Professional Documents

Culture Documents

Pages From AASHTO LRFD Bridge Design Spec 4th 2007

Pages From AASHTO LRFD Bridge Design Spec 4th 2007

Uploaded by

Amr Adel Hameed0 ratings0% found this document useful (0 votes)

141 views6 pageshand rail load from aashto lrfd

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthand rail load from aashto lrfd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

141 views6 pagesPages From AASHTO LRFD Bridge Design Spec 4th 2007

Pages From AASHTO LRFD Bridge Design Spec 4th 2007

Uploaded by

Amr Adel Hameedhand rail load from aashto lrfd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

138

AASHTO LRED Bripce Desion SPECIFICATIONS (SI)

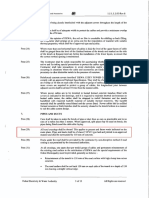

‘Table 13.7.2-1 Bridge Ralling Test Levels and Crash Test Criteria

Vehicle ‘Small Pickup | Single-Unit Van-Type Tractor-Tanker

Characteristics | Automobiles | Truck _| Van Truck Tractor-Trailer Trailer

WO) 7000 8000| 20.000 | 80000 | 220000 | 355000 355 000

B (ram) 1700_| 1700 [2000 2300 2450 2450 2450

G (mm) 550_| 550 i} 1250. 1630 1850 72050

Crash angle, @ [20° | 20" 2° 1S" 1s 1s 15°

Test Level Test Speeds (km/h)

TL 30] 30 30 NA NA NA NA

TL 7_| 70 70 NA NA NA NA

TLS To0_| 100 100 NA NA NA NA

TL4 100_| 100 100 80 NIA NIA NA

TLS 100_| 100 100 NA NA 80 NA

TL 100_| 100 100 NA NA NA 80

13.73 Railing Design

13.7.3.1 General 13.734

A traffic rling should normally provide a smooth

continuous face of rail on the traffic side. Steel posts with

ral elements should be set back from the face of rail.

Structural continuity inthe rail members and anchorages of

‘ends should be considered

‘Arailing system and its connection tothe deck shall

bbe approved only after they have been shown through

‘rash testing to be satisfactory for the desired test level

13.7.3.1.1 Application of Previously Tested Systems

A crashworthy railing system may be used without

further analysis and/or testing, provided that the proposed

installation does not have features that are absent in the

tested configuration and that might detract from the

performance ofthe tested railing system.

13,7.3.1.2 New Systems

New railing systems may be used, provided that

‘acceptable performance is demonstrated through full-scale

crash tests,

‘The crash test specimen for a railing system may be

designed to resist the applied loads in accordance with

Appendix A ofthis Section or NCHRP Report 350 with its

revisions.

Provision shall be made to transfer loads from the

railing system to the deck. Railing loads may be taken

from Appendix A of this Section,

Proinasions or depressions at rail openings may be

acceptable, provided that their thickness, depth, or

geometry does not prevent the railing from meeting the

crash test evaluation eritera,

Test specimens should include a representative

length of the overhang to account for the effect of deck

‘lexibility on the distance over which the railing engages

the deck.

C13.73.11

‘When a minor detail is changed on or an improvement

is made toa railing system that has already been tested and

approved, engineering judgment and analysis should be

used when determining the need for additional crash

testing.

13.73.12

SECTION 13 (SI): RAILINGS

Unless a lesser thickness can be proven satisfactory

during the crash testing procedure, the minimum edge

thickness for concrete deck overhangs shal be taken as:

For concrete deck overhangs supporting a deck-

‘mounted post system: 200 mm

© Fora side-mounted post system: 300 mm

‘+ For conerete deck overhangs supporting concrete

parapets or barriers: 200 mm

13.73.2 Height of Traffic Parapet or Railing

‘Traffic railings shall be at least 685 mm for TL-3,

810 mm for TL-4, 1070 mm for TL-S, and 2290 mm in

height for TL-6.

The bottom 75-mm lip of the safety shape shall not be

increased for future overlay considerations.

‘The minimum height for a conerete parapet with a

vertical face shall be 685 mm. The height of other

‘combined concrete and metal rails shall not be less than

‘685 mm and shall be determined to be satisfactory through

crash testing forthe desired test level

‘The minimum height of the pedestrian or bicycle

railing should be measured above the surface of the

sidewalk or bikeway.

‘The minimum geometric requirements for

‘combination railings beyond those required to meet crash

test requirements shall be taken as specified in

Articles 13.8, 13.9, and 13.10.

13.8 PEDESTRIAN RAILING

13.8.1 Geometry

‘The minimum height of a pedestrian railing shall be

1070 mm measured from the top of the walkway.

A pedestrian rail may be composed of horizontal

and/or vertical elements. The clear opening between

elements shall be such that a 150-mm diameter sphere

shall not pass through

‘When both horizontal and vertical elements are used,

the 150-mm clear opening shall apply tothe lower 685 mm

of the railing, and the spacing in the upper portion shall be

such that a 200-mm diameter sphere shall not pas through,

A safety toe ral or curb should be provided. Rails should

project beyond the face of posts and/or pickets as shown in

Figure A13.1.1-2,

‘The ral spacing requirements given above should not

apply to chain link or metal fabric fence support rails and

posts. Mesh size in chain link or metal fabric fence should

hhave openings no larger than 50 mam,

139

Preliminary design for bridge decks should comply

with Article A13.1.2. A determination of the adequacy of

deck reinforcement forthe distribution of post anchorage

loads to the deck should be made during the rail testing

program. Ifthe rail testing program satisfactorily models

the bridge deck, damage to the deck edge can be assessed

at this time.

In adequately designed bridge deck overhangs, the

major crash-telated damage presently occurs in short

sections of slab areas where the barrier is hit.

13.732

These heights have been determined as satisfactory:

‘through crash tests and experience.

For future deck overlays, an encroachment of SO mm,

leaving a 25-mm lip, has been satisfactorily tested for

safety shapes.

C3841

‘The size of openings should be capable of retaining an

average size beverage container

413.10

13.8.2 Design Live Loads

‘The design live load for pedestrian railings shall be

taken as w= 0.73 Nimm, both transversely and vertically,

acting simultaneously. ‘In addition, each longitudinal

clement will be designed for a concentrated load of 890 N,

which shall act simultaneously with the above loads at any

point and in any direction at the top of the longitudinal

element.

‘The posts of pedestrian railings shall be designed fora

concentrated design live load applied transversely at the

center of gravity of the upper longitudinal element or, for

railings with a total height greater than 1500 mm, at a

point 1500 mm above the top surface ofthe sidewalk. The

value ofthe concentrated design live load for posts, Pi. it

N, shall be taken as:

Py, = 8904+ 0.732 (3.8.2.1)

where:

L = post spacing (mm)

‘The design load for chain link or metal fabric fence

shall be 7.210 MPa acting normal to the entire

surface.

The application of loads shall be as indicated in

Figure 1, in which the shapes of rail members are

illustrative only. Any material or combination of materials

specified in Amicle 13.5 may be used.

k

1070 mm Min.

k

4070 mm Min,

Watway

Burtace

“

tty

|e

Figure 13.8.2-1 Pedestrian Ralling Loads—To be used on

the outer edge ofa sidewalk when highway traffic

separated from pedestrian traffic by a traffic

Railing shape ilustrative only.

13.9 BICYCLE RAILINGS

13.9.1 General

Bicycle railings shall be used on bridges specifically

designed to carry bicycle traffic and on bridges where

specific protection of bicyclists is deemed necessary,

AASHTO LRED Bruce Desicw SrEcIFICATIONS (SI)

13.8.2

‘These live loads apply to the railing. The pedestrian

live load, specified in Article 3.6.1.6, applies to the

sidewalk,

[SECTION 13 (SI): RalLNcs

13.9.2 Geometry

‘The height of a bicycle railing shall not be less than

1070 mm, measured from the top of the riding surface.

‘The height ofthe upper and lower zones ofa bicycle

railing shall be at least 685 mm. The upper and lower

zones shall have rail spacing satisfying the respective

provisions of Article 13.8.1

If deemed necessary, rubrails attached to the rail or

fence to prevent snagging should be deep enough to

protect a wide range of bicycle handlebar heights,

If screening, fencing, or a solid face is utilized, the

‘number of rails may be reduced.

13.9.3 Design Live Loads

Ifthe rail height exceeds 1370 mm above the riding

surface, design loads shall be determined by the Designer.

‘The design loads for the lower 1370 mm of the bicycle

railing shall not be less than those specified in

Article 13.8.2, except that for railings with total height

greater than 1370 mm, the design live load for posts shall

be applied ata point 1370 mm above the riding surface.

The application of loads shall be as indicated in

Figure 1. Any material or combination of materials

specified in Article 13.5 may be used

§

=

=

é

E

5

10700 minima

ire 13.9.3 Bicycle Railing Loads.

outer edge of bikeway when highway traffic is separated

from bicycle traffic by a traffic raling. Railing shape

istrative only.

13.1

13.92

Railings, fences or barriers on either side of a shared

use path on a structure, or along bicycle lane, shared use

path or signed shared roadway located on a highway

bridge should be @ minimum of 1070 mm high. The

1070-mm minimum height is in accordance with the

AASHTO Guide for the Development of Bicycle Facilites,

3rd Edition, (1999).

‘On such a bridge or bridge approach where high-speed

high-angle impact with a railing, fence or barrier are more

cely to occur (such as short radius curves with restricted

sight distance or at the end of a long descending grade) or

in locations with site-specific safety concems, ¢ railing,

fence or bartier height above the minimum should be

considered,

‘The need for rubrails attached to a rail or fence is

controversial among many bicyclists

13.12

13.10 COMBINATION RAILINGS,

13.101 General

The combination railing shall conform to the

requirements of either the pedestrian or bicycle railings, as

specified in Articles 13.8 and 13.9, whichever is

applicable. The traffic railing portion of the combination

railing shall conform to Article 13.7.

13.10.2 Geometry

‘The geometric provisions of Articles 13.7, 13.8, and

13.9 shall apply to their respective portions of a

combination railing.

13.103 Design Live Loads

Design loads, specified in Articles 13.8 and 13.9, shall.

not be applied simultaneously with the vehicular impact

loads.

13.11 CURBS AND SIDEWALKS

13.411 General

Horizontal measurements of roadway width shall be

taken from the bottom of the face ofthe curb. A sidewalk

‘curb located on the highway traffic side ofa bridge railing

shall be considered an integral part ofthe railing and shall

bbe subject to the crash test requirements specified in

Article 13.7.

13.112 Sidewalks

When curb and gutter sections with sidewalks are

used on roadway approaches, the curb height for raised

sidewalks on the bridge should be no more than 200 mm.

Ifa barrier curb is required, the curb height should not be

Tess than 150 mm, Ifthe height of the curb on the bridge

differs from that off the bridge, it should be uniformly

transitioned over a distance greater than or equal to 20

times the change in height.

13.113 End Treatment of Separation Railing

‘The end treatment of any traffic railing or barter shall

‘meet the requirements specified in Articles 13.7.1.2 and

13.713.

AASHTO LRED Brive DEsicn SPEctFICATIONS (SI)

13.412

Raised sidewalks on bridges are not usually provided

‘where the approach roadway is not curbed for pedestrians

cr the structure is not planned for pedestrian occupancy.

For recommendations on sidewalk width, see

Figure 13.7.1.1-1 and AASHTO’s A Policy on Geometric

Design of Highways and Streets.

During stage construction, the same transition

considerations will be given tothe provision of ramps from

the bridge sidewalk to the approach surface.

SECTION 13 (SI): RAILINGS 13.413

REFERENCES

AASHTO. 2002. Roadside Design Guide, 3rd Edition, RSDG-3. American Association of State Highway and

‘Transportation Officials, Washington, DC,

AASHTO, 2004. 4 Policy on Geometric Design of Highways and Streets, Sth Edition, GDHS-5, American Association of

State Highway and Transportation Officials, Washington, DC.

Alberson, D. C,,R. A. Zimmer, and W. L. Menges. 1997. NCHRP Report 350 Compliance Test 5-12 ofthe 1.07-m Vertical

Wall Bridge Railing, FHWA/RD-96/199, Federal Highway Administration, U.S. Department of Transportation,

‘Washington, DC.

Buth, C. E., W. L. Campise, L. I. Griffin, M, L. Love, and D. L. Sicking. 1986, Performance Limits of Longitudinal

Barriers, FHWA/RD-86/153, Test 4798-13, Federal Highway Administration, U.S. Department of Transportation,

‘Washington, DC.

Michie, J. D. 1981. NCHRP Report 230: Recommended Procedures for the Safety Performance Evaluation of Highway

Appurtenances. Transportation Research Board, National Research Council, Washington, DC.

Ross, H. E.,D.L. Sicking, R. A. Zimmer, and J.D. Michie. 1993. NCHRP Report 350: Recommended Procedures for the

Safety Performance Evaluation of Highway Features. Transportation Research Board, National Research Council,

Washington, DC.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Construction Stage Analysis 1475681905Document31 pagesConstruction Stage Analysis 1475681905Amr Adel HameedNo ratings yet

- Sikaflex ProDocument4 pagesSikaflex ProAmr Adel HameedNo ratings yet

- Heavy Duty Steel Shoring: Ground Support Systems (Aust)Document1 pageHeavy Duty Steel Shoring: Ground Support Systems (Aust)Amr Adel HameedNo ratings yet

- Technical Bulletin TB 42 Curing of ConcreteDocument39 pagesTechnical Bulletin TB 42 Curing of ConcreteAmr Adel HameedNo ratings yet

- Road Design Note 0604 Accepted Safety Barrier Products v18Document23 pagesRoad Design Note 0604 Accepted Safety Barrier Products v18Amr Adel HameedNo ratings yet

- Sec656 - Elastomeric Bearings & PadsDocument2 pagesSec656 - Elastomeric Bearings & PadsAmr Adel HameedNo ratings yet

- D0147-C-S600MH-2019 - Series 600 SBH Manhole BoxDocument1 pageD0147-C-S600MH-2019 - Series 600 SBH Manhole BoxAmr Adel HameedNo ratings yet

- Sec687 - Repair of Concrete CracksDocument8 pagesSec687 - Repair of Concrete CracksAmr Adel HameedNo ratings yet

- Bridge Technical Note 2018 - 006 Bonded Anchors Jan 2018Document3 pagesBridge Technical Note 2018 - 006 Bonded Anchors Jan 2018Amr Adel HameedNo ratings yet

- Operating Instructions - Standard Shoring - SBH Series 600 Manhole Shoring BoxDocument8 pagesOperating Instructions - Standard Shoring - SBH Series 600 Manhole Shoring BoxAmr Adel HameedNo ratings yet

- Road Design Note 0604 Accepted Safety Barrier Products 03 2020Document24 pagesRoad Design Note 0604 Accepted Safety Barrier Products 03 2020Amr Adel HameedNo ratings yet

- D0147-C-S600-2019 - Series 600 SBH Standard BoxDocument1 pageD0147-C-S600-2019 - Series 600 SBH Standard BoxAmr Adel HameedNo ratings yet

- Sec689 - Cementitious Patch Repair of ConcreteDocument9 pagesSec689 - Cementitious Patch Repair of ConcreteAmr Adel HameedNo ratings yet

- Sec706 - INSTALLATION OR REPLACEMENT OF UTILITY INFRASTRUCTURE WITHIN ROAD RESERVESDocument4 pagesSec706 - INSTALLATION OR REPLACEMENT OF UTILITY INFRASTRUCTURE WITHIN ROAD RESERVESAmr Adel HameedNo ratings yet

- Sec680 - Bonded AnchorsDocument8 pagesSec680 - Bonded AnchorsAmr Adel HameedNo ratings yet

- Sec614 - FormworkDocument9 pagesSec614 - FormworkAmr Adel HameedNo ratings yet

- Sec173 - EXAMINATION AND TESTING OF MATERIALS AND WORK (ROADWORKS)Document4 pagesSec173 - EXAMINATION AND TESTING OF MATERIALS AND WORK (ROADWORKS)Amr Adel HameedNo ratings yet

- Sec612 - Post-Tensioning of Concrete UnitsDocument11 pagesSec612 - Post-Tensioning of Concrete UnitsAmr Adel HameedNo ratings yet

- Sec613 - FalseworkDocument6 pagesSec613 - FalseworkAmr Adel HameedNo ratings yet

- Sec611 - Steel ReinforcementDocument7 pagesSec611 - Steel ReinforcementAmr Adel HameedNo ratings yet

- Temporary Work PDFDocument216 pagesTemporary Work PDFAmr Adel HameedNo ratings yet

- Sec610 - Structural ConcreteDocument52 pagesSec610 - Structural ConcreteAmr Adel HameedNo ratings yet

- 1 Input Data: Profis Anchor 2.8.0Document7 pages1 Input Data: Profis Anchor 2.8.0Amr Adel HameedNo ratings yet

- Dewa StandardDocument1 pageDewa StandardAmr Adel HameedNo ratings yet