Professional Documents

Culture Documents

8 8

Uploaded by

naveed alam0 ratings0% found this document useful (0 votes)

20 views6 pagesCSTR design

Original Title

8.8

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCSTR design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views6 pages8 8

Uploaded by

naveed alamCSTR design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

526

TABLE 8-4.

A

Specify X

+

Calculate T

Steady-State Nonisothermal Reactor Design

Chap. 8

Ways To Spsciry THE Sino a CSTR

B

Specify T

<

Calculate X

c

Specify V

+

Use Eqn. (8-55)

Production, uses,

‘and economics

From Eqn. (8-56)

L

From Eqn. (8-55) to plot Neg vs. 7

tL J

Calculate &

km Aetet

Calculate &

ke eter

Solve Eqn. (8-53)

for Xue = fT)

CB. —ta=kC aT —¥)) (0B Py = RCo ~ 4)

TA expl-EART)

T+ TA exp[-E/(RT)]

t + +

Fi if Plot Xzp and Xp

Calculate -14(X.7) Calculate -r4(X.7) aiadueeocty

L L

Calculate V Calculate V

v= Fak

Xan = conversion calculated from the mole balance

Xp = conversion calculated from the energy balance

Example 8-8 Production of Propylene Glycol in aa Adiabatic CSTR

Propylene glycol is produced by the hydrolysis of propylene oxide:

CH,—CH—CH, +H,0 5 cH,—CH—CH,

al

o OK OH

Over 800 million pounds of propylene glycol were produced in 2004 and the selling price

‘was approximately $0.68 per pound. Propylene glycol makes up about 25% of the major

derivatives of propylene oxide. The reaction takes place readily at room temperature when

catalyzed by sulfuric acid,

‘You are the engineer in charge of ap adiabatic CSTR producing propylene glycol by

this method, Unfortunately, the reactor is beginning to leak, and you must replace it, (You

told your boss several times that sulfuric acid was corrosive and that mild steel was a poot

material for construction.) There is a nice-looking overflow CSTR of 300-gal capacity stand-

ing idle; it is glass-lined, and you would like to use it.

You are feeding 2500 Ib/h (43.04 1b mot/h) of propylene oxide (PO.) to the reactor.

“The feed stream consists of (1) an equivolumetric mixture of propylene oxide (46.62 fi'/b)

and methanol (46,62 f'/h), and (2) water containing 0.1 wt % HSO,, The volumetric flow

rate of water is 233.1 {1'/h, which is 2.5 times the metranol-RO, flow rate. The corresponding

molar feed rates of methanol and water are 71.87 and 802.8 Ib mol/h, respectively. The

water-propylene oxide-methanol mixture undergoes a slight decrease in volume upon mixing

‘Sec. 6.6 CSTR with Heat Effects 527

(approximately 3%), but you neglect this decrease in your calculations, The temper-

ature of both feed streams is 58°F prior to mixing, but there is an immediate 17°F

temperature rise upon mixing of the two feed streams caused by the heat of mixing.

‘The entering temperature of all feed streams is thus taken to be 75°F (Figure E8-8.1).

Propylene oxide Faq — Top = 58° =58°

‘20 fo0 = 58°F Tog ee

Methanol Fuo—

TH?

Xe?

Figure E8-8.1

Furusawa et al.” state that under conditions similar to those at which you are

operating, the reaction is first-order in propylene oxide concentration and apparent

zero-order in excess of water with the specific reaction rate

k= Ae2/*T = 16,96 X 1012 (e73240087) ft

‘The units of F are Btu/Ib mol.

There is an important constraint on your operation. Propylene oxide is a

rather low-boiling substance. With the mixture you are using, you feel that you can-

not exceed an operating temperature of 125°F, or you will lose too much oxide by

vaporization through the vent system,

‘Can you use the idle CSTR as a replacement for the leaking one if st will be

‘operated adiabatically? If so, what will be the conversion of oxide to glycol?

Solution

(All data used in this problem were obtained from the Handbook of Chemistry and

Physics unless otherwise noted.) Let the reaction be represented by

A+B—+C

where

Ais propylene oxide (Cp, = 35 Btu/Ib mol -°F)*

B is water (Cp, = 18 Btu/Ib mol -°F)

‘T. Furusawa, H, Nishimura, and T. Miyauchi, J. Chem. Eng. Jpn.. 2, 95 (1969).

"Cp, and Cp, are estimated from the observation that the great majority of

low-molecular-veight oxygen-containing organic liquids have a mass heat capacity

of 0.6 cal/g-°C 15%.

Following the Algorithm

‘Two equations,

two unknown

528 ‘Steady-State Nonisothermal Reactor Design Cha

Cis propylene glycol (Cp, = 46 Btu/Ib mol -*F)

M is methanol (Cp, = 19.5 Btu/Ib mol -°F)

In this problem neither the exit conversion nor the temperature of the a

batic reactor is gven. By application of the material and energy balances we

solve two equations with two unknowns (X and 7). Solving these coupled equatic

we determine the exit conversion and temperature for the glass-lined reactor to

if it can be used to replace the present reactor.

1. Mole Balance and design equation:

Foo~ Fat =0

The design equation in terms of X is

FyoX

vn tee (8-1

2. Rate Law:

ry = ky (8-1

3. Stoichiometry (liquid phase, v = Up):

Ca = Col) (E8-i

4. Combining yields

rin Feat 1X

Q(I=X) I= 1)

Solving for X as a function of T and recalling that t= V/vy gives

(E81

-ear

aie (E84

This equation relates temperature and conversion through the mole balan:

5. The energy balance for this adiabatic reaction in which there is neglig

energy input provided by the stirrer is

i = O,Cp(T-To)

[AH Ga (Te) + ACp(T— Te]

This equation relates X and T through the energy balance. We see that |

equations [Equations (E8-8.5) and (E8-8.6)] must be solved with Xya =

for the two unknowns, X and T.

6. Calculations:

a, Heat of reaction at temperature T:?

Xeo, a

AHg,(T) = Hp. (Tz) + AC, (T— Tr) cco

HX.(68°F) : ~66,600 Btu/Ib mol

° HY and Hé are calculated from heat-of-combustion data,

Calculating the

parameter values

Plot Xyg a8 8

function of

temperature.

Sec. 86

CSTR with Heat Effects 529

H5(68°F) : ~123,000 Buu/Ib mol

H;(68°F ) : ~226,000 Btu/Ib mol

AH}, (68°F) = -226,000 - (123,000) - (-66,600)—(E8-8.7)

= 36,400 Bru/Ib mol propylene oxide

BCp= Cre Cry Crg

6 — 18-35 = —7 Btu/Ib mol :°F

AH, (1) = —36,400 ~(7)(T- 528) Tisin°R

b. Stoichiometry (Cyg. ,, T): The total liquid volumetric flow rate entering

the reactor is

Y= +o + Up

= 46.62 + 46.62 + 233.1 = 326.3 f'/h (E8-8.8)

= 300 gal = 40.1 f°

VY. 4018

Up 326.3 fe/h

Fx _ 43.0 Ib mol/h

Up 326.3 f/h

= 0.132 Ib mol/ft? (E8-8.9)

1.123 h

q = Fuo . 71.87 tb mol/h

renee 99” ana

1.67

Foo _, $02.8 Ib mol/h

. " =

Ne Ee SD DOU

= 18.65

©. Evaluate mole balance terms: The conversion calculated from the mole

balance, Xyq, is found from Equation (E8-8.5).

Xp = — 16:96 1012 h=")(0.1229 h) exp (=32,400/1.9877)

‘a

© T+ (16.96 10 h-#)(0.1229 h) exp(—

Xgp = —2984 X10") exp(=16,306/7)_ pis ino

1+ (2.084 x 10") exp(~16,306/7)"

4. Evaluate energy balance terms:

2OCp, = Cp, + O46, + Our,

= 35 + (18.65)(18) + (1.67)(19.5)

= 403.3 Bru/tb mol -°F

Ty = Toy + ATrig = 58°F + 17°F = 75°F

= 535°R (E8-8.11)

Ty = 68°F = 528°R

Steady-State Nonisothermal Reactor Design Chap. &

‘The conversion calculated from the energy balance, Xpp, for an adiabatic

reaction is given by Equation (8-29):

E O,Cp (7 To)

AF gx (Tp) + ACp(

Substituting all the known quantities into the energy balances gives us

Nog = —(403.3 Btu/Ib mol -*F\( = 933)°F

= 36,400 — 7(7 — 528)] Btu/Ib mol

Xen = 403.3(T— $35) (E8.8,

36,400 + 7(7— 528)

Xen =~ (8-29)

‘a

)

. Solving. There are a number of different ways to solve these two simulta-

neous equations. The easiest way is to use the Polymath nonlinear equation

solver. However, 1 give insight into the functional relationship between X and

T for the mole and energy balances, we shall obtain a graphical solution. Here

X is plotted as a function of T for the mole and energy balances, and the inter-

section of the two curves gives the solution where both the mole and energy

balance solutions are satisfied. In addition, by plotting these two curves we

can leam if there is more than one intersection (j.e., multiple steady states) for

which both the exergy balance and mole balance are satisfied. If numerical

root-finding techniques were used to solve for X and T, it would be quite pos-

sible to obtain only one root when there are actually more than one. If Poly-

math were used, you could lear if multiple roots exist by changing your

initial guesses in the nonlinear equation solver. We shall discuss multiple

steady states further in Section 8.7. We choose T and then calculate X (Table

E8-8.1). The calculations are plotted in Figure E8-8.2. The virtually straight

line corresponds 0 the energy balance [Equation (E8-8.12)] and the curved

Jine corresponds to the mole balance [Equation (E8-8.10)]. We observe from

this plot that the only intersection point is at 85% conversion and 613°R. At

this point, both the energy balance and mole balance are satisfied. Because the

temperature must remain below 125°F (585°R), we cannot use the 300-gal

reactor as it is now.

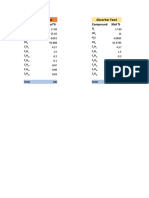

‘TABLE EB-8.1

Tr Xv New

€R) Eg. (E8-8.10)) Eg. (E8-8.12)]

0.108 0.000

0.217 0.166

9379 0.330

0.500 0.440

0.620 0.550

0.723 0.656

0.800 0.764

0.860 0.872

0.900 0.980

Don't give up! Head back to the storage shed to check out the heat exchange

equipment!

‘The reactor cannot

bbe used because it

will execed the

specified maximum

Sec. 86

Conversion, x

STA with Heat Effects 531 :

19)

09]

08

07

06

0.5]

oa

03

2]

on

835° '555—~«*TSS~C«CSSCISSCSCSS

TCR)

Figure £8-8.2 ‘The conversions Xp and Xyyg as a function of temperature.

Example 8-9 CSTR with a Cooling Coil

A cooling coil has been located in equipment storage for use in the hydration of

propylene ox

’ide discussed in Example 8-8. The cooling coil has 40 ft of cooling

surface and the cooling water flow rate inside the coil is sufficiently large that a con-

stant coolant

temperature of 85°F can be maintained. A typical overall heat-transfer

coefficient for such a coil is 100 Btu/h-ft?-°F, Will the reactor satisfy the previous

constraint of

Solution

125°F maximum temperature if the cooling coil is used?

If we assume that the cooling coil takes up negligible reactor volume, the conver-

sion calculated as a funetion of temperature from the mole balance is the same as

that in Example 8-8 (Equation (E8-8.10)]

1. Combining the mole balance, stoichiometry, and rate law, we have, from

Example 8-8,

Tisin

(2.084 X10!) exp (~16.306/7)

(E8-8.10)

i+¢

T+

°R.

2. Energy balance. Neglecting the work by the stirrer, we combine Equations j

(8-27)

UAC

Rae) ~ MAH fg (Ta) + SC p(T Ty] = LO,Cp(T~ To) (E8-9.1)

and (8-50) to write

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- CPEC As A Game Changer - The Express Tribune PDFDocument2 pagesCPEC As A Game Changer - The Express Tribune PDFnaveed alamNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- CPEC The Game Changer For Pakistan's Politics, EconomyDocument3 pagesCPEC The Game Changer For Pakistan's Politics, Economynaveed alamNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Algebra I Notes Functions and Function Notation Unit 4 Unit 4 - Functions and Function Notation Prerequisite SkillsDocument22 pagesAlgebra I Notes Functions and Function Notation Unit 4 Unit 4 - Functions and Function Notation Prerequisite SkillsThiyagu VasuNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- SociologyDocument13 pagesSociology8888488No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The 5 Pivotal Paragraphs in A Paper - Dynamic EcologyDocument20 pagesThe 5 Pivotal Paragraphs in A Paper - Dynamic Ecologynaveed alamNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 13 Engaging Ways To Begin An Essay PDFDocument13 pages13 Engaging Ways To Begin An Essay PDFnaveed alamNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Law, Order, and The Future of Democracy in PakistanDocument6 pagesLaw, Order, and The Future of Democracy in Pakistancity campusNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Outlines of Compulsory Subjects Pms 2016Document5 pagesOutlines of Compulsory Subjects Pms 2016Umer AhmadNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- BluetoothDocument19 pagesBluetoothnaveed alam100% (2)

- Law and OrderDocument20 pagesLaw and Ordernaveed alamNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Education in Pakistan: Problems and Their Solutions: DR - Khalid RashidDocument12 pagesEducation in Pakistan: Problems and Their Solutions: DR - Khalid RashidAamir RafiqNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Pakistan Economy Challenges ProspectsDocument14 pagesPakistan Economy Challenges ProspectsArslan AwanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- LogicsDocument2 pagesLogicsnaveed alamNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Challan FormDocument1 pageChallan FormFurqan ButtNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Material BalanceDocument17 pagesMaterial Balancenaveed alamNo ratings yet

- PIEAS Sample Test Paper For MS Engineers and ScientistsDocument11 pagesPIEAS Sample Test Paper For MS Engineers and ScientistsMohammad Faraz AkhterNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Risk-Assessment NDocument4 pagesRisk-Assessment Nnaveed alamNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)