Professional Documents

Culture Documents

Api 5LW PDF

Api 5LW PDF

Uploaded by

Paul Moreno0 ratings0% found this document useful (0 votes)

13 views13 pagesOriginal Title

API 5LW.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views13 pagesApi 5LW PDF

Api 5LW PDF

Uploaded by

Paul MorenoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

Recommended Practice for

Transportation of Line Pipe on

Barges and Marine Vessels

API RECOMMENDED PRACTICE SLW

SECOND EDITION, DECEMBER 1996

EFFECTIVE DATE, MARCH 1, 1997

American

L ) Petroleum

Institute

Recommended Practice for

Transportation of Line Pipe on

Barges and Marine Vessels.

Exploration and Production Department

API RECOMMENDED PRACTICE 5LW

SECOND EDITION, DECEMBER 1996

EFFECTIVE DATE, MARCH 1,1997

iD Petroleum

Institute

‘SPECIAL NOTES

API publications necessarily address problems of a general nature. With respect to pattic-

ular circumstances, local, state, and federal laws and regulations should be reviewed,

APL is not undertaking to meet the duties of employers, manufacturers, or suppliers to

warn and properly train and equip their employees, and others exposed, concerning health

and safety risks and precautions, nor undertaking their obligations under local, state, or

federal tows.

Information concerning safety and health risks and proper precautions with respect to par-

ticular materials and conditions should be obtained from the employer, the manufacturer or

supplier of that material, or the material safety data sheet. t

Nothing contained in any API publication is to be construed &s granting any right, by

implication or otherwise, for the manufacture, sale, or use of any method, apparatus, or prox

uuct covered by letters patent. Neither should anything contained in the publication be con-

strued as insuring anyone against lability for infringement of leters patent.

Generally, API standards are reviewed and revised, reaffirmed, or withdrawn atleast every

five years. Sometimes a one-time extension of up to two years will be added to this review

cycle. This publication will no longer be in effect five years aftr its publication date as an

‘operative API standard or, where an extension has been granted, upon republication. Status

of the publication can be ascertained from the API Authoring Department [telephone (202)

682-8000], A catalog of API publications and materials is published annually and updated

‘quarterly by API, 1220 L Street, N.W., Washington, D.C. 20008.

‘This document was produced under API standardization procedures that ensure appropri-

ate notification and participation in the developmental process and is designated as an API

standard. Questions concerning the interpretation of the content of this standard or com-

‘ments and questions concerning the procedures under which this standard was developed

should be directed in writing to the director of the Authoring Department (shown on the title

page of this document), American Petroleum Institute, 1220 L Street, N.W., Washington,

D.C. 20005,

API standards are published to facilitate the broad availability of proven, sound engineer-

ing and operating practices. These standards are not intended to obviate the need for apply-

ing sound engineering judgment regarding when and where these standards should be

utilized, The formulation and publication of API standards is not intended in any way to

inhibit anyone from using any other practices.

Any manufacturer marking equipment of materials in conformance with the marking.

requirements of an API standard is solely responsible for complying with all the applicable

requirements of that standard, API does not represent, warrant, or guarantee that such prod-

ucts do in fact conform to the applicable API standard,

All rights reserved. No part of this work may be reproduced, stored in a retrieval system, or

transmitted by any means, electronic, mechanical, photocopying, recording, or otherwise,

without prior weitten permission from the publisher. Contact the Publisher

API Publishing Services, 1220 L Street, N.W., Washington, D.C. 20005.

Copysight © 1996 Amercan Petroleum Insite

FOREWORD

Recommended Practice SLW shall become effective on the date printed on the cover but

may be used voluntarily from the date of distribution. This recommended practice is under

the jurisdiction of the Subcommittee on Standardization of Tubular Goods of the American

Petroleum Institute. Line pipe shipments on inland and marine waterways should be

designed to assure thatthe pipe will arive at the destination undamaged. The minimum

‘mandatory piles in force for such shipments shall be followed. The rules of governing regu

latory agencies shall be considered as basic, with the recommendations given herein as sup-

plementary thereto. These supplementary recommendations are the result of line pipe

Shippers’ experience that damage tothe pipe during shipment can consist of thrée principal

types as follows: 2

1 End damage: End damage to pipe can occur during loading and unloading, or from a lon-

gitudinal load shift against a bulkhead or an adjacent pipe.

'b, Abrasions or pecning: These result from’a rubbing’ or pounding action against some pro=

trusion such as the weld reinforcement of the adjacent pipe. This condition may result in ini-

tiation of fatigue cracks at the damaged areas during transit,

cc. Longitudinal fatigue cracks: These are initiated inthe pipe by vertical cyclical forces with

‘no apparent local abrasion or denting. Fatigue cracks result from a combination of static and

cyclic stresses produced by the weight of upper layers of pipe and/or other cargo giving a

slatic load, and a cyclic load caused by the vertical movement.

Such damage, called transit fatigue, has been reported in pipe with diameter-to-thickness

ratios as low as 12.5 and in Tine pipe grades from Grades B through X70. (See T.V. Bruno,

“How To Prevent Transit Fatigue To Tubular Goods.” Pipe Line Industry, July 1988, pp. 31—

34.) Cracks have been found at three general locations: along the edge of submerged-are

‘welds; in the pipe base metal at areas of denting, metal-to-metal contact, or abrasion; and at

the pipe ends.

‘The variables that influence transit fatigue include the magnitude of the static stress, the

‘number and magnitude of the cyclic stresses, the size of the contact area, the nature of the

bearing surface, the degree of surface damage, and the ambient environment. The stress lim-

its given in 3.3 of this document are intended to keep static and cyclic stresses to levels suffi-

ciently low to avoid transit fatigue. However, contact with hard surfaces, such as nailheads,

bolts or other debris, steel stanchions, wire cables, and so forth, can lead to transit fatigue

‘even when stresses are propetly controlled. Corrosive atmospheres such as might be encoun-

tered in humid coastal or industrial areas can accelerate fatigue damage.

‘Transit fatigue generally causes multiple cracks emanating from the area of surface con-

tact. A distinctive feature of transit fatigue is that cracks will usually be found at both the

inside and outside surfaces.

‘Adherence to the recommendations herein should prevent transit fatigue cracking. It is

also important to note that poor loading or shipping practices may lead to serious damage

that may result in pipeline leaks or ruptures.

‘API publications may be used by anyone desiring to do so. Every effort has been made by

the Institute to assure the accuracy and retiability of the data contained in them; however, the

Institute makes no representation, warranty, or guarantee in connection with this publication

‘and herchy expressly disclaims any liability or responsibility for loss or damage resulting

{rom its use or forthe violation of any federal, state, or municipal regulation with which this

publication may conflict.

Suggested revisions are invited and should be submitted to the dirsetor of the Exploration

and Production Department, American Petroleum Institute, 1220 L. Sirces, N.W., Washi

oa, B.C, 20008.

CONTENTS

Page

1 SCOPE. 1

2. GENERAL REQUIREMENTS.

21 Vessel Condition

22 Shipping Space...

2.3 Handling Equipment

2.4 Stacking Arrangement.

25. Bearing and Separator Strips

2.6 Side Protection...

2.7 Inspection

3. LOAD STRESSES...

3.L General

3.2. Static Load Stress

33, Maximum Static Load Suess.

3.4 Graphical Solution

3.5. Nomographic Solutions

Figures

1—Cantline Stowage - o

2—Chart for Determination of Equation Factor

3-Static Load Stress Calculation Chat...

‘4Example of Nomograph for Permissible Number of Tiers Based

on a G Factor of 0.4 (See 3.5) . ve 6

Recommended Practice for Transportation of Line Pipe on

Barges and Marine Vessels

1 SCOPE

“The recommendations in this document apply t0 transpor-

tation of API Specification SL. steel line pipe by ship or barge

fon both inland and marine waterways unless the specific

requirement of a paragraph in this document references only

‘marine or only inland waterway transport. Inland waterways

are defined as those waterways with various degrees of pro-

tection, such as rivers, canals, intracoastal waterways, and

sheltered bays. These waterways can be fresh or salt water

but are usually traversed by barges. Marine waterways are

defined as waterways over open seas with limited or no, pro-

tection from wind, current, waves, and the like. These arcas

are normally traversed by sea-going vessels. “These recom-

‘mendations apply to steel line pipe that is 2% inch outside

‘diameter (OD) and larger. An exception is thatthe recommen-

dations of Section 3 as concerned with load stresses are

exclusively applicable to API line pipe having diameter-to-

thickness (D/t) ratios of 50 and more. However, pipe with Dit

ratios well below 50 may suffer fatigue in transit under some

circumstances, as noted in the foreword.

‘These recommendations cover coated or uncoated pipe, but

they do not encompass loading practices designed to protect

pipe coating from damage. ‘These recommendations are not

applicable to pipe-laying vessels or supply vessels. They

‘ust be considered as supplementary to the existing rules of

‘governing agencies.

‘These recommendations are supplemental to. shipping

rules for the convenience of purchasers and manufacturers in

the specification of loading and shipping practices and are not

intended to inhibit purchasers and manufacturers from using

‘other supplemental loading and shipping practices by mutual

agreement.

2 GENERAL REQUIREMENTS

2.1. Vessel Con

ion

Cargo compartments should be reasonably free from any

foreign objects or material likely to cause either physical

‘damage, contamination, or chemical reaction with the pipe.

The bilge pumping system shall be in working order to

remove standing water from the cargohold.

2.2 Shipping Space

Pipe may be laid longitudinally or athwart the vessel to

take the best use of available space, A clearance of { foot

rust be left between the ends of the pipe and the vessel (or

‘oer eargo) to Facilitate unloading. Dimensions of hatch-

ways should be large enough to allow the pipe to pass in a

horizontal position unless special precautions are taken.

2.3 Handling Equipment

‘When end hooks are used for handling pipe, they shall be

designed to prevent end damage and shouldbe lined in the

axea of land (bevel face) contact with a cushioning material

(for example, a nonmetallic material such as rubber oF a

‘metallic material such as aluminum, but brass or copper shal

be excluded). ‘These hobks shall also have suficient width

and depth to ft the intemal curvature of the pipe. Rubber

aprons should be attached t0 pipe hooks to protect the pipe

ends unless adequate end protectors arc used. Lifting shall be

carried ut in such a manner that impact loads sufficient to

cause local denting or outof roundness of pipe body oF pipe

ends will not accur. When the pipe is loaded by loos its, all

necessary precautions shall be taken during loading and

unloading to prevent surface or other damage to the pipe.

2.4 Stacking Arrangement

24.1 STOWAGE

‘When stacking, one should consider the maximum weight

that the bottom layer of pipe ean withstand before deforma-

tion will occur. Short lengths should be placed on the top of

the stack.

Pipe in the hold ofa vessel during marine shipments shall

be cantline stowed.

Canaline stowage shall be defined as stowage without sepa-

rator strips (for example, nesting or pyramid fashion) but

including wood blocking every other tier on both sides of the

hull as illustrated in Figure 1. Ifthe top tier is partial load,

separator strips shall be used to secure additional blocking,

‘hich is used to secure the top ter of pip.

For inland waterway transit, pipe may be cantline stowed,

or separator strips may be used between successive ters of

Pipe.

Loaded pipe shall not contact the sides or bottom of the

vessel. However, each length of pipe shall be in contact

‘throughout its entire length with all adjacent pipe or blocking,

‘and precautions should be taken to minimize any lateral

movement.

Pipe with filler metal weld seams (SAW and GMAW) shal.

be positioned or padded in such a manner thatthe weld does

not contact the blocking or adjacent pipe. When horizontal

stripping (permissible only for transportation on inland water

ways) is used to load straight filler metal weld scam pips

(SAW and GMAW), the weld seam shall be positioned at 45

dogiees, #5 degrees, from vertical. When nested, pipe with a

straight filler metal weld seam (SAW and GMAW) shall be

positioned with the seam at Q degrees (in other words, 12

o'clock),

2 [API Recoumenoeo Pracrice SLW

Vesset ult

‘Wood blocking

Sido-bearing silo

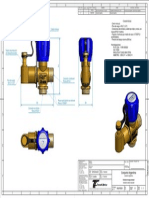

Figure 1—Cantline Stowage

24.2 LOADING ON DECK

‘The pipe shall be placed on a horizontal surface, and the

building of a wooden floor is recommended to eliminate con-

tact of the pipe with metallic protrusions and to compensate

for inclined planes. There shall be a sufficient number of

stanchions for the pipe to rest against. If the stanchions are

‘metallic, wood or rubber strips shall be interposed between

them and the pipe. Stowing cables or chains shall be isolated

from any contact with pipe through a protection medium

such as rubber strips. During transportation, the tension

of stowing cables or chains should be checked daily.

2.5 Bearing and Separator Strips

‘Wood-bearing and separator strips shall be a minimum size

of 1 inch x 2 inches. Metallic-bearing strips are prohibited.

Bearing strips shall be used to keep the bottom layer of pipe

above the hold bottom. ‘The spacing of these strips should be

as small as necessary but no greater than 4 feet unless stress

concentration calculations from Section 3 allow wider spac

ing to be used. For any loading arrangement, however, at

Teast 4 bearing strips per pipe stack must be used. For inland

‘waterway shipments, horizontal separator strips may be used

‘when the pipe is not nested. These horizontal strips should be

located dievetly above the bottom bearing strips

Additional blocking, if necessary, shall be used 10 mini-

mize lateral movement of pipe.

2.6 Side Protection

‘To prevent stress concentrations, wooden side-bearing

strips or wood blocking shall be provided so that contact with

the hull of the vessel or any protrusion is prevented.

2.7 Inspection

Purchaser's inspector shall have access to loading and

unloading facilites, with reasonable advance notice of load-

ing and unloading,

2.7.1 LOADING

‘Damaged pipe shall not be loaded on board. If damaged pipe

is detected on board, it should be noted on the bill of lading and

the pipe marked by the carrier to indicate pre-transit damage.

2.7.2 UNLOADING

Pipe damage detected during transit or unloading should be

promptly reported to the carrier and/or manufacturer and

appropriately marked and set aside for further inspection.

3 LOAD STRESSES

3.41 General

In order 10 minimize the possiblity of fatigue damage on

pipe having a Dit ratio of 50 or mote (as described in the fore

word), consideration shall be given to both the static and

dynamic forces that act upon the pipe during transportation

The following recommendations use the philosophy of set-

ting a maximum static Toad stress, The dynamic stress

induced in the pipe is dependent on the height of the waves,

the speed of the vessel, he length of the vessel, the response

of the vessel to the water surface, and the location of the pipe

along the axis of the vessel. The calculations to artive at this

stress commonly include a g factor of 0.4 to account for pos-

sible dynamic stresses. “Other g factors not less than 0.2 can

bbe used by agreement among the parties involved,

3.2 Static Load Stress

Static load stress is calculated from the equation:

65 = 0.426 2 n

F ose em 4 1]

©, = Satie load stress in psi.

n= numberof tiers.

D =speciied OD of pipe in inches.

1 =specified wall thickness in inches,

L. = specified length of pipe in feet.

W = width of bearing strips in fet.

B = effective number of fat bearing strips. As an alter

native to flat strips, bearing strips contoured to con-

tact the pipe for a minimum included angle of 30

‘degrees may be used. If such contoured strips are

used, the number of bearing strips calculated for

flat strips may be reduced to not less than % as cal-

culated above.

Not: The preceding cautions same that each length of pipe is in con-

{se dveughoat sel length hall cen pipe or Wockn

3.3 Maximum Static Load Stress

3.3.1. For inland-waterway transit the static Load stress shall

not exceed the specified minimum yield strength of the pipe.

Feconnienoeo PaACTCE Fon TRANSPORTATION OF Le Pars ON BARS

15a Marine VESSELS 3

8.3.2 For marine shipments, the static load stress shall not

exceed the specified minimum yield strength of the pipe

divided by (1 + g), where g is as given in 3.1

3.4 Graphical Solution

Figute 2 is a chart for obtaining the factor 0.426 D't for

16-inch OD and larger pipe of various wall thicknesses within

the scope of this recommended practice.

Figure 3 is a chart for the calculation of stresses for com-

monly obtained

o1sa4e-BW) ,

a

factors

‘The value of 0.426 DV oblained from Figure 2 is found

along the abscissa (horizontal axis) in Figure 3. The ordinate

of the intersection of this value with the proper

[uz i) “]

line represents the calculated static load stress.

Note: While the Hines

o[Qus2 eB) 41)

axe plo forthe mast common situations, intermediate values may be

Jerpoated. Any values not shorn om he lines may be calculated fon he

formula in 32.

3.5 Nomographic Solutions

Charts similar to that shown in Figure 4 may be developed

from the formulas given in 3.4 for a selected g factor, a fixed

‘number of bearing strips, a minimum width of bearing strip,

and a fixed length of pipe for ease in determining the per-

missible number of tiers stacked on the bottom layer for

various grades, diameters, and wall thicknesses of pipe.

0.426

Equation factor

5000)

4000

2000]

2000]

1009]

02

52 se

08

API Accoumenoco Practice SL

04 0S (08 (OF

Wal thickness, inches

Figure 2—Char for Determination of Equation Factor

10

14

(¢'¢ 289) yo" Jo so1we4 9 & UO peseg S121] JO JOQUINN ajqissiwied 104 ydesBOWON jo ejdwexa—y 2:n6

199) 2815 o 14BIay areURC.dy

0 0s ook osha

L

N

‘0 jo soquinu OL

1

t

|

|

i

i

zg

5

:

2

3

2

g

— ot = t ~{ oe

4} — os

WSN [\. Yeoelo

oapeng bon tendon Bx Wve bode |

API Related Publications Order Form

‘API Member (Check if

Date:

© ont ary

Inyotee To = U Usk ie fe Sip ‘Ship To ~ (PS wil nt der 103 FO, Bx)

am yy _

aero ans

sales ds _

yy SutePorince oy Suter

™ —_coutey ap cont

caster Datine Teepe Caster Oye eee No.

fax Facto {

(Gen) (antl Re)

PREPAID AND CREDIT CARD ORDERS DO NOT PAY SHIPPING AND HANDLING TO U.S. AND CANADIAN DESTINATIONS

( Paymont Enclosed § ‘ @ Please Bill Mo

© Payment By Charge Account: ea

vase Osa amican Eres Custom kunt Wo,

count No, ‘Stato Sales Tax ~ Tr mn Pemieu nte spurl walle asin ph

de iegasts e Me DC FGA MAS A, MM.

Name (i it nya or Cad) REND. ARSE TTC VEL a ers nr sed tha nal

ee rn pre eg fe et aren as a

iron Dae ‘Meso dec cee eee

Signatre Serpe nt Eee

(Order No.

‘602600 SL, aod Tipton of Ue Poe

osu ‘peel in Pp, Forty Fit ton $418.00

02050 Spee 4 Line he $ 70.00

| co2052 Spec SL, GRA lad or Lined Stel Poe -[s_ 65.00

‘02908 5B, Fil npeton of Mew ie Poe $75.00]

‘Shipping and Handling ~ Wook a spel a UPS or Fini Cis Nala US ad Gal, Subtotal

Onkol bec tet Aa eles tox neat

State Sales Tax (wae

Rush Shipping Charge — Federal Express, $10 in addition to customer providing Federal Express. 2

soount suber UPS Net Day $10 plus the actual shiping cass (19 Rush Shipping Charge (sel)

‘tems, UPS Seco Bay, a $10 ps eal shiping css (1-9 ite),

‘Shipping and Handling (sl)

Rush Butk Orders ~|9tms $10.09 ts a1 efor abit ie. OTE Sing SPINE Soon

orig resco be rc without Federal Express acown! mur. Total (i U5. Palas)

Bilt and Ship Orders ~ US. 14 Cana, per one ann pi atl shoes. Aller

vets, a dial (eta service) a 25% oer value. Al oer coos, fo UPS Seat Di, at

alia Wook vale

Mail Onlers American Petroleum Institute, Order Desk, 1220 L Street, N.W., Washington, DC 20005-4070

Fax Orders: (202) 962-4776 Phone Orders: (202) 682-8375

1340771196

-AdStional copies avaiable frm API Pubications and Distribution

(202) 682-8575

Information about AP! Pubkcations, Programs and Serves is

available on the World Wide Wb at: Fp ww ap org

American 1220 L Street, Northwest

Petroleum Washington, D.C. 20005-4070

Institute 202-682-8000

Order No. GosLw2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- NTC2162Document10 pagesNTC2162Edwin RinconNo ratings yet

- Asme b31.8 - 1999 (Gas Transmission and Distribution PipingDocument219 pagesAsme b31.8 - 1999 (Gas Transmission and Distribution PipingEdwin RinconNo ratings yet

- ASME B31.1c - Power Piping - Add 97-95Document140 pagesASME B31.1c - Power Piping - Add 97-95Edwin RinconNo ratings yet

- Válvula de Carga Pico ArgentinoDocument1 pageVálvula de Carga Pico ArgentinoEdwin RinconNo ratings yet

- 17-0180412 TerpelDocument1 page17-0180412 TerpelEdwin RinconNo ratings yet

- NTC2450Document9 pagesNTC2450Edwin RinconNo ratings yet

- 0707 Ing Edwin RincónDocument1 page0707 Ing Edwin RincónEdwin RinconNo ratings yet

- NTC1899Document19 pagesNTC1899Edwin RinconNo ratings yet

- Da Proceso 07-1-20439 115001006 199692Document20 pagesDa Proceso 07-1-20439 115001006 199692Edwin RinconNo ratings yet

- Remision HerreriaDocument10 pagesRemision HerreriaEdwin RinconNo ratings yet