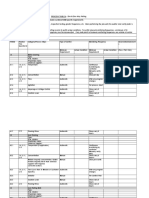

QUESSTIONNAIRE

TOPIC : APQP ,PPAPPFMEA,MSA&SPC MARKS :

DURATION : DATE :

FACULTY : PARTICIPANT:

Before (Tick the appropriate answer) After

1. APQP acronym means

a. Appropriate product quality planning

b. Advanced product quality planning

c. Advanced techniques product quality planning

2. The phase during which Process FMEA to be carried out

a. Product design & development

b. Product & process validation

c. Process design development

3. The MSA & SPC are carried out during

a. Product design and development

b. Product & process validation

c. Process design development

4. Control plan to be prepared for

a. Prototype, Prelaunch, Production

b. Receipt only

c. Receipt, In process & Final

5. Control plan should cover

a. Only receipt stage

b. Only final inspn. Stage

c. From receipt to dispatch

6. No. of documents / items to be prepared for PPAP submission

a. 14

b. 17

c. 18

d. 11

Page 1 of 6

�7. Minimum trial run quantity during significant production run

a. Min. 300 nos.

b. Min. 300 consecutive nos.

c. Min. 50 nos.

d. 300 nos. in one shift

8. Acceptance criteria for initial process study is

a. Cpk / Ppk / Index Value > 1.67

b. Cpk > 1.33

c. Cp and Cpk > 1.0

9. Qualified Laboratory documentation shall include

a. laboratory scope

b. In-house laboratory scope , NABL Certificate & scope of certification of external labs

c. External Labs NABL certificate

d. Certificate of equivalent body

10. The No. of situations for which notification & submission required is

a. 8

b. 12

c. 14

d. 11

11. Process FMEAs shall consider

a. Processes affecting Special Characteristics

b. Minor characteristics

c. Only Spl. processes

12. Appropriate INPUT documents are

a. Customer complaint

b. Warranty Claims

c. Past rejection / Rework data

d. Preliminary process flow diagram

e. All of the above

13. RPN Means

a. Risk priority number

b. Random priority number

c. Rare part number

d. None of the above

Page 2 of 6

�14. Example of ‘FAILURE MODE’ is

a. Diameter under size/over size

b. Ovality /Taper

c. Crack

d. All of the above

15. Potential Effects shall be considered in’

a. Next opn.

b. Next opn,/ Subsequent opn. customer,/end user

c. Customer

d. None of the above

16. The action shall be taken for

a. High RPN only

b. All RPN only

c. Lower RPN

d. High RPN and SEV > 8

17. The recommended action shall focus as a first priority

a. Reduction in SEV

b. Reduction in OCC

c. Reduction in DET

18. The SEV rating can be reduced only

a. Process is improved

b. Process is changed

c. Design is changed / Modified

d. Controls increased

19. The PFMEA shall be updated whenever

a. New failure mode is identified

b. New cause is identified

c. New customer compliant is received

d. Process is changed

e. All of the above

20. Control Plans (Prelaunch) shall include controls

a. Decided during trials

b. Decided during FMEA

c. Decided after PPAP

d. Decided during Production

21. Elements of a measurement system

a. Inspector, instrument, part, characteristic etc.

b. Inspector, instrument, part, characteristic, checking method etc.

c. Instrument

Page 3 of 6

�22. Appropriate statistical study to capture precision

a. Bias

b. Linearity

c. R&R

23. Appropriate statistical study to capture accuracy for one fixed range

a. Bias

b. Linearity

c. R&R

24. Appropriate statistical study to capture accuracy over the entire operating range

(Process Variation)

a. Bias

b. Linearity

c. Stability

25. Appropriate statistical study to capture variation in bias w.r.t time

a. Bias

b. R&R

c. Stability

26. Repeatability represents variation due to

a. Equipment / instrument

b. Appraiser

c. Appraiser part interaction

27. Reproducibility represents variation due to

a. Equipment / instrument

b. Appraiser

c. Appraiser part interaction

28. GR&R study acceptance criteria

a. GR&R > 30% of tolerance (tol.) or total variation TV)

b. GR&R < 10% tol or TV

c. GR&R < 10% tol or tv & upto 30% tol. or TV considering the cost of repair etc.

29. Acceptance criteria for Bias study is

a. > 30

b. < 30

c. Zero should lie between two bias limits

d. 90

30. Acceptance criteria for Kappa study is

a. > 75

b. <10

c. <40

d. None of the above

Page 4 of 6

�31. Statistical Process control is

a. 10% Product & Process Knowledge & 90% Statistic

b. 90% Product & Process Knowledge & 10% Statistic

c. 50% Product & Process Knowledge & 50% Statistic

32. Criteria for Evaluation of Sample or Process is

a. Average & Range

b. Average & Range & Standard Deviation

c. None

33. Two types of causes

a. Random causes & non random causes

b. Common causes & Special (Assignable) causes

c. Common causes & non random causes

34. Statistical control means, free from

a. Common causes

b. Chance causes

c. Assignable or Special. Causes

35. Conditions for checking statistical control using histogram

a. Double peak

b. Skewed distribution

c. Bell shaped

36. Conditions for checking statistical control using control charts

a. Any points outside UCL/LCL

b. Any consecutive 7 points above or below center line

c. Any consecutive 7 points upward or downward trend

d. All of the above

37. Objectives of control chart

a. To detect Assignable or Special causes

b. To maintain the process capability

c. To indicate the opportunity for improvement and confirm the improvement

d. All of the above

Page 5 of 6

�38. 16. Cp = 1.67, Cpk = 0.67, the required action is

a. Process variable to be reduced

b. Process average should be shifted towards target or nominal value of specification.

c. 100 % Inspection is required

39. Cp = 1.67, Cpk = 2.67 the required action is

a. Process variation to increased

b. Tolerance to be increased

c. Verify the calculation of Cp & Cpk

40. By SPC Implementation we can improve

a. Conformance to Specification

b. Quality of Conformance

c. None

d. Both a & b

Page 6 of 6