Professional Documents

Culture Documents

20 Tips On Prevention of Slagging Combined PDF

20 Tips On Prevention of Slagging Combined PDF

Uploaded by

Debabrata Ghosh0 ratings0% found this document useful (0 votes)

7 views2 pagesOriginal Title

20-Tips-on-prevention-of-Slagging-combined.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pages20 Tips On Prevention of Slagging Combined PDF

20 Tips On Prevention of Slagging Combined PDF

Uploaded by

Debabrata GhoshCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

se good walk owns and/or permanent cameras to idetiy

slag bfore it bacomes a problem inthe St the plant can then

Shit rom a "ermal to “aggresive sootbowing/ leaning

‘mote of operation to manage or remove the cinker online.

Take Acton rather than wating fra forced outage.

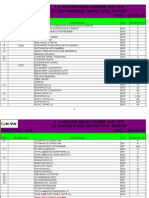

20 Tips to help Prevent Slaj

‘od coniol ofthe funace ext conto to minimize or top

slogging. (Proper & uniform 0} and Tempereture] Uniform

furnace eat conditions across the furnace (7/03)

Aepostion (Uniform gis more easy managed.

‘monkorng ofthe FEGT I KEY. Oporatrs need be aware of

FEGT to optimize their oanng srateges ona make

djstments. Trust but voy optical, scour and eacuatod

FEGT. High Velocty Trmoeoupla Testing isthe Gold standard

CfFEGT measurement HVT meatus bulk and decrote polnt

temperatures.

‘ert overuse OFA Ox can be "oo good” ~ the

bbonoisof overstaging willbe short ved

Practice “preventative” not “eactive” sot blowing by

leaning Water wall, reducing FEGT and lagging

onatons. Keeping the wal clean and lowering

‘eenacetemperturs can alto reduce NOx sometimes

se much 96 15%

‘ow your coal bore enters the nace (Operator

_warenes) Conrl the col quality sues that you

Ihave convo of, “Pent” coal qulty conto tats nthe

‘coal yard, Raw coal sings mts (oa pile

‘management, coo deying (il ovtet temperature]

nd fineness

Optimise lower fumace fl & ar interacons to

‘maximize water wal heat ebsorpon,

Pulverizer performances real to prventinglower

furnace slag/eiakers.Avoidthe "pet foctor

)S

to hel,

Prevent Slaggin;

Boller setting alr ngress minimized; fumace Os

not low with normal economizer exit O,

SH/RH Heating sutace areas optimized — Good

steam temperatures with FEGT ator less than ash

softening temperature.

Help pendant/platens clean themselves by

‘removing slag anchor points such a5 certain types

‘of wrapper tubes, alignment lugs and rigid

lignment/tie bats to allow some “swinging” of

the pendants.

Soot blowing technologies have also advanced a

long way from a pipe with two holes ~ Ensure

soot blower PM's. are being completed to

maximize soot blowing effectiveness.

Amount of heat absorbed by the water walls

.,tegulates Furnace Exit Gas Temperature. LOOK at

the water walls know what you're looking for.

(slageing Conditions)

Remember the boiler is # heat engine, get the

Inputs right. Fuel and air need to be in the right

places in the right amounts.

Bir heater i lean & well maintained: high DP oF

Leakage doesn’t lower furnace O, due to fan

capacity.

Practice prevention of slag rather than managing slag

fents Listen to your bolle when it tells you iti

fevers ~ high exit gas temperatures or FEGT, hot tubes,

vornting high spray flows, ash spills dark bottom ash or

‘iy ash, Shortness of breath ~ ID and FD fan limitations,

gh DPs and low wind box pressures

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Science Action BOOK-4Document62 pagesScience Action BOOK-4saisssms9116No ratings yet

- 101 Science EXPERIMENTS WITH PAPERDocument49 pages101 Science EXPERIMENTS WITH PAPERsaisssms9116100% (5)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- How To Make Playground Using TyresDocument117 pagesHow To Make Playground Using Tyressaisssms9116100% (5)

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Science Action-BOOK 5Document64 pagesScience Action-BOOK 5saisssms9116No ratings yet

- TATA320 Crane ManualDocument45 pagesTATA320 Crane Manualkatepol826450% (4)

- Simple Science ExperimentsDocument59 pagesSimple Science ExperimentsArsalan Ahmed Usmani100% (4)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Premium Transmission Gear BoxDocument80 pagesPremium Transmission Gear BoxShipra Shalini83% (6)

- Premium Transmission Gear BoxDocument80 pagesPremium Transmission Gear BoxShipra Shalini83% (6)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Fan Inspection ReportDocument24 pagesFan Inspection Reportsaisssms9116No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Book ChassisDocument52 pagesBook ChassisanglianwarriorNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Basic WeldingDocument40 pagesBasic WeldingVishnu Vardhan . C100% (9)

- Science Action - BOOK 3Document49 pagesScience Action - BOOK 3saisssms9116No ratings yet

- ASME Coal Sampling Test ProcedureDocument4 pagesASME Coal Sampling Test ProcedureRoby SzNo ratings yet

- Electrodes CalculationDocument6 pagesElectrodes CalculationVijay RajNo ratings yet

- Afs OimDocument135 pagesAfs OimRajesh TopiyaNo ratings yet

- List ASME Standards ListDocument1 pageList ASME Standards ListKeyur PatelNo ratings yet

- Schieldrop Schieldrop: Wesman WesmanDocument1 pageSchieldrop Schieldrop: Wesman Wesmansaisssms9116No ratings yet

- Amrita School of Engineering: Accredited by NAAC With A' GradeDocument2 pagesAmrita School of Engineering: Accredited by NAAC With A' Gradesaisssms9116No ratings yet

- North East of Scotland Science Consortium: Learning and Concept MapsDocument50 pagesNorth East of Scotland Science Consortium: Learning and Concept Mapssaisssms9116No ratings yet

- Troubleshooting Coal FeedersDocument3 pagesTroubleshooting Coal Feederssaisssms9116No ratings yet

- WasheryDocument4 pagesWasherysaisssms9116No ratings yet

- FRPDocument6 pagesFRPsaisssms9116No ratings yet

- Belt Conveyors: Mechanical Engineering Department Carlos III UniversityDocument19 pagesBelt Conveyors: Mechanical Engineering Department Carlos III UniversityMohamed MaherNo ratings yet

- Dome ValveDocument6 pagesDome Valvesaisssms9116No ratings yet

- Water Rocket Design ProjectDocument8 pagesWater Rocket Design Projectsaisssms9116No ratings yet

- Science Expeiments Using MirrorsDocument54 pagesScience Expeiments Using Mirrorssaisssms9116No ratings yet

- LOW COST EQUIPMENT For Sci Ence and Techno Logy EducatiDocument217 pagesLOW COST EQUIPMENT For Sci Ence and Techno Logy Educatisaisssms9116No ratings yet

- Science Action - BOOK 2Document46 pagesScience Action - BOOK 2saisssms911650% (2)