Professional Documents

Culture Documents

Company Profile Sinergi Servis Indonesia 2 PDF

Uploaded by

Doris Abadi0 ratings0% found this document useful (0 votes)

39 views24 pagesOriginal Title

Company Profile Sinergi Servis Indonesia 2.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views24 pagesCompany Profile Sinergi Servis Indonesia 2 PDF

Uploaded by

Doris AbadiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 24

SINERGI SERVIS INDONESIA

Specializing in:

Online Leak Sealing

PT. SINERGI SERVIS INDONESIA

‘Alamat : JI, Perum Bumi Indah No. 15 Ruko RD Tahap 1 Kutajaya Pasar Kemis Tangerang Banten

Email: sinergiservisindonesia@gmail.com

Telp: 081381393600

SCOMPANY IN BRIEF

We are a company that stands on the original Indonesian

with field specialists and valve reconditioning

repair leaks without shutting down the production process

or the online leak sealing

We have a lot of work in several companies, among

others , references petrochemical, power plant and other

industrial, and has compieted project with satisfactory results.

we believe could be a sub - contractor of your project.

We really appreciate it if you are interested in our company

and we look forward to working with your company.

We are also ready to work in our 24-hour full if indeed

we do the work shutdown or turn around. or there is

an emergency job leaks in pipes, flanges,elbows, gland

packing and valve bonnet (online leak sealing)

We also prepare workers, who experiendes job 24 - hour

emergency management

VISION and MISSION

Our Commitment is to become the leader in Online Leak

‘Sealing and Valve Repair arround Indonesia. We are

commited to our excellent service. we have a good

experienced team and qualified technical staff thats is

supported by excellent equipment, Procces and Quality

control system.

OUR MARKET

Our market has grown domestically. Expand arround

Indonesia, Like : Bandung, Tangerang, Java, Sumatera,

Kalimantan and other industrial park in Indonesia

Our Company is engaged in, among others :

> Online Leak Sealing

> Valve Repair & Reconditioning

PRODUCT FEATURE

Sealing Element :

> O-Ring

> Oil Seal

> Hydraulic Seals

> Pneumatic Seals

> Mechanical Seals

> Ete

HEAT EXCHANGER Competitive |

by Complying

> Tube Expantion

> Re-Tubing

> Cleaning Exchanger

> Bolting Service

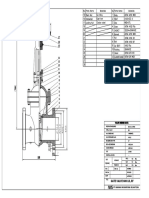

GATE, GLOBE AND CHECK VALVES PARALLEL SLIDE GATE VALVES

HATTERSLEY KTM HOPKINSON

HEATON KITZ TAYLOR REDUCING VALVES

TRIANGLE VELAN SHAW BAILEY

T KLINGER PETER SMITH SAMSON

CRANE KISHIKAWA BAILEY HOPKINSON

BONNY FORGE MALLEABLE DEWRANCE — BROADY

ALCO SAPAG YOSHITAKE

CONTROL VALVES BALL VALVES

SEVERN GLOCON MASONEILAN SERCK AUDCO KTM

SAMSON VALTEX WORCESTER NELES JAMESBURY

INTROL WAGI DAFRAM ARGUS

FISHER MOTOYAMA JAMESBURY KITZ

HONEYWEELL YAMATAKE HINDLE WAG!

ABB KENT NELES JAMESBURY | ATOMAC PLUG VALVES

FOXBORD we AUDCO_TUFLIN_DURCO

SAFETY VALVES BUTTERFLY VALVES

HOPKINSON FARRIS. TOMOE ORTON

FUKUI SEISAKUSHO crosay | AUDCO XOMOX

ANDERSON GREENWOOD BROADY DURCO MURBREY

ROCKWOOD SWEDEN LESER WOUTER WITZELL KEYSTONE

BAILEY BIRKETT NABIC SEETRU | VANESSA KITZ

REPAIR AND CALIBRATION OF KNIFE GAT!

IN CHEMICAL INDUSTRY PRODUCT

BEFORE REPAIR AND CALIBRATION

KNIFE GATE VALVE

MANUFACTURER : DEZURIK

VALVE SIZE : 42 INCH

P ONLINE LEAK SEALING

(Without any shutdown of the plant)

The sealtite method allows to stop various leaks

of different fluids :

> Steam

> Water

> Air

> Gas

> Hydrocarbons

> Chemical Product

:0~450 Bar

Pressure: O-709°C

Temperature

5 P Leakage Before Repair

The Process

The process consists in fitting, around the leakage part,

an enclosure which will be filled, under pressure,

with compound.

The enclosure can be :

>A specially manufactured box

(in case of leak on pipe or valve)

>AClamp

(In case of leak on flanges)

Leakage After Repair

We can fix a leak in an emergency

> Flange to flange leakage

> Gland packing valve leakage

> Pipe leakage

> Elbow leakage

> Tee pipe leakage

> Bonnet valve leakage

BRIEF EXPLANATION

Our company provides technicians - skilled Leakage Before Repair

technicians to be ready always on call if there

is an emergency occurrence of leaks in the

industry such as : power plants, petro-chemical

industry, gas products, yarn, pulp and paper.

This leakage, that are generally common in

the flange valve, pipe, elbows, gland packing

or in the valve bonnet.

We can do this leak repair work without stopping

the production process, so that companies can

save on expenses. if compared with the invented

process improvement (shut down)

or stopping the production process so that your Leakage After Repair

company will lead many suffered huge losses

which is the number of material waste,

fuel and the amount of time wasted.

SERVICE WARRANTY

For emergency work leaks, our company will

guarantee any leak repair work for three months

Before 5

and

After

Repair

e ( Without any shutdown of the plant )

Repair and

Recondition

yarway valve

and gate valve

Yarway valve

in condition

overhoul

Yarway valve

in condition

overhoul and

cleaned

Yarway valve

atter repair

testing and

painting

Ball Valve In The Field Piled

There are a lot of industries that are not familiar with the valve so that there

are a lot of repair the valve - the valve that has accumulated and discarded,

so that very large expenditure of funds by the company invented the purchase

of a new valve. here we try to offer the service valve on the service valve on the

service industries to conduct industrial expenditure cost saving and acceleration

when compared with buying a new valve. we also provide warranty repair of

6 months duration each valve repair.

INFORMATION ABOUT THE COMPOU!

COMPOUND

USABLE FOR

USABLE ON

‘Steam, Air, Water,

High Pressure,

Injected Boxes

‘On Pipe, Stuffing Box

High Temperature. Flange With Gap

PC 70 Max Pressure : 240 Bar

Max Temperature : 700°

‘Steam, Air, Water, Flange With Gap Reinforced

High Pressure, Injected Boxes Compond For

PC 70 B | Hist Temperature. Difficult, Mechanical

Max Pressure : 240 Bar

Max Temperature : 700°

Adjusting, Not To Be

Use On Water

PC 71

Hydrocarbon, Derived,High

Pressure, High Temperature

Max Pressure : 240 Bar

Max Temperature : 700 °c

Flange With Gap

Hydrocarbon, Derived,High

Flange With Gap

Reinforced

PC 74 B | Pressure, Hian Temperature] Injected Boxes Compound For

7 Max Pressure : 240 Bar Difficult, Mechanical

Max Temperature : 700 %° Adjusting

‘Compound Especialy

Steam, Air, Water Flange With Gap Recommended For

PC 72 Max Pressure : 240 Bar | Injected Boxes ‘Any injection

Max Temperature : 700 2° {rough The Bolts Of

‘The Flanges

‘Compound Usable Same asre7e

Steam, Air, Water On Boiled Joint And Pipe | Reinforced,

PC 76 B | waxPressure:70Bar | Which Have To Resist To | Compound Usable

Max Temperature : 30% | Important Variations Of | jccpsmcat

temperature Adustng

PC 77 Hydrocarbon, Derived Haan rosstne i

Max Pressure : 240 Bar | Temperature, Stuffing

Max Temperature : 700% | B0x0s Small Space Botwoon

Flanges Injection

PC 79 ACIDS Flange With Gap Compound Made With

Max Pressure : 140 Bar

Max Pressure : 240 Bar

Injected Boxes

PTFE

( WITHOUT ANY SHUTDOWN OF THE PLANT )

REPAIR ANDI

CALIBRATION

SAFETY

VALVES

For repair and calibration

safety valves we can

do in the field with

bring equipment

‘equipment in use

for repairs and

safety valve calibration.

This safety valve for our

repair and calibration

refers to the standard

API 527 for

safety valve.

We also sangup

work on safety valve

in significant amounts

and within the brief.

We also provide

warranty of six

mounths on|

any repairs and

calibration and also we

attached report and

test results of the calibration

certificate and also we can

Make new spare parts

made according to our own

with the original.

REPAIR AND CALIBRATION CONTROL VALVES

Control vaive for any repairs we costomarily include the replacement of spare

art such as: Body gasket, Packing stem, stem seal, Check actuator and spring conditions

‘and we also can Make spare part such as: Disc, Seat, Stem, Spring and Membrane

actuator. For every improvement we refer to international standards that we

using standard ANS! 816.104 for seat leakage testing and discnya while

for testing bodynya we refer to the API 598 standard.

We are also ready to work on the ground when the plant shutdown or in order

annual routine repairs.

: ‘SOME EXAMPLES OF SUCCESSFUL

LEAK REPAIR WORK ON DOING

Emergency ocours in goothermal

power plant leaks with

a prossure of 90 bar

and temperatures Nw

of 220 degrees Celsius

before the invented improvement

in PT. Geo Dipa Energi - Wonosobo Plant

‘Toam PT, SINERGI SERVIS INDONESIA Service aro conducting

mounting clamp at the point of leakage

(WITHOUT ANY SHUTDOWN OF THE PLANT )

‘Team PT, SINERGI SERVIS INDONESIA Service is doing the

installation of a second clamp at he point of leakage

(WITHOUT ANY SHUTDOWN OF THE PLANT )

‘Team PT, SINERGI SERVIS INDONESIA Service are conducting

mounting clamp and locking bolts and the installation

adaftor to perform injection on leak point

( WITHOUT ANY SHUTDOWN OF THE PLANT )

PT SINERGI SERVIS INDONESIA Serice Team is doing

compound injection leakage by high pressure and

high temperature in the area of leak point

(WITHOUT ANY SHUTDOWN OF THE PLANT )

PT, SINERGI SERVIS INDONESIA Service Team is

doing finishong after injection

leak and the leak has been successfully

can be stopped.

Sulfur gas leak repair work is done during

four days in caused a huge loak and away

location of power plant that was done and also

the pressure and temperature which is quite high.

For omergancy work such as this leak wo can do

on holiday or on the day - another great day and

we are also

ready work 24

hours a day for

the field

And we are also

ready to prepare

a fleet of 24-nours

‘emergency if,

there is leakage

B. Machining

berstock service valve

C. Seating Faces

Seating faces are set back by welding equipment NS

equipment that resembles the orniginal holder

D. Flange Faces

Flange faces are up and machining to fit the standard

corresponding to the thickness of the edge flange

dimensions and face

E. Gasket Replacement

Throughout the gland packing, gasket, and bolting will

be replaced with the new relevant standard.

F. Re-assemble and Testing

After re-installation, all valves are visually inspected,

dichek necessary for the operation and the pressure test

conducted in accordance with standard

G. Painting and Packaging

The entire internal surface of the valve will be protected

with a rust prevantative. after the valve would be painted,

coated, packed for shipment.

H. Certification

Certification test will be given a warranty service will be

made based on certification test

DOCUMENTATION

PT. SINERGI SERVIS INDONESIA Services take care of a number

of improvements in details of each item. A comprehensive

history for each component. Data can be provided with

a computerized PT. SINERG! SERVIS INDONESIA services. A repair

order drawn on file for each job. This allows tracking by

receiving the report, sales order and serial number.

Record of property stored in a database for cach customer.

Documentation is done specifically, information, item

supplied in accordance with customer demand.

Leakage

Gland

packing

control 5

valve packings

in PLTU gland with

Press. 60 fluid steam

Leakage Before Repair pane eta Leakage Before Repair

Repair Valve

leaks after gland

injection and packing

succeeded after

in doing injection

Emergency occurs

in power plant leaks

with @ pressure of

90 bar and Aleak

enneraies in the valve

of 400°C. packing

before the gland

invented

improvement

Leakage Before Repair

Flange leakage after

the injection valve Gland

repairs without ~ packing

stopping after

the production injection

process r

Leakage After Repair

HEALTH & SAFETY

PT, SINERGI SERVIS INDONESIA Service has

documentation of procedures for

improved safety valve that has become

a reference information in work, but we

will continue to enhance the opportunity

to audit all documentation and facilities.

All employes PT. SINERGI SERVIS INDONESIA

service working in the field required to

wear self-protection.

PROCESS VALVE REPAIR

& RECONDITIONING

Itis our commitment to restore valve and equipment

sent to our approach to be fixed up like new condition,

Below describe the process undertaken by

PT, SINERGI SERVIS INDONESIA service for recondition valve.

A. VISUAL SURVEILLANCE

When the customer equipment in our workshop,

an inspection a complete and thourgh equipment

necessary to know the state of and determine what

needs fixing. the equipment can be repaired and

then separated with equipment that can not be

repaired. When identified can be corrected, order

of work for each unit prepared with a detailed list

of work required.

B, DATA RECORDING

All data related to the vaive will be recorded to

determine the degree of damage and by what

method will be used to recondition the valve.

EARLY TEST

Before the repair, the entire valve will be tested

in accordance with standard

A. Dismantling, Cleaning and Inspection each valve

will then be separated from the componentsseparately,

after valve separating the components, will be cleaned

with some methods depends on the type of material

and the circumstances. cleaning methods including

bead blasting, wet abrasive blasting, high pressure

washing. after that all parts will be examined

individually. important material that will be inchemical

and metallurgical analysis. The result will be

ty incorporated into the inspection report.

i. ee

SOME EXAMP! Testortsu ESSFUL

LEAK REPAIR WORK ON DOING

Emergency leak in the area of pipe tee with a

medium hot water with a pressure of 10 bar

and at temperature 150°C in the chemical

production company in west java region

we do this work by making manufacturing

clamp for pipe installed at the tee area

of the leak. Leaks in the pipe tee after

the installation completed and adaftor clamp

and after the injection done, but the result is

very satisfactory and leaks can be stopped. Leakage Before Repaifl

This improvement is done without any

‘stopping the production process.

Leakage After Repair

i

ON LINE LEAK SEALING

METHODS GLAND PACKING LEAK

Emergency leak in the area of flange to flange Leakage Before Repair

with a medium hot water with a pressure of 32 bar

and at temperature 300°C in the chemical production

‘company in west java region. we do this work by

making manufacturing clamp for flange installed at

the flange to flange area of the leak

Leaks in the flange to flange after the installation

completed and adaftor clamp and after the

injection done, but the result is very satisfactory

and leaks can be stopped.

This improvement is done without any stopping

the production process,

Leakage After Repair

Gate valve High

Pressurre and

Temperature

area powerplant

J Gate valve

is in the process

improvement

insitu valve repair

and lapping process

Replacement Body gasket

packing bolt and nuts 4

painting certification

guarranty

wis 3

Gate valve after repair

Gate valve after repair

SOME EXAMPLES OF SUCCESSFUL

LEAK REPAIR WORK ON DOING

~_ Leakages in the pipeline

for 3-inch and 6-inch pipe

is corrosive condition with

hot steam media.

for the pressure of 20 bar

é and temperature of 160 C

7

Leakage Before Repair

The pipeline

for 3-inch and 6-inch

after repair and

injection

Leakage After Repair

Leakage After Repair

Leak repair work on the valve steam packing area will be

undertaken by a team in a private company engaged in the field

of chemical processing in the area west of java. for leaks in the

packing area, we can do with the time later than we did about

three to four hours duration depending on the position or the valve

area is located. To repair this leak we just do the drilling and

moderate in the manufacture of thereaded valve stem packing

area in order to adaftor set set to enter the compound injection

special heat-resistant and pressure.

Compound that we use is a compound that resists

heat and high pressure specifically designed

for media stem, water and air compound is

made by the French state

We are ready to repair a wide

range and

veriety of media leaks.

a leak that can not be handled

by industry

maintenance employees.

STANDARDIZATION SUPPORT

VALVE RECONDITIONING

4VApi Standard 598 for hand valve

2. Api 527 Standard for safety valve

$. Ansi B.16.104 for control valve

Insitu valve repair with portable lapping machine

Gate valve before repair Gate valve is in Gate vaive after repair

PLTU TANJUNG MAS the process improvement Power plant PLTU TANJUNG MAS

‘Semarang - Jateng ‘Semarang - Jateng

INSITU LAPPING GLOBE VALVE

GLOBE VALVE BEFORE REPAIR

Scope of work globe valve repair :

- Inspect & Report

- Make punch, Data and Overhoul

- Beadblast body & Components

- Lapping seat and Disc valve

- Polishing spindle

- Replace packing packing & body gasket material

- Re-assemble a _—

Eee vont Cortty Deer

- Painting

Testing methode in accordance GLOBE VALVE AFTER REPAIR

with Api 598 Site Chemical Industry West Java

Se

STANDARDIZATION SUPPORT

VALVE RECONDITIONING

Some examples of

leak repair without

stopping production

process occured in the

area pipe flange to flange

with media steam with

temperature to 400°C and

pressure of 97 kg/om2

this work is done

in an industry that engaged

in the petrochemical field

in west java who has powe

plant itself.

TOOLS

The tools which are needed for on line

leak sealing :

> Pump, pressure until 10.000 psi

> Injection gun

> adapter

> Caulking gun & chisel

> Drill gun & bit

> Compound injection

> Safety Equipment

We have also prepared

some specialized fleet

to handle leak repair

24 hours if the emergency

leak well al night and on

the day - the day other

major

EQUIPMENT

We have the equipment with a total value of 250.000.000 millid

werehouse, consisting of lathe machines, lapping machines, wel Se

machines, driling machines, test bench, milling machine, and traded comeuall

equipment. The amount of investment in equipment requires our commitment

and satisfactory for the smooth running of our work. ww

TOOLS AUTOMATIC PORTABLE LAPPING MACHINE

Specifically to repair

portable lapping gate

valve and check valve

in the site or insitu

lapping.

Ball Valve Ball valves are

Neles Jamesbur underway to

Size 8° NAS] 300 _—check the dismantling -

Before repair the part that is

damage

After the demolition ball was in the condition of damage or scratched.

To make improvements by means of ball - grinding ball until smooth and

her ball lapping up flash like the glass and in return to original size

Scope of work repair ball, Valve with actuator work :

- Dismantle valve, Actuator and positioner if applicable

- Inspect and Report - Polishing spindle/stem

~ Beadblast body and component - Replace packing & Body gasketing

- Grinding and lapping ball - Re-assemble, function / Leakage test & certify

feplacement seat (PTFE) - Painting and packaging

= Testing methode in accordance with API 598

SOME EXAMPLES OF SUCCESSFUL

LEAK,.REPAIR WORK ON DOING

This is one of our jobs that have been succes

we are working in a company that processes

refined sugar in the Anyer - Cilegon.

Avalve that is leaking valve bonnet of events

and conditions of the leak can be fixed only in

conditions did not stop production. with the NN

information to we do our job on-line.

The process consists in fitting, around the leakage part,

An enclosure which will be filled, under pressure,

with compound, The enclosure can be

> A specially manufactured box (in case of leak on pipe or valve)

> A Clamp (in case of leak on flanges)

To repair the leak without stop production we had a lot

of them that the customer is moving in the fields of :

Oil and Gas, Power Plant, Petrochemical Pulp and

Paper products, Mining, Foods and Beverages Product,

Milk, Drink and Industry - other industry.

We will always provide the best for each

Our service and our services will provide warranty

every job we do at your company.

CONTROL VALVE

Valve andActuator : Size velve 3/4 - 24” ANSI CLASS 150 - 2,500

(Pneumatic, Electric, dan Hydraulic type)

Set. Pressure Up to 10.000 Psig

For each control valve repair and calibration of our usually NN .

also provide all the needs spare parts such as body gaskets,

packing stem, stem seal, spring actuator, and we can also

provide spare parts other such as the valve stem, valve seat,

valve dsc, membrane actuator and control valve spare parts

needs of others. We are also ready for a full 24 hours if

needed for improvement in the condition plant or in an

emergency stop a short time.

SHUTDOWN AND TURN AROUND WORK

During the plant does not operate, we can utilize in workshop

to make improvements in place. Our workshop is equipped

lapping machine, Lathe machine, drilling machine, welding

machine, equipment to cut, also test bench

MAINTENANCE CONTRAC FOR VALVES

With support from the factory valve that is in our group,

We also can provide vaive maintenance contract overall

In the overall valve maintenance contract we provide some thing

that can be seen in the list below in form of a sercive contract.

4. Nurshing valve daily

2. Provide valves, spare parts, and equipment procurement

3. Provide stand by valve for the purposes of a sudden

4. Managing inventory to supply valves and spare parts

This includes the procurement of database management

software valve

MANPOWER

We have 15 permanent employees as a whole that consists of staff administrative and

operational staff. Apart from permanent employees, we also has 5 other employes on

instruments. The list of our : Technician, Electrician, Foremen, Fitters, welders, Material

Coordinator, Painters, Blasters, Insulators, and some experienced public workers.

Although these employees are employees who are under contract, they are willing

to be called al any time with short notice in PT. Lautan Energy Service Group, and

we are able to provide power our work, experienced engineers and technicians of

Se Various levels and catagories in a region

rine

This is a picture we took at the time

installation work on the flange clamp cover

exhanger a leak. Here our team of well

are doing the injection on leak point

with the media more or less steam and temperature

450°C also with less pressure

more than 100 kgicm2. We managed to do this job

less than seven days is caused because

site conditions and the location is quite difficult.

Here we also lists their images of our work

who are doing the installation of the pipe clamp elbow

a leak at the point of welding elbow. We will

always ready to work in accordance with any conditions

slale leakge and field condilions.

Our team at work is peoples

who have more experience and have followed

traiing - training that we provide and every

Our employees are also protected by insurance

There are so many industries that are not familiar with '

an improvement in on-line leak. J lia

So here we try to affer product service

Cur service of which we can do

repair such leaks in the area:

- Flange to flange valve or pipe

- Leaks in the pipeline corrosive

- Elbow a cracked pipe

- Gland packing an old valve

- Also on the bonnet gasket in the vaive area

This is one example

steam leakage

the area of the pipe flange to

flange and also include the images

for the manufacture of clamp

and the installation process.

Here we can see clearly

in the form of clamp and

the installation adaftor

server as a tool for injectable inclusion compound

Cosmos-resistant high temperature and High pressure

The jobs such as leakage

We only took two days

il, K

VALVE REPAIR & CONDITIONING

BUSINESS)ACTIVITIES =:

‘our activities can be catagorized as follow

IN-SHOP VALVE REPAIR

Isolation Valve ( hand valve )

- Gate Valve 2"-46" 150 #- 10,000 #

-Globe Valve 2" 24” 150 #- 2,500 #

-Check Valve 2" 30" 150 #- 2,500 #

- Ball Valve 2°-32" 150 #- 2,500 #

- Plug Valve 2°-12" 150 #- 2,500 #

- Butterfly Valve 2"-46" 150 #- 2,500 #

PRESSURE SAFETY VALVE

Comvertonal type, Balance type, Pilot

Operated type, Vaccum type

sizevalve —: 3/4- 12"

class 2 150 # - 2,500 #

Set. Preesure : Up to 10,000 Psig

INFRASTRUCTURE

Service facilities covering an area

approximately 200 m2 and is equipped with

special toolsfor valve repair. This includes

lathes machine, radial arm drill, 15” lapping

machines, spray booths, and other test

bench. Equipment, specialist in-situ lapping

equipment, work station, air compressors,

manual cranes, hydraulic press, and stick

welding equpment, benches stripping and

miscellneous hand tools.

PT. SINERGI SERVIS INDONESIA Service in support with

other companies and other heavy equipment

are transported through a subcontractor.

ee =

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- GB-T 91-2000开口销 PDFDocument7 pagesGB-T 91-2000开口销 PDFDoris AbadiNo ratings yet

- Tugas 2 PDFDocument1 pageTugas 2 PDFDoris AbadiNo ratings yet

- Tugas 2Document1 pageTugas 2Doris AbadiNo ratings yet

- GateDocument1 pageGateDoris AbadiNo ratings yet

- Pt. Amanah Nusantara Sejahtera - Hydrotest ProcedureDocument5 pagesPt. Amanah Nusantara Sejahtera - Hydrotest ProcedureDoris AbadiNo ratings yet

- DIB Vs DBB PDFDocument1 pageDIB Vs DBB PDFDoris AbadiNo ratings yet

- Use The Original Record Form of ARITA or Any Computer Management SoftwareDocument1 pageUse The Original Record Form of ARITA or Any Computer Management SoftwareDoris AbadiNo ratings yet

- 19-08-Equipment Maintenance History RecordDocument1 page19-08-Equipment Maintenance History RecordDoris AbadiNo ratings yet

- Oil & Gas - Petrochemical - Power Plant - MiningDocument5 pagesOil & Gas - Petrochemical - Power Plant - MiningDoris AbadiNo ratings yet

- TOOL Fixture & Tool ListDocument2 pagesTOOL Fixture & Tool ListDoris AbadiNo ratings yet

- Clamp Gapless ValveDocument1 pageClamp Gapless ValveDoris AbadiNo ratings yet

- Quality Assurance Manual PDFDocument73 pagesQuality Assurance Manual PDFDoris AbadiNo ratings yet

- Unib Ody Floating B All Valves: KVC Fire-Safe and Anti-Static ASME 150/300 One Piece, End EntryDocument4 pagesUnib Ody Floating B All Valves: KVC Fire-Safe and Anti-Static ASME 150/300 One Piece, End EntryDoris AbadiNo ratings yet

- KVC Product CatalogueDocument1 pageKVC Product CatalogueDoris AbadiNo ratings yet

- Gate Valve (Z41Y-600LB 6 - ) - ModelDocument1 pageGate Valve (Z41Y-600LB 6 - ) - ModelDoris AbadiNo ratings yet

- Soal PsikotestDocument8 pagesSoal PsikotestDoris AbadiNo ratings yet