Professional Documents

Culture Documents

Seminar Journal PDF

Seminar Journal PDF

Uploaded by

Vimal SudhakaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seminar Journal PDF

Seminar Journal PDF

Uploaded by

Vimal SudhakaranCopyright:

Available Formats

doi:10.3926/jiem.2010.v3n2.

p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

Product lifecycle management through innovative and

competitive business environment

Valentina Gecevska1, Paolo Chiabert2, Zoran Anisic3, Franco Lombardi2, Franc Cus4

1

University Ss. Cyril and Methodius (MACEDONIA); 2Technical University of Turin (ITALY);

3

University of Novi Sad (SERBIA); 4University of Maribor (SLOVENIA)

valeg@mf.edu.mk; paolo.chiabert@polito.it; anisic@uns.ns.ac.rs; franc.cus@uni-mb.si

Received February 2010

Accepted October 2010

Abstract: Product Lifecycle Management (PLM) is the process of managing the whole life

cycle of a product starting from generating an idea, concept description, business analyzes,

product design and solution architecture and technical implementation, to the successful

entrance to the market, service, maintenance and product improvement. At present, a wide

range of stakeholders including consumers, regulators, shareholders and public bodies are

demanding that companies address product management through all life cycle in a more

comprehensive and sustainable way. However, even if a company actually wishes innovate

its processes for improving the way to account for project management, it will face relevant

difficulties to deal with different guidelines, tools and methods currently addressing the

matter from various points of view. The purpose of this paper is to review literature on

PLM from an operational point of view with the objective to help companies to answer to

the main market needs.

Keywords: product lifecycle management, business process, competitiveness

1 Introduction

In today’s demanding global economy, product success depends on company’s

ability to beat the competitors to market with products that capture customers’

imagination with stylish yet appropriately functional content that performs as

Product lifecycle management through innovative and competitive business environment 323

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

required while being delivered at a price the market is willing to pay. In other

words, the products must be able to satisfy customer requirements for:

• Timing, Function, Performance, Style, and Price.

Since these variables frequently change during the course of a product lifecycle,

the innovation process must be able to account for change and easily

accommodate its demands on a systematic and repeatable basis.

Delivering the right product to market is only half the battle that today’s product

makers’ face. Best-in-class companies employ lean manufacturing and design for-

manufacturing initiatives to optimize the product lifecycle’s downstream processes

(Pol et al., 2008; Saaksvuori & Immonen, 2008; Grieves, 2009). The goal here is

to enable product development teams and manufacturing teams to work together

as early in the product lifecycle as possible to: minimizing production cost,

improving product quality, delivering more reliable products, providing easier to

service products, driving “green” initiatives that facilitate a sustainable

environment.

Product Lifecycle Management (PLM) enables the kind of convergence that

Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM)

prompted in the past. In the early 90s, ERP unified finance, HR, manufacturing and

warehouse systems. A decade later, CRM brought call centre and sales force

automation together. Now, Computer-Aided Design (CAD), Computer-Aided

Manufacturing (CAM), Product Data Management (PDM) and manufacturing process

are converging through PLM. Yet PLM is unique from other enterprise software

solutions because it focuses on driving top-line revenue from repeatable processes.

Through PLM, the products are a path to innovation, industry leadership, and top-

line growth (Saaksvuori & Immonen, 2008; Grieves, 2009; Bernard & Tichkiewitch,

2008; Stark, 2004).

2 Product lifecycle management approach

Product Lifecycle Management (PLM) is generally defined as a strategic business

approach for the effective management and use of corporate intellectual capital.

Today, challenges faced by product development teams include globalisation,

outsourcing, mass customisation, fast innovation and product traceability. These

Product lifecycle management through innovative and competitive business environment 324

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

challenges enhance the need for collaborating environments and knowledge

management along the product lifecycle stages. PLM systems are gaining

acceptance for managing all information about the corporation’s products

throughout their full lifecycle, from conceptualisation to operations and disposal.

The PLM philosophy and systems aim at providing support to an even broader

range of engineering and business activities (Pol et al., 2008; Stark, 2004).

PLM is a strategic business approach that applies a consistent set of business

solutions in support of the collaborative creation, management, dissemination and

use of product definition information across the extended enterprise from concept

to end of life – integrating people, processes, business systems and information.

PLM is an integrated, information-driven strategy that speeds the innovation and

launch of successful products, built on a common platform that serves as a single

repository of all product-related knowledge, data, and processes. PLM is the

process of managing the whole life cycle of a product starting from generating an

idea, concept description, business analyzes, product design and solution

architecture, technical implementation and product testing, to the successful

entrance to the market, service, maintenance and product improvement. PLM

gathered and make accessible data and information of all stages of this process.

As a business strategy (Pol et al., 2008; Saaksvuori & Immonen, 2008; Grieves,

2009; Bernard & Tichkiewitch, 2008), PLM lets distributed organizations innovate,

produce, develop, support, and retire products, as they were if they were a single

entity. It captures best practices and lessons learned, creating a storehouse of

valuable intellectual capital for systematic and repeatable re-use.

As an information technology strategy, PLM establishes a coherent data structure

that enables real-time collaboration and data sharing among geographically

distributed teams. PLM lets companies consolidate multiple application systems

while leveraging existing legacy investments during their useful lives. Through

adherence to industry standards, PLM minimizes data translation issues while

providing users with information access and process visibility at every stage of the

product’s life.

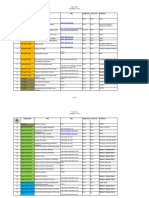

PLM systems support the management of a portfolio of products, processes and

services from initial concept, through design, launch, production and use to final

disposal (Figure 1) (Siemens PLM, 2009). They coordinate products, project and

Product lifecycle management through innovative and competitive business environment 325

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

process information throughout new product introduction, production, service and

retirement among the various players, internal and external, who must collaborate

to bring the concept to fruition.

Figure 1. “Structure of PLM System”. Source: Siemens PLM, 2009.

The PLM concept gives the strategies to organize and to manage product

information the entire life cycle, from concept to re-cycling of the product through:

• Share the updated product information's within the organization to design,

manufacturing, marketing and procurement divisions,

• Collaborate internal team with external users, suppliers and customers for

iterating new designs,

• Maintain a repository of product information for design reuse and to reduce

part redundancy,

• Systematically gather and analyze customer or market product

requirements,

• Streamline sourcing team to identify a list of preferred suppliers for

purchasing custom and standard parts,

• Streamline resource management and analyze the cost-benefits of

allocating resources for specific projects.

Management and distribution of enterprise information by PLM system is realized

on different data levels, as:

Product lifecycle management through innovative and competitive business environment 326

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

• ICT

o Compliance with existing legacy system

o Integration of PLM and ERP/CAD systems

• Processes

o Fragmented and unalterable

o Modeling, controlling, improving

• Data & Objects

o Different data formats; Standard data representation (IGES, STEP…)

o Preserving data integrity along the time; Supporting data evolution

• Methods & Tools

o Specific tools (CAD, CAE)

o New development methodologies (Six Sigma, Axiomatic design…)

• People & Organization

o Functional organization promotes incommunicability

o Supply chain approach

3 Establishing of PLM

There are companies that supply software to support the PLM process. That

software itself is just a tool and cannot make many contributions if the PLM process

is not defined first and understood by its users whom it should contribute to at the

end. Setting up PLM within the company is a process and project itself (Kecojevic

et al., 2010).

Select operations that should be managed as a part of the PLM across the company

business would be:

Product lifecycle management through innovative and competitive business environment 327

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

• Customer relationship management (CRM) system for managing customer

record,

• Enterprise resource planning (ERP) system for managing financial records,

• Supply chain management (SCM) system for managing supplier support,

• Human resource management (HRM) system to manage the employee

record,

• Requirement management (RM) system for managing of requirements,

• Project management (PM) system for managing capabilities provide project

scheduling, tracking, and resource management while the change

management is driving the execution of these projects via the process

workflows and part/document management capabilities.

• Product data Management (PDM) system for managing product data and

workflows.

Fist step in establishing PLM would be understanding and analyzing the company

way of work, organizational structure, roles and responsibilities within the

organization. Each of the PLM operational systems should be defined to specify who

is contributing to the system, how the information is shared and responsible person

appointed for each of the systems. It is not necessary that all those operation

systems are integrated within one software tool, and usually for small and medium

companies they won’t be, while on the other side big companies might need to

adopt available software and tools to their specific needs.

As an example, for IT companies (Kecojevic et al., 2010), for collaborative software

development projects can be used as SCM system where reusable implementation

blocks can be stored. However, it is important that they are well organized and

that information about its assessablity is available for all developers within the

company, as well as that effective process is established for contributing creation

and updating of those building blocks.

Similar applies, for example, for the ERP system where the solution can be some of

the project management tools that are already used in the company.

Product lifecycle management through innovative and competitive business environment 328

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

4 Application of PLM

4.1 Medium to large enterprises

In the current economic climate, addressing global business challenges is the top

priority of most medium and large enterprises. Whether they want to expand their

customer base in new markets, or to leverage more cost competitive resources,

conducting their business globally is a necessity (Pol et al., 2008). To sustain an

advantage, they have to overcome the challenges of a dispersed organization,

while still empowering individual team members to excel.

PLM concept offers comprehensive solutions to help enterprises address their

challenges and create competitive advantage. Five areas where medium and large

enterprise should have achieved success include:

• Managing new product introduction, to create a winning product portfolio.

• Achieving concurrent engineering globally, to be faster to market.

• Creating platforms for reuse, to reduce cost and speed product

customization.

• Managing product and manufacturing complexity.

• Supporting products currently in-service, to ensure they are available for use at

minimum cost.

4.2 Small to medium enterprises

Small and medium enterprises have special needs and limited resources. PLM

concept brings a complete solutions designed specifically for them; solutions that

help them respond better to their customer’s needs.

Small businesses need a product lifecycle management solution designed from the

ground-up –one that is pre-configured with the industry's best practices, and offers

fast and affordable deployment. Fully integrated PLM solutions are designed to

provide what small and medium enterprises need to maximize their innovation

strategy, and easily scale to meet their needs tomorrow.

Product lifecycle management through innovative and competitive business environment 329

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

One producer of that type of PLM software solutions is Siemens PLM software

(Siemens PLM, 2009). It helps mid-sized manufacturing companies to transform

their process of innovation by applying preconfigured best practices to everyday

engineering tasks and processes. Companies using PLM software benefit from:

• Securing their corporate design data while facilitating access by authorized

personnel

• A more successful move from 2D to 3D

• Increasing their design reuse, facilitated by a powerful and flexible search

capability

• Streamlining their engineering process with simple design review and

release workflows and effective change management

• Error reduction through more effective collaboration between their

departments and the elimination of mistake manual handoffs to

manufacturing

• Rapid deployment of a full-featured product data management (PDM)

solution

• Low total cost of ownership.

5 PLM Metrics Development Process

The questions often asked in business and commerce are how well do we know

we’re doing, and how do we know what we’re doing is working? There is important

to find out the metrics process for measuring what is important and meaningful

(Grieves, 2009). The only way to find out answers to these questions is to measure

the processes and outcomes of these processes. As PLM transforms the way

companies do business, it is important that companies understand how well they

are doing. To determine the effectiveness of PLM implementation within any

context, PLM processes and outcomes need to be measured. Measurement of PLM

requires the development of metrics that are important and meaningful to the

process. It is essential that what is identified as a metric is relevant, appropriate

and important, since typically what gets measured gets done.

Product lifecycle management through innovative and competitive business environment 330

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

The objective of the metrics development process is to identify, develop, and

articulate PLM metrics that would help companies implementing PLM determine the

extent to which their PLM efforts are paying off. The PLM assessment process

model shown at the Figure 2, conceptually presents the metrics development

process.

Figure 2. “PLM Assessment Process Model”.

The PLM processes, including ideation, design, build, service, disposal, and

recycling, on one hand influence the determination the key performance indicators

of success on the other hand the execution of the strategies and initiatives depends

on them. The key performance indicators are directly impacted by the

organizational strategies and initiatives. In other words, the organizational goals

and objectives define what the organizational considers success which should

determine the key performance indicators. Key metrics are derived from the

performance indicators. The key metrics measure what is relevant and important to

the organization as outlined by the organizational strategic plan. Outcomes of the

assessment and analysis using the key metrics impact the organizational strategic

plan. These metrics are all tied to business objectives related to growth, revenue,

and profitability.

PLM metrics can be applied at various levels of complexity:

• At the very basic Level 1 Input metrics are measured. At this level, the

question is whether the organization is applying appropriate resources to the

PLM process, i.e. investments.

Product lifecycle management through innovative and competitive business environment 331

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

• At Level 2, metrics are used to determine if the appropriate PLM processes

were implemented, e.g., Requirements Management, Sourcing and

procurement, Distribution Quote/order generation.

• Level 3 focuses on customers being reached.

• Level 4 and 5 metrics examine the efficiency whether the outputs meet the

needs of customers are being met (e.g., requirements traceability,

visualization, concepts, design capture & accessibility, change control &

change capacity, configuration management, commercial cost of risk,

product quality) and effectiveness, if desirable results are being achieved

(e.g., generation of new business, software integration, cost performance,

market share, cost reduction, design reuse).

• At the highest Level 6 metrics are used to measure the impact of the

implementation of PLM by measuring the extent to which procedures and

controls have been integrated and the return on investment. Level 6 metrics

are the most complex and difficult to measure. These include waste

reduction, innovation/ new products, continuous improvement, and

sustainable green manufacturing.

6 PLM Business Value

When the enterprise implements the PLM concept in work, than it can move

forward strategically while achieving near-term results and can establish a platform

for innovation. As the enterprise address specific business issues and builds a solid

foundation for future success through PLM platform, it will be able to realize

measurable innovation benefits both immediately and over the long term, shown

on the Figure 3.

Traditionally, companies brought their products to market in time-consuming serial

processes that delayed the participation of downstream contributors, such as

suppliers, manufacturing experts and service/maintenance providers. By allowing

to the enterprise to execute as many lifecycle tasks as possible in parallel

processes, PLM enables to the enterprise to streamline and collapse critical stages

in the product lifecycle. PLM delivers aligned, accurate, and highly synchronized

product knowledge to multiple disciplines early in product lifecycle – thereby

Product lifecycle management through innovative and competitive business environment 332

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

avoiding the cost and scheduling impact that comes when late suggestions and

unexpected concerns arise from downstream players. PLM enables to the

enterprise to beat the competition to market with innovative product content that

carries first to-market advantages and drives early product sales.

Figure 3. “PLM business value”.

6.1 Increase profitable growth

PLM allows the enterprise to create, capture and share the product-related

requirements, expectations and preferences of targeted customers and markets

and align these requirements with specific innovative content that customers want

for a price they can afford at the time when it is needed. PLM concept gives new

product ideas against quickly rising customer requirements and cost effective

manufacturability. Global cross-functional teams collaborate in real time on the

development process, each contributing their unique experience and perspective.

Knowledge and “lessons learned” are captured for potential re-use in a process of

continual innovation. PLM facilitates mass customization by enabling to rapidly and

costs effectively deliver customized product offerings that satisfy the needs of

individual customers and targeted market segments. PLM combines the advantages

of configuration management with option and variant management. These state-of-

the-market capabilities allow the enterprise to perform portfolio planning in as

flexible and continuous a process as possible.

Product lifecycle management through innovative and competitive business environment 333

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

6.2 Reduce build costs

PLM allows the enterprise to reduce cost across all of the stages in the product

lifecycle – which in turn, enables to minimize the cost of the product offerings that

plan, develop, manufacture, and support.

For example, by leveraging PLM to understand the time and resource impacts of

proposed design changes and requirements changes, the enterprise’s team can

make decisions that minimize lifecycle and product costs. By using PLM to catch

design flaws up front in the lifecycle, the team can avoid the cascading rework and

cost associated with changing the products during the manufacturing stages of the

product lifecycle. Also, the enterprise’s team can use PLM to incorporate the

concerns of the maintenance and service groups into the product designs and

minimize warranty costs. By digitally creating and re-using the manufacturing

plans, plant information and manufacturing processes, the enterprise can reduce

the overall operational costs. The enterprise can also use PLM to implement virtual

prototyping that enables to reduce the validation costs associated with physical

prototyping.

Implementation of the PLM concept in the enterprise enables to cost effectively

deliver product enhancements, derivatives, niche offerings and add-ons that

extend the profitable duration of the product lifecycle. PLM facilitates this objective

by enabling to create product platforms that accelerate start up processes,

minimize take to market cost and maximize the revenue generated by a product’s

initial release.

PLM enables the enterprise to maximize the re-use of the best-practice processes,

intellectual capital, human resources, product plans, production plans, production

facilities and value chains across a continuing set of take-to-market programs and

complete set of product and production management capabilities.

7 Conclusion

Although a quite new method with short history PLM has proven itself to be useful

for all management levels within the company in both vertical and horizontal

organization. By making relevant historical information structured and available

PLM is used both for those who are doing execution and decision makers within the

Product lifecycle management through innovative and competitive business environment 334

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

organization answering to the rapid changes in the business environment. A

business approach for coordinating design process through the implementation of

PLM systems is proposed for improving design coordination in SMEs. Firstly, this

business approach is based on a method for analysing informal collaborative

practices and modelling detailed design processes. Secondly, these processes are

implemented by using PLM technologies. Multi-level workflows are implemented to

control progress of design schedule from project management level to document

lifecycle management level.

Acknowledgments

This paper represents analysis made under support of 144959-TEMPUS-2008-IT-

JPCR Project, titled: “Master Studies and Continuing Education Network in Product

Lifecycle Management with Sustainable Production”.

References

Pol, G., Merlo, C., & Legardeur, J. (2008). Implementation of collaborative design

processes into PLM systems. International Journal of Product Lifecycle

Management, 3(4), 279-294. doi:10.1504/IJPLM.2008.027006

Saaksvuori, A., & Immonen, A. (2008). Product Lifecycle Management. Berlin:

Springer-Verlag. doi:10.1007/978-3-540-78172-1

Grieves, M. (2009). PLM: Driving the Next Generation of Lean Thinking. New York:

McGraw-Hill.

Bernard, A., & Tichkiewitch, S. (2008). Design of Sustainable Product Life Cycles,

Berlin: Springer-Verlag.

Stark, J. (2004). PLM: 21st century Paradigm for Product Realisation. Berlin: Springer-

Verlag.

Kecojevic, S., Lalic, B., Maksimovic, R., & Palcic, I. (2010). Product Lifecycle

Management of IT Project. Proceedings of the Conference Trend 2010, Serbia,

221-225.

Product lifecycle management through innovative and competitive business environment 335

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

doi:10.3926/jiem.2010.v3n2.p323-336 JIEM, 2010 – 3(2): 323-336 – Online ISSN: 2013-0953

Print ISSN: 2013-8423

TEMPUS MAS-PLM project: Master Studies and continuing education network for

Product Lifecycle Management with Susstainable Production, Tempus Programme,

European Commission, Agreement N0.144959, EC, 2009-2012.

Siemens PLM (2009). PLM. Retrieved from www.siemens.com/plm.

©© Journal of Industrial Engineering and Management, 2010 (www.jiem.org)

Article's contents are provided on a Attribution-Non Commercial 3.0 Creative commons license. Readers are

allowed to copy, distribute and communicate article's contents, provided the author's and Journal of Industrial

Engineering and Management's names are included. It must not be used for commercial purposes. To see the complete

license contents, please visit http://creativecommons.org/licenses/by-nc/3.0/.

Product lifecycle management through innovative and competitive business environment 336

V. Gecevska; P. Chiabert; Z. Anisic; F. Lombardi; F. Cus

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 4DRC 4D-V4 Richie User ManualDocument9 pages4DRC 4D-V4 Richie User ManualMarco Antonio Esquivel Talavera67% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- S2I Test Cards 1 2Document4 pagesS2I Test Cards 1 2Niño Francisco AlamoNo ratings yet

- Sample Resignation LetterDocument1 pageSample Resignation Lettershaikhjaved1No ratings yet

- AICTE Sponsored Faculty Development Programme On Recent Advances in Pharmaceutical Analysis at School of Pharmacy (Revised) 22-02-2014 To 08-03-2014Document3 pagesAICTE Sponsored Faculty Development Programme On Recent Advances in Pharmaceutical Analysis at School of Pharmacy (Revised) 22-02-2014 To 08-03-2014shaikhjaved1No ratings yet

- Rolling Advt No 03 FP 2012Document11 pagesRolling Advt No 03 FP 2012shaikhjaved1No ratings yet

- Model English Q-Paper Class ViiiDocument32 pagesModel English Q-Paper Class Viiijoydeep_d3232No ratings yet

- DL H61M VG3Document50 pagesDL H61M VG3shaikhjaved1No ratings yet

- JR - 2012 WebsiteDocument17 pagesJR - 2012 Websiteshaikhjaved1No ratings yet

- MASTA Hypoid & Spiral Bevel Gear Design & Rating ModulesDocument2 pagesMASTA Hypoid & Spiral Bevel Gear Design & Rating Modulesshaikhjaved1No ratings yet

- Surface Finish TerminologyDocument30 pagesSurface Finish TerminologyXin YuNo ratings yet

- EagleBurgmann MG1 enDocument5 pagesEagleBurgmann MG1 enMohammad Hafiz OthmanNo ratings yet

- DP Misc 15121 DriversDocument1,771 pagesDP Misc 15121 DriversbukhoriNo ratings yet

- RevolutionDocument8 pagesRevolutionpedram vakiliNo ratings yet

- Se Lab FileDocument45 pagesSe Lab FileA Royal TrapNo ratings yet

- Honeywell GLAC01A4J DatasheetDocument52 pagesHoneywell GLAC01A4J DatasheetFranco MaderaNo ratings yet

- 22.12.2020 BP Khare Sir New LA PPT (2) 2Document63 pages22.12.2020 BP Khare Sir New LA PPT (2) 2DebrahanathNo ratings yet

- Harc Snoop Test OperationDocument7 pagesHarc Snoop Test OperationMajdiSahnounNo ratings yet

- Ey Top 10 Business Risks Facing Mining and Metals 2017 2018Document14 pagesEy Top 10 Business Risks Facing Mining and Metals 2017 2018Jorge HinojosaNo ratings yet

- Bognar Sik Suranyi: de Wilde Goes Wild: Politicization of The Public Debate in Hungary Surrounding The EU Quota of RefugeesDocument38 pagesBognar Sik Suranyi: de Wilde Goes Wild: Politicization of The Public Debate in Hungary Surrounding The EU Quota of RefugeesEva BognarNo ratings yet

- The Basics of Used Oil SamplingDocument12 pagesThe Basics of Used Oil Samplingman_iphNo ratings yet

- Global Marketing Contemporary Theory Practice and Cases 1st Edition Alon Test BankDocument41 pagesGlobal Marketing Contemporary Theory Practice and Cases 1st Edition Alon Test Bankrowancanjj0s6i100% (33)

- From Wikipedia, The Free Encyclopedia: Jump To:, For Other Uses, SeeDocument19 pagesFrom Wikipedia, The Free Encyclopedia: Jump To:, For Other Uses, Seenassamerg23No ratings yet

- Chapter 8 Noli Me Tangere Publish in BerlinDocument4 pagesChapter 8 Noli Me Tangere Publish in BerlinAnthonyNo ratings yet

- Implicit Simulations With Ls Dyna Introduction andDocument36 pagesImplicit Simulations With Ls Dyna Introduction andVirginija BortkevičienėNo ratings yet

- Why Homework Should Be CompulsoryDocument6 pagesWhy Homework Should Be Compulsorycfzgiuilf100% (1)

- Kubler George The Shape of Time Remarks On The History of Things PDFDocument149 pagesKubler George The Shape of Time Remarks On The History of Things PDFhoare612No ratings yet

- Different Types of Wiring Systems and Methods of Electrical WiringDocument14 pagesDifferent Types of Wiring Systems and Methods of Electrical Wiringkalu chimdiNo ratings yet

- CE 324 - Module 1Document13 pagesCE 324 - Module 1jrpogicocNo ratings yet

- OBIEE 10G-11G - Level-Based Hierarchy GerardNico - Com (BI, OBIEE, OWB, DataWarehouse)Document7 pagesOBIEE 10G-11G - Level-Based Hierarchy GerardNico - Com (BI, OBIEE, OWB, DataWarehouse)p_k_vinodNo ratings yet

- 2014 Organizational Behavior 7th Edition Test BankDocument24 pages2014 Organizational Behavior 7th Edition Test BankAndrewFoleydegk100% (34)

- DemianDocument6 pagesDemianapi-309951387No ratings yet

- PST Personal Survival TechniquesDocument228 pagesPST Personal Survival Techniquesdbahidb100% (1)

- Reference Manual For US Milk Powders (USDEC 2005)Document120 pagesReference Manual For US Milk Powders (USDEC 2005)syalcinkaya100% (1)

- Daoism PDFDocument28 pagesDaoism PDFAnonymous DueHs55MoJNo ratings yet

- Ad 62Document40 pagesAd 62renjith rsNo ratings yet

- 380-1059 Kit Engine Overhaul D8RDocument7 pages380-1059 Kit Engine Overhaul D8RglobalindosparepartsNo ratings yet

- Brand Failure in Pakistan: Content Analytic Findings: Maliha Khaqan, Aisha Siddiqui, Kamran SiddiquiDocument15 pagesBrand Failure in Pakistan: Content Analytic Findings: Maliha Khaqan, Aisha Siddiqui, Kamran SiddiquiSami AstanaNo ratings yet

- Chit Tun ZawDocument46 pagesChit Tun ZawNaing AungNo ratings yet