Professional Documents

Culture Documents

Stdcom ch3 PDF

Stdcom ch3 PDF

Uploaded by

K40 ratings0% found this document useful (0 votes)

18 views28 pagesOriginal Title

stdcom_ch3.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views28 pagesStdcom ch3 PDF

Stdcom ch3 PDF

Uploaded by

K4Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 28

STANDARD

PRECAST

STAIRCASES

STANDARD PRECAST STAIRCASES

CHAPTER 3

Highly skilled workers are required to construct staircases in-situ because the step configuration

of staircases could not be possibly made without skilled carpentry. The result is longer

construction duration,

Using precast etaircasee will shorten the construction duration. It aleo allowe operational access

instantly to all floor areas. When constructed as non-critical structural components, stairwells can be

Used as access for the delivery of construction materials.

3.1 Architectural Design Considerat

‘The proposed standard precast concrete staircase is designed for use in residential, commercial and

institutional developments. It is possible for an architect to specify standardised precast staircases

according to Architectural Reference Sheet STO, instead of detailing staircases, Once the floor to

floor height is determined, the architect would merely have to indicate the type of staircase

Components on the drawings and the contractor can then buy these components off the shelf from

the precaster, Using precast components would also eliminate the frequent construction errors in

riser height in in-situ construction.

Standard Prefebricated Building Components | 34

Bree eee

3.2. Structural Design Considerations

Precast stair slabs are usually designed to span longitudinally into the landings at right angles to the

stair fights or span between supporting beams. In monolithic construction, the stair slab can be

designed with continuous end restraints over the supports. But in instances where staircases are

precast, the construction is generally caried out after the main structure, wth pockets or recesses

left in the supporting slabs or beams to receive the stair fights. With no appreciable end restraints,

a precast star slab could therefore be designed as simple slab between supports.

In design, the dead load is calculated along the sloping lengths of the stairs but the live and finishing

loads are based on plan area. If the risers were to be covered with fishes, addtional loads would

have to be added in the design.

The effective span is measured horizontally between the centres of the supports or the actual

horizontal length of the precast stair stab where dry connections are used at the supports, The

thickness of the waist is taken as the slab thickness.

The basic span-effective depth ratio may be increased by 15% to 23 (=20 x 1.18) ifthe stair fight

‘occupies at least 60% of the span. This will apply to precast stair stabs without landings,

The supporting nibs of the precast stair slab may be constructed with elther dry or wet connections

(extended bearings). The design of reinforcement of the nibs can be based on:

+ Simple bending

+ Strut and tie force model

+ Shear tition

‘Theories and examples of the various design approaches can be obtained in the Structural Precast

Concrete Design Handbook by BCA. Small diameter rebars should be used at the nibs as a result

of the structural dimensions adopted.

32| standara Prefabricated Building Components

SUT

3.3. Standard Precast Staircase Dimensions

In practice, the number of risers and the riser height ofa staircase have always been dictated by the

storey height of a building. This would result in different riser dimensions. Prefabricating stair fights

with many different riser dimensions would not be economically viable,

Standard precast staircases for residential projects have already been developed by Housing and

Development Board (HDB) and the private sector The main difference between HDB housing and

private housing is the variation in floor to floor height. As most private developers prefer higher

headroom, the number of risers and the riser height would vary accordingly.

‘The Committee considered the design aspects related to the aesthetic, fabrication, handling and

erection of precast staircases and incorporated the following two distinet architectural features in the

standard precast concrete staircase:

+ Alignment of nosing of the frst fight ished with the nosing of adjacent fight.

+ Simple and lined through intersection at the sofft of staircases where the fights and

landings meet.

‘The Committee also proposed to limit the riser height to 165mm and 175mm, with a tread dimension

to 250mm. These dimensions are suitable for fire escapes. For school development projects, 150mm

riser with 300mm tread (instead of 250mm) are recommended dimensions required by the Ministry

Cf Education, for safety reasons.

Standard Prefabricated Building Componente [33

STANDARD PRECAST STAIRCASES.

‘The following sketches show the recommended staircase dimensions for private housing and

commercial developments.

TYPICAL SECTION AT STAIRCASE LANDING

Riser = 165mm, Tread = 250mm

|

on

|

TYPICAL SECTION AT STAIRCASE LANDING

Riser = 175mm, Tread = 250mm

3.4| stenaara Protanricated Bullaing Components

STANDARD PRECAST STAIRCASES

Architectural Reference Sheet STO1 provides the recommended riser flight combinations, which

ould be used as reference for designers to select the appropriate floor height dimensions, For

‘example in residential developments, @ designer could use staircases with 175mm riser for a floor to

floor height of 3,150mm, for fire escape. In luxury residential developments, staircases with a 165mm

riser would be appropriate for a floor to floor height of 3,300mm.

‘The recommended width of standard staircase is ideally sot to allow for a 1,000mm clearance

between handrails and edging kerb. In addition, it allows designers to include or exclude an edging

kerb (or buffer zone) of 75mm width to one side of the staircase. The provision is intended for the

fixing of balustrades, which could be welded to the base plate, cast in the welding pocket, or bolted

to the concrete surface by cast in socket.

Standard Prefabricated Building Components | 38

SUPE ee

3.4. Prefabrication and Labelling

Precast concrete staircases are cast on their sides or face down using precision-engineered stee!

mould and offformed finished with nosing groove lines. The quality of end product is therefore

assured. Dimensions such as the tread and riser should be fixed, to maximise the general usage of

standard moulds. The Committee encourages designers to adopt the recommended dimensions as

in Table 1, 2 and 3 of Reference Sheet STO1 in their designs

The Committee also recommends designers to make use of the dimensions and details presented

In the Architectural Reference Sheets, The labelling system for Stair Flight Type based on the

following system,

sto / 180

Is defined as:

ST = __ Standard Precast Stair Flight

10 = Number of Risers per Stair Flight

150 - _ Riser dimension (in mm)

3.5 Reference Sheets

346| stonaara Prefabricated Building Components

BZN na eee)

rehitectu erence Sheet: ST01

RECOMMENDED DIMENSIONS FOR STANDARD PRECAST STAIRCASE

Table | 150mm riser staircase.

Stair Flight Flight 2 Flight Floor to floor Height

Type (Riser Nos.) (mm)

sT10/150 10 3000

sTHriso u 3300

ST12/150 12 3600

Note: Standardised 300mm tread, recommended for school development projects.

Table 2. 165mm riser staircase.

1° Flight 20 Flight Floor to floor Height

(Riser Nos.) (Riser Nos.) (rm)

sT10/165 3300

Note: Standardised 250mm tread,

Table 3 175mm riser staircase.

4 Flight 2° Flight Floor to floor Height

(Riser Nos.) (Riser Nos.) (mm)

ST8/i175 2800

ST9ITS 3150

ST10/175 3500)

sTtt75 3850

sT12/175 4200

Note: Standardised 250mm tread,

aa

BOX OUT CONNECTION DETAIL

TYPE 1

BOX OUT CONNECTION DETAIL

TYPE2

Dry oints to be used where staircase

STANDARD PRECAST STAIRCASES

Architectural Reference Sheet: STO4

GENERAL NOTES FOR STANDARD PRECAST STAIRCASE

1. In practice, the number of risers and the riser height of a staircase have always been dictated by the

storey height of a bullding. This would result in different riser dimensions. Due to the cost of mould,

prefabricating stair flights with many different riser dimensions would not be economically viable,

2. The Committee recommends designers to limit the riser height to 165mm and 175mm. with a tread

dimension to 250mm. For school development projects, 150mm riser with 300mm tread (instead of

250mm) are recommended dimensions required by the Ministry of Education, for safety reasons.

3, The architectural features of the proposed precast staircase are:

+ Alignment of nosing of the first fight flushed with the nosing of adjacent flight

+ Simple and lined through intersection at the soffit of staircases where the flights and

landings meet

4, The proposed precast staircase would be suitable for fire escape. However it could be modified by

Qualified Person to suit the intended usage.

5. The recommended width of the standard staircase is ideally set to allow for 2 1,000mm clearance |

between handrails and edging kerb of 75mm to one side of the staircase for the fixing of balustrades.

|

Precast concrete staircases are cast on their sides or face down using precision-engineered steel |

mould and of-formed frished with nosing groove lines, |

340| standard Prefabricated Building Components

SIEMENS

Architectural Reference Sheet: STOS

STANDARD PRECAST STAIRCASE DETAILS (DRY JOINT)

TYPE: STIO/65

SECTION 8-8

Standard Pretebricated Building Components | 344

a2

BPP eee

Architectural Reference Sheet: STO6

STANDARD PRECAST STAIRCASE DETAILS (WET JOINT)

TYPE: STIO/I65

SECTION AA

DETAIL E

Standard Prefabricated Building Components

RUPE

Architectural Reference Sh:

HDB’S PRECAST STAIRCASE DETAILS

France

ee

eae Su

uw

fe

Standard Prefabricated Building Components | 343

BUTT

Structural Reference Sheet: STOS

GENERAL NOTES FOR STANDARD PRECAST STAIRCASE

(DRY AND WET JOINT)

ncret

1. Minimum grade of concrete in all reinforced concrete elements shall be C40, normal weight concrete,

2. Nominal cover to reinforcement shall be 25mm.

3. Surface finishes shall be off-form,

4. It shall have @ minimum fire rating af two hours.

Reinforcement

1. Allreinforcement shall conform to the latest BS4449 with a minimum yield stross:

+ T= Denotes 460 Nimm? high yield deformed bar, Type 2

+ R= Denotes 250N/mm? for mild steel bars

2. _Allstee! fabric shall conform to the latest BS4483 with a minimum yield stress of 485N/mme.

D nsideration:

1. Walls shall be designed in accordance with the provisions of 88110.

2. Precast stair fight was designed as simply support slab between landings.

3. When completed, stair fight shall be restrained by cast in-situ landing

Dry Joint Construction Sequence

A

Landings shall be cast in-situ before the placement of precast stair fights,

Leveling timber or steel section shall be used, to ensure flushed soffit when completed

When dry joint is to be adopted at seating nib, U-loops at landings and ends of stair fight shall be

bent and interlocked with each other after the placement of stair fight. Alternatively, interlocking

rebars could be inserted after the placement of stair fight on landings. (Reference Sheet ST02)

Nominal star fight / landing contact bearing shall be 78mm.

Wet Joint Construction Sequence

Landings shall be cast in-situ before the placement of precast stair lights

Levelling timber or steel section shall be used, to ensure flushed soffit when completed,

The cast in-situ strip will prevent water seeping through the joint, suitable for staircases subjected to

wetting and drying. (Architectural Reference Sheet S03)

‘Temporary props / levelling timber or stee! sections shall be used to ensure cast in-situ concrete infll

achieve the required strength during installation

Nominal stair fight / landing contact bearing shall be 75mm.

34| Standard Prefabvicated Building Components

Structural Reference

STANDARD PRECAST STAIRCASE REINFORCEMENT DETAILS (DRY JOINT)

TYPE: STIO/165

345

Standord Prefabricated Building Component

Fee ae ee

Structural Reference Sheet: ST10

STANDARD PRECAST STAIRCASE REINFORCEMENT DETAILS (WET JOINT)

TYPE: STIO/N65

DETAIL

FLIGHT PLAN

a46| standers Prefabricated Building Components

STANDARD PRECAST STAIRCAS

Structural Reference Sheet: ST11

HDB’S PRECAST STAIRCASE REINFORCEMENT DETAILS

ak SCHEDULE TRE

E be

3

i

i

ra Ae

le BS i

é i

€ EF

foo

| at

a

&

, Ht

ro

ouyam—ofhh u

Lit

‘Standera Prefabricated Building Components | 347

Brn ee ee

Structural Reference Sheet: ST12

(Sheet 1 of

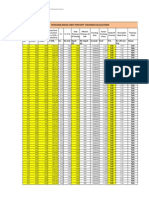

DESIGN TABLE - PRECAST STAIRCASE FLIGHT AND NIB

Live Load = 2.5kN/m? and 3.0kNim?

Main Reinforcement Main Reinforcement

88 88 88 Be

T1250 R6 @ 125 —] R6@ 100

B10 B12 B12, B12

sTiones - R6 @ 150

86 87 87 87

ST8/175 - - R6 @ 150 - - R6 @ 150

4 86 B6 S 86 86 g

Live Load | Live Load Nib Live Load] Live Load Nib

(2.5kNim?) | (2.5kNim?) | Reinforcement | (3.0kNim?)| (3.0kNim?) | Reinforcement

Finishes Finishes

iSie

ST14/150

Re @ 12% RE @ 125

@125 iO @

R6 @ 150

sT9n75 Ré @ 150 R6 @ 150

ei : Bu Br

sT10/175 Re @ 150 R6 @ 150

87 87 2 <

sTiin7s — = R6 @ 150 R6 @ 125

87 88 2 S

sTi2t7s RG @ 125 RE @ 125

ee B10 ¢

Note:

1 Design parameters: fou=40Nimm Cover=35mm

fy=4B5Nimmémesh; fy=460NImm?Fbars};_y-250NImm (mid ste!)

2 Finishes are taken as 1.2kNin?

a [78a] — Denotes Top reinforcement using B9 mesh

B10] - Denotes Bottom reinforcement using 810 mesh

4 The proposed standard recast concrete staicase s designed for eacetime use. Nevertheless, where there is

nly ene siacase leading to household shelters the Professional Engineer or Qualifod Person would have to

‘ary out e detailed design in complance with Givi Defence requirements,

310) standard Pretabriceted Building Components

Type | Live Load] Live Load Nib Live Load] Live Load

(4.0kN/m?) | (4.0kNim?) | Reinforcement | (5.0kNim?)| (5.0kN/m?)

+ +

Finishes Finishes

SUPP

al Reference

of 2)

DESIGN TABLE - PRECAST STAIRCASE FLIGHT AND NIB

Live Load = 4.0kN/m? and 5.0kNim*

Main Reinforcement Main Reinforcement

sT10/150 - RO @ 150 R6 @ 100

BS 57,

sT11/180 R6 @ 100 R6 @ 100

B12 B12

BB BB

sT12/150 R6 @ 100 Bi2+ B12+ R6 @ 100

Ti0@200 | T10@100

sT10/165 RG @ 125 RE @ 125

ST8i75 R6 @ 150 R6 @ 150

STOITS RG @ 150 R6 @ 125

sT10/175 R6 @ 125, R6@ 125,

STHI/I75 RG @ 125 R6 @ 100

sT12/175 R6 @ 100 R6 @ 100

Design parameters: fou=40Nimm?; Cover=35mm

‘ye485Nimm%(mesh): fy=460Nimm2(T-bars); _fy=2S0Nimm?(mid steel)

Finishes are taken as 1.2kNim?

89 = Denotes Top reinforcement using 89 mesh

B10] - Denotes Bottom reinforcement using B10 mesh

‘The proposed standard precast concrete staircase is designed for peacetime use. Nevertheless, where thers is

only one staircase leading to household shelters, the Professional Engineer or Qualified Person would have to

carry out a detailed design in compliance with Chil Defence requirements,

4 Building Components | 349

Bg eee

Structural Reference Sheet: ST13

DESIGN EXAMPLE = - — PRECAST STAIRCASE ST 10/165

|

ee

ign Dats

Material

Conerete feu = 40Nimm?

Welded Mesh fy = 485Nimmt

Mild Steel fy = —.250NImm?

Cover to reinforcement = 25mm

Fire Rating = 2hours

Loading

Design Live Load = 4.0kNim?

320

nderd Pretebricated Building Components

STANDARD PRECAST STAIRCASES

Consider per metre width of staircase

Slope length of stair

Weight of waist plus steps

Live Load

Ultimate Load, F

Structural Reference Sheet: ST13

VF 2B

3.415m

(0.183 x 3.415 + 0.275 x 0.165 x 10+2) x 24

18.00kNimn

4.0 x2.99

= 11.96KNm

= 14x 1800+ 16x 11.96

= 44.36kNim

Bending Reinforcement

‘Assuming no effective restraint at support.

Ultimate 8M at mid-span

M

Effective depth,

Use d

zd

Use 2d

Therefore z

As

Use welded mesh type 87

Fxt

=e

44.34 x 2.99

8

= 16.57kNmim

163-25 -10+2

123mm

120mm

0.5 + V(O25-M= (Waa)

0.5 + V(0.25- (1857 x 10" = (09 x 1000 x 120" x 40)

0.987

0.95

114mm

M

O85 xtyxz

16.57 x 10°

005 x 485 x 114

315mmeim

(Main reinforcement 7mm dia. @100mm cic, secondary reinforcement 7mm dia. @ 200mm clo)

Therefore, provided As

385mmeim

Standard Prefabricated Building Components | 224

GN eee

Structural Reference Sheet: ST13

M_ = 1657 x 10°

ba 1000 x 1202

= 115

2 xtyx As ras

ia: AS Prov

= 2 x 486 x 315

3 385

= 265Nimm?

Tension modification factor, ® = 0.55 + _(477- fy)

720(09+ M_)

bx@

= 085 + (477-265)

720 (09+ 1.16)

= tat

Clause 3.10.22, Part 1, BS8110 (1997), basic span / depth ratio of staircase fight

= 20x1.15

= 23

Minimum effective depth, d L

‘® x Span/Depth Ratio

= 2990

441x23

= 92mm < 120mm ‘Therefore, OK

3.22| stonsard Pretabricated Building Components

90

STANDARD PRECAST STAIRCASES

Structural Reference Sheet: ST13

Pe

52, 30

Reaction at supporting nibs,

Bending Moment,

(At Section x)

Effective depth,

Therefore,

Use mild steel,

Use R6 @ 150mm cle,

2H

zd

As

lel

44.34x 0.8

22.47KNIm

90 +30

120mm

Vxa,

22.17 x 0.120

2.66kNmim

‘85mm - 25mm - §mm

65mm

0.5 + \(O25-M= OabeTeu))

0.5 + V(O25- 266 x 10" (0.9 x 1000 x 65" x 40)

0.98 (<2id = 0.95)

61.8mm

M

O95 xfyxz

2.66 x 10°

0.95 x 250 x 61.8

481mm%im

188mm*im

Standard Prefabricated Building Compononts | 323

Bere

Structural Re

nce Sheet: ST13,

Check Anchorage

Fy 0.95 fy As

0.95 x 250 x 28 x 10°

6.65kN

Minimum bending radius, r= Fy X

a

Where = 6mm

a 450mm

fou 40NImm?

Therefore r BB 85x108 x 1 + 2(6+150)

6 2x40

2 149mm

2 250

Provide ' 2750 > 250 Therefore, OK

Check Hang-up Reinforcement

Heng-up reinforcement, a v

095%

22.17 «102

0.95 x 250

83mmeim

For practical reason, provide at every R6 nib reinforcement a looped R6 as hanger steel, as below.

Bending baronet

Hanger ete!

3:24 | stangara Protan)

sated Building Components

SUELO

Structural Reference Sheet: ST13

25

400,

a

TYPICAL REINFORCEMENT DETAILS AT UPPER FLIGHT

TYPICAL REINFORCEMENT DETAILS AT LOWER FLIGHT

Standard Peefabricated Building Components | 325

Berrie

Structural Reference Sheet: $713

Check Shear

Shear force, Vis 22.47KNIm

vez 22.17 x 108

1000 x 65

0.34Nimm?

188 x 100%

00 x 65

= 029%

0,79 (4) (4001e) *(fur25)"2

%m

1.25

0.79 (0.2)"° (400/65) (40/25)"*

“ar Pad 1 a hae ee

= O77Nimm? — > 0.34Nimm?

3:26| stangara Prefabricated Building Components

Therefore, OK

STANDARD PRECAST STAIRCASES

Structural Reference Sheet: ST13

‘eran

PLAN

SECTION 2-2

‘Standard Prefabricated Building Components

327

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- A Displacement-Based Analysis and Design Procedure For Structural WallsDocument8 pagesA Displacement-Based Analysis and Design Procedure For Structural WallsmanpreetkhanujaNo ratings yet

- 1405 - 12 Light Cross Section Elematic Hollow Core PlankDocument1 page1405 - 12 Light Cross Section Elematic Hollow Core PlankmanpreetkhanujaNo ratings yet

- 1505 - 16 Elematic Cross Section Elematic Hollow Core PlankDocument1 page1505 - 16 Elematic Cross Section Elematic Hollow Core PlankmanpreetkhanujaNo ratings yet

- Raft Area Calculations: Tower NoDocument1 pageRaft Area Calculations: Tower NomanpreetkhanujaNo ratings yet

- Raft ThicknessDocument6 pagesRaft ThicknessmanpreetkhanujaNo ratings yet

- Chapter 8Document10 pagesChapter 8manpreetkhanujaNo ratings yet

- Seismic Behavior and Design of Composite Steel Plate Shear Walls PDFDocument73 pagesSeismic Behavior and Design of Composite Steel Plate Shear Walls PDFmanpreetkhanujaNo ratings yet