Professional Documents

Culture Documents

Wire-Rope-Sling Hitch PDF

Wire-Rope-Sling Hitch PDF

Uploaded by

Fatih Dani PrasetioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wire-Rope-Sling Hitch PDF

Wire-Rope-Sling Hitch PDF

Uploaded by

Fatih Dani PrasetioCopyright:

Available Formats

The rated capacity of a sling

and what it means to you

T

D/d RATIOS he rated capacity of a sling factors that affect the overall

When a sling is rigged varies depending upon the type strength of the sling, including:

as a basket, the of sling, the size of the sling,

> Splicing efficiency.

diameter of the and the type of hitch. The American

bend where the sling Society of Mechanical Engineers > Design factor (5 is standard).

contacts the load

> Number of parts of rope in the sling.

can affect the sling’s

lifting capacity. > Type of hitch (straight pull, choker

hitch or basket hitch).

> Diameter around which the body of

the sling is bent (D/d ratio).

(ASME) requires that all wire rope

> Number of legs.

slings be tagged with the name or

trademark of the manufacturer, the > Diameter of the pin (or hook) over

rated capacity for specific configura- which the eye of the sling is rigged.

tions and the diameter or size of the

sling. Under no circumstances shall > Angle at which the sling is used.

a sling’s rated capacity be exceeded. > Hook or other end attachment rated

The user should maintain this identi- capacity.

How much the lifting fication so that it is legible during the

capacity is affected life of the sling. All persons using DESIGN FACTOR

can be calculated by the sling should read the tag and The rated capacities for wire rope

dividing the diameter understand the information on it. slings are based on a design factor

of the bend where the of 5 per ASME B30.9. The design factor

The rated capacity of a wire rope

rope contacts the load and other factors are used to calculate

sling is based upon the Minimum

(represented by “D”) the rated capacities.

Breaking Force (MBF) of the wire

by the diameter of

rope used in the sling and other Design factors have been established

the rope or the

component rope that allow the sling to give efficient

diameter in a multi- service to the user.

part sling (represented

by “d”). For example, APPLY STANDARD D/d RATIOS TO DETERMINE EFFICIENCY

if the diameter of the OF VARIOUS SLING CONSTRUCTIONS

bend (“D”) is 10 and Mechanically-spliced, single-part slings 25 times rope diameter

the component rope

Hand-spliced, single-part slings 15 times rope diameter

diameter (“d”) is 1/2,

Braided multi-part slings of 6 parts 25 times component rope diameter

the D/d Ratio is

10 ÷ 1/2 or 20. Braided multi-part slings of 8 parts 25 times component rope diameter

Helically laid multi-part slings 25 times component rope diameter

Hand-tucked grommets and mechanically

5 times sling body diameter

joined grommets

When D/d ratios smaller than those shown above (or those shown in the footnotes below

Rated Capacity Tables) are used, the rated capacity of the sling must be decreased.

2 Union A WireCo WorldGroup Brand

How wire rope slings are used

HITCHES

How wire rope slings are configured or the sling damaged by the load, and

to lift a load is called a hitch. Most lifts when the lift requires the sling to hug

use one of three basic hitches. the load. Never choke a load so that any

part of one eye or splice is in the part of

VERTICAL EYE AND EYE HITCH

the sling that passes through the other

If one eye of the sling is attached to

eye to form the choke.

the lifting hook and the other eye is

attached to the load, this is called a Two notes of caution: Always pull

vertical eye and eye, or straight, hitch. a choker hitch tight before the lift is

A tagline should be used to prevent made. It should never be pulled down

load rotation that may damage the sling. during the lift. Also, never use only

one choker hitch to lift a load that VERTICAL HITCH

When two or more slings are attached

could shift or slide out of the choke.

to the same lifting hook, the total hitch

becomes, in effect, a lifting bridle and

BASKET HITCH

the load is distributed equally among

A basket hitch is formed when both

the individual slings.

eyes of the sling are placed on the lifting

Slings used at an angle have a lower hook, thereby forming a circular basket

rated capacity than one used vertically. of the sling. This type of hitch distributes

the load equally between the two legs

CHOKER HITCH of the sling, within limitations.

In the choker hitch, one eye of the sling

is attached to the lifting hook, while the LIFTING BRIDLES

sling itself is drawn through the other When you attach two or more slings to

eye. The load is placed inside the “choke” the same lifting hook, or are connected CHOKER HITCH

that is created while the sling is drawn to a link rigged onto the hook, the total

tight over the load through the eye. hitch becomes a lifting bridle, distrib-

uting the load among the individual

Choker hitches reduce the lifting slings. When using two or more slings

capability of a sling since the wire rope as a lifting bridle, remember that the

component’s ability to adjust during the sling angle affects the slings’ rated

lift is affected. You should only use a capacities. Also, the location of the

choker hitch when the load will not be lift’s center of gravity will affect the

seriously damaged by the sling body, load on each sling leg.

REDUCTION IN EFFICIENCY OF WIRE ROPE

WHEN BENT OVER PINS OF VARIOUS SIZES

BASKET HITCH

Union A WireCo WorldGroup Brand 3

Sound lifting practices

T here are four primary factors to take into

consideration when lifting a load.

location of the center of gravity is also necessary

to determine sling loadings.

They are: (1) the physical parameters of the load; If the load has small diameter corners, protective

(2) the number of legs and the angle they make blocking or “softeners” must be used so that sling

with the horizontal; (3) the rated capacity of the capacity isn’t reduced. Also, if lifting a painted

sling; and (4) the condition of the sling. object or an object with a finished surface, padding

or softeners may be needed between the sling and

PHYSICAL PARAMETERS OF THE LOAD the load to protect the load.

The size of the object to be lifted, and particularly

the location of lifting points, will affect sling NUMBER OF LEGS AND ANGLE WITH THE HORIZONTAL

selection. The weight of the lift, while a critical As the angle formed by the sling leg and the hori-

component, is only a part of the information. The zontal decreases, the rated capacity of the sling

Calculating the load of basket hitches and bridles

W hen you’re calculating the load

of basket hitches and bridles,

remember that as the horizontal angle

If the load is hanging free, the normal

choke angle is approximately 135

degrees. When lifting and turning a

LOAD FACTOR

GUIDELINES

of a sling decreases, the resultant load load using a choker Leg Load

on each leg increases. hitch, it is not angle factor

uncommon to 90° 1.000

The horizontal angle of bridles with

have a severe 85° 1.003

three or more legs is measured the 80° 1.015

bend at the

same way as hori- 75° 1.035

choke. When

zontal sling angles of 70° 1.064

a choker hitch

two-legged hitches. If 65° 1.103

is used at an 60° 1.154

a bridle is designed

angle of less 55° 1.220

with different leg

than 120 50° 1.305

lengths, it may 45° 1.414

degrees, you

result in different 40° 1.555

must reduce the

horizontal 35° 1.743

hitch’s rated capacity as shown in the

angles. 30° 2.000

chart at right. You always must adjust

The load

the rated capacity of the wire rope sling

on each leg must be

whenever you use a choker hitch to shift, CAPACITY DECREASES

calculated based on the position of WITH ANGLE

turn or control a load, or when the pull

the slings and the location of the lift’s Angle Rated

is against the choke in a multi-leg lift.

center of gravity. of choke Capacity

As always, if more than one sling is in degrees Percent*

ADJUSTING THE RATED CAPACITY used and the legs are not vertical, a Over 120 100%

OF A CHOKER HITCH further reduction in rated capacity 90-120 87%

Due to the body of the sling being used must be made for the sling angle. 60- 89 74%

30-59 62%

in the choke, there is a reduction in

Warning: Choker hitches at angles 0-29 49%

rated capacity. This is reflected in the

greater than 135 degrees are not *Percent of sling’s

choker rated capacity tables. Another rated capacity in

recommended since they are unstable.

reduction that must be considered is a choker hitch.

Extreme care should be taken to deter-

due to the “angle” of the choke (not

mine the angle of choke as accurately

the angle of the leg of the sling).

as possible.

4 Union A WireCo WorldGroup Brand

THREE-STEP FORMULA FOR CALCULATING

LOAD PER SLING LEG

also decreases. In other words, the smaller the These calculations assume that the center of gravity

angle between the sling leg and the horizontal, is equal distance from all of the lifting points, and

the greater the load on the sling leg. The minimum the sling angles are the same. If not, more compli-

angle allowed is 30 degrees. cated engineering calculations are needed.

1. Divide the weight of your total load by the number

RATED CAPACITY

of legs you are using. This gives you the load per

The rated capacity of a sling must never be exceeded.

leg if the lift were being made with all legs lifting

The rated capacity is based both on sling fabrication

vertically.

components (minimum breaking force of rope used,

splicing efficiency, number of parts of rope in sling 2. Measure the angle between the legs of the sling

and number of sling legs) and sling application and the horizontal plane.

components (angle of legs, type of hitch, D/d

ratios, etc.) 3. Multiply the load per leg that you calculated in

step 1 by the load factor for the leg angle you are

If you are using one wire rope sling in a vertical using. Use the Load factor guidelines table on the

hitch, you can utilize the full rated lifting capacity next page to determine the load factor.

of the sling, but you must not exceed that lifting

capacity. The result is the actual load on each leg of the sling

for this lift and angle. The actual load must never

If you are using two wire rope slings in a vertical exceed the sling’s vertical rated capacity.

hitch (called a 2-legged bridle hitch) in a straight

lift, the load on each leg increases as the angle Warning: Slings shall not be used with horizontal

between the leg and the horizontal plane decreases. angles less than 30°.

Whenever you lift a load with the legs of a sling at CONDITION OF SLING

an angle, you can calculate the actual load per leg Each sling must be inspected daily. If the sling does

by using the following three-step formula. not pass inspection (See Page 9), do not use.

EXAMPLES OF HOW TO CALCULATE SLING LEG LOADS

1. Total load is 1,000 lbs. divided by

two legs – 500 lbs. load per leg

if vertical lift.

2. Horizontal sling angle is

60 degrees.

3. Multiply 500 lbs. by 1.154 load

factor (from table) = 577 lbs.

actual load per leg.

1. Total load is 1,000 lbs. divided

by two legs – 500 lbs. load per

leg if vertical lift.

2. Horizontal sling angle is 45 degrees.

3. Multiply 500 lbs. by 1.414 load factor

(from table) = 707 lbs. actual load per leg.

2. Horizontal sling angle is 30 degrees.

1. Total load is 1,000 lbs. divided by two legs – 500 lbs. 3. Multiply 500 lbs. by 2 load factor (from table) = 1000 lbs.

load per leg if vertical lift. actual load per leg.

Union A WireCo WorldGroup Brand 5

Rigger’s 10-step checklist

1. WEIGH AND MEASURE 6. BALANCE THE LOAD

Before you lift, be sure you know Always place the eye or link in the

exactly how much weight you’re base (bowl) of the hook to prevent

moving, how far you have to move it point loading on the hook. In a basket

and how high you must lift it. Make hitch, always balance the load to

INSPECT YOUR sure the load’s weight is within the prevent slippage.

EQUIPMENT,

WIRE ROPE, rated capacity of the sling, including

WIRE ROPE SLINGS consideration of sling leg angles and The sling’s legs should contain or

AND ASSEMBLIES load’s physical parameters. support the load from the sides above

REGULARLY the center of gravity when using a

> Inspection should 2. USE THE RIGHT HITCH basket hitch. Be certain that the

be performed by a Decide how to connect your load to slings are long enough so that the

person with special the lifting hook and how to attach rated capacity is adequate when you

training or practical the sling to the load. consider the angle of the legs.

experience.

3. CHOOSE THE RIGHT SLING 7. TEST THE RIGGING

Each load is different. Be sure to Before you make the lift, tug lightly

calculate the proper rated capacity on the rigging to be certain that

?

NEED MORE

for the angles and hitch involved as

well as the right type and style for

the job.

blocking, sling and load protection

are in place, then lift slightly off the

ground and re-check the lift.

INFORMATION? If D/d ratios are smaller than those 8. STAND CLEAR AND LIFT

> When it comes indicated, the sling’s rated capacity To prevent injury, move away from

to using wire rope must be reduced. Choose a sling with the areas between the sling and load

slings and assem- the proper end attachments or eye and between the sling and the crane

blies, knowledge is protection as well as attaching hook or hoist hook. Let the lifting

your most important hardware. Pad all corners in contact device and rigging work for you.

tool. We know this with the sling to minimize damage

guide can’t answer to the sling. Avoid the temptation to use your

every question you muscles to prevent swinging or

have about wire 4. INSPECT THE SLING movement. Use a tagline or tether.

rope slings and Check the sling closely to be sure Be sure to keep clear of the

assemblies. it is in good condition and able to suspended load.

make the lift. Follow all the appro-

If you have more priate OSHA guidelines and ASME 9. AVOID SHOCK LOADING

informational needs, regulations. You cannot change Lift slowly with a steady application

contact your Union the length of a sling. If a different or power. Don’t make sudden starts

distributor or district length is needed, get a sling of the or stops, either in lifting or swinging

sales manager. required length. the load.

5. RIG UP, NOT DOWN 10. RETURN TO STORAGE

Always attach the sling to the load After you’re done with your lift,

first, then attach it to the hook. inspect the sling for possible damage.

If damaged and not usable, destroy

the sling immediately. Otherwise,

return it to your sling storage rack

until your next lift.

6 Union A WireCo WorldGroup Brand

Inspection and removal criteria for wire rope slings

Before using slings, inspect them to be sure they meet the requirements for that application.

HOW OFTEN TO INSPECT WHEN TO REPLACE YOUR WIRE ROPE SLING

Both AMSE Standard B30.9 and OSHA require that According to ASME B30.9, you must remove a wire

wire ropes receive two types of inspections: rope sling from service immediately if any of the

following conditions are present:

1. A DAILY VISUAL INSPECTION The person

handling the sling must do this each day and 1. RATED CAPACITY TAG Missing or illegible sling

should check for major damage or deterioration identification tag.

that would weaken the sling and for obvious

2. BROKEN WIRES For single part body slings

signs such as broken wires, kinks, crushing,

and strand laid grommets: 5 broken wires in one

broken attachments and severe corrosion.

strand in one rope lay or 10 broken wires in all

2. ADDITIONAL INSPECTIONS AT REGULAR strands in one rope lay. For cable-laid, cable-laid

INTERVALS These are based on frequency of grommets and multi-part slings, use the following

sling use, severity of service conditions, the nature guidelines.

of the lifts and prior experience based on service

ALLOWABLE BROKEN WIRES

life of slings used in similar circumstances. A

designated person who has a working knowledge Cable-laid grommet 20 per lay

of wire rope must conduct these inspections. Less than 8 -par t braid 20 per braid

8-par t braid or more 40 per braid

Inspection shall be made at least annually and shall

include a record of the inspection or of apparent

conditions to provide the basis for a continuing 3. METAL LOSS Wear or scraping of one-third the

evaluation. Inspection shall be conducted on the original diameter of the outside individual wires.

entire length of the sling, including splices, end 4. DISTORTION Such as kinking, crushing or bird-

attachments and fittings. caging. Look closely for wires or strands that may

have been pushed out of their original positions in

HOW TO INSPECT the rope.

The following procedures are offered as a guide

for conducting inspections: 5. HEAT DAMAGE Any metallic discoloration or

loss of internal lubricant caused by heat exposure.

1. Place the sling in a position that enables the

inspector to access and see every part of the sling. 6. DAMAGED END ATTACHMENTS Cracked, bent

or broken fittings. Also, any evidence that eye

2. Clean off all dirt and grease with a wire brush or splices have slipped, or tucked strands have moved.

rags to reveal wires and fittings.

7. BENT HOOKS No more than 15 percent over

3. Examine the entire length of the sling thoroughly, the normal throat openings (measured at the

especially the parts showing the most wear. narrowest point) or twisting exceeding 10

4. Pay special attention to fittings and end attach- degrees is permitted.

ments and areas of the sling next to these fittings. 8. METAL CORROSION Severe corrosion of the

5. Find the most worn or damaged section of the rope or end attachments that has caused pitting

sling and carefully check it against removal criteria. or binding of wires. Light rusting doesn’t normally

affect a sling’s strength.

6. Label or identify all slings you’ve inspected.

7. Keep records of all inspections, including dates HOW TO DISPOSE OF A REJECTED WIRE ROPE SLING

and conditions of slings. Once the inspector has determined a sling is no

longer usable, he should tag it immediately, “Do Not

8. Immediately destroy all slings you’ve rejected.

Use.” The sling should then be destroyed as soon

9. Store slings you want to reuse in a safe place as possible by cutting the eye and fittings from the

away from damaging weather, heat and dirt. rope. This will prevent accidental reuse of the sling.

Union A WireCo WorldGroup Brand 7

You might also like

- Wire Rope BookletDocument27 pagesWire Rope BookletVasanth RaghavanNo ratings yet

- Final Project Report - OrnithopterDocument74 pagesFinal Project Report - Ornithoptermkpradyumna100% (4)

- RC Plane DesigningDocument20 pagesRC Plane DesigningSandeep Kr. Mishra92% (12)

- Certex Wire Rope Slings LR Rev3Document34 pagesCertex Wire Rope Slings LR Rev3jogi oscar sinagaNo ratings yet

- Wire Rope Slings: General InformationDocument16 pagesWire Rope Slings: General Informationegy pureNo ratings yet

- Block Rotation and Rope Stability PDFDocument3 pagesBlock Rotation and Rope Stability PDFAnshul AsthanaNo ratings yet

- Wire Rope Slings: Recommended Guideline For Proof Test Procedures ForDocument22 pagesWire Rope Slings: Recommended Guideline For Proof Test Procedures Fordonnyars1979No ratings yet

- Round SlingsDocument9 pagesRound Slingswalkerproductions20009116100% (1)

- Wear Analyse Groove ZPMC SheaveDocument7 pagesWear Analyse Groove ZPMC SheaveGer BosNo ratings yet

- Liftex Catalog 2016Document60 pagesLiftex Catalog 2016Alberth Mauricio Casteblanco GomezNo ratings yet

- Instructions For The Safe Use Of: ShacklesDocument2 pagesInstructions For The Safe Use Of: ShacklesAmeerUlHaqNo ratings yet

- Crane Sheave - Early FailuresDocument14 pagesCrane Sheave - Early FailuresMichael WoodNo ratings yet

- Chapter01 ShacklesDocument38 pagesChapter01 ShacklesHamzahrudin SunandarNo ratings yet

- Presentación Stahl PDFDocument24 pagesPresentación Stahl PDFStiven PeñaNo ratings yet

- Learner Guide - RBDocument61 pagesLearner Guide - RBEducation 2.0No ratings yet

- Working Safely With Wire RopeDocument5 pagesWorking Safely With Wire Ropedcsamaraweera100% (1)

- Cargo Net l3 Ast Le Adma 314Document6 pagesCargo Net l3 Ast Le Adma 314Anwar DeenNo ratings yet

- EOT Crane Maintenance ManualDocument99 pagesEOT Crane Maintenance ManualAvishek DasNo ratings yet

- Fleeting Chain Blocks-Mod 5Document5 pagesFleeting Chain Blocks-Mod 5Vitor OlivettiNo ratings yet

- REPORT Model of Wire RopesDocument32 pagesREPORT Model of Wire RopesalexremNo ratings yet

- Taglineuse PEERREVIEWDOCDocument56 pagesTaglineuse PEERREVIEWDOCMohamed Said0% (1)

- Lifting+Matters+Q3+2021 210930 WEB LRDocument36 pagesLifting+Matters+Q3+2021 210930 WEB LRAlex Sandro Borges PereiraNo ratings yet

- Ohs-Pr-09-19-F07 (A) Steel Wire Rope InspectionDocument1 pageOhs-Pr-09-19-F07 (A) Steel Wire Rope InspectionShafie ZubierNo ratings yet

- 4ductor Engl PDFDocument8 pages4ductor Engl PDFNilesh MahajanNo ratings yet

- King Lifting Crane Hire Specification GuideDocument216 pagesKing Lifting Crane Hire Specification Guidemohan115No ratings yet

- 3 (1) Leea Advice On Eyebolts PDFDocument2 pages3 (1) Leea Advice On Eyebolts PDFReda MashalNo ratings yet

- Diagnosing Bridge Crane Tracking Problems (ILH Magazine Version)Document2 pagesDiagnosing Bridge Crane Tracking Problems (ILH Magazine Version)Gary J. Davis, P. E.100% (1)

- BS 7121 Part 2Document68 pagesBS 7121 Part 2Fenner ElectromechanicalNo ratings yet

- Casar Steel Wire RopesDocument32 pagesCasar Steel Wire Ropessgupta_615796No ratings yet

- RiggingDocument129 pagesRiggingInnocent BhaikwaNo ratings yet

- Integra Lift Planning Course Presentation 21 June 2007Document118 pagesIntegra Lift Planning Course Presentation 21 June 2007mohamed fahsNo ratings yet

- Multiple Crane LiftingDocument11 pagesMultiple Crane LiftingAbdul Majid ZulkarnainNo ratings yet

- Annual Report: Lifting Standards WorldwideDocument20 pagesAnnual Report: Lifting Standards WorldwideUlviyye ElesgerovaNo ratings yet

- Chains Slings and Rigging ProgramDocument34 pagesChains Slings and Rigging ProgramRuperto Caruanambo MalcaNo ratings yet

- WireRopeBasics ClassificationFeaturesDocument5 pagesWireRopeBasics ClassificationFeaturesbibin2010No ratings yet

- Abacus HoistDocument22 pagesAbacus Hoistomiti Engineering systemsNo ratings yet

- Technical view-Presentation-Outrigger-MatsDocument19 pagesTechnical view-Presentation-Outrigger-MatsKranthi KumarNo ratings yet

- Lifting Beams vs. Spreader BeamDocument10 pagesLifting Beams vs. Spreader BeamAkram BadranNo ratings yet

- TUV&IICS4 1 Offshore Crane Sep19 KwanDocument5 pagesTUV&IICS4 1 Offshore Crane Sep19 KwanmnvijaybabuNo ratings yet

- Carton Policies and ProceduresDocument4 pagesCarton Policies and ProceduresJohnNo ratings yet

- Overhead CraneDocument4 pagesOverhead Craneahmedzizo_2No ratings yet

- Lift EngineeringDocument3 pagesLift EngineeringyogihardNo ratings yet

- Chain Block & Lever HoistDocument8 pagesChain Block & Lever HoistHarris ShehzadNo ratings yet

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories, Non-Fixed Load Lifting Attachments - Version 2 PDFDocument15 pagesLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories, Non-Fixed Load Lifting Attachments - Version 2 PDFopreamihNo ratings yet

- Rigging - Sling HitchesDocument54 pagesRigging - Sling HitchesIng. Alejandro Valencia HerreraNo ratings yet

- Wire RopesDocument22 pagesWire RopesMehmet Ali100% (1)

- Lifitng GuideDocument56 pagesLifitng GuideinrsafetyNo ratings yet

- En13411 1 ThimbleDocument1 pageEn13411 1 ThimbleDieseru Emojevwe ChristopherNo ratings yet

- Replace Wire RopeDocument7 pagesReplace Wire RopeBistok MarbunNo ratings yet

- Yale PE2 Lever Hoist - 40192 ADocument16 pagesYale PE2 Lever Hoist - 40192 AAthox QhurienNo ratings yet

- Lifting Beams and Spreaders SI 8.3Document2 pagesLifting Beams and Spreaders SI 8.3reda mesbahNo ratings yet

- CranesDocument36 pagesCranesgaziahmad100% (2)

- Hand Chain Hoist InspectionDocument4 pagesHand Chain Hoist Inspectionerwin piliangNo ratings yet

- Lloyds Thorough Examination and Inspection of Mobile Cranes and Crawler CranesDocument134 pagesLloyds Thorough Examination and Inspection of Mobile Cranes and Crawler CranesChiheb Kaaniche100% (1)

- A Guide To Shackles For Lifting Purposes: BenefitsDocument14 pagesA Guide To Shackles For Lifting Purposes: BenefitsArsalan AhmadNo ratings yet

- Mobile Crane Operator Exam OutlineDocument1 pageMobile Crane Operator Exam OutlineHermon PakpahanNo ratings yet

- 25 Specialized Rigging: Four-Leg GantriesDocument32 pages25 Specialized Rigging: Four-Leg GantriesVinicius Monteiro AmaralNo ratings yet

- Wire Rope SlingsDocument27 pagesWire Rope Slingsnasirfahim100% (1)

- Rigging TechniquesDocument27 pagesRigging TechniquesDeepak ShettyNo ratings yet

- Wire GuideDocument28 pagesWire GuideRuben Bartolome GarciaNo ratings yet

- Rigging GuidelinesDocument14 pagesRigging GuidelinesMalik AtikNo ratings yet

- 24 Hour Hovering Machine Conceptual DesignDocument15 pages24 Hour Hovering Machine Conceptual DesignKarad KaradiasNo ratings yet

- Video Link - Https://Youtu - Be/Lp-RszcmorqDocument5 pagesVideo Link - Https://Youtu - Be/Lp-Rszcmorqapi-316603468No ratings yet

- Potential Flow 2-Dimensional Vortex Panel Model: Applications To WingmillsDocument54 pagesPotential Flow 2-Dimensional Vortex Panel Model: Applications To WingmillsAlice BotNo ratings yet

- Introduction To Fluid Mechanics - 2005Document27 pagesIntroduction To Fluid Mechanics - 2005Ranu GamesNo ratings yet

- Qprop Theory PDFDocument14 pagesQprop Theory PDFAlvin AnthonyNo ratings yet

- Hypersonic Glide Vehicle Design ConsderationsDocument35 pagesHypersonic Glide Vehicle Design ConsderationsIan M Mair100% (1)

- A Computational Procedure To Define The Incidence Angle On Airfoils Rotating Around An Axis Orthogonal To Flow DirectionDocument9 pagesA Computational Procedure To Define The Incidence Angle On Airfoils Rotating Around An Axis Orthogonal To Flow DirectionFranzAnzuresFroitzheim0% (1)

- Design of Stiffened Slabs-On-grade On Shrink-SwellDocument23 pagesDesign of Stiffened Slabs-On-grade On Shrink-SwelljoneNo ratings yet

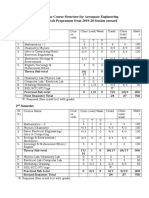

- Semester-Wise Course Structure 4-Year B - Tech ProgrammeDocument54 pagesSemester-Wise Course Structure 4-Year B - Tech ProgrammeHarsh KumarNo ratings yet

- Propeller Aerodynamics PDFDocument11 pagesPropeller Aerodynamics PDFMaurizio Bernasconi100% (2)

- Rexca Anak JamitDocument36 pagesRexca Anak Jamitjohn mwangiNo ratings yet

- Aircraft Winglets 2 PDFDocument26 pagesAircraft Winglets 2 PDFAlen S T100% (1)

- Lockheed Martin - The Complete Beasley IIDocument75 pagesLockheed Martin - The Complete Beasley IIpaulbowesNo ratings yet

- GASCo Flight Safety - Summer 2015Document36 pagesGASCo Flight Safety - Summer 2015Adrian BistreanuNo ratings yet

- The Albatross Design ReportDocument50 pagesThe Albatross Design ReportSobin SanthoshNo ratings yet

- Mechanical Lift Categorization: Risk Questions Yes NoDocument1 pageMechanical Lift Categorization: Risk Questions Yes NomohammedNo ratings yet

- Aircraft Design ReportDocument91 pagesAircraft Design ReportGrassrehLeNo ratings yet

- Modeling and Control of Gas Lifted Oil WellsDocument13 pagesModeling and Control of Gas Lifted Oil WellsRoshan SharmaNo ratings yet

- Fluid Mechanics: Lecture Notes ofDocument22 pagesFluid Mechanics: Lecture Notes ofAlsharksi AviationNo ratings yet

- Robotpilóta Rendszerek: Budapesti Műszaki EgyetemDocument78 pagesRobotpilóta Rendszerek: Budapesti Műszaki EgyetemNaguibNo ratings yet

- A.2. Design of Conventional AircraftDocument29 pagesA.2. Design of Conventional AircraftAndres PradillaNo ratings yet

- Teachers Pack FINAL AC16092016Document26 pagesTeachers Pack FINAL AC16092016ozar100% (1)

- Problem StatementDocument3 pagesProblem StatementGajananNo ratings yet

- Enhancement of Aerodynamic Performance of A Formula-1 Race Car Using Add-On DevicesDocument8 pagesEnhancement of Aerodynamic Performance of A Formula-1 Race Car Using Add-On DevicesSpitfirecripNo ratings yet

- Airplane Flight AnalogyDocument8 pagesAirplane Flight Analogypetroetpaulo2006No ratings yet

- OrnithopterDocument8 pagesOrnithopterSabik Nainar0% (1)

- VALVEDocument13 pagesVALVENabaz MuhamadNo ratings yet