANo ratings yet

- Erection Material List JGS320Document2 pagesErection Material List JGS320Rashid Mahmood JaatNo ratings yet

- MIME4530 MidTerm LastyearDocument4 pagesMIME4530 MidTerm LastyearRiasat AzimNo ratings yet

- Tds-Cpd-Sikalastic 601 BC-usDocument5 pagesTds-Cpd-Sikalastic 601 BC-usgamini pereraNo ratings yet

- NX Pit-Type Furnaces: The NX Turnkey Nitriding/Nitrocarburizing SystemDocument2 pagesNX Pit-Type Furnaces: The NX Turnkey Nitriding/Nitrocarburizing SystemBartek HajaNo ratings yet

- Analysis Sheet For Direct & Indirect Unit Costs: MakingDocument48 pagesAnalysis Sheet For Direct & Indirect Unit Costs: MakingBogale TemesgenNo ratings yet

- Acid Cleaning For Nickel Alloys Pages From Handbook of Engineering Practice of Materials and Corrosion by Jung-Chul (Thomas) EunDocument9 pagesAcid Cleaning For Nickel Alloys Pages From Handbook of Engineering Practice of Materials and Corrosion by Jung-Chul (Thomas) EunMohammad TaherNo ratings yet

- Toleranc e FitsDocument39 pagesToleranc e FitsIvan SilvaNo ratings yet

- Defect DefinitionsDocument2 pagesDefect DefinitionsVarro NinaNo ratings yet

- TDS SN Thickener 636Document2 pagesTDS SN Thickener 636Robert AditjiptoNo ratings yet

- 145 Pro-Grip Aluminium Systems: Installation GuideDocument10 pages145 Pro-Grip Aluminium Systems: Installation GuideGonzalo Agulló FernándezNo ratings yet

- Classification of Machine ToolsDocument8 pagesClassification of Machine ToolsMuhammad Qasim Jameel100% (1)

- Material Borrow From F&DDocument1 pageMaterial Borrow From F&DRizkiHusniNo ratings yet

- Methods of DryingDocument2 pagesMethods of Dryingvijay kumar honnaliNo ratings yet

- All Position E 6013 MSGP ElectrodesDocument2 pagesAll Position E 6013 MSGP ElectrodesNaveen ParthasarathyNo ratings yet

- 5 PDFDocument15 pages5 PDFRaju GummaNo ratings yet

- WB56S M.M.A. welding electrode specificationsDocument1 pageWB56S M.M.A. welding electrode specificationslathasri78No ratings yet

- Spotfast® Fasteners: Allows Permanent Joining in Metal To Metal and Metal To PCB/plastic PanelsDocument8 pagesSpotfast® Fasteners: Allows Permanent Joining in Metal To Metal and Metal To PCB/plastic Panelscthembree6No ratings yet

- H&R MFG CatalogDocument47 pagesH&R MFG Catalogssenn02No ratings yet

- Ke ProfileDocument4 pagesKe Profilekermech21607No ratings yet

- Stepping Stones For Early ReadersDocument13 pagesStepping Stones For Early ReadersRica Mae Lingat BruanNo ratings yet

- Aarti Plastic Industries Company OverviewDocument9 pagesAarti Plastic Industries Company Overviewagarwalsagar88No ratings yet

- Iso 10684Document26 pagesIso 10684Jay GaneshNo ratings yet