Professional Documents

Culture Documents

Commando Lab NABL Scope PDF

Commando Lab NABL Scope PDF

Uploaded by

fimozuk0 ratings0% found this document useful (0 votes)

78 views8 pagesOriginal Title

Commando lab NABL scope.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

78 views8 pagesCommando Lab NABL Scope PDF

Commando Lab NABL Scope PDF

Uploaded by

fimozukCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

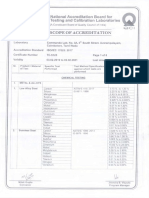

National Accreditation Board for

Testing and Calibration Laboratories

(A Constituent Board of Quality Council of India)

SCOPE OF ACCREDITATION

Laboratory Commando Lab, No. 3A, 5" South Street, Avarampalayam,

Coimbatore, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2017

Certificate Number TC-5123 Page 1 of 8

03.02.2019 to 02.02.2021 Last Amended on 15.02.2019

[Sl | Product / Material Specific Test ~~) Test Method Specification ~~ Range of Testing

| of T against which tests a | Limits of Detection

=.) perfonned __.

CHEMICAL TESTING

STM E 415: 2

Is 8811: 1998

Vanadium

Mitali Gupta Jitendra B. Vispute

Convenor Program Manager

National Accreditation Board for

Testing and Calibration Laboratories

(A Constituent Board of Quality Council of India)

SCOPE OF ACCREDITATION

Laboratory Commando Lab, No. 3A, 5" South Street, Avarampalayam,

Coimbatore, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2017

TC-5123, Page 2 of 8

03.02.2019 to 02.02.2021 Last Amended on 15.02.2019

Method Specification —] Range of Testing 7]

| Limits of Detection

2s

Phosp!

[Chromium

i

|. Aluminium &its |S

| Alloys Cc | Is 7658: 1975

- (RA 2005)

Is 11035-1984

. | Copper Bits = BS EN 15076: 2015

| Alloys

0.010 % 10 0.02%

J

Mitali Gupta Jitendra B. Vispute

Convenor Program Manager

Laboratory

Accreditation Standard

Certificate Number

Validity

3

- LofTest

| Product / Material | Specific Test

National Accreditation Board for

Testing and Calibration Laboratories

(A Constituent Board of Quality Council of India)

SCOPE OF ACCREDITATION

Commando Lab, No. 3A, 5" South Street, Avarampalayam,

Coimbatore, Tamil Nadu

ISONEC 17025: 2017

TC-5123,

03.02.2019 to 02.02.2021

Page 3 of 8

Last Amended on 15.02.2019

Test Method Specification | Rar

| against which tests are

performed

MECHANICAL TESTING

| Performed

| MECHANICAL PROPERTIES OF METALS” |

| Ferrous & Non

Ferrous alloys

Products

Ter ‘est at

Elevated temperature

(50°C to 600°C)

i

af

|

Steel

| Stainless Stee!

| Cast iron

| Yield Stress

Tensile Stress”

“Sof iongaton

| ISO 6892-2 : 2011

_| ASTME 21: 2017

IS 1608-Part 1. 2018

| ASTM A 370 - 2017

ASTM EB/E8M — 2016

| ISO 6892-1: 2016

IBR 1950

ASTM B 557M.2015

Ferrous & Non

| Ferrous alloys

| Products

| Steel,

Stainiess Steel,

| Copper,

| Aluminium

Welded Metal and

| Alloys

|

‘a

tall Gupta

Convenor

"Tensile Stress.

"| 1S 2825 — 1968 (RA 2012)

| ASME SEC IX : 2017

BS EN ISO 15614-1.2016

| 1S 7307-1:1974 (RA 2003)

HBR 1950

Jitendra B. Vispute

Program Manager

National Accreditation Board for

Testing and Calibration Laboratories

(A Constituent Board of Quality Council of india)

SCOPE OF ACCREDITATION

‘Commando Lab, No. 3A, 5” South Street, Avarampalayam,

Coimbatore, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2017

Certificate Number Te-5123 Page 4 of 8

Validity 03.02.2019 to 02.02.2024 Last Amended on 15.02.2019

I. | Product/ Material | Specific Test | Test Method Specification" Range of Testing!)

of Test Performed against which tests are _Limits of Detection

I | performed i Jj

Ail Weld Tensile Test

Proof Stress IS 7307-1:1974 (RA 2003)

__ IBR 1950 =

100 Nimm” to 1500

Nim

400 Nimim to 1800

| ae Nimm?

‘% Elongation 1 (5% é

= n Area rat epg | 2 1H10 80"

Ferrous & Non Fillet Weld test ASME SEC IX— 2077 | Qualitative

| Ferrous | | 1S 7307-1:1974 (RA 2008) —_ Applied load up to

Alloys | | BSENISO15614-1:2016 | 380kN

| Products: | IBR 1950 |

| Steel,

“Yield Stress

| Stainless Steel | Ten:

| Weld Specimen —— ae

Ferrous &Non | Transverse Root and | 1S_3600 (Pt. 5) - 1983 ~T Gualitative

Ferrous | Face Bend test | (RA 2010) |

Steel | ASME SEC Ix - 2017 (Mandrel dia: 12, 16,

| Stainless Steel | BS ENISO 15614-1:2016 | 20, 24, 32, 40, 48, &

Copper | IBR. 1950 | 64mm) 90°, 180° |

| Aluminium | bend i

| Applied oad upto |

Welded Metal and = ae 38 pits. |

| Alloys ‘Transverse Side Bend | ASME SEC IX- 2017 Qualitative

test [1S 3600 (Pt. 6)~ 1983 i

| (RA 2008) (Mandrel dia: 12, 16

IS 7307-1:1974(RA 2003) 20, 24, 32, 40, 48, 8

1S 2825 ~ 1969 (RA 2012) | 64mm) 90°, 4808 |

| BS EN ISO 18614-1:2016 | bend

| Applied load up to

AO

Convenor Program Manager

i

i

|

Laboratory

Accredit

Certificate Number

Validity

Si-] Product / Material |

of Test

ion Standard

National Accreditation Board for

Testing and Calibration Laboratories

(A Constituent Board of Quality Council of India)

SCOPE OF ACCREDITATION

Commando Lab, No. 3A, 5" South Street, Avarampalayam,

Coimbatore, Tamil Nadu

ISO/EC 17025: 2017

TC-5123

03.02.2019 to 02.02.2021

Page 5 of 8

Last Amended on 15.02.2019

Test Method Specification | Range of Testing |)

| against which tests are Limits of Detection

_| perfor

| Ferrous

Steel

Stainless Steel

"Fracture Test

| Stainless Steel,

Copper,

Aluminium |

Welded Metal and |

aes

1S" Ferrous

| Ferrous

Alloys

| Shear Test

| Helical Compression

| Springs

ii. | Ferrous & Non Fiatiening Test

Ferrous |

| Steel,

| Stainless Steel,

Copper. i

NOS

Mitali Gupta

‘Convenor

“(ea z000)

| ASTM A 370 - 2017

| BS EN ISO 15614-1:2016

| ASME SEC Ix - 2017

IBR 1950,

| BS EN ISO 15614-12016

IS 7307-1. 1974 (RA 2008)

| IS 8242-1979 (RA 2010)

TIS 7906 (Pt 7)

(RA 2009) Cl: 3.4:1975

|S 2328-2005 (RA 2011)

|

| (Mandrel dia: 12, 16,

20, 24, 32, 40, 48, &

| 64 mm) 90°, 180"

| bend

| Applied load up to

380KN

* Qualitaive

(Applied load

| upto 380KN)

| Qualitative

80N - 380KN

(Bush Dia: 5, 8, 12

| 16, 20mm)

| Qualitative

‘ON — 380 kN

~Y Qualitative

(Pipe OD : 10mm to

80.0 mm

Pipe Thickness

| 2mm to 10. mm

be

Jitendra B. Vispute

Program Manager

‘ Testing and Calibration Laboratories

tihaw (A Constituent Board of Quality Council of india)

SCOPE OF ACCREDITATION

Laboratory Commando Lab, No. 3A, 5" South Street, Avarampalayam,

Coimbatore, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2017

Certificate Number TC-5123, Page 6 of 8

Validity 03.02.2019 to 02.02.2021 Last Amended on 15.02.2019

[SU] Product 7 Material” | Specific Test | Test Method Specification] Range of Testing

| of Test Performed | against which tests are | Limits of Detection

[| Tube and Pipe |

12. | Ferrous @Non 7 Rockwell Hardness Test | 1S 1586 (Pt) 2012

| Ferrous Alloys | ASTM E18 - 2018

| Products Steel, | ASTM A 370 - 2017

Stainless Steel,

| Copper,

i

i

~~ Vickers Hardness Test

| Brinell Hardness Test rME 1100 to 450 HBW

5/750

| 'S 1500(Pt-1}-2013

|

| | 100 10450 HEW

' Charpy impact Test | 1S 1787-2014

| (25°C to -196 °C) | 1S 1499-1977 (RA 2015)

i BS EN ISO 15614-1:2016

Stainless Stee! | 180 148-1:2016

Copper - | ASME SEC x ~ 2017

| Aluminium ‘ASTM A 370: 2017 | ito 2805

| 7 | Ferrous ASTM E 381: 01 (2012) | (SB xto 55x

ie See C2 i Mageeicaboal

Titan Gupta itendra B. Vispute

‘Convenor Program Manager

Laboratory

Testing and Calibration Laboratories

(A Constituent Board of Quality Council of India)

SCOPE OF ACCREDITATION

Commando Lab, No. 3A, 5" South Street, Avarampalayam,

Coimbatore, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2017

Certificate Number

Validity

TC-5123 Page 7 of 8

03.02.2019 to 02.02.2021 Last Amended on 15.02.2019

'SI] Product /Material | Specific Test | Test Method Specification | Range of Testing/ |

| Performed against which tests are

“Stainless Steel

Copper

Aluminium,

| Ferrous

Steel

Stainless Steet

| Copper

| Aluminium

and §.G. Iron

18 7739:

1S 13045: 1991 (RA 2012)

| IS 11371: 1985 (RA 2007)

| IS 12573: 1988 (RA 2010)

| IS 3600 (Part 9): 1985 (RA

sr SO seme _

Miciosiructural Analysis 1S 7730: 1875 (RA 2010) | Gualiatve,

IS 7754: 1975 (RA 2012) | (40x, 10x, 200x,

| 1S 11959: 1987 (RA 2009) i 400x, 1000 x)

| 1S 3600 (Part 9): 1985 i

| (RA. 2008)

| ASM Metals Hand Book VoL

| ASTM ES: 11

" Rapareni Grain Size 7 aa 7 Qualitative

By automatic image | ASTM E112-13 | ASTM No 1 to 10

| analyzer method i | 100x)

| Comparison Method Se $b

Non Metallic ‘ASTM E45:2013 Qualitative

Ineusionby Automatic | ASTME 1245:09(2016) (Thin, Heavy or)

Image analyzer method Thick

| Type A, B,C, D)

| ASTM E 2667: 16a

| Determining Nodularity | ASM Metal Handbook

| & Nodule count by | Vol.9:2000,

[image analyzer method _| ASTM A 247: 2016

‘Micro Examination, 1SO0-946-Part 2: 2077 Qualitative

Graphite classification (60x, 100x, 200%,

by image analysis i 250x, 400%)

| Determination of Volume | ASTM E562: 2017 15% to 95 %

| Fraction of Phase _

Intergranular - corrosion | ASTM A 262 - 2015

Test !

Tai Gupta Jitendra B. Vispute

Convenor

Program Manager Sy

@& National Accreditation Board for

XO Testing and Calibration Laboratories

(A Constituent Board of Quality Council of india)

a

SCOPE OF ACCREDITATION

Laboratory Commando Lab, No. 3A, 5" South Street, Avarampalayam,

Coimbatore, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2017

Certificate Number TC-5123, Page 8 of 8

03.02.2019 to 02.02.2021 Last Amended on 15.02.2019

[Si] Product Material | Specific Test 1 Test Method Specification

| | of Test | Performed | against which tests are

|_performed

| Pract

| Ferrous alloys Pitting Corrosion Test | ASTM G 48: 2077 ~~~ [0.001 gto 220 ¢

| Stainless steel__ Method A

ry Wb

Mitali Gupta Jitendra 6. Vispute

Convenor

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 5446 CR Sheet Sample 3 PDFDocument1 page5446 CR Sheet Sample 3 PDFfimozukNo ratings yet

- 5445 CR Sheet Sample 2 PDFDocument1 page5445 CR Sheet Sample 2 PDFfimozukNo ratings yet

- Pages From 390385780 ASM Specialty Handbook Aluminum and Aluminum AlloysDocument1 pagePages From 390385780 ASM Specialty Handbook Aluminum and Aluminum AlloysfimozukNo ratings yet

- 5444 CR Sheet Sleeve PDFDocument1 page5444 CR Sheet Sleeve PDFfimozukNo ratings yet

- Commando Lab NABL ScopeDocument8 pagesCommando Lab NABL ScopefimozukNo ratings yet

- Bs 1610 11958 13571Document3 pagesBs 1610 11958 13571fimozukNo ratings yet