Professional Documents

Culture Documents

API 653 Part 2

Uploaded by

AliDadKhan0 ratings0% found this document useful (0 votes)

128 views93 pagesAbove ground storage tank

Original Title

API 653 part 2

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAbove ground storage tank

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

128 views93 pagesAPI 653 Part 2

Uploaded by

AliDadKhanAbove ground storage tank

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 93

(CODEWEST API-S53 PRESTUDY GUIDE 2007

copritohr6 207. w.eSue) & CODEWESTALL MITT RESORVED.C0 NOT COPY VITHOUT PERMISSION

172, Dry pyrophorie material presents a problem because:

2. the material contains lead end special precautions must be taken.

‘the material poison and can be absorbod when skin contacts i.

© the mteral Becomes gas especialy wen wet

4. the material seltlgnites when exposed to al

178. 1n eau refinery fd service name three locations in wich AST inlornal corrosion wil most kel be

‘ound natal

‘a. Halfway up the tank, northside of the tank, and centr of tank bottom,

by Preseurehvacuum vents, roof manways, and oof raters

Tonk eters, door sheets, and craw of ozzes,

16. Vapor space, the iquélevel ina, and batom,

74, Hot tong caustic can cause accelerated and geneva coreson. Such corrosion thrives when the

temperature rises above

2 180hF

bo Tse

© SOF

6.1008

75, When visual nepacting tank booms for op-side corosin a sirong ight is cesar. What

‘inimutn wattage halogen ight does API RP 575 recorvend?

2. 60-wat

2. ao-watt

6 Toonatt ‘

25a aC

{1 winen statsteal methods wre used n saamiy he probable condton a ean Bolen, wht

‘contol the number of UT measurements taken?

The ime the tank ibe out of seve.

The eze a he fank and the degree of underside corrosion found

The surface cendton ofthe tank betom alates andthe pattern of readings,

6. The amount of hammer testing and the exoerience of he operator

“7. Wat slze coupon fs recommends for rerval fom a tank botlom to check for underside corosion?

6. Twent fou inch squsre.

5. Ninimum of 12 Inches each way.

e Sxinch square

Rectangle sight inches by four inchs.

78, Where Is the area of highest tess in an AST?

2. otto shel ont

1 sheliosotem jot

€ sumpto-botiom join.

3. mar-way-toshel joint

‘COPYRIGHT 8 2th? -CODEWEST- ALL RIGHTS RESERVED DO NOT COPY WTHOUT WITTEN PERISSION

‘a

CODEWEST APL-S53 PRESTUDY GUIDE 2007,

cope 9207+, COLEY 8 CODENESTALL FISTS RESERVED 2007 OPE WITHOUT PERISSION

70, acartly controle a tests used oes 2 tank forests "What mavimum al pressure may DE

a.2ibn’

5. Binchas, of wats

05 bin’

6.35KPa

60. mening sists nna ara ces mae ren see onus 2S

nen mating 6 cf teste at an angi of ntless nan ogress,

236,45

b.2.15

224,20

at

‘11, The minimum tuinaton fr visual Inspection © {ect canis for genera viewing

228

B15

18

ai

so. The miner sina for vuainspectan of smal onomaes {oct canes.

2.100

bs

50

425 .

ae, Penang a i apraye on eos cha nota wa, Hew er should you wal before

checking for 2 120K?

a. Atleast 12 hours but 24 nous prefered,

8 A ees of 10 hours bat 24 Pours prefrree

Auer 1 houts but 36 hours refed,

5 Atleast # ours but 42 nours

os aan penaang otis sprayeon he case she balm wal 20 nats this est called?

a, Bubble test examination.

6. Wieting examination

.Vraval examination,

SL abeorpion examination

as what tne mx a presi that asommende fox ESSN the extemal botom of tank

ora bubble est?

‘a. Sinches of water

bsuing

© 3psl

13 pascals

en none A eT EBEUED 007 COP THON MRTTENFSRISSON

38

CODEWEST API-853 PRESTUDY GUIDE 2007

“coPriottt ©2007. W, COLEY § COOEWESTALL RIGHTS RESERVED-DO NOT COPY WITHOUT ERBISSION

126, A method for checking for Weld leaks inthe bottom and in the shells

2. ultrasonic sound instruments.

use ofa vacuuen box

hammer toting

6, magnetic parte testing

87, What must be physically done before making welding rept oa riveted tank?

‘2. The contractor must est the waders used for welding of vets.

1. The toughness ofthe sles! must bo checked by laboratory testing

The weldabiy ofthe stot must be confirmed by physical testing

The vets mus be cautee to prevent any impurties from geting ino the welds

£88. Wy is two pass welding recommended for seal woking leaking rivets?

2. Two pastes are required because the rivets woakened bythe wading,

Smal weting beads are beter for sea! wating an & takes 2 passes to provide enough weld

©. Too fet pass may be poor due to hydrocarbon contaminaion.

Rivets are righ etengih sel. Te fst pass hardens the rvet andthe nd annesss

69, Name the tree types of record required for AST.

1. Design and constuction, lowest temperature tank has operated, and OSHA inspectons,

©. Beaign, reconstruction, cperaing dala and inapecton recorcs.

€,Beslgn and constiucton, repa/ateraton, and inspection record,

1. Constuetion, government permis, and inspection records

‘20, Howrlong shoul the AST records be maintained?

‘a. Maintain the records as required by OSHA

Keep te ost thee ingpactons clus the orginal consruction dat,

©. One half he serve if of each tank

4. Toughout the service Iie ofeach tank

‘copritir © 2007-CODEWESY- ALL RIGHTS REBERVED -DO NOT COPY WITHOUT WATTEN PERMISSION

CODEWEST API-853 PRESTUDY GUIDE 2007

CCOPYROHT © 2007s. W.COLEY 8 CODEWEST-ALL FIGHTS RESERVED-DO NOT COPY WITHOUT PERMISSION

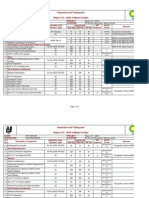

‘ABLSTS ANSWER CODE

‘tion [ ANSWER, paragraph | Guestion | ANSWER, parear jeston | ANSWER, paragraph

Number Number Number

2 Ferewar 49 [a 7a3

4 ar —_terae

eas a [726

236. af 726

4.3.18 50 [a 727

bAzz ‘si er27

422 ee te728

az3 63 [7280

ba238 IZA

47282

37283

7283

ai264

3.1285

7286

b7z8

brz8

272.10

72.10

7240

Ta

733

733

733

738

St

55

ra

37

38

,

80,

ca

22,

ca

ee

65

68

67

88

“coFYGH © 2067 -CODEWEST: ALL RIGHTS RESERVED -DO NOT COPY WITHOUT WRITTEN PERIISSION

‘00

‘CODEWEST APLSSS PRESTUDY GUIDE 2007

cop 2107-3. WEOLEY # CODENESTALL ROHTS RESERVED-0O NOT COPY WITHOUT PERBISSION

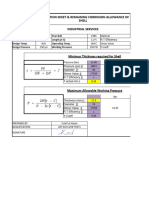

ANSWER TO CALCULATION PROBLEM

‘57, An AST was bil and pet in sence 1890. The misimum ickness ofthe baltom course was 035,

‘Sle oti course was constucted using 30.5 inch thick plates, Tho tank was not spected

roe uni 2006 The cess ofthe Soto couree was measured and founs to be 0.42 inch.

‘Betrmie the eresion rte and fhe calzuaed remaining He ofthe tank,

6

a. 0.0% and 8 years

D.do0d# yr and'.4 years

0.0044" and 18 years

‘4 0.005%yr and 14 years —

eeuar hema, OS*OAT" O08 ,

Sparen aon 190-2006 16

REMAWING LIFE

tinmistneen 042035" _ OT"

OT aye

Fe erosion wate ODOSTYR —OD05I97

copra 6207 -CODEWEST- ALL RIGHTS RESERVED - DO NOT COPY VITHOUT WRITTEN PERINSSION

o

CODEWEST APLS53 PRESTUDY GUIDE 2007

coprivakr © 200s, W.09U8Y & COOENESTALL FIGHTS RESERVED-00 NOT COPY WITHOUT PERAMSSION

ct ONS: Re.

‘30 Definitions of Terms, Symbols and Abbreviations.

4.-when working wth austenite stains stoesin the 200 series, what does the eter

‘the number, ie, 204L of 918L?

«2, Unage of sicko! molecule

1 Law carbon ranges.

Lightness of chrome sting,

1. Lead requires for welding electrode.

2. What ype of tee! doesnot normaly hava alloying elements intentionalyeded?

2. Dupox stainless steal

1. Stanioss sleet.

Carton stee.

4. Ferte stale ste

28, What does HAZ usually stan for?

a. Hysrogen Associated Zoning

Heat Atectea Zone.

© Hardened Aloy Zone.

4 Helghiened Amine Zone.

4. Which ofthe stele ists below is considered "ow alloy ste”?

8. ascr-12t,

B15 130,

6 8Gc-1Mo.

186 BN

‘5. Which ofthe stele sted below is considered tobe martensite stainless steo!?

2. Ais Type 247

BLAIS Type 3108

AIS Type 410,

AISI Type 321,

6.Afamy of alloys containing nickel as @ major alying element (greater than 30%) fs known as nickel

‘Dace ays. Whieh ofthe alloys Isted below isnot 2 ricke! base?

2 Inconel alloy 718

2.256120 N

Inconel alloy 628.

{Nel sicy 200,

‘copyRicitt ©2007 - CODEWEST: ALL RIGHTS RESERVED -D0 NOT COPY WITHOUT WRITTEN PERMISSION

2

‘CODEWEST APL.S53 PRESTUDY GUIDE 2007

‘COPYRIGHT © 2007-4 COLEY & CODEWEST-ALLNGHTS RESERVED.OO NOT COPY WITHOUT PERIASSION

7. There ae four categotes of ssinlas stools tha are charactarize by ther metalurgical structure at

oom temperature, our fame are iste below. Three ofthe four are correct and one snot. Which s

the incorrect one?

2. Austen.

Graphic.

© Fert

4. Manensiic.

{8 What does the symbol CO, stand or?

2, Carbonated oxygen.

Carbon menoxie.

© Carton dixie.

4. Cakium oxide

8, What doos DNB stana for?

‘a. Data Noted Beforenana,

® Deleoutanzer Naptha Boor

1 Determining Nuclear Benet

1. Deparure fom Nuceate Boing,

+10, What does the symbol 0 stand for?

2. Helium dioxide.

Hydrogen torte

© Water

Helm aos

+1 What does the symbol HAZ stand for?

13 H,O AMfected Zone,

Heavy Amine Zone.

Heat Afected Zone,

1, Hyorogen Acted Zone

42, What does mpy stand for?

‘3. Miles per year

Bais per year

‘ Magnetic penetration vied

Meters per yard

42.7 Bile Fracture.

+1 Auden rap facture under etess (residual applied) where the materia exhibits le o 60

‘evideneo of suctiy or paste deformation scaled

2. decarburaation recurs

b temper emeritiement.

© gage ie face

6 brite Facts

‘coPYRicltT © 2007 -CODEWEST. ALL RIGHTS RESERVED -D0 NOY COPY WITHOUT WRITTEN PERINSSION

3

CCODEWEST API.E53 PRESTUDY GUIDE 2007

“coPriOKT ©2007. W-COLEY & CODEMESTAL RIGHTS RESERVED.DO NOT COPY WITHOUT PERIISSION

2, Three o the sicels liste below are susceptible to bile fracture, Pck the one thats not

1. Carbon te

15,300 sens of stainless soe.

Low aly steel

1.400 series of stainless steels

‘5, Three factors when cca combined ten to cause bie fracture. Which ofthe four factors sted

below does not belong?

‘a. The meterats fracture toughness (esata to crack ike fas) sow.

2: The sue, shape and siess concenvaton ofa flaw tends to lead to fale

The tempecaureis high enough to duce faire

{6 The amount of residual ang appied svesses on he flaw is enough to cause fracture.

4.1n most cases, bite fracture oocursenly at temparaturs below the Charpy impact

emperatre, the point atwhieh te toughness of the material drops off sharply.

faire

ranston

© esta!

stale

‘5. Wha yeor id the ASME Bale and Pressure Vessel Code, Section Vil, Dsion {begin to require

toulginens os evita for veseos operating at cold temperatures?

2.1987

b. 194 .

21905

31903

6. Bre fracture can occur during abien! tempers cusing a hydro-test ue to:

‘2. unusual loading and high toughness atthe testing temperature

B. hgh impact streseae and plasty at he testing temperature.

hgh suesses and iw toughness atthe testing temperate.

‘high etrongthmatarial and temperatures below 100 degrees F.

7. How do you mitigate bite Fracture of new equipment?

«2, Use only 400 sores staness stools

1, Use only 200 seresstaness steels.

Use material specicaly designed for low temperature operation per ASME B&PY Code,

{Use rataial designed for igh temperature operation per ASME BAPV Code,

42

+ Wat types of material are sfacto by mechanical afigue cracking?

1.200 and 40 series stainless sloes are affected.

Only carton stots sect.

€ Alenginoerng alloys ae affoctes

{6 Monel and copper containing metals are affected.

Mechanical Fatigue.

ccoPrmiolt © 2007 -CODEWEST- ALL RIGHTS RESERVED -DO KOT COPY WITHOUT WRITTEN PERMISSION

4

CODEWEST APL.653 PRESTUDY GUIDE 2007

Ccomyront © 207 -.W, LEY & CODEWEST ALL RGHTE RESERVED.20 NOT COPY WITHOUT PERMISSION

2. Tes pee of equipment wits machanlelioaing hat are alectod by mechanical fatigue cracking are

ated below. One ofthe four Rams listed below ie ot corack Pik the Inorreet Hem,

‘2 Rotating shats on cenifugal pumps that have sees concentrations due okey ways.

Smal ameter siping that vvates because of adjacent equipment

1 Large, heavy, cast steel compressor eases.

4. High pressure drop contel valves or steam reducing stations that have sevous vibration problems.

8. A fatigue falure exhib what type of"ingerprint” or appearance?

‘9 The fle exits» hash mark ype of fingerprint tht radiates from th crack origin

The fore exits a clam shel” ype of fngerprint that has eancantc rings called "beach marks

The fare exhibits a way (ype of fngerpin tet s random in nature,

‘6 The falure exhibits a ragged rough typeof igerprin that emanates fromthe fare point

4. The best defense against mechanical fatigue cracking is which helps minimize stress

‘concentation of components that aren ele sence

12, e material selection

good desian|

© these ofthe thinnest material avaiable

1, good operations

5, NDE tachniques suchas.

arose of sess concentration

‘and_can be used to detect fatigue cracks at known

2.£T, AE LT

BP. MT, SUT.

© AET, WENT, RFEC

RT, bu ui

43.2 Atmospheric Corosion

4. nwhat ype of envronment would atmosphere corrosion be most sovero?

4. Marne environments, and moist polluted industial environments

1. Desert environments, and cod dy rural environments.

Areas exposed tothe morning sun and prevaing winds,

‘.Farnorth environment th maximum exposure o cod and snow.

2 What materials are aflected most by atmosparic corresion?

2. Nickel 209, Inconel, snd incoly.

', Monet, Tanlum, Duranickel alloy 301

©. 300 series stalloss steals, and cast fon

1. Carbon steal, ow alloy stale, and copper alloyed aluminum,

2. bare carbon see! ne Is lcsted next to cooing tower wth mist fom the lower onthe ine, what

‘would you expect to happen ithe pipe Is only protected by aluminum pal?

_2. Severe extemal oxidation de to atmospheric conditions.

£. The pant wl protect the lne ard no corrosion wil occur

{© Minor atmosphere corosion couls be expected

1. Notting Wi happen. Te concitons for corrosion are not present,

‘COPYRIGHT @ 2007 - CODEWEST: ALL RIGHTS RESERVED -00 NOT COPY WATHOUT WRITTEN PERIESSION

98

(CODEWEST API-653 PRESTUDY GUIDE 2007

“COPYRIGHT 207.11, COLEY & CODEWEST ALL RIOTS RESERVED-DO NOT COPY WITHOUT PERANSSION

4 How many mils per year would you expecta carbon sce ie to lose If exposed to a marine

envionment?

3. 20mey

b5my

2 10mpy

6 Smpy

65, Whatis the atmosphere corosion rate carton stelis exposed ina ty rural environment?

a tmpy

bs may

2 2moy

2 thin-lm epoxy phenotc

©. thins coal tar opoxy

© thick fim vl ester

6 theketim epoxy

4 What ype of ning would you select, using Tables in API 652 63, for crude ol & aromatics at an

‘operaing temperature of 200" F.

«thick epoxy

8 trinsimcosl tar epoxy

thinsfim epory polyamide

6 thinks vinyl ester

‘Sopris ©2007 - CODEWEST. ALL RIGHTS RESERVED D0 NOT COPY WITHOUT WITEN PERISSION

“28

CCODEWEST AP1.53 PRESTUDY GUIDE 2007

(COPYRIGHT © 2007, W.COLEY& CODEWEST.ALL RIGHTS RESCRVED.CO NOT COPY WITHOUT PERAVSION

5. Linings (thin thick tlm are both applied ater

2. scratching the surface thoroughly,

'.seraping he surface thoreushy.

white or near-white abrasive Biasting

6. brush basting.

6. What typeof ring is preerred where intemal coreson has occured?

thik lm

hi ln

© mil soate

6 primer coot

7. A prope installed thin or hick fm nr can have a ife expectancy of

2. about 1 years

10620 years

12.25 yee for thi lm fer and 30 yer for thik im ner.

1. greater tnan 20 year,

8, How many coats are often required to gettin ning?

a t2coats

6.2.3 coals

e455 coals

4.5.8 coats

9, How many coats are required to get atk fim ting?

2.28 coats

several

8

© 12 coats

6 Boots

‘APLP 652-SECTION 7-SURFAGE PREPARATION

1. Whats the major cause oftring fare?

2 Inadequate surface preparation.

Use of out of date tang materia

©, Using thectam costings where thin-flm would work

4. Using hi-fi coating where tic fi require.

2. The effective removal of soluble sls from the surace that ners tobe aplled is achieved by

1. the use of caustic wash

1. the use of sodium enlorie water rinse

high pressure or ultahigh prossure water jeting,

6. vigorous hand cleaning

‘coPYitGiT © 2007 -CODEWEST. AL RIGHTS RESERVED -D0 NOF COPY WITHOUT WRITTEN PERMISSION

30

CODEWEST API.853 PRESTUDY GUIDE 2007

‘COPYRIGHT 2007-1. COLE & CODEWESTALL RIGHTS RESERVED 00 NOT COPY WITHOUT PERIESSION

8. Whats the prefered tecnique forthe repair of perforations of steel tank bottom?

2. instal a fiberglass patch,

Weld on stool patch late

Pad wel,

4. nstall a wooden patch

4, Abrasive blasting should not be performed if the temperature ofthe steel surface is less than

dagroes F- above the dew point,

ange

5. Abrasive basting sould not be performed i the relative huis greator han percent

gees

4

6. The anchor pester required or instalation of rings i pica mis and generaly

increases wi

the thickness ofthe fining

a 15 P1882, 7.5

bee

810

tots

APIRP 652.SECTION €-INING APPLICATION

1. Proper on-site storage condions, mixing, applying, end curing of tank bottom liner are essentat

procedures, and be recommendations shouldbe olowed

2. ommedusers

Diner inspectors

jussicton's

manufacturers

2. Soventbome fnings require entiation of the space adjacent tothe ting,

8. Forced

b slow

© Gradual

4 Regu

‘coprntae © 2007 -CODEWEST- ALL RIGS RESERVED - DO NOY COPY WITHOUT WRITTEN PERMESION

at

(CODEWEST APLS53 PRESTUDY GUIDE 2007

‘COPYRIGHT © 2007. W. COLEY & CODEWEST-ALL RIGHTS RESERVED-20 NOT COPY WITHOUT PERWSSION

‘APLRP 652-SECTION 9.INSPECTION

In oréer tha liner specications are met, the ner should be inspected during al phases ofthe work and

‘once every 5 years ater instalation.

©. afr te tank has been placed in sevice

©, once every 10 yeats ater installation.

6. upon completion of he work.

Hosiay tasting of tick-fim linings shall be carried out witha

2, utresoni equipment.

B ahigh voltage detect.

dye penetant esting.

<4. ow votag (675 vols) wet sponge dotctr.

Holiday testing of tin fim tank bottom Inings shouldbe pectomed with a ow-votage

‘wet sponge detector

vots)

apes

B388

SECTION 10-£V os

‘A propery appli ining wl provide a service ie of 20 years. Some ning systems (ckfm

laminates) have provided of servioe if

2.10.20 years

12-18 yeare

6 15-18 years

16.25.20 years

IMtning degradation is detectog, te of coating degradation must be estabished a well

‘whether oF nol the existing ining is Suable Tora ropa.

cause and extent

Locatzed fares, such as bstor, pinholes, delamination or mechanical damage are all examples of

‘where

2 top coating ofan exstng liner is applicable.

total nee removal and replacement is applicable,

© spat repairs are usually appicable

4, deineation of te ne is required before deciding onthe mode of rept.

[COPYRIGHT © 2107. CODEWEST: ALL RIGHTS RESERVED -DO NOT COPY WITHOUT WRITTEN PERHSSION

92

[CODEWEST APL.S53 PRESTUDY GUIDE 2007 '

APLRP 652-SECTION 41 MAXIMIZING LINING SERVICE LIFE

BY PROPER MATERIAL SELECTION AND SPECIFICATION ‘

Corrosion protection forded by an interna ning the corrosion rate on the topside ofthe

{nk bottom and allows the service interval Between Tank Inspections tobe maximizee,

2, sugments |

mitigates

«. supplements

4. ampttce

2, Tank rings do not last forever. Typical, they become _over te.

2. oes effective

acquiesce i

© maieatle

toughened

Which of the isted tems would not be Included in @ writen specication fora tank bottom ting?

2, Tensecompressive strength ofthe cued line.

5: Stet pate preparation and weld surace quay

© Apptcatorquaiicatons and submissions

14. Nood far wal hikness macsuremerts

APLRP 652-SECTION 41.SAFETY

1. Porto the application of internal tank rings, proper _of employees regarding aafe work

SF hoo is required .

a traning

B selecting

ing

6 testing

The chemical make-up of high perfomance intemal tank lining materials can present heath hazards to

workers Foot handled propesy. Which of the eaures of information led below shold be Sons

byallemployees where thay canbe concisely intrmed about the materiale being used?

2, NACE recommendations,

© Ounertuser requirement,

© MSDS sheet,

6 OCAW datasheets,

[NOTE : THE THIRD EDITION OF API682 LEFT OUT THE RECOMMENDATION THAT THE BOTTOM

LINING EXTEND 18-24 INCHES UP THE TANK SHELL. API MAY NOT DROP THIS QUESTION FROM

THEIR COLLECTION,

133

‘CODEWEST API.G53 PRESTUDY GUIDE 2007

CcoPrRGHT © 2007-.W, COLEY 6 CODEWESY-ALL RIGHTS RESERVED.DO NOT COPY WITHOUT PERIASSION

SECTION

Te, 882,1

2 Pubisatons: No quoons asked

alalaiaal

‘

x

ee,

aa

3,

Ba,

EE

63, Table?

62863, Tabea 182

a4

S218841

9.2, Tabi

6:3 Table?

Ielelale lolalelola|

BRRRRBBeB|

‘COPYRIGHT © 207 -CODEWEST- ALL RIGHTS RESERVED -00 NOT COPY WITHOUT VIRITTEN PERMISSION

14

CODEWEST API.683 PRESTUDY GUIDE 2007

[copra © 2007. W. COLEY& CODEWEST ALL RIGHTS RESERVED.00 NOT COPY WITHOUT PERSSON

ASIIE SECTION V- NDE - PRACTICE QUESTIONS

The. Is responsible for examination equipment calibration records.

1. Cade User

2° NDE technician calates hs o¥n equipment and

53. company that manufactures te NDE equipment

4 Authored inspector

2.Attoast, opy{es) of an NDE procedure must be avaiable tothe Manufacturers

‘Nondediwcive Examination Personnel al the works

4.two

Bone

none

4. ther sno raquiremont

‘3. The ference between an inspection and an examination per Section Vof the ASME Codes

‘Inspections are NDE functions performed by contactors

2 ‘examinations are QC functons performed by the manufacturers employees

5. "inspeosons are performed bythe Authorized Inspector

4 28S atove

4, How mustalt Nondestuctve Exeminetion Personnel be qualified hen Atice 1 is referenced?

4. pr he manufacturer's POR's

2. er the requirements oftheir employers wren practice

3. Miwa wi spely the reuse eae jue

4 they ae aways qualified por ASNT SNT-TO-A

5. Which ofthe folowing is not par ofthe minimum content of writen radiographic procedure?

4. ype of screens used it ny

2 type of emulsion used

3. mbrand & designation

4: maximum Xerayvolage or isotope used

6. How can compliance wih a writen rsclographic procedure be demonstrated?

4. by showing the flm othe AL

2. by confirming the aocuracy of the radiographs wih a weldar or welding foreman

5 by vereyng the proper density and demonstrating the lal image requirements

4 by damensirating the aquired sensi by showing the"2T” hol in a hole ype Il

7. Wat fished surface is required of butt welds?

4. ol surface cracks must run vertically the centr

2 al suriace cracks must run herizontally in tho conse

53 thay mast rot have any Fregulaiies of contours that will mask defects or interfere wth interpretation

4 thoy must not have any undercut or pinholes that wll ask defects or hterfae wth interpretation

‘CoPYAIGHT © 2007 -.CODEWEST. ALL RIGHTS RESERVED -00 NOT COPY WITHOUT WRITTEN PERISSION

35

‘CODEWEST APLS53 PRESTUDY GUIDE 2007

“coPrRct 6 2007s. WOOLEY & CODEWEST AL RIGHTS RESERVED.00 ROT COPY WITHOUT PERANSSION

{8 One reason fora sytem of radiographic fm identioston i:

4. toe the fim manufacturer

2 so the location of defects il be rabeable to te weldment

8. to Keap track of ow mut fn Is used orbiting purposes

2 so the welders wil kw where to have te fim placed by te raciographer

8. ntensving sereens may be used

4. only when rasiograping stright

2 en for Polaroid Se-1668 instant reciographs

5: wen perorming radiography i accordance with ASME Secton V, Article 2

{for color radiograph only

10.108 may be whattypes?

wie

2 hole

2 rack

4982 above:

11. Viewing fii fr radiographs shall

1. be smal, warm and comfortable anough for atemon naps

2 have adjestable lighting ith variable temperature contra tlm storege

3. be bright and ary wth ts of ferns and plants

4 have subdued backgroure Eghtng that wil not cause glare on the fm

12. The drecton of the central beam of radiation should be ‘he area of interest

vwmeneves praia:

41 as cose as possible to

2 centers on

ne more than 18° rom

4 atleast 99" fom

13, Wore are hole fype IOs placed when radiographing welds?

4. always inthe center ofthe weldrent

2 adjacent to a on the weld but nein the area of interest

53. enthe fm side

4. pone of the above

14. Wnere are lation markers placed i they are to sppear as 2 rediographic Image?

4m the pat to be radlagraphed

2 nthe fm nthe dark room

5. the Il topside over the "2 hole

4. 1R Sebove

16, The ll is normally placed on which side of part?

1. the 1s optional so doesn't mater

2. the fim side, the same side ofthe pat to be Inspected as the comparator

43 the souroo sige excert whan inacoessiblty prevents hand placement on that side

4 the fm se: the eam else of he pat to be inspected a the fm

‘COPYRIGHT © 2007 -CODEWEST- ALL RIGHTS RESERVED -D0 NOT COPY WITHOUT WRITTEN PERISSION

136

CCODEWEST APL.6S3 PRESTUDY GUIDE 2007

“COPYRIGHT © 2007-s. W, COLEY 8 COOEWESTALL UOHTS RESERVED 00 NOT COPY WITHOUT PCRIISSION

16, What designation is uso to inicatethe Ia! is onthe fi side?

4. thie onty noted on the radiographic report -thero i no other designation used

2 the welder noted Ion the weld map

5 te fl may nat be placed on the fm side

4. lead leter"F placed next boron the [al

17. How many ls shoulé appear on each radiograph?

4. there must alas be one on every radiograph ad it must appear asa radiographic image

2 there must aways be one on every radograph but noed not appear 2s aradlographic Image

5 there must ays be two on every redograph and t must appear a a radiographic image

“4 tdapanc onthe coniguraton uses set up the shot (panoremic muff, single shot, et.)

+16, Shims may be placed under Isto simuate wed enforcement to assure the density inthe area of

Inrest sno more than Tighter than te censty rough tho

1.10%

2.25%

216%

45K

40, Wich of te flioning blemishes is permit on fm as long as they do not interfere wih

Interpretalen and donot mask or bocore confused with decontnules in he are of interest?

4. fogging & false indleatons from defective screens

2 seathes, crimp, stale marks & drtness

5 proceecing dolore suchas steaks & water marks

fStottie above

20. The minimum density requirements for single fm viewing re

4.1.8 for tim made wth gamma ray and 20 for fim made wih an Xray machine

2.40 for fim made with gamma ray ad 4.0 for fim made wth an X-ray machine

4.2.0 for fim made vith gamma ray and 1.8 for fim mae wih an Xray maching

4 no mare than 26% lighter in any area than the density in the darkest area

24, When usog only ane 1A! par fim density measurements may var thyough the area of interest by no

‘move then ‘or adonal Ie willbe required.

4. minus 15% or plus 90%

2 plus 188% 07 mrs 30%

5 plus 1.8 Xratio of average densities

4 pomore fan 15% frm the denlyof he sop wedge

22, Which ofthe below is an essental indication of sensitiv forimage qually ofa radiograph?

4. eisply ofthe welders stampings

2. clear visible lation markers

5 kl of the designated Nole or essartial wire ofthe IA used

“proper deny varios within 60% ofthe thickness

‘convict © 200 -CODEWEST- ALL RIOHTS RESERVED .D0 NOT COPY WITHOUT WRITTEN PERMISSION

‘a7

CODEWEST APLSSS PRESTUDY GUIDE 2007

CCoPriit © 2007-J.W.€LEY & COOEWESTALL RIGHTS RESERVED-DO NOT COPY WITHOUT PERAISSION

28, Exoossive backscato in indicted by:

4 ead lettoe“F* being vibe onthe reograph

2. a dark mage ofthe lead letter "8" ona ighter background

5 any mage of hele eto "Bn the Becxground of the fim

4.3 ightimage ofthe lead leer °° ono dark background

24, tank is but wt pate under 2 Inches tick. The geometric unsharpness ofthe raclographs shal nat

‘exceud,

4.0010"

2.0020"

5 0030"

40.040"

25, The Flonng information may not be Included in the documentation accompanying the radiograph:

4, source to object estanco an fm brand & designation

2 number of exposures & fim Kentfeaton

2 eource sie

4 development te & exact shim material specications

26. When te radiographs are presented lo the Authorized inspector

4. he wilnterpret tem and indicate the dspostion of each fm an the repor,

2. he wl view tem ony efter a good lunch pad for bythe NDE tecicien

5: the menclacturr wil have interpreted all ne fim anc wl have indicated the disposition of each onthe

Teport ond will have also Included le other information require toon he repar.

4.traaeyreans wi be manne wit a permanent marker by lke tours to naoate which technsian

hem.

27. Which ofthe folloning isnot a type of lscontnulty quid penetant examination is effective in

‘toctng

400d abuts & laminations

2 subourane eacks

23. pinnoles

4 Seams

28, Which of he following i an essential variable for Liquid Penetrant procecure?

4. port examination cleaning details

2 ater, Shapes & S205 0 be examined

5. decease in penetrent dell time

4 proveesing det or removal of excess penetra,

28, Revisions to PT procedures may be required if heres

4.3 change in surace preparation

2. schange of substation in type or famly of penetrant materials

23. a change in he method of applying developer

4 Alot the above

‘coPYeji © 207 -CODEWEST. ALL RIGHTS RESERVED -DO NOT COPY WITHOUT WRITTEN PERNISSION

138

(CODEWEST APLs83 PRESTUDY GUIDE 2007

‘COPYRIGHT © 087 -J.W, COLEY & CODEWEST-ALL RIGHTS RESERVED-00 NOT COPY WITHOUT PERMISSION

20, Which of the flowing penetant techniques may not be used?

1. sobent removable

2 had dying fluorescent

2 water washable

4. post emulsiying

231, What materi require the use of tested and cetted quid penetants es tothe contaminants inthe

penetra?

4. carbon stoas with > 9% chrome

2 aluminum

53 hlckel base ays & Otani

4 copper

22, What condton must the surface ta be examined be In prior to conducting the examination?

4. dey & free of ll remectal demagnetization matorals & eects

2 dey& feo of anol, gfeas9, It, cal or thor extraneous matter for 1" on all sides of te area tobe

‘xamined

2. ree ol subeurace defects previously detectes by othr methods

4. dry ee ofentranoous matter for 2" on at sides ofthe ara be examined

£38, How shall PT indications be evaluated per ASME Artie 6?

4. por universal accoptance standards in ASNT SNT-TC-14

2 Intermsof te acooplance standards of te referencing code section

4 porthe specific reqlvements In appordicN.5.3 of APTOS

4, per the OunerUser proecures for NE

4, The minimum period of crying time ater inal cleening is.

4. teas S minutes to assure tht al the lesning solution hes evaporated prior to applying the ponetrant

2. aminimim Sime established o assure that al tha cleaning souton has evaperatod poo applying he

enetrant

3, atleast 15 minutes to assur thatthe clsaning solution has evaporated prior to applying the

penetant

4, atleast 10 minute to assure that athe cleaning olution has evaporsted prior to applying the

penetrant

25, Which of he folowing isnot 2 suitable means of removing ponotant

+. fusing wate washable panetrant wih water spray of ss than 80 PS! 110 F|

2 steaming water washable penetrant at 200 PSI to remove

§ wing sotent removable penetant wih ait free eth

4 rinsing post emsting panerant ta temperature & pressure as recommended by the manufacturer

36, Without special qualification ponetant testing can be performed between, degrees,

1. 50 degrees F to 135 Degrees F

2.50 grees Fto 125 deareos F

5, TRdogrees F to 130 Degroos F

45D degrees F to 10 Degrees F

CCOPYaIGT © 2907 -CODEWEST- ALL RTS RESERVED -DO NOT COPY WITHOUT WRITTEN PERIISSION

9

CODEWEST APL.S53 PRESTUDY GUIDE 2007

COPYRIGHT © 2007 -J.W.COLEY & CODEWESTALL HGH RESERVED-D0 NOT COPY WITHOUT PERISSION

37. When PT examination so be performed above or below,

lemperatve range intended using 8

the procedure is qualified forthe

41. 50 degrees F to 125 degrees F —- Image Quatty Indicator

2.50 degrees F to 125 degroes F — fli indeator

53.50 degrees Fo 125 degrees F — comparator

4.50 degrees F to 125 degrees F and DAC curve

38, Fluorescent penetant examination shal nt follow

41, UT thickness measurement

2 racography Because the esiual relation wil cause fase indcatons

5. Edy curent examination

4 color conan PT examination

238, The emulsification time fr pope omulsieatin of a post emutsyng penarent

4.90 seconds

2.6 minutos

3.10 mrutes

4. as determined experimentally

40, When removing water washable penetrant te spray of water may not excsed?

4.100 agrees F & 50 psi

2°00 degross F & 60 9s

43. 110 dogtess F 50 psi

14170 depress F 55 psi

4, Water washabe and post emulsihing penetrants may be ered using culated air as long a the

‘surlace ofthe par does not exceed:

1.100 dogrees F

2 110 degrees F

8. 212 egress F

4.125 cogroas F

42, Deleted

42, Five ypcal of cscontnutise detectable by the magnetic particle method are:

4. seams, aw carbon content, old shuts, laminations and bad daveloning

2 cracks, causte embritiement, seams, and siconiotope matic syndrome

5 excessive wols seam rinorcemant, cracks, cold shuts, seams, fw Viscosity

4 rks, lps, seams, cold shuts and laminations

‘COPYRIGHT ©2807 -CODEWEST. ALL RIGHTS RESERVED -DO NOT COPY WIHOUT WRITTEN PERMISSION

40

‘CODEWEST APLSS3 PRESTUDY GUIDE 2007

Ccopyincsr © stor -s.W, COLEY & CODEWESTALL RIGHTS RESERVED.DO NOT COPY WITHOUT PERMISSION

44, Whats the magnetic particle exemintion medium?

4. the surfaces of arcomagnete work pleces 1

2. dy, wet or fuorescent ferromagnetic particles

5a iype of smal meta particles,

4. igh fon content enamel o atx coatings |

45, Ifeoatings are etn place during MT examination, !

4. the parties used must bs the same color asthe ooating

2. coatings are not allowed to be let in piace - all coatings must be removed, '

5. the prooedure must be demonstrated as capable of detecting indications through the maximum

thlgeness ofthe coating pled i

4. allindications must be varied wth penerant examination in sdtion to the magni particle |

‘examination

46, What type of aiscontinly isthe magnetic parte method most sensitive? 1

4. subsurtace dlscantinuites:

2 slag inclusions not open to the surface ,

5 near discontinuities perpenciular to the lines of fax |

4 high rik! alloy wld defects

47, Wen perorming fuorescent MT examiners shel allow. {or thir eyes to seust 1

‘tg the darkened conditions. |

4. S minutos a

2.90 seconds f]

4 tominutes

48. The intensity ofthe biack ght used shal bea minimum of

41800 2 Jem? 12" tom the surface ofthe part bing examined

2.600 nl /em on the surface of th part being examined

11800 Vem? 16" from the surface of the part bong examined

4.1000 Vn on the surtace ofthe part beng examined

49, Normally cry particles may not be used on surfaces above: 1

4. 800° and 138°

2 ambient temperatures

5.600"F end 135°F

4. te manufacturers recommendations

5

50, Magnetic fi strength may be verted by using

1. anamp moter to determine ifthe Fld within + 10% of fl scale

2 the proper 1Gl manufactured using all magnetealy ilenca materials

83. an ofr meter o determine ithe fed Is within 8% of fl scale

4 ple staped magnetic partee fed indleator or afl! law shims

‘Corr © 267 -CODEWEST- ALL RIOHTS REBERVED BO NOT COPY WITKOUT WRITEEN PERIESION

‘at

CODEWEST APLS83 PRESTUDY GUIDE 2007

“CoP 2007 JW COUEY & CODEWESTALL RGIS RESERVED.00 NOT COPY WITHOUT PERMISSION

51. Alexarinations wil be conducted wit euficlent overlap to assure an minimum of

‘coverage?

1.90%

2.10086

5.80%

490%

52, When using he prod technique the maxémum prod spacing alowed is

4.1 foot

2 Biches

5 V2toat

4 Binches

53, Magnotic particle equlpment with ammetors must be callrated

1. always pr to each use

2 after every 10 examination sessions

5 below and after each examination

4. porto first uee tthe equipment hes not been used fra year or more,

64, AG yokes must be able tot

4 40 pounds at the maximum spacing o be used during examinations

2.10 pounds ata maximum spacing of #8 Inches or 1 172 feet

40 pounds at @ maximum spacing of 1.6 Umes tre length ofthe yoke legs

410 pounds a he maxirum spacing o Be Used during examinations

55, MT equipment with arumeters must be calbratod toa standard

pounds eta maximum spacing of

4, supplos by te MT equipment manufacturer

2 supple bythe ISO NET standards commition

4 bacoable oa Natons! Standard

4 welded by a qualited welder or elding operator qualified in aceordance with ASME Section V

156, What isthe maximum temperature of materials covered under SE 7577

+. ast E

2 act

3 BOF

4 200° F

57, $6787 provides guide nes forthe_metied for messurng thickness.

4. scan

2. contac pulse echo

3. Submergod radiant echo

4 fealtne 172 e2ho

‘COPYRIGHT © 007 -CODEWEST-ALL RIGHTS RESERVED -DO NOT COPY WITHOUT WRITTEN PERAUSSION

a

(CODEWEST APLS53 PRESTUDY GUIDE 2007

‘copyitant © sor -J.W.COLEY & COBEWEST.ALL RIGHTS RESERVED-DO NOT COPY WITHOUT PERAISSION

58, Apulse echo instrument measures the__of he urasonc pulse though the pat.

a

vey

transittme

59, Reference biocks used to calbrate equipment should have an uasonic velocity

4. of = 456°x9

2. of less than 10,000 inches

83. the same as the pice tbe tested

4 bases on sheer wave impact

160, Which is nota type af thickness measurement instument?

4. Faw detectors with ORT readout

2. Flaw detects with CRT floor Scan pressure readout

53, Flaw detectors wi CRT and cect ckness readout

4 Desotthicinese readout

61. For measuring hn sections which type of search unit is goneraly used?

1. Highly damped igh quency

2) Hignyatenuete, tow frequency

5. Higny damped, ow frequency

4) SUHe singe elomant

2. Wns usin w dest contact, sng element search unt he dio start a

4. based onthe average value ofthe ceplay

2. symoronized tothe nial pulse

3. equaltbe=m*

4. always athe top

165. Wan parfrring a compete calibration of an instrument using a delay Ine single element search unit

calration Bons shoud be:

4. Atleastve~ one near the maximum thickness of he range tobe measured and one near the mid

range

2, Atleast wo 2 1 inch block and a6 inch Block ofthe same velocity

3. Atleat free blecks wih a minimum difernce in thickness between each of atleast 1 inch

44 Atleast wo wi a thickness near the maximum of tha range to be measured andthe oer block near

{he minimum hiss

‘COPYRIGHT ©2007 -CODEWEST- ALL RIGHTS RESERVED -00 NOT COPY WITHOUT WRITTEN PERIBSSION

a3

CODEWEST APLS53 PRESTUDY GUIDE 2007

‘Coprison @ 207s. W, COLEY 8 CODEWEST.ALL RIS RESERVED.00 NOT COPY WITHOUT PERMISSION

(64, When calibrating a UT instrument using Case i, what minimum number of tet blocks should be Uses

‘when the inure must be completly calibrated with te delay Ine sesrch unt?

165, When using dual search unts theres an inherent eror cue othe:

4, eletance between the unis

2. veiooty rate averages

4, Vee path that te sound beam tavels

‘4 geometry ofthe spacial cataton blocks required

‘86, When messuring materiss at high tempertures the readings ae high by a factor of:

1. 19 per Soe

2 19 per iF

3.5% per

41% per 100%

67. When developing a detaiad UT thickness measurment procedure which ofthe folowing doesnot

‘need tobe consded?

4. Enulpment

2 ghtng eondtions|

2 Sane repro and upon,

68, Which ofthe folowing woul not be included ina UT report

4. examination procedure

2, Calration blacks, size anc material type

53, censty readings

4, Six, frequency, ard type of search unit

‘cOPYRGT © 207 -CODEWESY. ALL RIGHTS RESERVED -D0 NOT COPY WITHOUT WRITTEN PERMISSION

‘as

CODEWEST APLS53 PRESTUDY GUIDE 2007

COPYING © 200 J. 1%. COLEY 8 CODEWESTALL UOHTS RESERVED BO NOT COPY WITHOUT PERMISSION

ASME SECTION V ANSWER KEY

Ta Ts6) wa, TaTaT

2 [a 150 40/3, 473.1

3 [4,170 a [4,787

[27-1206] 42 | Deleted

eared a8 [4 1720

[3,271.2 a4 [ 2.7731

ps, 12222 48 [3.7744

al ara a8 [3,720

93,7202 arf. TrrT

70 [4-238 aoa -777

aaa Fase 42 [47-731

423 T2978 a0 47-764

43 [2.277 ata r7r6

4 [4 278 2 41-752

48 [8.7277 fa) a3 4761

46 [4.72771 (b) se 4 762

ara TaT72 56 [3.776

48 3,72773 a6 [4797-17

9 [47-281 er] 2, 787-1.

20 | 37-202, 38 [4,787 42

2a 4, F202, 38

223.7205, 60

25 [4.7208 cl

2a | 27205) 62

25 4281 83

2637292 84

ar 27620 8

2a] 3, 7821 a

20 Tt sr

30 [2,56 mo

31] 3, Tat

322

33.[2, 7-980)

34] 2, T53)

8 [2.764

36/2 182

ST] 3, 7865,

38 47-654

‘COPYRIGHT © 2007 -CODEWEST: ALL RIGHTS RESERVED -00 NOT COPY WITKOUT WRITTEN PERMISSION

45

CODEWEST APIS53 PRESTUDY GUIDE - SEPT 2008

‘COPYRIGNT © 206 -.W.COLEY 8 CODEMIEST.ALL RIGHTS RESERVED.00 NOT COPY WITHOUT PERIASSION

ASME SECTION IX WELDING - PRACTICE QUESTIONS:

1. The purpese ofthe WPS and PAR iso determine tht:

the welder is qvaifed

the base metas are song enough

the welmont has the desced properties

the sl ofthe welder

“The WPS tats:

ronessent! variables

essential varables

Supplomentary essontal variables required

atlottne above

“The POR musts

essential vasables and supplementary essen! variables when notch toughness is requires

ronessental variables

‘welder qulifetion varables

atotine above

Whats the earest Eaton of Section X recognized by the current edton?

1958

some

4987

4982

5. New Welding Procedure Spectations must mest the ition and adionda of

‘Sesto Ik

4.4962

2 current (lest mandatory)

2 988

41998

6. Each shall conduct the tests required by Section D1o quality the WPS's used

‘uring ie constuction, Allerton, oF repr.

4. Welder or welding operator

2. Manufseturer or ontractor

3 Inspector

4 allot the above

17 The records of procedure, welder and welding operator qualifation must be evalabe tothe

1, Manufacture of Contactor

2. Welder

3. Authorind Ingpector

4 Foreman

cori 0. COLEYCODEWESTAL GTS RESERVED-0 HOT COPY WTHOVT PERSSON

4

‘CODEWEST APLS53 PRESTUDY GUIDE ~ SEPT 2006

CCoPYiuGiT © 205-.W. COLEY & CODEWEST-ALL RIGHTS RESERVES 00 NOT COPY WITHOUT PERMISSION

8. A welder cualtyng wt a groove weld in platen the 46 poston equaled to weld groove welds in

late and pipe over 26° 0.0. nthe postions.

4. Overhead

2 Flat & hoteontal

42. Flat & overead

& Hodzontal

‘9. A welder qualifying wi pate fet welds inthe 3F andl 4F postions is quali to weld groove welds In

ploteinthe postions.

3. Flat only

2 Flat and horizontal

3. Flat and vorcat

4. None ofthe above

10. A welder qusifying by making a groove weld on pipe wih an O.D. of 34" in he SG postion fs qualified

fo weld groove wold

4.12" 0.0. Pipe inthe overhead postion

2.6°0.0. Pips nthe vertical postion

23.3" 0.0. pipe inthe horizontal psiton

“None ofthe above

“1. n genera, qualification on groove welds also qualfies a welder to make:

4. Stud welds

2 Overhand welds

2 Filet weide

A. Alofthe above

42. Charpy Vnoich toss are performed to determine a weldments

“Tensile etrength

Ductal

y

Note toughness

Allaf above

13. Awalder making @ groove wed Using the SAW process on Pt materials may be qualified using

‘adography.

1 Twe

2 Fae

“4. When a testo specimen breaks in the base metal ouside ofthe weld or fusion sno, the strength

recorded may be below tne spect tense and be accepted.

1.3.5%

1

2

5

4

COPYRIGHT © 2006-1. W,COLEY & CODEIESTALL RIGHTS RESERVED.00 NOT COPY WITHOUT PERIERSION

or

CODEWEST APL.653 PRESTUDY GUIDE SEPT 2006

LcopyRtai © 208s. W.COLEY & CODEWESTAUL RIGHTS ACBERVED.DO NOT COPY WITHOUT PERMISSION

415, Guided-bend epecimens shall have no open defects inthe weld or hea ffcted zone exceeding

‘measured in any doco on the convex surface of the specimen afer bending

sane

Zane

ue

4. None ofthe above

16, When using racographs to qually welds, the acceptance standards used are found in:

4. ASME Section V

2° ASME Secton IX

2 ASME Secton il

4. The referencing code

17. AWPS must describe:

4. Essental variables

2. Nonessential variables

3. Supplementary essen variables when required fr notch toughness,

4. Allo ine above

18. APOR must deserve:

1. Nonessentl variables

2 Essental variables

4. Results of Welder Qualiicaton tests

4, Project deseripion & NDE methods

19,The____ ust cortiy the POR as accurate,

1. Inspector

2. Manufacturer or contractor

5 Welder

44 lof the above

20, For the SMAW process Is an essential verabe for the WES.

4. Groove design

2 Post Wels heat weatment (PIVHT)

3. Root

4 Method of ceaning

21, Forthe SAW process, son essential variable for the WPS,

4. Supplemental powdered filer motal (if used)

2 Fillor motaldlameter

5. Preneot maintenance

4. Adlon or delet of peering

22, The basi purpose of tosting a welders to establish tho welders

1, Knowledge of welding quirements

2. Abily te deposit sound wold metal

§3. mechonical abil to operate equipment

44. General tte toward welding inspectors

(CoPYiuoHT ©2005 -J.W. COLEY & CODEWEST ALL RIGHTS RESERVED-00 NOT COPY WITHOUT PERIESSION

ue

CODEWEST APLS53 PRESTUDY GUIDE ~ SEPT 2008

(COPYRIGHT © 2006 W COLEY & CODEWEST-ALL RIOTS RESERVED-0O NOT COPY WITHOUT PERMESION

28, The ecard ofa wees performance testis calle

1.PaR

2. war

3. wes

4. wea,

24, Ifa welder qualified with the manual SMAW process on Jan. t, 1997 and last welded with manus

'SMAW on March 16, 197, would he stl be qualited on October 7, 19572

1. Yes

2.No

25, Avwelder qualifying with te SMAW process with a double welded grcove weld fs qulfid to wel

1. Without backing

2 Wit bare metas

3. wit backing oly

4 wi Pt backing only

26, Immediate reteats of welders qualficatons coupons

1, shall use the same method

2. May use any metnes

5 Arenotalowed

4. Require Inspector approval

27. Woler performance quaification records must desrbe al the vaables spocifed.

4. Cesena & nonessential

2. Nenessentah

2 escent

4. Brazing

28, Avelder depositing 1/2 of weld mln thes ayers ina groove weld with the SMAW process ie

‘ualfled to dopost up to of weld meta

18

ar

5. Max tobe wolded

aie

28,"P" numbers are uso to designate groups of

4. Blectrodes

2 Fasc

3. Base melas

dni

20, A welder qualtying with P-No.21 is quatfied towels

1. PA -PAt OPA Patt

2 Ps-Pé

3.7.21 -P.25 0 P-21- P25

4 P21 to P21 only

‘CoPraiak ©2008-, W.COLEY & CODEWEST-ALL RIGHTS RESERVED.D9 NOT COPY WITHOUT PERMISSION

8

‘CODEWEST API.553 PRESTUDY GUIDE - SEPT 2006

‘CoPyayon © 2008-s. COLEY & CODEWESTAL Rls RESERVED.00 NOT COPY WITHOUT PERKISSION

31. Section X groups welaing electrodes by

1. AWS cass

2 ASME specication

asa

4 number

132, Ferrous weld metal chemical composion may be designated using

4. °P number

2 Welder tb.

3."At number

4 page numer

39, Forwelderquaiicaton wth the SMAW process |s an essential varabl

4. Base metal thickness

2 Peening

5: Perumbar

4. Blecvode diameter

£4, Each welder must be assigned

41. P eumber

2 Unique denier

3. Hood & gloves

4 Inspector

35, Awelder qualification coupon welded inthe 2G postion of SI16" thick plate material must have how

‘any root an face bens

36, AWPS shall have:

4. the weldecreterencea.

2 the POR reterencod

5. he NACE retorenced,

44. the PDO referenced

7. Walding in the 16 postion qualifies a welder in what postion?

1. norzonal

2.verea

3 tat

4 ovemend

£38, Which ofthe fllonng isan excental variable for quaifiation of an SMAW welcing procedure?

1° number

2 joint design

5. dameter ofthe electrode

4 ppe ameter

Covrac se-. cotEY 8 CODEMESAL HOTS RESERVED-00 NOT COPY ADT PERUSSION

‘CODEWEST APL.S53 PRESTUDY GUIDE - SEPT 2006

‘COPYRIGHT © 208-1, COLE & CODEVIESTALL RIGHTS RESERVEDOO NOT COPY WITHOUT PERMISON

39, Awelder may be quatified by RT it

4. The frst ofthe fest production weld is raiogreshed,

2. the frst 6" ofthe frst production weld i radiograph ithe processes & mode alowed,

4 Ifthe frat production wold passes mechanical ess.

4 Ifthe frst producton wel Is passed by MT examination

40, Awalder may be qualified using RT in these processes except for

4. GMAW (shortiruling mode)

2. GMAW (pused-are)

3. GMAW (spray-areh)

4 SMAW

‘COPYRIGHT. t88- JM, COLEY &. CODEWEST.ALL IGITS RESERVED.0 NOT COPY WITHOUT PERMISSION

ist

‘CODEWEST APL-S53 PRESTUDY GUIDE - SEPT 2008

‘COPYRIGHT © 208-. W. COLEY& CODEWEST ALL Rls RESERVED.00 NOT COPY WITHOUT PERMISSION

ASME SECTION x ANSWER KEY

3 OWE

W100

7 aW-f00.1

racawe 100-5

2-aw-100:3

2rawe108.

s-awet0s,

SsLaw-ae1s

4aWer 8

0,|2-ow-461 9 OWES

ni, W308

i2.[3.0WeIr

3.4, ow-a04

14,4 GW. 163

5:|3, ow-t63

76.12, aW=81

a7], ow2007

6.2, ow-2002

“0.]2 ow-2002

20.12, W253

21.[1, W254

22.[2, OW-1002 230

23,4, QW-300.5 8 QW-201.4

‘2a [2 aw-s22.1

25.13, oW4024E OWSTOD

26.1, aW-321

20.3, oW-#s2.1

28, |3, W=i20

30,[3, W237

Si ]a.awast

s2:|s,aw-aar

35, [ 5, QW.355

34 [2-aw-a013

35] 1.aW52 +

36.12, w-200.176)

37_|3.QW-308.1 & WASTE

38 [1 ow.253

30,2 oW-aDe

ao. owss04

° 182

CODEWEST API653 PRESTUDY GUIDE ~ SEPT 2008

CCoPyivat© ate JW. COLEY & CODEWESTALL RIGHTS RESERVED. NOT COPY WITHOUT PERMISSION

PRacmice| FOR APIRP S77

WELDING AND INSPECTION METALLURGY

forthe traning anc expecence requed tobe an American Welding Society

4s replacement

bis nota replacement

«6, can bo sed as aerate

4 may be used 26a substitute

2. APLST7 all welds to be inspected,

requires

requis 50% of

©, Goes not quire

4. requis a representative number of

4. Who detomines the welds tobe inspected?

‘2. Operating upenisors andlor Facity Manager.

» Maltenanoe superdsors andlor welding supervisors

«, Welding lespacters andlor engineers.

4. Federal OSHA inspectors andor State inspectors

4, Who shoul bo consulted on any cral, specialized or complex welding issues?

‘8 Aweling engineer.

A maintenance engines.

2A Satay engineer

1. A Welding superior.

5, The shortest stance between the weld oot and the face of filet wel is calle:

‘4. Chord stance.

Bb Aredtance,

Actual treat

1. Tangent stance,

6. What ype of carbon are cutng process removes rotten metal with a jet of a?

‘Carbon ar ar blowing (CAA),

», Acarton are cuting (CAC-A)

© Carbon plasma area cutng (CPAA-C).

{Carbon fager ar removal (CLA),

7. Arc bows. ‘ofan are trom kts normal path because of magnetic ors,

bending

1. dircting

© detection

3 dstorton

(COPYEUGHT 8 2905. W.COLEY & CODEWEST-ALL RIGHTS RESERVED.00 ROT COPY WITHOUT PERMISSION

‘83

‘CODEWEST API-S53 PRESTUDY GUIDE - SEPT 2006

(COPYRIGHT 2205 W.COLEY& CODEWEST-ALL RIGHTS RESERVED D0 NOT COPY WITHOUT PERMISSION

8. The distance from the tp ofthe welding electrode tothe adjacent surface of te weld pools called

‘a Eletode dstance,

, Weld stance,

«, Poo stance,

‘6. Alength

8. A ascontinutyresutng from an ao, consisting of any located remolteg ta, heat affected metal, oF

‘change in the sutace pofie of any matal objects alles

a. an iroguariy

®. an anomaly

© an are ste.

5, awelder oor

10. A group of welding proseeses that produces coalescence of work pieces by heating them with an are

Ta cabed

«2. ecetylane welding,

goat welding.

© ecalescence welding

srewaldng.

14. fusion weld hate made without flr meta scales

a. a synthesis wel

», an autogenous weld

©. moten vets,

1. shore meta wes

12. Amaterial r dovice placed agains the backside ofthe weld jin, at both sides of weld in

‘woldng, to support and retain motion wold metals eallod

2. backing

© atusion consumable.

© anassisance te

1. consumable neon.

49. The ac of penetrating @ thin component with the welding are while hot ap welding or n-senvice

welding sealed

1 excessive penetration.

burnhrough,

fusion meting,

malt down.

“14. fracture type discontiny characterized by a sharp ip and high ratio of length and width to

‘pening deplacement scaled

2. efractre,

Ba faw.

a crack

@.afesure,

‘COPYRIGHT © 208-. W.COLEY & CODEWWEST-ALL RIGHTS RESERVED-00 KOT COPY WITHOUT PERIESSION

184

‘CODEWEST APL653 PRESTUDY GUIDE - SEPT 2008

‘COPYRIGHT © 2006 -s.W. COLEY & COOEWEST ALL. AOS RESERVED.DO NOT COPY WITHOUT PERMISSION

15, A wal with this term used to cescribe a condition In itwilldesignate rejecabalty ofthe weld, What is

this ter?

2. Fw

Discontinuity.

Blemish

Detect,

16. Wat san interupton ofthe typical structure ofa materia, such as afck of homogenety in ts

‘mechanical, metalurical. or physical characterises caled?

a Menor

b. Adisoontouty.

Ablemish

«Am impertecton

17. The meta or aloy metal added in making a welded joint is cao:

2. fusion meta

©, matiod meta

© moten metal

6 ler metal

18. A non-standard term used to describe weld ntrace is:

2. bevel tin.

grove ine

©. afsion ine

4. penetraton ine

10. Th porton of te base metal whose mechanical properties or microstructure have beon altred by

tho heat of wolsing or tecmalcuting Is cated

2. heat penetration region.

B: temper affected zone,

fusion affected area

heat afected zone

20, If foreign sod materials entrapped in a weld (slag, Fux, oxites, et) tis referred to as:

afew,

be detec.

an nchsion,

an imperterton

2, Ajoint oat contin n a groove wel in which wold metal doos not extend trough the joint hekness

Teale

2. slag nctesion

ban unnishes weld to,

© petal wele

«incomplete joint penetration

‘COPYRIGHT © 200-s. W.COLEY& CODEWEST-ALL RIGHTS RESERVED-00 NOT COPY WITHOUT PERINSSION

155

CODEWEST APLS53 PRESTUDY GUIDE SEPT 2008

‘eoPYAIGHF ©2008 -y. W-COLEY & COOEWEST-ALL RIGHTS RESEAVED.00 NOT COPY WITHOUT PERMISSION

22, Which ofthe tees indus isnot a qualfed inspector?

‘2. Cetied API 510 inspector,

AWS CW

©, ASNT Lev! inspectr.

4. National Boaré Commissioned inspector.

23, Whatis another common term fr a mage Qualty Incietor?

1. Photometer.

24, The datanc the weld metal extends from the welé face into a jon, exclusive of weld reinforcernent is

‘ales:

2. pnt wold distance

joint penetraton.

¢ joint tachment.

ont eat aected zone

25, Which ofthe joints std below isnot considered "in type"?

2. Buttoint

Filet in

1 Comer joint

Lap oin

25, Anon tana ter indizating 2 Wald diecontinly in whic usin Ad nator between wel mata

‘and fusion faces or ajoning weld beads Is refered to 2s:

2. srcblow.

1. burnstrough,

lack of ion.

6 lemelar tear

27. Ape ot cont wt separation or weakness goreray lend paral te worked sre

‘ammelalis calod

2. alametar

an oveiap

a lamination

6. asin ine

28. A crack that runs approximately parallel tothe wed axis is calle:

alam crack,

6a crectonal sack

8 naar clscontnuly

6 a longitude rack

‘COPYANGHT 0206-1. COLEY & CODEWEST.ALL RIGS REBERVED-DO NOT COPY WITHOUT PERMISSION

156

‘CODEWEST APL-S53 PRESTUDY GUIDE— SEPT 2006

‘coPyRici 8 2006. W-COLEY & CODEWES-AU RIGHTS RESERVED.0O NOT COPY VITHOUT PERMISSION

28, Ia welder "hammers or mechanically works the metal using impact bows, what Walled?

«Peering

Hammering,

©, Mechanical stress roving

Knocking slag.

20, tra metalisnoatad toa temperature pir to welding or rtiating thormal operations, is called:

8. post nest

preheat

© paren meta eating.

«primary heating

831. Two places of pat are to be joined by butt welding. The plates have boon beveled, The two plates

‘are separated approximately 11" pro o welding, Whats this opening called?

2 Wold space.

A weld separation

Awoldg gap.

root opening,

52, Aweld thats made to hold parts ofa welément In proper alignment unl the final welds ae made I

ales

fa tack wold

ba fastonor wo

© an atlachment weld

4. an nil wel

28, crack wit ts major ais oriented approximately perpendicular to the weld exis is called:

1. anonivectonal rack

1 a perpendicular rack

© slamelar crack.

6. a ransverse crack

34. A groove meted int th base metal adjacent othe wel oe or weld foot and et uniied by wold

‘mela ical

2. an under f.

6: alongtudina groove

© an undercut

4 gidrecfonal groove

35, An individual who holds an engineering degree an is knowledgeable and experienced inthe

‘gineering disciines associated with welding Is

2. a welding engineer.

aweidng spect.

© a motargst

4. awelding expen,

‘COPYRIGT 208 -J.W.COLEY & CODEWEST-ALL RIGHTS RESERVED.D0 NOT COPY WITHOUT PERMISSION

7

‘CODEWEST APLSS3 PRESTUDY GUIDE - SEPT 2008

LComYRIGIT © 2008 -s, W.COLEY & CODEWESTALL RIGHTS RESERVED.0O NOT COPY WTHOUT PERMISSION

38. Weld metal n excess of the quan required to fia jini cle

a. excess wold

weld reinforcement

weld strengthening

agora wold

857. Tivee ofthe tems leted below ae welding inspection activites that can be separated into thee

‘lages corresponding fo the welding work process. Which one does rol belong?

2. Tasks pir fo welding

©. Tasks curing welding operations,

Tasks upon completion of weld.

Tasks in selecting personne

38, Some of he quay contol tems dealing wih procedures ard qualticaton records of wear for an

Inspector fo ascess are lated below. Which cf ha 4 tems does not belong”?

Make sure WPS(s) are propery qualified and meet applicable codes, standards and specications

©. Make sure procedure quaicaton coords (POR) are propery performed & supported by WPS{S),

© Make sure PWHT information is eval,

Make sure welder performance qualifications (WPO) meet requirements forthe WPS,

30, What does an Inepactor do fhe a that improperly marked flor materials or naperopite base

‘materiale are onthe job?

2. Callie welding engineer.

5. Acoopt them eandtonaly,

Notify the welder foreman,

40, WhoIs responsible forthe quality and casmanship of weldments?

The weler,

1. The walding foreman,

€ The inspector

Tho welding engineer.

“41, When an inspector completes physical checks, visual examinations end resus of NDE and

‘Unacooptable wockranship is found, what should be done?

Nott the welder.

©. Calle walding engineer.

© Aczapt the workmanship the Roms are minor.

6 Reject the workmanship.

42, Some othe hazards thatthe inspector would mee commonly encounter in he presence of welding

‘ar isted below. Which tem does not belong?

2. Aroradiaton.

B.Arreontarinaton

© Heat

16 Nowe.

‘COPYRIGHT © 200-3. 1, COLEY & CODEWEST.ALL RIGHTS RESERVED.00 NOT COPY WITHOUT PERMISSION

‘158

‘CODEWEST APLES9 PRESTUDY GUIDE - SEPT 2008

‘COPYRIGHT © 2008 -s. Wi COLEY & CODEWEST ALL RIS RESERVED-00 NOT COPY WITHOUT FERBISSION

42, Whats the source of ultraviolet and inkared ght connected with wesing.

‘a The sunight on some jobs.

1 The welders elete are.

The Xray technicians equipment.

44. The NDE teonniians use of an ntared t

48, Wats the danger faced in an enclosed space if welders using a gasshildod process fr

welng?

2 Itcan cause air-bome pares.

© Itcan generate onic gases.

¢Itean sause an oxygen cefelent environment

6. ean cause burs t be stn.

45, Which of te basic arc welding processes isthe most widely used?

2. GMAW

bSMAW

©. GTAW

SAW

4, Home shieling proved forthe arc when using & consumable covered electrode in shaded metal

‘are welding?

‘2. Shleng ls provided from a fux tom the center of a tubular aectode

'. Shleding is provided from the sig coming fam the elecrode covering,

© Shieleng is provided by a shielding gas.

4. Shisting is provided from the decompostion ofthe electrode covering.

47. What are some disadvantages or iitaons of shelled metal arc welding?

‘2, Diu to shld the weld zone in a crafts and it has a low tolerance for contaminants on fer oF

‘base metal,

'b, Welding are must be protected rom al drafts andthe equipments moce expensive,

. Dapostio rates are low and slag must be removed at stops and sar,

6. Siag requires removal between passes and backing material is required fr root pass welding,

48 What oes the DCEN stand fr when used to describe the GTAW weld process?

{. DGEN stands for direct centored electrode.

.DCEN stands for direct curentelectode-negative

© DCEN stands for dominant contaminant elimination codular.

CEN stands fe distance containing electron-negatve.

49, What are some ofthe advantages to ges tungsten are welding?

2 Its the only consumable electrode process that can be used to weld most commercial metals and

‘atoys.

». Itpreduoes high purly welds and Ilalows fo excatent contol of root pass weld penetration.

©. thas aRgn depositon rate and motalugicl benefits fat can be dtved from 2 fx

{itis considered an al- postion process and thas a high producti rate compared with manly

‘welling studs to base metal

‘COPYRIGHT © 2008-s, W COLEY & CODENESALL RIGHTS RESERVED-00 NOT COPY WITHOUT PERMISSION

488

CODEWEST APLGS9 PRESTUDY GUIDE - SEPT 2006

‘COPYRIGHT 6 200-1. COLEY& CODEWEST-ALL RIGHTS RESERVED-DO NOT COPY WITHOUT PERMISSION

‘50, What a welding procoss that produces fas freezing weld pool and fs generally suited for joining

thin sections or oot passes.

a. cuaWs

bSMAW

FAW

c.GTAW

'51, What yp of wala process normally employs 8 semlautomstc mose and depends on a fx from 8

tubular electrode that contains a sheling gas fom an external suppiod gos?

a. sMAW

bFCAW

8 GMAW

4 craw

52, What ype of wolg s used extensively in shop preesute vessel fabrication and pipe manutacturing?

a FOAW

B.cTaW

© SMAW

4.sAW

‘53, What ype of welding process is predominant miedo welding insulation and reractry support

in fo (NK, pressure vessols and heater casings?

saw

bsMaW

sw

'54, ASME Section K requires a witen Welding procedure speciicaton (WPS). What does the WPS

‘provide forthe weléer?

4 Itprovites at of documents such as ASME, API 571, el. thatthe welder must foow.

2 itproviee guidelnes or the welder to prevent him fromh making mechanical erors in welding

ltprotdes 9 record ofthe welding data and variables used to weld a test coupon and the test resus.

4 Itprovies drecton fr the weer wile making production welds to ASME Code requirements.

155, Escotal variates, the mechanical properties of the weld

a indicate

Bdreet

offen

specty

58, Non-essential variables do not the mechanical properties ofthe weld.

ii

‘copriicir ©2008 -s, W, COLEY & CODEWEST-ALL RIGHTS RESERVED-00 NOT COPY WITHOUT PERIASSION

‘160

‘CODEWEST API.655 PRESTUDY GUIDE - SEPT 2008

Ccopritont © 2008-s W COLEY 8 CODENESTAUL RIGHTS RESERVED-00 NOT COPY WITHOUT PERISSION

S57. Ifyou change an essential variable in the WS you must

‘a. make sure the change is writ n onthe WS.

we e now WPS.

© requ the WPS.

4 lat he change 28 a supement to he WES.

158, Ithere are supplementary essential variables, they ae reated as, han they apply.

2. esconial variables

-non-essental variables

other requirements

6. end user drectons

£50, Thre of he lems sted below are exsental varabes. One isnot an essential variable, Mark the

incorrect itn

2. Base meta

Welding poston.

© Groove design,

6, Wetding technique.

60, Forte POR, test sample selection and testing requirements are defined

«2, Nationa! Boar of Boller and Pressure Vessol Inspection Code

1. APIR® 677, Weldng Inspection ané Metalurgy

ASME BAPY Code, Secon IX

ASME BEPV Code, Section V.

(01. Who SIIALL evew the WDE andthe POR prior to welding?

2. Omens

© Inspectors.

Contactors

6. Superisors,

(62, Fouritoms that must be included on the POR are listed below, One of these fur fs incorec. Mark

‘th incorrect Rem,

‘4. Conticaton signature ard dato.

Name ofthe nidual that prepared the procedur,

©, WP5{s) that he POR supports.

4. Welding process used

168, Wat isthe range of welding P-cumbes for Tesnium and itaniu-base aloys?

‘2 P-No. 1 thoogh Pao. 11

B.P-No. 51 rough Po. 54

1 PeNo. 21 through P-NO. 25,

‘4. P-No.81 through P-No. 62

“COPYRIGHT © 20h W.COLEY & CODEWEST.ALL RIOTS RESERVED.90 NOT COPY WITHOUT PERMISSION

‘ot

‘CODEWEST API.653 PRESTUDY GUIDE ~ SEPT 2006

‘copys #200. W COLEY & CODEWESTALL firs RESERVED-D0 HOY COPY WITHOUT PERMISSION

14 Why ae base metals assigned P-numbers in ASME Section IX?

8 It done to make it easier forthe welder.

© Its done fo simpy the classe of ler metal used in welding

©: Ils done to reduce the numberof welding procedure qualifications requires.

6 Its done to make the Inspector's and supervisor’ jobs simples.

£85. Why are eloctodes and welding rods assigned numbers?

a. Its done to simply te classes of ler metas used in welding.

Bis done to reduce the numberof welding procedure and performance qualifications requied

Its done to mace the inspector’ and superiors jobs easier.

4. ts done to make the welders job simp.

(68. Whatis the A-rumber grouping based upon?

«itl based one type materia tha the weld metals used upon

© itis based on the chemical eompostion of the deposited weld metal

6 is basod on the usbily characteristics of he mata

Iti based on the comparable base metal ulimate srength values.

67, Why do you sora waldng consumables in warm helting ovens aftr they have been removed from

‘he manufactures packaging?

‘2. This fs done to preserve the manufactrers expiration dates on the ro.

Tris done fo keep te temperature down especally in hol cimates

©. The s done to reduce exposure to moisture

4. Ths I done to make sure alls ar located in a.centra place of easy access.

(68, Wnycheuld low hydrogen slectodae be cored soparatay fom othor typos of electrodes ith

higher hydrogen content?

‘4, Because this can be another souree fr hyskegen pick-up.

b, Because they wl pick up charecterstcs ofthe cher electrodes.

© Baoause tis can be a soure for excess nifegen pick-up.

4. Because the low-hycrogen electrodes wil contaminate the other electrodes,

(69. Avalder may be qualified three diferent ways, Four are fst below. Which the incorrect one?

2. Quali by ralography of test coupon

5. Qualitea by an intel prodcton weld

6 Qualfod by bend test fa test coupon,

4. Qualied by the wittn akay of the contacto.

70. lf any essential variable sted forthe welding process changes:

4. the welder dows not have fo re-qualty for tat process.

b. the welder must re-qualy for that process.

«the welder can gual for tat process by an exemption from fs employs.

the welder an qual for thal process by an excepton fom te testng agency.

COPYRIGHT 208-.. COLEY & CODEWEST-ALL RIGHTS RESERVED-D0 NOT COPY WIEHOUT PERMISSION

402

(CODEWEST APL.S83 PRESTUDY GUIDE~ SEPT 2008 y

CCopYR4air © 2006. W. COLEY & CODGWESTALL RIGHTS AESERVED-D0 NOT COPY WITHOUT PERMESSION

71. Ita radiographic examination is used fo: qualification of a welder, the minimum length ofthe coupon

to be examined i

1. 4inches and it in ncudes at inact two thirds the rcumferenca for pipe coupons. i

12 Inches and f includes atleast one raf the crcurferenca fr pipe coupons.

© Binches ane Includes the entre weld circumference for pipe coupons.

4. B inches andi includes the entre wel forthe pipe coupons. .

72 Rls fr qutfcton of wing corto sing agaphyreaite sen |

‘oor sonia

2.1 foot

Db Binches

© Steet

Diet i

73. Welder perfomance qulfiaton expires ifthe welding process is not used ducing &

period |

2.40 month

SB fourmanth

esx month |

6. beve month

74, What the dfrition of non-destructive examination? 7

4 Itisinepacton methods, which alow materia tobe examined without changing o destroying teit

Usefulness. -

b.Ilis inspection metnods approved by ASNT, which alow materials tobe examine by, UT, RT, ET, (

Vr AF PT. ACEM and MY. ‘

«. te inspection methods, which require materi oe examined by minimal destrucivo mothods by

certified personne.

4's inpscon methods, which require materials to be examined by personnel who are qualified end |

‘cenfis.

75, What ar the most commoniy uses NDE methods used during weld inepeeton? NOTE: SELECT THE Hl

ANSWER THAT HAS ALL THE CORRECT METHODS! |

5

ie

78, Were would you lok for slg inclusion scones? |

2. Base meta zone and the HAZ.

3 Wes metal zone and wel terface.

© Base metal zane and the weld metal Btween passes,

4. Wee interface zone and wel oe o rent surface

‘convict 926 , W. COLEY & CODEWEST-ALL Rais RESERVED.20 NOY COPY WITHOUT PERMISSION

163 :

‘CODEWEST APL.S53 PRESTUDY GUIDE SEPT 2008

‘COPYRIGHT 6 208. COLEY B CODEWEST-ALL RCHTE RESERVED.OO NOT COPY WTHOUT PERISSION

‘TT Which NDE method is the most acceptable for lap Jlnt?

et

bur

RT

oer

78. What ie the most capable NDE method for hing a clscontnuly such ss incomplete fusion in joint?

avt

bar

RT

aur

79. When welding carbon ste, whats the malor cause o ack of fusion in al welding processes?

proper wecing speed,

5. Improper heat input anc improper welding technique.

Not using alow hydrogen alecredo, improper sriekéng

1. Improper are lang coir

80, When welding stainless stot, whats the cause of undercut?

a. Fast travel speed,

Improper heat input.

©. Improper ar length contol

6. Improper elesning.

‘51. When welding stainless sta! what woul cause porsiy in the weld?

2, Improper heat input and improper joint des.

© Improper shielding, not using law hydrogen electrode, & wen in @ Nigh suur area

High heat input andar length cont

{Improper leaning end are length conto.

£2, Wien wezing carbon steel, how would you contr! burn through?

2. Reduce the travel speed,

Control the ac lent

«Use proper heat input

6. Use proper leaning methods.

62, Who i responsible for establishing writen mater verieaton program (Ply?

2. The inspector.

1. The cumeruser.

The welder

1. The contactor

£84, What document gives guidelines for material contol and verieaton?

2 NBIC latest exiton

ASME BAPV Code Sec. V

C.APIRP S77

API RP S78

cone 2e-JW GLEY §COBEHESTAL BETS RESERVED ONOTCOP THOU PRHESON

34

‘CODEWEST API-S5S PRESTUDY GUIDE - SEPT 2006

“GOPYRIOIT © 2008 -J. W. COLEY& CODEWEST ALL RlOT® RESERVED.D9 NOT COPY WITHOUT PERMISSION

85, Visual examination isthe most extensively used NDE method fr inspecting welds, Direct visu !

“exomination is conducted when aooess s sufcent to pace the ye win ofthe surface.

‘a4 Inches to 18 inches ;

Bg ines to 24 inchs |

€,Binches to 20 inches

46. 0Inches © 35 inches fl

86, Direct yeual examination of @ weld must be done atan angle of not ess then _ ofthe surface to

be examined

2.25 degrees

B30 degrees

35 degrees ,

a0 degrees |

47. Remote examination of welds may use lds such as telescopes, borescopes, fberscopes, cameras or

‘cher cutable nstumets, provided |

«they havea resolution atleast equivalent o that which tained by direct visual examination.

they havea grataracuty than the eye and the inspection would be bef then a dec visu

«©. they have good perception & the inspection would be epproxmately equal to s direct visual exam. |

16 tey have sent to fns the possible detocts that acrect visual am would produce.

188, How often must an invidval using visual inspeson of walis complete @J+t Jaegeraype eye vision fl

test?

sony -

& Semiom

© ‘Semen t

Tren

80, Wich visual inspection tcl sted below sa mechanical ad for visual inspecting welds?