Professional Documents

Culture Documents

S3000 Common Rail Test System Data

Uploaded by

صلاح طه السيدOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S3000 Common Rail Test System Data

Uploaded by

صلاح طه السيدCopyright:

Available Formats

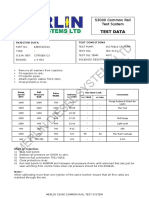

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 095000-0360 TEST PUMP: SUITABLE CR PUMP

TYPE: 970950-0036 TEST OIL: ISO 4113

O.E.M. REF: VAUXHALL/OPEL/RENAULT/SAAB TEST OIL TEMP: 40°C

ENGINE: 3.0L SOLENOID RESISTANCE @ 20°C - 600m

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

Purge System & Check for

1000 1000 700 N/A - -

Leaks

1500 1350 900 95-100 <60.0 <90.0 Max Fuel

400 250 700 10-13 <30.0 <12.0 Idle

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

400 150-250 700 N/A - - S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-0510 Testing Prerequisites

16600-8H800 Mount Suitable Test Pump

Type Designation:- ref alla148p765 Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- NISSAN X TRAIL Test Oil Temperature- 40 C

EM

Engine:- EURO 3 Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 135-145 <50.0 Max Fuel

400 250 700 20-22 <30.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 095000-0530 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: TOYOTA LANDCRUISER TEST OIL TEMP: 40°C

ENGINE: 3.0TD, 1KD-FTV SOLENOID RESISTANCE @ 20°C - 600m

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

Purge System & Check for

1000 1000 700 N/A - -

Leaks

1500 1350 900 110-120 <60.0 <90.0 Max Fuel

400 250 700 12-16 <30.0 <12.0 Idle

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

400 150-250 700 N/A - - S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-0570 Testing Prerequisites

Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- Test Oil Temperature- 40 C

EM

Engine:- Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 75.0-79.0 Max Fuel

400 250 700 10-15 <30.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 095000-0750 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: TOYOTA LANDCRUISER TEST OIL TEMP: 40°C

ENGINE: 3.0TD, 1KD-FTV SOLENOID RESISTANCE @ 20°C - 600m

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

Purge System & Check for

1000 1000 700 N/A - -

Leaks

1500 1350 900 110-120 <60.0 <90.0 Max Fuel

400 250 700 12-16 <30.0 <12.0 Idle

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

400 150-250 700 N/A - - S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-0880 Testing Prerequisites

16600-AU600 Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- NISSAN PRIMERA Test Oil Temperature- 40 C

EM

Engine:- EURO 3 Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 95-105 <50.0 Max Fuel

400 250 700 15-20 <30.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-0940 Testing Prerequisites

Mount Suitable Test Pump

Type Designation:- -- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- TOYOTA HI-ACE Test Oil Temperature- 40 C

EM

Engine:- -- Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 85-95 <50.0 Max Fuel

400 250 700 14-16 <30.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-5080 Testing Prerequisites

Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- OPEL MERIVA Test Oil Temperature- 40 C

EM

Engine:- 4EE2 - ISUZU Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 90.0-95.0 <50.0 Max Fuel

400 250 700 10.0-12.0 <30.0 Idle

2000 1350 Run pump only N/A <12.5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-513# Testing Prerequisites

AW402-AW4 Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- NISSAN X TRAIL Test Oil Temperature- 40 C

EM

Engine:- EURO 3 Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 145-160 <50.0 Max Fuel

400 250 700 12-14 <30.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

D

PART No: 095000-5473 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

LT

O.E.M. REF: ISUZU-N SERIES TEST OIL TEMP: 40°C

ENGINE: - SOLENOID RESISTANCE @ 20°C - 600m

S

EM

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

ST

SY

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

L

Purge System & Check for

1000 1000 700 N/A - -

Leaks

SE

1500 1350 900 98-103 <50.0 <75.0 Max Fuel

400 250 700 2-4 <30.0 <12.0 Idle

IE

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

D

400 150-250 700 N/A - - S.O.I

N

Start of Injection

LI

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

ER

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

M

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

D

PART No: 095000-5600 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

LT

O.E.M. REF: MITSUBISHI L200 TEST OIL TEMP: 40°C

ENGINE: SOLENOID RESISTANCE @ 20°C - 600m

S

EM

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

ST

SY

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

L

Purge System & Check for

1000 1000 700 N/A - -

Leaks

SE

1500 1350 900 137-142 <50.0 <75.0 Max Fuel

400 250 700 12-16 <30.0 <12.0 Idle

IE

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

D

400 150-250 700 N/A - - S.O.I

N

Start of Injection

LI

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

ER

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

M

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-5650 Testing Prerequisites

Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- NISSAN PATHFINDER Test Oil Temperature- 40 C

EM

Engine:- YD25 Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Comments

RPM BAR cc/1000 Leak

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 180.0-190.0 <50.0 Max Fuel

400 250 700 24.0-28.0 <30.0 Idle

2000 1350 Run pump N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

D

PART No: 095000-5780 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

LT

O.E.M. REF: MAZDA TEST OIL TEMP: 40°C

ENGINE: SOLENOID RESISTANCE @ 20°C - 600m

S

EM

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

ST

SY

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

L

Purge System & Check for

1000 1000 700 N/A - -

Leaks

SE

1500 1350 900 100-110 <50.0 <75.0 Max Fuel

400 250 700 9-13 <30.0 <12.0 Idle

IE

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

D

400 150-250 700 N/A - - S.O.I

N

Start of Injection

LI

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

ER

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

M

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-5800 Testing Prerequisites

6C1Q-9KJ46 Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- FORD TRANSIT Test Oil Temperature- 40 C

EM

Engine:- PUMA 2.2 EURO 4 Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 100-110 <50.0 Max Fuel

400 250 700 17-20 <30.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

D

PART No: 095000-6021 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

LT

O.E.M. REF: NISSAN X-TRAIL TEST OIL TEMP: 40°C

ENGINE: - SOLENOID RESISTANCE @ 20°C - 600m

S

EM

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

ST

SY

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

L

Purge System & Check for

1000 1000 700 N/A - -

Leaks

SE

1500 1350 900 87-92 <50.0 <75.0 Max Fuel

400 250 700 15-17 <30.0 <12.0 Idle

IE

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

D

400 150-250 700 N/A - - S.O.I

400 400 040 2.5-3.0 - - Pre Injection

N

LI

Start of Injection

ER

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

M

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 095000-6131 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: OPEL TEST OIL TEMP: 40°C

ENGINE: 1.7 CDTI SOLENOID RESISTANCE @ 20°C - 600m

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

Purge System & Check for

1000 1000 700 N/A - -

Leaks

1500 1350 900 115-125 <60.0 <90.0 Max Fuel

400 250 700 17-23 <30.0 <12.0 Idle

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

400 150-250 700 N/A - - S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 095000-6240 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: NISSAN NAVARA TEST OIL TEMP: 40°C

ENGINE: 2.5L SOLENOID RESISTANCE @ 20°C - 600m

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

Purge System & Check for

1000 1000 700 N/A - -

Leaks

1500 1350 900 115-120 <50.0 <75.0 Max Fuel

400 250 700 14-18 <30.0 <12.0 Idle

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

400 150-250 700 N/A - - S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-6250 Testing Prerequisites

Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- NISSAN PATHFINDER Test Oil Temperature- 40 C

EM

Engine:- Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Comments

RPM BAR cc/1000 Leak

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 190.0-200.0 <50.0 Max Fuel

400 250 700 20.0-25.0 <30.0 Idle

2000 1350 Run pump only N/A <12.5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 095000-7060 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: FORD TRANSIT TEST OIL TEMP: 40°C

ENGINE: 2.4L SOLENOID RESISTANCE @ 20°C - 600m

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

Purge System & Check for

1000 1000 700 N/A - -

Leaks

1500 1350 900 112-120 <50.0 <75.0 Max Fuel

400 250 700 13-19 <30.0 <12.0 Idle

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

400 150-250 700 N/A - - S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-7581 Testing Prerequisites

Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- Test Oil Temperature- 40 C

EM

Engine:-

Solenoid Resistance @ 20°C -

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 70-72 <50.0 Max Fuel

400 250 700 8-10 <20 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-7610 Testing Prerequisites

Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- Test Oil Temperature- 40 C

EM

Engine:-

Solenoid Resistance @ 20°C -

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 100 <50.0 Max Fuel

400 250 700 9-12 <30.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 095000-7640 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: TOYOTA RAV4, COROLLA VERSO TEST OIL TEMP: 40°C

ENGINE: 2.2L SOLENOID RESISTANCE @ 20°C - 600m

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

Purge System & Check for

1000 1000 700 N/A - -

Leaks

1500 1350 900 88-98 <60.0 <90.0 Max Fuel

400 250 700 8-13 <30.0 <12.0 Idle

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

400 150-250 700 N/A - - S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 095000-7670 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: TOYOTA TEST OIL TEMP: 40°C

ENGINE: D4D 2.0L SOLENOID RESISTANCE @ 20°C - 600m

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

Purge System & Check for

1000 1000 700 N/A - -

Leaks

1500 1350 900 80-90 <50.0 <75.0 Max Fuel

400 250 700 7-9 <30.0 <12.0 Idle

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

400 150-250 700 N/A - - S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-7730 Testing Prerequisites

Mount Suitable Test Pump

*SIN ON OLD

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- Test Oil Temperature- 40 C

EM

Engine:- Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 108-112 <50.0 Max Fuel

400 250 700 8-10 <30.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-7780 Testing Prerequisites

Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- Test Oil Temperature- 40 C

EM

Engine:- Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 100-110 <50.0 Max Fuel

400 250 700 10-12 <30.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

D

LT

Injector Designation:- 095000-7850 Testing Prerequisites

Mount Suitable Test Pump

Type Designation:- Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- Test Oil Temperature- 40 C

EM

Engine:- Solenoid Resistance @ 20°C - 600 m

ST

Pump Speed Rail Pressure Pulse Width Delivery Max Back Leak Comments

RPM BAR cc/1000 Mm3st/ccmin

SY

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

EL

1500 1350 900 98.0-103 Max Fuel

400 250 700 8.0-10.0 <20.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

S

400 150-250 700 N/A - S.O.I

IE

Start of Injection (S.O.I)

D

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

N

Note:-

When calibrating more than one injector of the same number ensure that all flow

LI

rates are matched through the set.

ER

M

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 095000-7890 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: SUBARU LEGACY, OUTBACK TEST OIL TEMP: 40°C

ENGINE: 2.0D SOLENOID RESISTANCE @ 20°C - 600m

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

Purge System & Check for

1000 1000 700 N/A - -

Leaks

1500 1350 900 125-135 <60.0 <90.0 Max Fuel

400 250 700 14-18 <30.0 <12.0 Idle

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

400 150-250 700 N/A - - S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA TEST CONDITIONS

PART No: 295050-0010 TEST PUMP: SUITABLE CR PUMP

TYPE: - TEST OIL: ISO 4113

O.E.M. REF: MAZDA 3, 6, CX7 TEST OIL TEMP: 40°C

ENGINE: 2.2 L SOLENOID RESISTANCE @ 20°C - 600m

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3901.

Close protective cover.

Pump Rail Max Back Leak

Pulse

Speed Pressure Delivery Comments

Width

RPM BAR cc/1000 cc/1000 cc/min

Purge System & Check for

1000 1000 700 N/A - -

Leaks

1500 1350 900 155-165 <60.0 <90.0 Max Fuel

400 250 700 13-17 <30.0 <12.0 Idle

Run pump

2000 1350 N/A <12.5 <25.0 Seat Test

only

400 150-250 700 N/A - - S.O.I

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection T031-3052.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

MERLIN S3000 COMMON RAIL TEST SYSTEM

You might also like

- S3000 Common Rail Test DataDocument20 pagesS3000 Common Rail Test Dataaddelyn_robescu8794100% (7)

- S3000 Common Rail Test System DataDocument28 pagesS3000 Common Rail Test System DataInkanata Sac94% (16)

- S3000 Common Rail Test System DataDocument28 pagesS3000 Common Rail Test System DataFernando SanchezNo ratings yet

- Siemens Injector Test Data New6Document20 pagesSiemens Injector Test Data New6cartronix2010100% (2)

- Delphi Injector Test PlansDocument21 pagesDelphi Injector Test PlansZauron Kent Touchit67% (6)

- Boschinjectortestplans 29 WEBDocument156 pagesBoschinjectortestplans 29 WEBedward06No ratings yet

- Siemens Injector Test Data New6 PDFDocument20 pagesSiemens Injector Test Data New6 PDFJuan David Cepeda GonzalesNo ratings yet

- Bosch CR Pumps Test Data PDFDocument146 pagesBosch CR Pumps Test Data PDFInyectronix Vyh100% (2)

- Siemens Injector Test Data New6 PDFDocument20 pagesSiemens Injector Test Data New6 PDFJose HasinNo ratings yet

- Inyectores Delphi Tabla ValoresDocument30 pagesInyectores Delphi Tabla Valoresbruttus139No ratings yet

- Denso Type CR Injector ShimsDocument11 pagesDenso Type CR Injector ShimsCostinDodenech100% (2)

- Modifikacii HP 3Document5 pagesModifikacii HP 3pankituna5487No ratings yet

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 pagesInj. Pump Calibration Data: 1. Test ConditionsEdinson Ariel Chavarro Quintero100% (2)

- Spare Parts Denso Common Rail InjectorsDocument10 pagesSpare Parts Denso Common Rail Injectorserdemsecen100% (5)

- TWO-SPRING NOZZLE HOLDER DATADocument60 pagesTWO-SPRING NOZZLE HOLDER DATAHector Jamaica100% (6)

- Bosch Injectoarek0008Document25 pagesBosch Injectoarek0008Polmot ImpexNo ratings yet

- Adjust 2-spring Nozzles and Nozzle HoldersDocument41 pagesAdjust 2-spring Nozzles and Nozzle HoldersCostas Ponehundred75% (4)

- DENSO X2 InstructionDocument13 pagesDENSO X2 InstructionAnonymous 5tkF5bFwO100% (3)

- Denso Injector Catalogue: Update 05/2020Document23 pagesDenso Injector Catalogue: Update 05/2020davide100% (1)

- VDO Diesel IAM Roadmap Q3 2018 ENDocument13 pagesVDO Diesel IAM Roadmap Q3 2018 ENLuis Miranda100% (2)

- EDocument34 pagesEEdinson Ariel Chavarro Quintero100% (1)

- Common Rail Injector Repair Tool Sets Instruction ManualDocument17 pagesCommon Rail Injector Repair Tool Sets Instruction ManualAnonymous 5tkF5bFwO100% (1)

- Marks On Bosch Common Rail InjectorsDocument25 pagesMarks On Bosch Common Rail InjectorsBarkat HussainNo ratings yet

- EPS 205 Frequently Asked Questions 2 8.28 PDFDocument32 pagesEPS 205 Frequently Asked Questions 2 8.28 PDFDarshan Diesel100% (2)

- Injection Pump Test Specifications 092000-512#Document3 pagesInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- Denso PDFDocument36 pagesDenso PDFGiovaniBalzani95% (22)

- Denso Cri Repair Guide v4Document22 pagesDenso Cri Repair Guide v4Oscar Delgado100% (4)

- Zexel VRZ PumpDocument12 pagesZexel VRZ PumpOscar Diaz Galvez80% (10)

- Pe and Tics Type Injection Pump Connector Part Numbers For North AmericaDocument9 pagesPe and Tics Type Injection Pump Connector Part Numbers For North AmericaSubhojit Samonta100% (1)

- CRI Injector Shim RefDocument5 pagesCRI Injector Shim RefGuler Rahim100% (3)

- Denso Control Valve & Rod 2016Document4 pagesDenso Control Valve & Rod 2016Екатерина КалашниковаNo ratings yet

- Common Rail Spare Parts ListDocument52 pagesCommon Rail Spare Parts Listcartronix2010100% (3)

- DELPHI Nozzles CatalogDocument16 pagesDELPHI Nozzles Cataloganshel100% (1)

- KIA INJECTION DATADocument2 pagesKIA INJECTION DATAEdinson Ariel Chavarro Quintero100% (2)

- Denso CR Injector Repair Kits 2015 PDF 1481112829Document22 pagesDenso CR Injector Repair Kits 2015 PDF 1481112829reza100% (1)

- 62 Bosch Crin Repair Instructions enDocument38 pages62 Bosch Crin Repair Instructions enBoris100% (29)

- Common Rail Parts CatalogueDocument20 pagesCommon Rail Parts CatalogueJUAN PABLO ACOSTANo ratings yet

- For Authorized Service Dealers Only: Fuel Injection Pump Technical Service Bulletin on PCV Unit Disassembly and Assembly ProcedureDocument4 pagesFor Authorized Service Dealers Only: Fuel Injection Pump Technical Service Bulletin on PCV Unit Disassembly and Assembly ProcedureDenisEcheverri100% (3)

- Denso CR Injector & Pump Repair Kits 2016Document24 pagesDenso CR Injector & Pump Repair Kits 2016Euro Diesel100% (7)

- 3239F592TDocument2 pages3239F592TAnderson London67% (3)

- MANUAL - Bosch CRIN 2.0 and 3.0 Common Rail InjectorsDocument24 pagesMANUAL - Bosch CRIN 2.0 and 3.0 Common Rail InjectorsLUIS SAENZ100% (4)

- JCB DELPHI PUMP-9520A500-509S03 - Iss 03Document7 pagesJCB DELPHI PUMP-9520A500-509S03 - Iss 03Ravikant Saini100% (2)

- Piezo ElectricmeteringDocument7 pagesPiezo Electricmeteringeko sulistyo utomo100% (1)

- Dpico: Inj. Pump Calibration DataDocument6 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniNo ratings yet

- Denso g4Document6 pagesDenso g4DenisEcheverri50% (4)

- Si460 PDFDocument4 pagesSi460 PDFFranky Fernandez100% (1)

- 4m41 Pump160061130 Bomba VE VRZ EE14E 11162 VRZ Service ManualDocument117 pages4m41 Pump160061130 Bomba VE VRZ EE14E 11162 VRZ Service Manualesyjam67% (3)

- Denso HP2 PUMP RepairDocument13 pagesDenso HP2 PUMP Repairphyladelphya4144100% (22)

- Fit For The Future:: Everything For Diesel ServiceDocument68 pagesFit For The Future:: Everything For Diesel Servicemihai37100% (2)

- Dpico: Inj. Pump Calibration DataDocument10 pagesDpico: Inj. Pump Calibration DataGiovaniBalzani100% (3)

- Common Rail Spare Parts ListDocument57 pagesCommon Rail Spare Parts Listbuztedcgycom67% (3)

- Denso FIRAD Catalogue PDFDocument20 pagesDenso FIRAD Catalogue PDFdchosgo2639No ratings yet

- Repair Denso PumpsDocument77 pagesRepair Denso PumpsAka Diesel93% (14)

- 101603-9093 Zexel Test DataDocument5 pages101603-9093 Zexel Test DataAnderson London100% (5)

- Illidio SerraDocument24 pagesIllidio SerraVictor GarciaNo ratings yet

- Denso-Injector PDFDocument20 pagesDenso-Injector PDFZauron Kent TouchitNo ratings yet

- Delphi Injector Test Plans 9 WebDocument26 pagesDelphi Injector Test Plans 9 WebAdrian MacayaNo ratings yet

- Merlin Diesel Systems Ltd injector calibration and testing documentationDocument126 pagesMerlin Diesel Systems Ltd injector calibration and testing documentationLucas Man100% (2)

- Delphiinjectortestplans 12WEBDocument30 pagesDelphiinjectortestplans 12WEBkampee100% (1)

- Siemens Pump Test Plans 4Document10 pagesSiemens Pump Test Plans 4DJAMel LNo ratings yet

- Delphi Spare Parts: Ref NO. Photo Oem NoDocument4 pagesDelphi Spare Parts: Ref NO. Photo Oem Noصلاح طه السيدNo ratings yet

- Cat Catalog Rev. 1Document15 pagesCat Catalog Rev. 1صلاح طه السيدNo ratings yet

- Nozzles and Spare Parts For: Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPSDocument9 pagesNozzles and Spare Parts For: Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPSصلاح طه السيدNo ratings yet

- Informacion de Toberas Precion y Bar.Document36 pagesInformacion de Toberas Precion y Bar.Jorge Rodolfo Yanez Escudero100% (1)

- Nozzles Catalogue: Automotive and Marine NozzlesDocument140 pagesNozzles Catalogue: Automotive and Marine NozzlesGiovaniBalzaniNo ratings yet

- Nozzles and Spare Parts For: Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPSDocument9 pagesNozzles and Spare Parts For: Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPSصلاح طه السيدNo ratings yet

- Stamping Reference GuideDocument170 pagesStamping Reference GuideMiguel Rojas100% (2)

- Nozzles and Spares For: Electronic Injectors Eui/Eup/Heui/UisDocument3 pagesNozzles and Spares For: Electronic Injectors Eui/Eup/Heui/Uisصلاح طه السيدNo ratings yet

- Denso PDFDocument12 pagesDenso PDFbruttus139No ratings yet

- Denso PDFDocument12 pagesDenso PDFbruttus139No ratings yet

- Study 175 Full ReportDocument113 pagesStudy 175 Full ReportAnonymous AXG8oYNo ratings yet

- Performance Analysis On 4-S Si Engine Fueled With HHO Gas and LPGDocument7 pagesPerformance Analysis On 4-S Si Engine Fueled With HHO Gas and LPGCornel BordeiNo ratings yet

- CatSU Engineering Chemistry Course Materials Provide Overview of Fuels and Energy GenerationDocument10 pagesCatSU Engineering Chemistry Course Materials Provide Overview of Fuels and Energy GenerationRomeo San GasparNo ratings yet

- WorldEnergyBalancesHighlights FinalDocument597 pagesWorldEnergyBalancesHighlights FinalDavid Rosenstand0% (1)

- Chapt 8 (Grade 10)Document15 pagesChapt 8 (Grade 10)Myint Myint HtweNo ratings yet

- Mineral Resources & Energy SourcesDocument3 pagesMineral Resources & Energy SourcesRAZE GAMER ZINDABADNo ratings yet

- Vertical Well All CasesDocument21 pagesVertical Well All CasesbhupenderNo ratings yet

- JETT Study on Bioethanol from Agricultural WastesDocument8 pagesJETT Study on Bioethanol from Agricultural WastesvitaNo ratings yet

- Prycegas LPG Personnel (Trainee)Document2 pagesPrycegas LPG Personnel (Trainee)Марк Артём Лимот АпаллаNo ratings yet

- ENG - Daily Record Utility - Maret 2016Document28 pagesENG - Daily Record Utility - Maret 2016hrd pelangiNo ratings yet

- Blending GasolineDocument32 pagesBlending GasolineDanu Bratakusuma100% (1)

- Vapor Phase Upgrading With NREL's Davison Circulating RiserDocument2 pagesVapor Phase Upgrading With NREL's Davison Circulating RiserNattapong PongbootNo ratings yet

- CR Calibration GasketsDocument4 pagesCR Calibration GasketsMiguel ChaconNo ratings yet

- Edexcel IGCSE Chemistry Topic 4: Organic ChemistryDocument3 pagesEdexcel IGCSE Chemistry Topic 4: Organic ChemistryAli Hasan MaherNo ratings yet

- Ge Progress Test 1 Level 2Document3 pagesGe Progress Test 1 Level 2Hà VânNo ratings yet

- Material Balance EquationsDocument4 pagesMaterial Balance EquationszazoNo ratings yet

- Cta Group Project ReferencesDocument6 pagesCta Group Project ReferencesDinaShieldDinaNo ratings yet

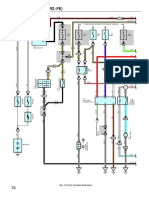

- Engine Control (3Rz-Fe) : 2001 Toyota Tacoma (Ewd440U)Document8 pagesEngine Control (3Rz-Fe) : 2001 Toyota Tacoma (Ewd440U)Omar ZernaNo ratings yet

- OIL REFINING PROCESSES Ver1 PDFDocument97 pagesOIL REFINING PROCESSES Ver1 PDFHiếu NguyễnNo ratings yet

- Lec 17Document3 pagesLec 17مروان ابراهيم حمد عبدNo ratings yet

- Datasheet - FluidScan LibraryDocument2 pagesDatasheet - FluidScan Libraryhouston machacaNo ratings yet

- 5000m3 LPG Tank FarmDocument2 pages5000m3 LPG Tank FarmLpgTankFarmNo ratings yet

- Revamping a CDU to Increase Safety and Reduce EnergyDocument4 pagesRevamping a CDU to Increase Safety and Reduce Energydharmendra singh bhatiNo ratings yet

- Petrochemical IndonesiaDocument43 pagesPetrochemical IndonesiaElfara PuspitaNo ratings yet

- Digboi MilestonesDocument3 pagesDigboi MilestonesIqubal HussainNo ratings yet

- SI NZ Power Station DataDocument490 pagesSI NZ Power Station DataJafar SadiqNo ratings yet

- Motorcycle Carburator Theory and TuningDocument5 pagesMotorcycle Carburator Theory and TuningRubisel Guillen EsparzaNo ratings yet

- COAL AND PETROLEUM: EXHAUSTING OUR RESOURCESDocument8 pagesCOAL AND PETROLEUM: EXHAUSTING OUR RESOURCESParam SukhwaniNo ratings yet

- Lecture 1-Gas Supply SystemDocument28 pagesLecture 1-Gas Supply SystemMuhammad FakhriNo ratings yet

- Final Test For Chemical Engineering - Brian Widyadhana-5213422045Document7 pagesFinal Test For Chemical Engineering - Brian Widyadhana-5213422045Brian WidyadhanaNo ratings yet