Professional Documents

Culture Documents

Document 2 NCZR 15022016

Document 2 NCZR 15022016

Uploaded by

Sergio RayasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Document 2 NCZR 15022016

Document 2 NCZR 15022016

Uploaded by

Sergio RayasCopyright:

Available Formats

ISSN (ONLINE): 2454-9762

ISSN (PRINT): 2454-9762

Available online at www.ijarmate.com

International Journal of Advanced Research in Management, Architecture, Technology and

Engineering (IJARMATE)

Vol. 2, Issue 2, February 2016

Escalator Speed Control

Roshan Varghese Rajan1, Ganesh. H2, Sumith Mathai3, Faizal.S4, Aby Thomas Baby5

UG student, PSN College of Engineering & Technology, Tirunelveli, India 1,2,3,4,5

roshanmelel@gmail.com

Abstract—Escalator speed control is a smart mechanical Many people, especially the children and old finds it difficult

arrangement which facilitates the entry and exit from an

to manage the sudden speed difference occurred when they

escalator more stable and easy. The current scenario only

step from the floor to the escalator or vice versa. Many

promotes the young and physically healthy persons to use the

technology to full extend. Here arises the need for a better

inexperienced and physically week are not able to make

escalator design which facilitates the travel of every people themselves comfort with the sudden speed change. But for

possible. Traditionally the escalator moves at a constant speed this we cannot decrease the speed of the escalator to that level

from the entrance to the exit. Many people, especially the because it will eventually slow down the total speed of the

children and old finds it difficult to manage the sudden speed system which is not likely to happen. Because the time cannot

difference occurred during the entry and exit of an escalator. be made sacrificed in this fast moving world. Here arose the

Frequent accidents occur in this way in the traditional escalators need of engineering to provide better safety and comfort to the

which makes restrictions to the travel of the children and old

people who use the escalator. So we aim at decreasing the

people. The “Escalator Speed Control” is a mechanical

relative speed so that it is easy to enter and exit, to and from an

arrangement which allows the entrance or exit, to or from an

escalator more balanced. A new layer of chain drive is made escalator.

installed which moves in only at half the speed of the remaining

escalator. This facilitates the gradual speed rise there by As a result of studies and research made in the present

eliminating the chance of accidents. situation a remedial solution to exit this problem, the design

of “Escalator Speed Control” was made. Escalator speed

Index Terms—Chain Drive, Escalator, Gear Box, Speed control is a mechanical arrangement which facilitates the

Reduction

entry and exit from an escalator more stable and easy by

I. INTRODUCTION decreasing the relative speed of entry or exit.

Escalator is a locomotive device which is mainly installed

A new layer of chin drive is installed in the top and bottom of

in public places like airport, railway stations, shopping mall

the escalator. The power possessed for chain drive movement

and other commercial buildings. It facilitates the to and fro

is from the end shaft of the escalator itself. So we need no

movement of people and goods from one floor to another.

additional motor or power source to drive the new technique

Escalator is a mechanical device which continuously moves at

that is installed. The chain drive moves only in the half speed

a constant speed. People find it difficult to enter and exit an

of the main escalator, which make the relative speed of the

escalator due to the variation of speed when stepping in and

escalator decrease and making it safer and comfortable.

moving out. The sudden change from rest to motion occurs

Frequent accidents occur in this way in the traditional

when we enter or exit an escalator, as an effect of Inertia. The

escalators could be thus eliminated by the arrival of this new

current situations only promote the young and physically

technique which takes away the restrictions to the travel of the

healthy persons to use the technology to full extend.

children and old people.

Nearer to many of the escalators we could find the warning

The “Escalator Speed Control” is a mechanical arrangement

boards which warn us for being extra conceit. Many

which allows the gradual speed rise there by eliminating the

escalators prohibit its usage by the children and the old age

chance of accidents. So for a safer and comfortable escalator

without guidance. Here arises the need for a better escalator

travel it is advised to install this new and innovative

design which facilitates the travel of every people possible.

mechanical arrangement in every part of the world. Let’s

Traditionally the escalator moves at a constant speed from the

move to new highs more safely and comfortably by using the

entrance to the exit.

“Escalator Speed Control”.

All Rights Reserved © 2016 IJARMATE 25

ISSN (ONLINE): 2454-9762

ISSN (PRINT): 2454-9762

Available online at www.ijarmate.com

International Journal of Advanced Research in Management, Architecture, Technology and

Engineering (IJARMATE)

Vol. 2, Issue 2, February 2016

II. STUDY OF SUBJECT perpendicular shafts, adjusting the rotation angle by 90

POWER TRANSMISSION THROUGH GEAR degrees.

Power transmission is the movement of energy from its Herringbone gears:

place of generation to a location where it is applied to

performing useful work. Power transmission is normally To avoid axial thrust, two helical gears of opposite hand

accomplished by belts, ropes, chains, gears, couplings and can be mounted side by side, to cancel resulting thrust forces.

friction clutches. A toothed wheel that engages another These are called double helical or herringbone gears

toothed mechanism in order to change the speed or direction

Rack and pinion

of transmitted motion.

Rack and pinion gears are used to convert rotation (From

the pinion) into linear motion (of the rack). A perfect example

A gear is a component within a transmission device that

of this is the steering system on many cars. The steering wheel

transmits rotational force to another gear or device. A gear is

rotates a gear which engages the rack. As the gear turns, it

different from a pulley in that a gear is a round wheel which

slides the rack either to the right or left, depending on which

has linkages ("teeth" or "cogs") that mesh with other gear

way you turn the wheel. Rack and pinion gears are also used in

teeth, allowing force to be fully transferred without slippage.

some scales to turn the dial that displays your weight.

Depending on their construction and arrangement, geared

devices can transmit forces at different speeds, torques, or in a GEARS FOR CONNECTING INTERSECTING SHAFTS

different direction, from the power source

GEAR CLASSIFICATION 1. Straight Bevel Gear

Gears or toothed wheels may be classified as follows:

1. According to the position of axes of the shafts. Bevel gears are useful when the direction of a shaft's

The axes of the two shafts between which the motion is to be rotation needs to be changed. They are usually mounted on

transmitted, may be shafts that are 90 degrees apart, but can be designed to work at

a. Parallel other angles as well. The teeth on bevel gears can be straight,

b. Intersecting spiral or hypoid. Straight bevel gear teeth actually have the

c. Non-intersecting and Non-parallel same problem as straight spur gear teeth as each tooth

engages; it impacts the corresponding tooth all at once.

GEARS FOR CONNECTING PARALLEL SHAFTS Just like with spur gears, the solution to this problem is to

Spur Gear curve the gear teeth. These spiral teeth engage just like helical

Teeth is parallel to axis of rotation can transmit power teeth: the contact starts at one end of the gear and

from one shaft to another parallel shaft. Spur gears are the progressively spreads across the whole tooth.

simplest and most common type of gear. Their general form is On straight and spiral bevel gears, the shafts must be

a cylinder or disk. The teeth project radically, and with these perpendicular to each other, but they must also be in the same

"straight-cut gears". Spur gears are gears in the same plane plane. If you were to extend the two shafts past the gears, they

that move opposite of each other because they are meshed would intersect. The bevel gear has many diverse applications

together. Gear ‘A’ is called the ‘driver’ because this is turned such as locomotives, marine applications, automobiles,

by a motor. As gear ‘A’ turns it meshes with gear ‘B’ and it printing presses, cooling towers, power plants, steel plants,

begins to turn as well. Gear ‘B’ is called the ‘driven’ gear. railway track inspection machines, etc.

Parallel Helical Gear NON-INTERSECTING AND NON-PARALLEL

The teeth on helical gears are cut at an angle to the face of

the gear. When two teeth on a helical gear system engage, the 1. WORM AND WORM GEAR

contact starts at one end of the tooth and gradually spreads as

the gears rotate, until the two teeth are in full engagement. Worm gears are used when large gear reductions are

needed. It is common for worm gears to have reductions of

This gradual engagement makes helical gears operate much 20:1, and even up to 300:1 or greater.

more smoothly and quietly than spur gears. For this reason,

helical gears are used in almost all car transmissions. Because

of the angle of the teeth on helical gears, they create a thrust Many worm gears have an interesting property that no

load on the gear when they mesh. Devices that use helical other gear set has: the worm can easily turn the gear, but the

gears have bearings that can support this thrust load. gear cannot turn the worm. This is because the angle on the

worm is so shallow that when the gear tries to spin it, the

One interesting thing about helical gears is that if the angles friction between the gear and the worm holds the worm in

of the gear teeth are correct, they can be mounted on place.

All Rights Reserved © 2016 IJARMATE 26

ISSN (ONLINE): 2454-9762

ISSN (PRINT): 2454-9762

Available online at www.ijarmate.com

International Journal of Advanced Research in Management, Architecture, Technology and

Engineering (IJARMATE)

Vol. 2, Issue 2, February 2016

III. PROPOSED METHODOLOGY

PRINCIPLE USED Speed

Speed reduction occurs when a gear with lesser teethed When the escalator moves at a defined rate of speed, only

gear is meshed with a gear with more gear teethes. In this, a the half speed is achieved by the top and bottom chain drives

simple mechanical gear arrangement is been made to facilitate which are connected to them.

the speed reduction. Whenever two gears are meshed together

the rotation will be always in the opposite direction. So to Relationship

make similar direction movement possible an idle gear is Revolutions in gear α Speed of escalator

made installed. Or we can conclude that an equal change in revolution of

The speed of the drive is made exactly half in the top and gear result in an equal change in speed of escalator

bottom chain drives in order to co-match the revolutions

made. WORKING PROCEDURE

Consider a person stepping on to the relatively slow

GEAR BOX moving chain drive. Since having only half the actual speed of

The Escalator Speed Control is the mechanical the escalator in the chain drives makes the person more

arrangement which consist of mainly three drives namely a comfortable and allows him to maintain in an equilibrium

driver gear, an idler gear and driven gear. This arrangement is position.

made after the following Conditions. As the chain drive moves and reaches the main escalator

Condition 01 - The driven gear of the Escalator Speed the person is made to make his second step to the fast moving

Control System is the extension made in the shaft of the main escalator. But it is note able that even though stepping to a fast

escalator. This facilitates in the single motor usage in the moving escalator makes no discomfort to the person since the

whole system. relative speed of the chain drive and the real escalator is

Condition 02 - An Idler is to be installed in between the two comparatively low by the new and innovative technique

gears namely, the driver and driven gear. This facilitates the namely the “Escalator Speed Control”.

rotation of the driver and the driven gear in the same The person experiences a more stable movement in

direction. between the drives. This eliminates the chance of accidents

Condition 03 - The Driven gear is to be designed in such a and this makes them more user friendly to all age categories.

way that the number of gear tooth’s present driven gear should

be double to the number of tooth’s that are present in the

driver gear. These make sure that the speed is made half

between the chain drive and the escalator.

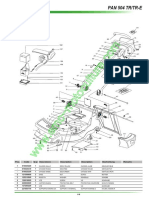

FIG-02

The above shown is a diagrammatic representation of the

“Escalator Speed Control”. A new layer of chin drive is

installed in the top and bottom of the escalator namely, the top

FIG-01 chain and bottom chain. The power possessed for chain drive

movement is from the end shaft of the escalator itself.

COMPARISION OF PROPERTIES The driven gear of the Escalator Speed Control System is

The following are the comparative studies made by the extension made in the shaft of the main escalator. So we

comparing the traditional escalator system and the proposed need no additional motor or power source to drive the new

system of “Escalator Speed Control”. Different properties are technique that is installed. When a complete revolution is

considered and studied. been made by the driver gear, only a half revolution is made

by the additional gear inside the gear box, which make the

Revolutions relative speed of the escalator decrease and making it safer

When a complete revolution is been made by the driver and comfortable. Frequent accidents occur in traditional

gear, only a half revolution is made by the concerned gear escalators is eliminated by this new. The working is simple

inside the gear box. and cost of installation is also affordable.

All Rights Reserved © 2016 IJARMATE 27

ISSN (ONLINE): 2454-9762

ISSN (PRINT): 2454-9762

Available online at www.ijarmate.com

International Journal of Advanced Research in Management, Architecture, Technology and

Engineering (IJARMATE)

Vol. 2, Issue 2, February 2016

I. CONCLUSION

[3] Cangialosi, Paul (2001). "TechZone Article: Wide and Close Gear

The “Escalator Speed Control” is a mechanical Ratios". 5speeds.com. Medatronics. Retrieved 28 October 2012

arrangement which allows the gradual speed rise there by

Authors Profile

eliminating the chance of accidents. So for a safer and

comfortable escalator travel it is advisable to install this new Roshan Varghese Rajan (First Author) is pursuing

and innovative mechanical arrangement in every part of the his Bachelor of Engineering degree in Mechanical

world. This ensures the safety to every person using it. Engineering from PSN College of Engineering and

Technology, Tirunelveli, India. His aim is to involve in

Research and to become an Inventor. His areas of

REFERENCES interest are Engineering Mechanics, Kinematics and

[1] Uicker, J. J.; G. R. Pennock; J. E. Shigley (2003). Theory of Machines Dynamics.

and Mechanisms. New York: Oxford University Press.

[2] Paul, B. (1979). Kinematics and Dynamics of Planar Machinery.

Pretice Hall.

All Rights Reserved © 2016 IJARMATE 28

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rexroth Hexagon Socket Head Cap Screws Metric - UNCDocument12 pagesRexroth Hexagon Socket Head Cap Screws Metric - UNCSympatyagaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- D815 Technical SectionDocument233 pagesD815 Technical SectionRZW RNo ratings yet

- Maryland Metrics - Thread Data ChartsDocument4 pagesMaryland Metrics - Thread Data ChartsAnonymous VC68Xndnu9No ratings yet

- Mesin Perkakas FraisDocument69 pagesMesin Perkakas FraisFauzi AkbarNo ratings yet

- Bombas Tuthill MolinoDocument31 pagesBombas Tuthill MolinoMilca Palacin50% (2)

- Pan504tr Pan504tre 2006Document8 pagesPan504tr Pan504tre 2006Yves FabregatNo ratings yet

- MF 240Document2 pagesMF 240RizwanAli100% (1)

- ISO 7040 2012 (Tuercas Hexagonales Normales Autofrenadas (Con Anillo No Metálico) - Clases de Alidad 5, 8 y 10)Document10 pagesISO 7040 2012 (Tuercas Hexagonales Normales Autofrenadas (Con Anillo No Metálico) - Clases de Alidad 5, 8 y 10)otNo ratings yet

- 060320Document3 pages060320ORPNo ratings yet

- External ISO Metric Trapezoidal Screw Threads Table Chart Sizes TR8 - TR315 - Engineers EdgeDocument8 pagesExternal ISO Metric Trapezoidal Screw Threads Table Chart Sizes TR8 - TR315 - Engineers EdgeDiaconu Vlad CatalinNo ratings yet

- Iso3408 4 2006 - Standard5105 BallscrewDocument26 pagesIso3408 4 2006 - Standard5105 BallscrewsomenameNo ratings yet

- Somta Drill Sizes For Tapping PDFDocument1 pageSomta Drill Sizes For Tapping PDFabhinishane100% (1)

- OCS-B1510-SP Book-V1.2-601-17274Document105 pagesOCS-B1510-SP Book-V1.2-601-17274Rodolfo Barrón LópezNo ratings yet

- Dial Indicators: SERIES 3 - Large Dial Face and Long StrokeDocument2 pagesDial Indicators: SERIES 3 - Large Dial Face and Long StrokeAkmalNo ratings yet

- Landon Stradcutter - 1 - 1 - 5 - A - GearsPulleyDrivesSprocketsPracticeProblemsDocument4 pagesLandon Stradcutter - 1 - 1 - 5 - A - GearsPulleyDrivesSprocketsPracticeProblemsLandon StradcutterNo ratings yet

- Introduction To GearsDocument16 pagesIntroduction To GearsCA RVNo ratings yet

- M Etric Threads: Max L Product InternaDocument2 pagesM Etric Threads: Max L Product InternajimboNo ratings yet

- BME-020 B-3 (Unit 10)Document19 pagesBME-020 B-3 (Unit 10)Raghavendra Nallan ChakravarthulaNo ratings yet

- Maryland Metrics - Thread Data ChartsDocument3 pagesMaryland Metrics - Thread Data ChartsSachin JawaleNo ratings yet

- 4 Science Pulleys Gears Gear Quiz AnswersDocument2 pages4 Science Pulleys Gears Gear Quiz Answersstephendix50% (2)

- LK-1910 LK-1920: Parts ListDocument42 pagesLK-1910 LK-1920: Parts ListJos BlowNo ratings yet

- PowerCoil Inserts Metric Inch SpecsDocument3 pagesPowerCoil Inserts Metric Inch SpecsAce Industrial SuppliesNo ratings yet

- Chennai Institute of Technolohy, Chennai - 600 069: Department of Mechanical EngineeringDocument8 pagesChennai Institute of Technolohy, Chennai - 600 069: Department of Mechanical EngineeringKishore RaviNo ratings yet

- System Plast FHGHBHBCDocument1 pageSystem Plast FHGHBHBCgetaNo ratings yet

- Numeros de Parte Cuchillas BobcatDocument2 pagesNumeros de Parte Cuchillas BobcatwalterNo ratings yet

- Section FDocument42 pagesSection FcblairNo ratings yet

- Friction ScrewsDocument51 pagesFriction ScrewsMewnEProwt100% (1)

- Hs Bolt SpecificationDocument6 pagesHs Bolt SpecificationncristiNo ratings yet

- Copia de Catalogo Transmision de PropelDocument2 pagesCopia de Catalogo Transmision de PropelFrancisco Javier González LópezNo ratings yet

- Bolens G12Document16 pagesBolens G12Samantha ChapmanNo ratings yet