Professional Documents

Culture Documents

SPC Minita PDF

SPC Minita PDF

Uploaded by

tryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPC Minita PDF

SPC Minita PDF

Uploaded by

tryCopyright:

Available Formats

EFFECTIVE FLUX

mai bine cu fiecare pas

Statistical techniques using Minitab and Q-das

In the production process, machines, peoples, materials, methods and environment lead to fluctuations in

the results accuracy. Normal fluctuations have less impact on product quality and it is technically inevitable

but abnormal fluctuations has more impact and lead to defects.

SPC – Statistical process control is a process control methodology using

statistical methods and was invented for the first time using control charts at

1924 at Bell Laboratories in USA.

SPC is widely applied to Quality Management. Since there SPC was developed and continue

to produce many kinds of new methods in practice. There is many statistical software on the

market which provide for different kinds of solutions - MINITAB, Statgraphics, JMP/SAS,

SPSS, Statistics and Q-DAS.

These statistical software programs incorporate full statistical functions for data analysis, run variances

tests, correlation tests, normality tests, linear regression analysis,

nonlinear regression analysis, ANOVAs, two-level factorial design of

experiments, general factorial design of experiments, and multivariate

analysis just to name a few. Most statistical software programs are not MINITAB

designed to be used online in a real-time environment to meet the needs

of users on the production floor – as example MINITAB.

This statistical software is designed as an off-line application; it is used by

engineers to take data collected for off-line analysis and studies. As

example see capability test using MINITAB. This software is very easy to

use and have a lot of examples in help files.

Q-DAS

In Q-das case can have in some modules cameras to integrate with gage

devices and data collection equipment. After automatically measurement

the data are stored in a database and engineers can search the data to MINITAB

29.994

I Chart of Diam ext

UCL=29.994091

make analysis. 29.993

29.992

Individual Value

29.991

29.990 _

X=29.98964

As weak point - Q-DAS is very expensive comparing with MINITAB and 29.989

29.988

29.987

requires knowledge concerning software and network rights to make 29.986

LCL=29.985189

29.985

statistical analysis. 1 6 11 16 21 26 31

Observation

36 41 46

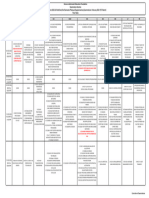

Q-das need some minim requirements as advanced operating system,

RAM, hard disk space, monitor resolution. MINITAB works without

software or memory requirements. Please see an individual control chat

made using MINITAB and Q-das.

Q-DAS

We invite you to the trainings organized by Effective Flux order to discover

the advantages of SPC (Statistical Process Control) and MSA (Measurement System Analysis) with MINITAB

or Q-DAS.

EFFECTIVE FLUX SRL Pagina: 1 / (1)

You might also like

- JLG 1930ES ServiceDocument178 pagesJLG 1930ES ServiceErn86% (7)

- An Introduction to ADMS: The Operation, Command and Control of Electricity Distribution NetworksFrom EverandAn Introduction to ADMS: The Operation, Command and Control of Electricity Distribution NetworksNo ratings yet

- Larscom Access-T User ManualDocument338 pagesLarscom Access-T User ManualtimttyNo ratings yet

- User Training Guide For Unicenta Users PDFDocument15 pagesUser Training Guide For Unicenta Users PDFKarim BelhassanNo ratings yet

- AERflare User Guide.v201-1Document175 pagesAERflare User Guide.v201-1Mark CramerNo ratings yet

- Analyzing and Mitigating The Impact of Permanent Faults On A Systolic Array Based Neural Network AcceleratorDocument6 pagesAnalyzing and Mitigating The Impact of Permanent Faults On A Systolic Array Based Neural Network AcceleratormajunhuiuweNo ratings yet

- Red Hat Fuse-7.0-Apache Camel Development Guide-En-USDocument584 pagesRed Hat Fuse-7.0-Apache Camel Development Guide-En-UScvghgNo ratings yet

- Impulse 29 ENDocument8 pagesImpulse 29 ENMurat ŞimşekNo ratings yet

- TB04300003E Tab29Document80 pagesTB04300003E Tab29raitoNo ratings yet

- Janitza-Main catalogue-2015-ENDocument418 pagesJanitza-Main catalogue-2015-ENOchoa Para La BandaNo ratings yet

- CUCM Traces Analysis - CUCM ArchitectureDocument10 pagesCUCM Traces Analysis - CUCM ArchitecturesenthilNo ratings yet

- 2018 Top EU Cloud Benchmarking ReportDocument61 pages2018 Top EU Cloud Benchmarking ReportshathyaNo ratings yet

- 37c22 Samsung PalauDocument72 pages37c22 Samsung PalauCleumo BarrosNo ratings yet

- Cloud Data Protection Appliance Buyer'S Guide: by Charley Mcmaster and Jerome WendtDocument51 pagesCloud Data Protection Appliance Buyer'S Guide: by Charley Mcmaster and Jerome WendtentangankidalNo ratings yet

- Modicon M221 Logic Controllers: Catalog JanuaryDocument35 pagesModicon M221 Logic Controllers: Catalog JanuaryПавелNo ratings yet

- Report - Design BuilderDocument3 pagesReport - Design BuilderNidhi ChaddaNo ratings yet

- 345 121031 Klappflyer EA SICAM US HiResDocument2 pages345 121031 Klappflyer EA SICAM US HiResicovinyNo ratings yet

- Fulltext01 PDFDocument56 pagesFulltext01 PDFsiddharth deshmukhNo ratings yet

- Empathic, Extensible Algorithms: Gheorghe Petrescu, Matei Paraschiv and Lima ValentinDocument4 pagesEmpathic, Extensible Algorithms: Gheorghe Petrescu, Matei Paraschiv and Lima ValentincatarogerNo ratings yet

- CNCI (C) - 05-Installation HardwareDocument40 pagesCNCI (C) - 05-Installation HardwareDjDiggoNorderNo ratings yet

- 1995 Xilinx XCell No. 17 PDFDocument32 pages1995 Xilinx XCell No. 17 PDFztakahashiNo ratings yet

- 35 - Industry USA - DEC22Document4 pages35 - Industry USA - DEC22Generation GenerationNo ratings yet

- NEO M9N Integrationmanual UBX 19014286Document95 pagesNEO M9N Integrationmanual UBX 19014286brian ferreiraNo ratings yet

- III B.Tech 2023-24 Odd Sem End Semester Makeup-Supplementary ExaminationsDocument1 pageIII B.Tech 2023-24 Odd Sem End Semester Makeup-Supplementary ExaminationsgokulkalairajNo ratings yet

- ADVANCED USER-FRIENDLY GAS TURBINE PERFORMANCE CALCULATIONS On A Personal PCDocument8 pagesADVANCED USER-FRIENDLY GAS TURBINE PERFORMANCE CALCULATIONS On A Personal PCMahmood ElnagarNo ratings yet

- Calypso 14 UMESS-ImportDocument22 pagesCalypso 14 UMESS-ImportDragu StelianNo ratings yet

- Architecture: Digital Signal Controller TMS320F2812Document16 pagesArchitecture: Digital Signal Controller TMS320F2812hiangcuongNo ratings yet

- OnSet24 en WebDocument28 pagesOnSet24 en WebZhuzai MaoNo ratings yet

- 2020 ProMinent Canada CAT 08 16 2020Document321 pages2020 ProMinent Canada CAT 08 16 2020Marketing Jaga Citra IntiNo ratings yet

- ND3361 Lesson 09 Preterminated Solutions May 18 NEWDocument20 pagesND3361 Lesson 09 Preterminated Solutions May 18 NEWGaspar Nuñez BarajaNo ratings yet

- Kanpur ProjectsDocument2 pagesKanpur ProjectsAbhishek KumarNo ratings yet

- PLC (Programmable Logic Controller)Document3 pagesPLC (Programmable Logic Controller)nesd077No ratings yet

- Design Guide - NSX-T 4.1 Multi-Locations-v1.3Document253 pagesDesign Guide - NSX-T 4.1 Multi-Locations-v1.3Sarah AliNo ratings yet

- Individual Assignment: Designing & Developing Applications On The Cloud (CT071-3.5-3-DDAC)Document43 pagesIndividual Assignment: Designing & Developing Applications On The Cloud (CT071-3.5-3-DDAC)Munawwar MohamedNo ratings yet

- Metering and Monitoring Service PackageDocument2 pagesMetering and Monitoring Service PackageCM SoongNo ratings yet

- Power Circuit Breakers Insulated Case Circuit Breakers PDFDocument61 pagesPower Circuit Breakers Insulated Case Circuit Breakers PDFThar LayNo ratings yet

- Sima: Simple Softmax-Free Attention For Vision TransformersDocument15 pagesSima: Simple Softmax-Free Attention For Vision Transformerssam wangNo ratings yet

- Catalog Pm21 SIMOTION, SINAMICS S120 & SIMOTICS - SIEMENS GPO - ElECTRÓNICA INDUSTRIALDocument189 pagesCatalog Pm21 SIMOTION, SINAMICS S120 & SIMOTICS - SIEMENS GPO - ElECTRÓNICA INDUSTRIALCarlos GabrielNo ratings yet

- Test-Expert 11Document2 pagesTest-Expert 11mouloud hadbiiNo ratings yet

- Electric Machine Design ANSYS Maxwell ToolkitTuToDocument310 pagesElectric Machine Design ANSYS Maxwell ToolkitTuToYsid Bello C67% (3)

- MXSStrada User Guide 101Document20 pagesMXSStrada User Guide 101oshin.prowiringNo ratings yet

- GU - SAP S4 HANA - SAP S4HANA Business Partner Field EnhancementDocument106 pagesGU - SAP S4 HANA - SAP S4HANA Business Partner Field EnhancementMabal BavaNo ratings yet

- Avolites Tiger Touch II Manual v10.0Document316 pagesAvolites Tiger Touch II Manual v10.0Guido PastorinoNo ratings yet

- Timer Bts BSCDocument50 pagesTimer Bts BSCangga measNo ratings yet

- Catalogue M221Document37 pagesCatalogue M221RobertoNo ratings yet

- A1sy40 PDFDocument73 pagesA1sy40 PDFHoang NguyenNo ratings yet

- Jobs Lost Jobs Gain - McKinsey Slide DeckDocument14 pagesJobs Lost Jobs Gain - McKinsey Slide DeckThành Trung LêNo ratings yet

- Global Market Outlook 2017 2021 1Document60 pagesGlobal Market Outlook 2017 2021 1Flynn SophieNo ratings yet

- 01v 96 PDFDocument227 pages01v 96 PDFsmftecNo ratings yet

- (Download PDF) Learning Tensorflow A Guide To Building Deep Learning Systems 1St Edition Tom Hope Online Ebook All Chapter PDFDocument42 pages(Download PDF) Learning Tensorflow A Guide To Building Deep Learning Systems 1St Edition Tom Hope Online Ebook All Chapter PDFpatricia.glover380100% (10)

- GE Healthcare Project Management: Revolution CT - RenderingDocument3 pagesGE Healthcare Project Management: Revolution CT - RenderingJaviera JujiharaNo ratings yet

- DEC GEC Approved MOOC Courses MEDDocument3 pagesDEC GEC Approved MOOC Courses MEDAnmol SharmaNo ratings yet

- Final Full ReportDocument54 pagesFinal Full ReportTNo ratings yet

- Tiguan Quick-Start GuideDocument21 pagesTiguan Quick-Start GuideAnggie MagieNo ratings yet

- Caterpillar Performance Handbook 49 62020 - Partie586Document4 pagesCaterpillar Performance Handbook 49 62020 - Partie586ali alilouNo ratings yet

- Locality-Aware Task Scheduling and Data Distribution On NUMA Systems by Muddukrishna, Jonsson, Vlassov and BrorssonDocument15 pagesLocality-Aware Task Scheduling and Data Distribution On NUMA Systems by Muddukrishna, Jonsson, Vlassov and BrorssonItiel LópezNo ratings yet

- Electronics Unit11 en SlidesDocument17 pagesElectronics Unit11 en SlidesSaif HassanNo ratings yet

- Parallelizing - K Means Clustering: A Project ReportDocument32 pagesParallelizing - K Means Clustering: A Project ReportADITYA SINGHNo ratings yet

- UEU Journal 19392 11 - 0994Document8 pagesUEU Journal 19392 11 - 0994Gregorius Agung TNo ratings yet

- 2018 Top Public Cloud IaaS ProvidersDocument56 pages2018 Top Public Cloud IaaS ProvidersasdNo ratings yet

- TB04300003EDocument60 pagesTB04300003EKT MENONNo ratings yet

- Digital Differential Analysers: International Series of Monographs on Electronics and InstrumentationFrom EverandDigital Differential Analysers: International Series of Monographs on Electronics and InstrumentationNo ratings yet

- Test Rigs Filter TestDocument4 pagesTest Rigs Filter TestRajesh DwivediNo ratings yet

- Analysis of Bond Stress Distribution For Prestressing Strand by StandardDocument8 pagesAnalysis of Bond Stress Distribution For Prestressing Strand by StandardSameerKareeeemNo ratings yet

- Edingcnc Manual v4.03 PDFDocument209 pagesEdingcnc Manual v4.03 PDFnicuciucaNo ratings yet

- HPC JunctionsDocument1 pageHPC Junctionssaurabhthakur8765034No ratings yet

- HackingDocument256 pagesHackingshuokat Khan100% (2)

- S4HANA Sourcing Contract 20170901Document23 pagesS4HANA Sourcing Contract 20170901Toni FontanetNo ratings yet

- 2nd Quarter Long Quiz ICT 11Document1 page2nd Quarter Long Quiz ICT 11vansrodNo ratings yet

- Repadmin Examples - Active DirectoryDocument7 pagesRepadmin Examples - Active DirectoryvinoopnvNo ratings yet

- CATALOG - GABRIEL - MODELOS HD-Catalog-2019Document344 pagesCATALOG - GABRIEL - MODELOS HD-Catalog-2019WERNER SILVA ALVAREZNo ratings yet

- Is 6044 1-2013Document17 pagesIs 6044 1-2013tapas bera0% (1)

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- Template Users GuideDocument426 pagesTemplate Users GuideRoberto Hernandez AmecaNo ratings yet

- Determination of Soil Properties From Standard Penetration Test Complemented by Torque Measurement (SPT-T)Document5 pagesDetermination of Soil Properties From Standard Penetration Test Complemented by Torque Measurement (SPT-T)Mohamed KadryNo ratings yet

- Installation and Operating Guide: Photovoltaik Module Production Series ACDocument10 pagesInstallation and Operating Guide: Photovoltaik Module Production Series ACClyde FairbanksNo ratings yet

- Methanol Technical Data Sheet PDFDocument1 pageMethanol Technical Data Sheet PDFmkgmotleyNo ratings yet

- Drilling and BlastingDocument5 pagesDrilling and BlastingPramodNo ratings yet

- USB2ISA Users GuideDocument33 pagesUSB2ISA Users GuideRafael SilveiraNo ratings yet

- Syllabus Civil AssamDocument154 pagesSyllabus Civil AssamAnurag DebNo ratings yet

- Link Belt 210-X2LFDocument4 pagesLink Belt 210-X2LFronalNo ratings yet

- Gts 226Document165 pagesGts 226Juan De Dios CastroNo ratings yet

- Secadores KaeserDocument13 pagesSecadores KaeserDiego Laya PicadoNo ratings yet

- Closed Loop Speed and Position Control of DC MotorsDocument7 pagesClosed Loop Speed and Position Control of DC Motorslizhi0007No ratings yet

- Transformer Protection Calculations PDFDocument44 pagesTransformer Protection Calculations PDFngocanhvyNo ratings yet

- AIRBUS Aditive ManufacturingDocument75 pagesAIRBUS Aditive ManufacturingХардип ЗинтаNo ratings yet

- Rajagiri School of Engineering and Technology: Rajagiri Valley, Kakkanad. Third SemesterDocument37 pagesRajagiri School of Engineering and Technology: Rajagiri Valley, Kakkanad. Third SemesterAmrita VenkitaramaniNo ratings yet

- Electronic Mail SecurityDocument20 pagesElectronic Mail SecurityVasantha KumariNo ratings yet

- Hand Book Jumper SettingDocument30 pagesHand Book Jumper SettingRanjeet SinghNo ratings yet