Professional Documents

Culture Documents

F-22 Park Jet (Parts Templates Scaled 120 Non-Tiled) PDF

Uploaded by

Vikram DamleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F-22 Park Jet (Parts Templates Scaled 120 Non-Tiled) PDF

Uploaded by

Vikram DamleCopyright:

Available Formats

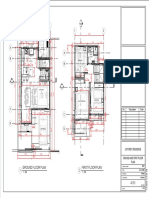

29 deg bev el (.

12")

F3

Reinforce this area with a strip of

Canopy Turtledeck support F2 fiberglass cloth and resin (top and bottom)

0.90 "

(Make 2) F1

(Make 10 and laminate)

Cut bulkhead in half

along this line before

assembly (will re-attach

29 deg bevel (.12") during assembly)

Cut bulkhead in half

Cut bulkhead in half

along this line before

Install turtledeck support here assembly (will re-attach

along this line before Cut slot to fit

assembly (will re-attach

F5 during assembly)

during assembly) carbon tube spar

Forward fuselage side

upper half F4

29 deg be

vel (.12 ") F3

(Make 2) F4 Stabilator

F2 29 de g bevel

(.1 2")

(Make 2)

T1 T1

34 deg bevel (.15")

Taper bevel as shown (keep full height)

(Make 1 each from 1/8" ply)

vectoring motor mount

Epoxy to motor

Side plates for thrust

Forward fuselage side

stick here

F2 F3 Heat and twist this section T2

lower half

until the aft end is vertical

(Make 2)

34 deg bevel (.15") Taper bevel as shown (keep full height)

Nosecone

Epoxy to motor

34 deg bevel (.15")

stick here

T3 (Make 8)

Forward fuselage Turtledeck top

bottom (Make 2)

T4 Nose cone top

(Make 1)

(3/8" sq hardwood)

(this piece is slightly over size in

Movable portion of

motor mount stick

template (use to help

width to allow trimming to shape) carve to shape)

1.87 "

34 deg bevel (.08") T5

34 deg bevel (.08")

Inlet diverter

Forward fuselage top (Make 2 from 3mm) Temporary bulkhead

Inboard inlet side

(Make 1) to help position fuselage Install aft fuselage sides here

(groove edge and attach

Optional launch grip fairings

(Make 2 from 3mm)

Stabilator pivot tubes

sides on wing during Make 2 and sand to shape

with epoxy)

assembly (Make 4) T1 T2 T3

Fuselage top spine

0.30 "

(Make 1)

34 deg bevel (.08")

Main motor mount stick

6-32 bolt pivot (secure with nut)

Aluminum tube bearing with

4

(3/8" sq hardwood)

Cut channel to

Tab fits into Tab fits into clear stab pivot tube

slot in wing Cutout to clear

rudder servo

slot in wing

Tail booms T4 T5

(Make 10 and laminate

4.80 "

Motor stick cutout

5 each to make two booms)

Wing

Stabilator servo

Fuselage centerline support (Make 1)

and motor mount

Thrust vector servo

(HS-85MG shown)

(Make 2 and laminate)

2 Cut slot for fuselage

center spine

Cut slot for fuselage

center spine

34 deg bevel (.15")

Scale in inches

Aft fuselage side

(Make 2)

0 2 4 Vertical tail braces

(groove edge and attach

34 deg bevel (.15")

Stabilator pivot tubes

28 deg bevel (.12")

with epoxy)

Vertical tail slot (cut at 28 deg angle)

63 deg bevel (.26")

6")

bevel (.2

Vertical tail base fairing (opt)

63 deg

(Make 2 and sand to fit)

Install aft fuselage sides here

")

.5

l(

eve

b

g

de

76

Bevel an

d

flush wit trim as required

h fuselag

e sides to fit

Aft fuselage top piece

(Make 1 from 3mm Depron)

fi t

ired to

d tr im as requ s

n e

Bevel a h fuselage sid

it

flush w

76

de

g

be

v el

(.5

")

63 deg

bevel (.

26") Trim pieces for outboard of vertical tail

63 deg bevel (.26") (Make 2 from 3mm Depron)

Jig for setting vertical

Vertical tail

34 deg bevel (.15")

tail dihedral

(Make 2)

(Make 2)

Bevel edges of

nozzles as shown

Aft fuselage bottom

(Make 1)

28 deg bevel (.12") 28 deg bevel (.12")

28 deg bevel (.12")

F/A-22 Raptor Park Jet

Bevel edges of Vertical tail brace (Make 2)

Designed by Steve Shumate

nozzles as shown Cut angled slot after gluing this piece to the wing Copyright © 2007

May be printed for personal use only

34 deg bevel (.15")

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bomba FlightDocument2 pagesBomba FlightGustavo HRNo ratings yet

- Fasteners Lecture 11-20-03Document67 pagesFasteners Lecture 11-20-03laponggaNo ratings yet

- 031 - Btech - 08 Sem PDFDocument163 pages031 - Btech - 08 Sem PDFtushant_juneja3470No ratings yet

- Planning For Information NetworkDocument32 pagesPlanning For Information NetworkChandraAdsenubiiNo ratings yet

- Design of Bolted Beam Splice Connections According To EC3Document11 pagesDesign of Bolted Beam Splice Connections According To EC3Franklyn Genove100% (2)

- Us06-106 850 01 01 02 PDFDocument6 pagesUs06-106 850 01 01 02 PDFF2CANALESNo ratings yet

- Acids and Bases Part 3 (Weak Acids) EdexcelDocument2 pagesAcids and Bases Part 3 (Weak Acids) EdexcelKevin The Chemistry TutorNo ratings yet

- EM000039Rev1 PDFDocument1 pageEM000039Rev1 PDFGustavo RiveraNo ratings yet

- Planning and Site Investigation in TunnellingDocument6 pagesPlanning and Site Investigation in TunnellingJean DalyNo ratings yet

- 8-0-SP1 Designer BPM Process Development HelpDocument260 pages8-0-SP1 Designer BPM Process Development HelpEric CaceresNo ratings yet

- Particle Swarm Optimization - WikipediaDocument9 pagesParticle Swarm Optimization - WikipediaRicardo VillalongaNo ratings yet

- Phys114 Ps 1Document11 pagesPhys114 Ps 1Reine Amabel JarudaNo ratings yet

- GFF (T) ... MenglischNANNI (DMG-39 25.11.05) PDFDocument38 pagesGFF (T) ... MenglischNANNI (DMG-39 25.11.05) PDFjuricic2100% (2)

- Microbial Enhanced Oil Recovery (Meor)Document7 pagesMicrobial Enhanced Oil Recovery (Meor)Yomel Ramzi100% (1)

- Op Amp TesterDocument2 pagesOp Amp TesterPhay KhamNo ratings yet

- Chip DielDocument45 pagesChip DielJUANCANEXTNo ratings yet

- Interfacing Seven Segment Display With LPC1769Document18 pagesInterfacing Seven Segment Display With LPC1769Gurudatta Palankar0% (1)

- Ecg Signal Thesis1Document74 pagesEcg Signal Thesis1McSudul HasanNo ratings yet

- Bombas Pentax SADocument48 pagesBombas Pentax SAAgustin CahuanaNo ratings yet

- Wastewater Treatment Options For Paper Mills Using Waste Paper/imported Pulps As Raw Materials: Bangladesh PerspectiveDocument4 pagesWastewater Treatment Options For Paper Mills Using Waste Paper/imported Pulps As Raw Materials: Bangladesh PerspectiveKool LokeshNo ratings yet

- VAPORISERDocument62 pagesVAPORISERAshish ChavanNo ratings yet

- 9C606C.64 To 65Document24 pages9C606C.64 To 65SHIRISHA YADAVNo ratings yet

- While We Sleep - A Story of Government Without Law by Alan R. AdaschikDocument165 pagesWhile We Sleep - A Story of Government Without Law by Alan R. Adaschikwbradleyjr18739100% (2)

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- Floor Plans & ElevationsDocument6 pagesFloor Plans & Elevationsbryan cardonaNo ratings yet

- Toyota Vios Ecu Wiring DiagramDocument4 pagesToyota Vios Ecu Wiring DiagramSri Yuniati17% (6)

- Ic703 ServiceDocument57 pagesIc703 Servicewalters2No ratings yet

- Udyam Registration Certificate UDYAM-MH-26-0097771Document3 pagesUdyam Registration Certificate UDYAM-MH-26-0097771Suresh D ChemateNo ratings yet

- CFJV00198BDocument360 pagesCFJV00198BCheongNo ratings yet

- Water System PQDocument46 pagesWater System PQasit_mNo ratings yet