Professional Documents

Culture Documents

Preventive Maintenance Schedulre Zamil IOM PDF

Uploaded by

Mohamed Elarabi0 ratings0% found this document useful (0 votes)

9 views1 pageOriginal Title

Preventive maintenance Schedulre Zamil IOM.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pagePreventive Maintenance Schedulre Zamil IOM PDF

Uploaded by

Mohamed ElarabiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

ZAC-10040-MAN-0001.01_B

PREVENTIVE MAINTENANCE SCHEDULE

Page 105 of 232

FREQUENCY OF MAINTENANCE, MONTHS

ITEM

1 3 6 12

Clean air fiters & replace if required. x

Clean evaporator coll, drain pan & drain line. x

lean condenser coil x

Check blower belttension/wearicrack and replace it, if required. x

Lubricate blower motor/condenser motor (if applicable) x

Check alignment of pulleys. x

Cheekiclean electrical connections, controls & control box. x

Check motors, blower bearings & lubricate it. x

Checkal electrical control components, wing terminals ete. forspark, |x

Overheating & loose connections, Heplace/correct as necessary

Check all damper operation, Repairireplace as required x

Check insulation flanking, Repaititeplace as required, x

Check loose bolts/screws & tight as necessary. x

CCheck fr rustc/dentec/damaged body parts & repatrepint as necessary. x

‘Check mountings (pring slatornubber pads). Repairreplace as necessary x

Check flexible canvas connections & duct work. Repaireplace as required. x

Run test all motors and check the amperage, abnormality ete x

Fun teal compressors and check the amperage, noise, olTevel, pressure |

ef, and correct them accordingly

Check the thermostai/control devices for correct operation, callbratel x

re-adjust as required,

‘Apply corrosion inhibitor/contact cleaner as required x

‘Check al pressuresTieriperalures as applicable and salty the operation &

performance. x

NOTE: Always observe for abnormal noise or vibration,

MAINTENANCE TOOLS/EQUIPMENT REQUIRED

STANDARD : Screw drivers (Slot & Philips), adjustable wrenches, pliers, refrigeration wrenches & socket set wrenches,

pulley puller, etc,

SPECIAL — : Manifold gauge set, R-134a charging cylinder, belt tension checker, leak detector, vacuum pump with

electronic gauges, thermometer & hook type ammeterivoltmeter/ohmmeter.

a

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

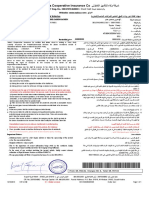

- InsuranceDocument1 pageInsuranceMohamed ElarabiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- رواية الحديقة السرية (إنجليزي - عربي) PDFDocument108 pagesرواية الحديقة السرية (إنجليزي - عربي) PDFMohamed ElarabiNo ratings yet

- كلام العقلاء PDFDocument6 pagesكلام العقلاء PDFMohamed ElarabiNo ratings yet

- Report RD 15 02 2019 22 29 30 PDFDocument1 pageReport RD 15 02 2019 22 29 30 PDFMohamed ElarabiNo ratings yet

- Medif PDFDocument4 pagesMedif PDFMohamed ElarabiNo ratings yet

- Ahmed Nashat Ahmed Khalil: Pipe FitterDocument5 pagesAhmed Nashat Ahmed Khalil: Pipe FitterMohamed ElarabiNo ratings yet

- Vav SVX08L en - 05132019Document72 pagesVav SVX08L en - 05132019Mohamed ElarabiNo ratings yet

- Ahmed Nashat Ahmed Khalil: Mechanical SupervisorDocument5 pagesAhmed Nashat Ahmed Khalil: Mechanical SupervisorMohamed ElarabiNo ratings yet

- عيادة الملحدين دكتور هيثم طلعتDocument299 pagesعيادة الملحدين دكتور هيثم طلعتBlâçk Ârmÿ100% (1)

- ىنابملا ةرادإ ماظن Building Management System: Course outlineDocument2 pagesىنابملا ةرادإ ماظن Building Management System: Course outlineMohamed ElarabiNo ratings yet