Professional Documents

Culture Documents

Testing of Overspeed Protection

Uploaded by

Chaman MishraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Testing of Overspeed Protection

Uploaded by

Chaman MishraCopyright:

Available Formats

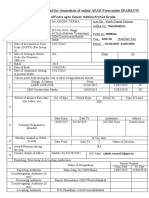

Doc. No.

SERVICE & MAINTENANCE

Rev. ind.

Testing of Overspeed Protection and Trip

Valves 2

STI No. Page

Instruction

4430-01E 1 (1)

Instruction for testing of the hydraulic trip valves and/or

overspeed protection

The trip valves in the turbine protection system must be tested for correct function at

intervals given in the section Periodic Attention.

The test will not interfere with the normal operation of the turbine.

The three Channel Overspeed Protection Module has an on board frequency generator that

can generate a test signal for testing the overspeed protection function. This function and

associated relay outputs are used during the trip valve test.

Conditions

The test is performed during operation or at turning gear operation

We reserve all rights in this document and in the information

Conditions (among others) if the test is to be performed with turning gear in operation:

contained therein. Reproduction, use or disclosure to third

• The hydraulic system must be in operation.

Parties without express authority is strictly forbidden.

© Siemens Industrial Turbomachinery AB

• The trip system must be reset.

• The hydraulic oil must be reset.

• The speed monitor must be reset.

There must not be any alarm for fault in the speed monitoring equipment.

Performing

The test function is invoked by selecting the actual trip channel to be tested.

Only one module in the Overspeed Protection Group may be in Test Mode at any

Time.

When the test is invoked, the simulated speed will start at a predefined level and then

slowly be raised above the tripping speed level (110%).

1. Select Test Channel A, B or C

2. As the test is performed with a simulated overspeed above the trip limit (>110 %), an

alarm for trip for the corresponding speed channel should appear and the trip valve in

the hydraulic system should indicate open (tripped) position. Se Notes below.

3. Acknowledge alarms.

4. Repeat items 1-3 for the other channels.

Note! If indication for tripped tripping valve does not appear at item 2,

interrupt the test and begin fault tracing.

Note! the open position is calculated from the 1 of 3 test pressure AND

the measured feedback voltage from the feeding end of the trip

valve solenoid (There is no physical position indication

feedback from the trip valve).

SE-612 83 FINSPONG, Sweden Siemens Industrial Turbomachinery AB

Based on: Author SIT/VAS/Bo Karlsson

Ref.des.: Appr. AQI/Gunilla Strand

Doc. Kind.: DC103 Operating instructions Language en

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- MTBFDocument11 pagesMTBFAbdessamad HoudafNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Construction Schedule With S-CurveDocument23 pagesConstruction Schedule With S-CurveJp Gallardo100% (2)

- Suggested Procedure For Earthquake AnalysisDocument4 pagesSuggested Procedure For Earthquake AnalysisThomas John Doblas AgrabioNo ratings yet

- Handbook of Petroleum Refining ProcessesDocument5 pagesHandbook of Petroleum Refining Processeselsayed amerNo ratings yet

- Benefits of Value EngineeringDocument13 pagesBenefits of Value EngineeringrubydelacruzNo ratings yet

- Bridge EngineeringDocument134 pagesBridge Engineeringsatydevsinghnegi83% (12)

- Bearing Capacity of Shallow FoundationDocument124 pagesBearing Capacity of Shallow FoundationWaqas QureshiNo ratings yet

- Strut-And-tie Modelling of RC PilesDocument223 pagesStrut-And-tie Modelling of RC PilesAlberto Ruiz-Cabello López67% (3)

- Tech Spec Flow OrificeDocument63 pagesTech Spec Flow OrificeSHIVAJI CHOUDHURY100% (1)

- Abp 2Document1 pageAbp 2Chaman MishraNo ratings yet

- TG Performance ChartDocument9 pagesTG Performance ChartChaman MishraNo ratings yet

- Q. How To Register at "Agmoocs" Website and Enroll For The Courses?Document4 pagesQ. How To Register at "Agmoocs" Website and Enroll For The Courses?Chaman MishraNo ratings yet

- NPC Query Management PDFDocument1 pageNPC Query Management PDFChaman MishraNo ratings yet

- Cheemi SBWZ Temperature Transmitter PDFDocument2 pagesCheemi SBWZ Temperature Transmitter PDFNguyen SonNo ratings yet

- Wbcs ExaminationDocument19 pagesWbcs ExaminationMUMPI RAHAMANNo ratings yet

- Who Can Learn Diploma CivilDocument19 pagesWho Can Learn Diploma CivilGururaj TavildarNo ratings yet

- Vivek Rajendra Dusane: ObjectiveDocument4 pagesVivek Rajendra Dusane: ObjectivebhavikaNo ratings yet

- What Are The Different Types of Functional Testing?Document5 pagesWhat Are The Different Types of Functional Testing?khan 2003No ratings yet

- Muhammad Sohail Khan: Registered With Pakistan Engineering Council PEC REGISTRATION NO: Electro/12321Document2 pagesMuhammad Sohail Khan: Registered With Pakistan Engineering Council PEC REGISTRATION NO: Electro/12321Engr. WajahatNo ratings yet

- GSB PDFDocument4 pagesGSB PDFsachin sNo ratings yet

- Structure 1Document34 pagesStructure 1Yoon Myat BoNo ratings yet

- Basic Dimension: A Basic Dimension Is A Numerical Value Used To Describe TheDocument1 pageBasic Dimension: A Basic Dimension Is A Numerical Value Used To Describe TheAnonymous DP6iO3DfQNo ratings yet

- ExtrusionPower Datasheet EnglishDocument1 pageExtrusionPower Datasheet EnglishmipcadNo ratings yet

- Aspen HYSYS Dynamics DatasheetDocument2 pagesAspen HYSYS Dynamics DatasheetAgency2No ratings yet

- CSDocument2 pagesCSharry khanNo ratings yet

- MTechCE MadrasDocument64 pagesMTechCE MadrasMd Zeeshaan100% (1)

- Technical Solutions Engineer Internship - JDDocument2 pagesTechnical Solutions Engineer Internship - JDRishi RusiaNo ratings yet

- Listado de PapersDocument81 pagesListado de Paperssanrodrigo2No ratings yet

- LMI - PID-Robust PID Controller Design Via LMI Approach - (Ge2002)Document11 pagesLMI - PID-Robust PID Controller Design Via LMI Approach - (Ge2002)PereiraNo ratings yet

- Information Required For Generation of Online APAR Form Under SPARROWDocument2 pagesInformation Required For Generation of Online APAR Form Under SPARROWAshish VermaNo ratings yet

- AGH English Course ListDocument22 pagesAGH English Course ListAzharuddin Ehtesham Farooqui100% (1)

- Iso 2857-1973 A2-1986Document2 pagesIso 2857-1973 A2-1986azitaggNo ratings yet

- AcharyaInstitute of Management VS Dayananda Sagar College of EngineeringDocument7 pagesAcharyaInstitute of Management VS Dayananda Sagar College of EngineeringAdmission DetailsNo ratings yet