Professional Documents

Culture Documents

Objective Chemistry

Uploaded by

Shivam KurreyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Objective Chemistry

Uploaded by

Shivam KurreyCopyright:

Available Formats

BILASPUR

SESSION 2019-20

PROJECT REPORT ON

GREEN CHEMISTRY-BIODIESEL

AISSCE CHEMISTRY PRACTICAL CODE - 043

GUIDED BY :- SUBMITTED BY :-

MRS.ANUPRIYA YADAV VYOM GUPTA

ROLL NO:-

Chemistry investigatory Project (2019-20) Page 1

ACKNOWLEDGEMENT

I would like to express my special thanks of gratitude to

my teacher Mrs.Anupriya Yadav Mam as well as our

Principal Dr.SV John Sir who gave me the golden

opportunity to do this wonderful project on the topic

Green Chemistry - Biodiesel , which also helped me in

doing a lot of research and I came to know about so

many new things I am really thankful to them .Secondly I

would also like to thank my parents who helped me a lot

in finalizing this project within the limited time frame.

Chemistry investigatory Project (2019-20) Page 2

Certificate

This is to certify that Master VYOM GUPTA , student of

class 12 A has successfully completed the project on

Green Chemistry- Biodiesel under the guidance of

Respected Mrs. Anupriya Yadav Mam during the year

2019-20 in partial fulfillment of chemistry practical

examination conducted by AISSCE ,New Delhi.

INTERNAL EXAMINER EXTERNAL EXAMINER

PRINCIPAL SIGNATURE

Chemistry investigatory Project (2019-20) Page 3

Declaration

I hereby declare that the project work entitled

“Green Chemistry – Biodiesel“ , submitted to

Department of Chemistry , Jain International

School Bilaspur is prepared by me .

Vyom Gupta

Class 12th A

Chemistry investigatory Project (2019-20) Page 4

INDEX

SI. No. Contents Page No.

1. Objective 6

2. Intoduction to Green 7

Chemistry

3. Principle of Green Chemistry 8-10

4. Introduction –Biodiesel 11-12

5. Feed stock for Biodiesel 12

6. Activity1- Preparation of 13-14

Biodiesel

7. Biodiesel Reaction 15

8. Uses of Biofuel 16-19

9. Biofuels Resources in India 19-23

10. Conclusion 24

11. Bibliography 25

Chemistry investigatory Project (2019-20) Page 5

OBJECTIVE

The objective of this project is to study green

chemistry – Bio Diesel and also to study

Extraction process of Bio Diesel , its uses ,

resources, advantages and it`s potential`

Chemistry investigatory Project (2019-20) Page 6

INTRODUCTION TO

GREEN CHEMISTRY

Green chemistry, also called sustainable chemistry, is an

area of chemistry and chemical engineering focused on

the designing of products and processes that minimize

or eliminate the use and generation of hazardous

substances. Green chemistry is the design of chemical

products and processes that reduce or eliminate the use

or generation of hazardous substances. Green chemistry

applies across the life cycle of a chemical product,

including its design, manufacture, use, and ultimate

disposal. Green chemistry is also known as sustainable

chemistry.

Chemistry investigatory Project (2019-20) Page 7

PRINCIPLES OF GREEN CHEMISTRY

1.Prevention

It is better to prevent waste than to treat or clean up

waste after it has been has been created.

2.Atom Economy

Synthetic methods should be designed to maximize the

incorporation of all materials used in process into the

final product.

3.Less Hazaradous Chemical Synthesis

Wherever practicable , synthetic methds should be

designed to use and generate substances that posses

littke or no toxicity to human health and the

environment.

4. Designing Safer Chemicals

Chemicals products should be designed to affect their

desired function while minimizingg their toxicity.

Chemistry investigatory Project (2019-20) Page 8

5.Safer Solvents and Auxiliaries

The use of auxiliary substances (e.g., solvents ,

separation agents etc ) should be made unnecessary

wherever possible and innocuous when used.

6.Design for Energy Efficiency

Energy requirements of chemical processes should be

recognized for their environmental and economic

impacts and should be minimized. If possible , synthetic

methods should be conducted at ambient temperature

and pressure.

7.Use of Renewable Feedstock

A raw material or feedstock should be renewable rather

than depleting whenever technically and economically

practicable.

8.Reduce Derivative

Unnecessary derivatization (use of blocking groups

,protection/non protection, temporary modification of

physical/chemical processes)should be minimized or

avoided if possible, because such steps require additional

reagents and can generate waste.

Chemistry investigatory Project (2019-20) Page 9

9.Catalysis

Catalytic reagents (as selective as possible) are superior

to sticometric reagents.

10.Design for Degradation

Chemicals products should be designed so that at the

end of their function they break down into innocuous

degradation products and do not persist in the

environment.

11.Real-time analysis for Pollution Prevention

Analytical methodologies need to be further developed

to allow for real-time , in process monitoring and control

prior to the formation of hazaradous substances.

12.Inherently Safer Chemistry for Accident

Prevention

Substances and the form of a substance used in a

chemical process should be chosen to minimize the

potentials for chemicals accidents, including releases,

explosions and fires.

Chemistry investigatory Project (2019-20) Page 10

INTRODUCTON – BioDiesel

Bio-diesel is an eco friendly , alternative diesel fuel prepared

from domestic renewable resources i.e. vegetable oils (edible ,

non-edible) and animal fats .These natural oils and fats are

made up mainly of triglycerides.These triglycerides when

compared ,show striking similarities to petroleum derived

diesel and are called bio-diesel.As India is deficient in edible

oils ,non edible oils may be the material choice for producing

bio diesel .For this purpose ,Jatropha Curcas has been

identified for India as the most suitable Tree Borne Oil seed

(TBO) for production of bio diesel both in view of the non

edible oil available from it and its presence throughout the

country. The capacity of Jatropa Curcas to rehabilitate

degraded or dry land ,from which the poor mostly derive their

sustenance,by improving land`s water retention capacity ,

makes it additionally suitable for upgradation of land resources

. Presently , in some Indian villages , farmers are extracting oil

from Jatropha and after settling and decanting it they are

mixing the filtered oil with diesel fuel. Although , so far the

farmers have not observed any damage to their machinery ,

yet this remain to be tested and PCRA is working on it .The fact

remain that this oil needs to be converted to bio-diesel

through a chemical reaction – trans-eesterfication . This

reaction is relatively simple and does not require any exotic

material .IOC (R&D) has been using a laboratory scale plant of

100kg/day capacity for trans-esterification;designing of larger

capacity plants in the offing. These large plants are useful for

Chemistry investigatory Project (2019-20) Page 11

centralized production of bio-diesel. Production of bio-diesel in

smaller plant of capacity e.g. 5 to 20kg/day may also be started

at decentralized level.

FEED STOCK FOR BIO-DIESEL

Commonly used feedstocks for the

production of biodiesel include

soybean, rapeseed/canola, used

(waste) vegetable oils, and tallow

(animal fat). Mustard biodiesel is

being studied at the University of

Idaho, and Montana State

University is conducting research on

camelina for biodiesel production.

Safflower, sunflower, and hazelnut

produce oil that could be used for

biodiesel. Warm climate tree oils

such as palm oil and jatropha are

used as biodiesel feedstocks in

some parts of the world.

Feedstocks for biodiesel are

generally chosen based on price

and performance. Some are better

for cold temperature conditions. All

the above feedstocks have

alternative uses and markets, so the

prices can fluctuate depending on

demand.

.

Chemistry investigatory Project (2019-20) Page 12

ACTIVITY 1 - PREPARATION OF BIO-DIESEL

REQUIREMENTS:-

Vegetable OIL

Antifreezer

Lye (NaOH)

Blender

Scales

Plastic Containers

Funnels

Plastic Bottle with lid

Duct Tape

Thermometer

STEPS INVOLVED:-

Step 1: Measure out 200 ml of antifreeze and put it in

one plastic container.

Step 2: Add in lye so that the antifreeze is absorbed.

Step 3: Cover container and mix well by shaking it. It is

mixed when it starts to feel warm and is foamy. The

mixture has now become sodium methoxide.

Chemistry investigatory Project (2019-20) Page 13

Step 4: Blend 1 liter of vegetable oil with the sodium

methoxide in a blender for 20 minutes.

Step 5: Pour mixture into a bottle and wait 8 hours until

the byproduct, glycerin, separates form the biodiesel.

The glycerin will be on the solid on the bottom.

Step 6: Separate out the biodiesel by pouring into a glass

bottle.

Step 7: Prepare a wash bottle by poking a small hole in

the corner of the bottle and covering it with duct tape.

Step 8: Wash the biodiesel by pouring it into the wash

bottle and adding in ½ a liter of water. Roll the bottle

around to mix it and then remove the duct tape and

drain the water.

Step 9: Repeat the washing process until the biodiesel is

clear. This may need to be done numerous times over

the course of a week to complete the process. Store the

biodiesel in a glass container until ready to use.

Chemistry investigatory Project (2019-20) Page 14

Bio-diesel Reaction

Animal & plant fats & oils are typically made of triglycerides

which are esters of free fatty acids with the trihydric alcohol,

glycerol. In the transesterification process, the alcohol is

deprotonated with a base to make it a stronger nucleophile.

Commonly, ethanol or methanol is used. As can be seen, the

reaction has no other inputs than the triglyceride & the alcohol.

Normally, this reaction will precede either exceedingly slowly or

not at all. Heat, as well as an acid or base are used to help the

reaction more quickly.

Chemistry investigatory Project (2019-20) Page 15

USES OF BIOFUELS

1. Transportation

More than 30% of energy consumed in the United States is

used for vehicle transportation. Across the globe, transport

takes account of 24% of energy and more than 60% of

absorbed oil. This means that over a third of oil is used to

operate vehicles.

The main problem with alternatives is that solar, wind and

other alternative power is not practical for transportation.

Experts believe that efficient breakthroughs in practical

technology advances are still decades away.

In short, biofuel can be turned into a hydrogen steam that is

meant to be used in adjoining fuel-cell. More major car brands

have already invested in stations for biofuel-powered vehicles.

2. Energy Generation

In addition to producing fuel for transportation, fuel cells have

a power-generating application that is available for electricity.

Biofuel can be used to generate power in backup systems

where emission matters most. This includes facilities such as

schools, hospitals and other forms located in residential areas.

In fact, the largest market for biofuel to turn into energy

generation for over 350,000 homes from landfill gas in the

United Kingdom.

Chemistry investigatory Project (2019-20) Page 16

3. Provide Heat

Bioheat has grown over the past few years. As the primary use

of natural gas that comes from fossil fuel, the heat that comes

from hydraulic fracturing will lead to the production of natural

gas. While natural gas does not need to come from fossil

material, it is also able to originate from the recently grown

material.

A majority of biofuel that is used for heating is substantial. As

wood is the most practical method to heat, houses that use

wood burning stoves rather than gas or electricity. A blend of

biodiesel will reduce the emission of both nitrogen and sulphur

dioxide.

4. Charging Electronics

According to scientists from Saint Luis University, a fuel cell

was developed with cooking oil and sugar to generate

electricity; consumers will be able to use these cells instead of

generating electricity. Consumers may be able to use fuel cells

in place of batteries to charge anything from computers to cell

phones. While they are still in the process of development,

cells have the potential to become a ready source of power.

Chemistry investigatory Project (2019-20) Page 17

5. Clean Oil Spills and Grease

Biofuel is known to be environmentally-friendly, biofuel can

also help to clean up oil spills and grease. It has been tested to

work as a potential cleaning agent for areas where crude oil

contaminated the waters.

6. Cooking

While kerosene is the most common ingredient to use for

stoves and non-wick lanterns, biodiesel works just as great.

7. Lubricate

Diesel fuel is required to reduce the sulphur concentration as

sulphur provides the most lubricity of fuel. This is important

when it comes to keeping the engine properly functioning and

to avoid premature infection failure.

8. Create energy when fossil fuel runs out

As the oil supply is starting to run out. This has caused us to

question how fuel can be extracted without destroying the

environment. Biofuel –will help the government create a stable

method of producing energy that is cost-effective.

Chemistry investigatory Project (2019-20) Page 18

9. Reduce cost and need for imported oil

More than 84% of the world’s petroleum is used in the United

States. Despite the increase in fuel demands, the U.S. has

recently started to decrease the need since 2006. This allows

biofuels to become the best factor in energy reduction.

Analysts say that replacing imported oil with biofuel will help

to stabilise the economy when oil is disrupted.

Biofuel Resources in India

Energy consumption is increasing at 6.5 per cent per annum,

while reserves of petroleum are decreasing day by day. India’s

share of crude oil production is about 1 per cent of global crude

oil production, whereas consumption amounts to 3.1 per cent

of global consumption. A no. of private and Government

organizations are involved in production and distribution

biofuel in India.

The leaders in biofuel processing in India are, D1 Oil Plc,

Reliance Industries Ltd, Godrej Agrovet, Emami Group, Aatmiya

Biofuels Pvt Ltd., Gujarat Oelo Chem Limited (GOCL), Jain

Irrigation System Ltd., Nova Bio Fuels Pvt. Ltd.,

Sagar Jatropha Oil Extractions Private It is wise to consider the

oil yield potential of different edible and non-edible crops ,

before selecting the crop as suitable source of biodiesel

production. Considering the food grain scarcity in developing

countries like India, edible major crops may be spared as a

Chemistry investigatory Project (2019-20) Page 19

potential source for bio-diesel production. Typical feed stocks

for biodiesel production are soybean, canola/rapeseed,

sunflower, cottonseed, palm seed and palm kernel, corn and

mustard seed oil. Pork, beef and poultry fat and grease also can

be converted to biodiesel. Palm oil and animal fat may have a

high free fatty acid content, which causes soap formation that

has adverse effects on downstream processing and leads to

yield reduction. The detailed agricultural biofuel potential of

India is estimated

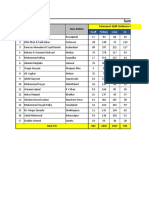

SI No Crop Type Oil yield ( ,000 l/ ha )

1. Microalgae 47.5- 142.5

2. Oil palm 6.0

3. Jatropha 2.0

4. Canola 1.25

5. Rapeseed 1.2

6. Sunflower 1.0

7. Soyabean and corn 0.5

Table 1 Oil yield potential of different crops.

The blending mandate of 5% ethanol with gasoline in nine

states of India in 2003 was enhanced to include 20 states in

2006. In 2010, the National Policy on Biofuels approved a target

20% blending with biofuels by 2017.

Chemistry investigatory Project (2019-20) Page 20

Alcohol requirement (M 2011- 2012- 2013- 2014-

ltrs) 12 13 14 15

Portable Sector 1550 1660 1780 1900

Industrial Sector 1100 1160 1210 1280

Blending (5%) 1090 1150 1200 1260

Totalalcohol requirement 3740 3970 4190 4440

Highestexpected

2400 2400 2400 2400

availability

Deficit 1340 1570 1790 2040

Table 2: Alcohol potential of India.

Algae have been in contention as one of the major source of

biodiesel in near future. Cultivation of algae does not

necessarily need prime agricultural land and can be grown

under desert like conditions using brackish and saline waters

that are unfit for terrestrial crops the water used for algal

cultivation does not compete for agriculturally important

activities . Various studies in design of Raceway ponds with

varying design parameters like water depth, stirrer design,

velocity of circulation, sparging of gas and gas compositions,

and rate and type of algal harvesting with recirculation of

media and partial replenishment of media/media components,

have been undertaken .

Chemistry investigatory Project (2019-20) Page 21

Cost effectiveness and better resilience have been the key

characteristics of open pond based algal systems compared to

photo bioreactors. The open ponds are usually reported to be

dominated by two to six species of microalgae with a range of

evolutionary advantages; rapid growth, resistance to

predators, tolerance to high levels of dissolved oxygen . Open

pond system is 10 times less expensive compared to photo

bioreactors . Wet-land rice cultivation field may be used for

micro algae growth as an intercrop with rice without affecting

rice yield.

Second generation or cellulosic ethanol is produced from

agricultural residues containing cellulosic biomass– such as the

stalks, leaves, bagasse, and husks of rice, wheat, wood chips,

sawdust or energy crops . Praj Industries has finally started

construction of second generation cellulose based bioethanol

plant in India. At $25 million plant, cellulosic ethanol will be

made from agro-waste unlike first generation fuel that is made

from food crops.

Chemistry investigatory Project (2019-20) Page 22

carbon dioxide emission

Production of biofuel

Chemistry investigatory Project (2019-20) Page 23

CONCLUSION

Green chemistry is very important in present time

because, at present time the need of amount of energy

is increasing very rapidly. It is also important because

the present source of energy which is mainly fossil fuel is

harmful for the nature and environment . A substitute

for fossil fuels are required as a source of energy, the

substitute can be biofuels. Biofuels are prepared from

organic matter and thus they are not harmful for the

nature and environment . Biofuels are cheaper as

compared to fossil fuels and as well as safe for the

environment .

Chemistry investigatory Project (2019-20) Page 24

Bibliography

http://www.icbse.com

http://www.en.wikipedia.org

www.omicsonline.org

farm-energy.extension.org

Survey of India

Class 12th NCERT Book

Chemistry investigatory Project (2019-20) Page 25

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shell Case StudyDocument4 pagesShell Case Studyemmamorrison1996No ratings yet

- DHG PVE DD 3 ME SPC 005 - Spec For Gas Turbine Compressor PackageDocument56 pagesDHG PVE DD 3 ME SPC 005 - Spec For Gas Turbine Compressor PackageThanh Tin NguyenNo ratings yet

- Workover Class NotesDocument47 pagesWorkover Class NotesSorin100% (1)

- Final Proposal For Oil and Gas AcademyDocument11 pagesFinal Proposal For Oil and Gas AcademyMohamad Abdulghani50% (4)

- Up Preboard 2004Document37 pagesUp Preboard 2004Dave Rone ChristianNo ratings yet

- +rostrupnielsen1984 - (Catalytic Steam Reforming)Document117 pages+rostrupnielsen1984 - (Catalytic Steam Reforming)Faris Hamidi100% (1)

- Company Profile GAS Maret 21Document118 pagesCompany Profile GAS Maret 21Adi Nugraha MbetutNo ratings yet

- Final LUS EvaluationDocument36 pagesFinal LUS EvaluationNextgenNo ratings yet

- 335 SOGIP MasterplanDocument56 pages335 SOGIP Masterplanenolray83% (6)

- Biogas TechnologyDocument35 pagesBiogas Technologyraghunath670743No ratings yet

- BP Statistical Review 2019Document64 pagesBP Statistical Review 2019Pedro Mentado100% (1)

- RenaeableDocument11 pagesRenaeableMukesh SainiNo ratings yet

- BP Strategic AnalysisDocument13 pagesBP Strategic Analysisnetline5No ratings yet

- Third SemesterDocument33 pagesThird SemesterShadab Aslam0% (1)

- Natural Gas MSDSDocument4 pagesNatural Gas MSDSvinay1999No ratings yet

- Environmental Assesment CO2 Emmision Salt CreekDocument259 pagesEnvironmental Assesment CO2 Emmision Salt Creekpeter.baars9809No ratings yet

- 7 PetrochemDocument28 pages7 PetrochemMaisarahNo ratings yet

- GAR Guide To Energy Arbitrations - 4th EditionDocument258 pagesGAR Guide To Energy Arbitrations - 4th EditionPaula ZambranoNo ratings yet

- Uniform Requirement 2019Document36 pagesUniform Requirement 2019Asif KhanNo ratings yet

- 1884 0x0 TALIS Your Partner For Water and Sewage EN 02 2012 PDFDocument36 pages1884 0x0 TALIS Your Partner For Water and Sewage EN 02 2012 PDFkad-7No ratings yet

- Rig Brochures Odfjell Drilling Rig Brochure SkjermvisningDocument9 pagesRig Brochures Odfjell Drilling Rig Brochure SkjermvisningBima MahendraNo ratings yet

- Calorific ValueDocument2 pagesCalorific ValuePatrick Pedroso QuengaNo ratings yet

- 2630-PM-BECB0514 Instructions PDFDocument17 pages2630-PM-BECB0514 Instructions PDFgalexieNo ratings yet

- Bharat Petroleum Corporation LTDDocument15 pagesBharat Petroleum Corporation LTDsagunkumarNo ratings yet

- Flare Gas Recovery - by Reliance Industries Ltd. (Refinery Division)Document3 pagesFlare Gas Recovery - by Reliance Industries Ltd. (Refinery Division)sriram84No ratings yet

- Introduction PDFDocument16 pagesIntroduction PDFRizki KhikmawatiNo ratings yet

- Fuel Stations 2020 PDFDocument39 pagesFuel Stations 2020 PDFDonald OmechNo ratings yet

- Petroleum Industry Report 2021 22Document90 pagesPetroleum Industry Report 2021 22Test testingNo ratings yet

- PNGRB R-Gsr720-E 2010Document21 pagesPNGRB R-Gsr720-E 2010pravesh sharmaNo ratings yet

- Brochure Compressors Screw Oil InjectedDocument2 pagesBrochure Compressors Screw Oil InjectedusanthanNo ratings yet