Professional Documents

Culture Documents

ASTM D1510 - I2 No PDF

ASTM D1510 - I2 No PDF

Uploaded by

PLASTIC LAB CBD0 ratings0% found this document useful (0 votes)

38 views8 pagesOriginal Title

ASTM D1510 - I2 No.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views8 pagesASTM D1510 - I2 No PDF

ASTM D1510 - I2 No PDF

Uploaded by

PLASTIC LAB CBDCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

$i intecnaonal standard was deepen accordance wih intermaoaly soya

=" Bevctipment ef Ttenational Standard, Guides and Revmmencatons a

Designation: D1510 - 16a

Standard Test Method for

pep om smarting eed in Deco on Pil fr he

‘he Matte Orunton Tee Harrah Cas

Carbon Black—lodine Adsorption Number’

“This standard i ted wor the ined designation DIS

ign sdoption in the case of revision the year last einen

the number immediately following the designation indias the yee of

‘A number in parentheses secies the yer ast cape

‘upersrp epsilon (ences an etoile since the ast revision bf teapgal

‘Thi standard hasbeen approved for ase by agencies ofthe US. Deparment of Defense.

L. Seope

11 This test method covers the determination of the jodine

adsorption number of earbon black,

1.1.1 Method A is the original test method for this determi-

nation and Method B is an alternate test method using

automated sample processing and analysis.

1.2. The iodine adsorption number of carbon black has been

shown to decrease with sample aging. New SRB HT todine

Standards have been produced that exhibit stable iodine

number upon aging. One or more of these SRB HT fodine

‘Standards are recommended for daily monitoring (x-charis) 0

censure that the results are within the control limits of the

individual standard. Use all SRB HT Iodine Standards for

standardization of iodine testing (see Section 8) when target

values cannot be obtained,

1.3 The values stated in SI units ate to be regarded as

standard. No other units of measurement ate included in this

14 This standard does not purport to address all of the

sujety concems. if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica:

bility of regulatory limitations prior 10 use.

2. Referenced Documents

2.1 ASTM Standands:?

1799 Practice for Carbon Black:

Shipments

11900 Practice for Carbon. Black—Sampling Bulk Ship-

ments,

D483 Practice for Evaluating Precision for Test Method

impling Packaged

"This est mois nd the jaindcton oF ASTM Conte D2s on Carbon

‘Block an is he diet responsibility of Sbeomsnitee D2421 un Carbon Black

Surface Ares ad Rel Properties

Cant etn approved Nov. 1. 2016 Published November 2016 Originally

spyroved in 1957 Las previous edn approved in 2016 8 DISIO 16. DO

{US201510:160.

* For seernesd ASTM Sanda, vs the ASTM website, wast.

‘contact ASTM Custonce Servi a sige atm org. Foe Antal Book of ASTH

Standards vlan information, rele woth sandr Docu Summary pap 09

the ASTAE webs,

‘Standards in the Rubber and Carbon Black Manufacturing

Industries

482i Guide for Carbon Black— Validation of Test Method

Precision and Bias

£969 Specification for Glass Volumetric (Transfer) Pipets

2.2. European Standards:*

ISO/EN/DIN 8655-3 Piston-operated volumetric apparatus

Part 3: Piston burettes

3. Summary of Test Methods

3.1 In Test Method A, a weighed sample of carhon black is

treated with 2 portion of standard iodine solution and the

‘mixture shaken and centrifuged. The excess iodine is then

titrated with standard sodium thiosulfate solution, and the

adsorbed iodine is expressed as a fraction of the total mass of

black.

3.2 In Test Method B, a weighed sample of carbon black is,

treated with a p: ne solution using au

automated sample processor where the mixture is. sticed,

settled and aliquoted for automatic tration. The excess iodine

is titrated with standard sodium thiosulfate solution, and the

adsorbed iodine is expressed as a fraction of the total mass of

black,

4.

ignificance and Usé

4.1 The iodine adsorption number is useful in characterizing

carbon blacks. Itis related to the surface area of carbon blacks

and is generally in agreement with nitrogen surface area. The

presence of volatiles, surface porosity, or extractables will

influence the iodine adsorption number. Aging of carbon black

ccan also influence the iodine number.

5. Apparatus

5.1 Vials, glass, optically clear type, with polyethylene

stoppers, 45 cm’,

5.2 Gravity Convection Drying Oven, capable of maintain-

ing 125 5°C.

5.3 Bure, either of the following may be used:

® vibe fom Inteoaional Organization for Stanrzatin (80), 1 ch de

18 Ye-Cense, CPS6, CH-I211 Ganev 20, Switzer htm co.

CenyigH AST erste 100 Bo Hat Oi, PO Sx C0, Wet Conschostn, PA H-2H6, Und Sie

310

|

|

|

|

&

Ay v1510 - 16a

53.1 Digital Burei, 25-em? capacity, with 0.01-cm’ inere-

emt counter and zero reset control, OF

5.32 Bure, glass 25-cm, Class A, side-arm filling, gradu

ated in 0.05 cm’ and with automatic zero.

54 Repetitive Dispenser, 25-cm® capacity, 0.1% repro-

ucibility and calibrated to within 0.03-cm* accuracy.

55 Balance, analytical, with 0.1-mg sensitivity.

5.6 Centrifuge, with minimum speed of 105 radis

(1000 ean)

52 Volumetric Flask, 2000-cm with standard taper stopper

58 Funnel, large diameter, with standard taper joint to ft

tne 2000-cm flask.

59 Glass Bottle, amber, 2000-cm°, with standard taper

stopper

5.10 Glass Jug, approximate capacity 20-dm’.

5.11 Stirrer, approximately 300 by 300 mm for mixing

5.12 Stirrer, approximately 100 by 100 mm for ttrating

5.13 Desiecat

5.14 Miscellancous Class A Glassware, and equipment

necessary t0 carry out the test as written.

5.15 Mechanical Shaker, with atleast 1 in, stroke length and

a minimum of 240 strokes/min,

5.16 Automatic Titrator.

5.17 Redox Flectvode, combined platinum ring electrode

with an Ag/AgCVKCI reference electrode and a ceramic frit,

5.18 Volumetric Flask, 500 em* with standard taper stopper.

5.19 Flas

5.20 Automatic Sample Processor and Titration Apparatus

equipped with disposable filter*

250 em! with ground glass stopper.

6, Reagents and Solutions

6.1 Purity of Reagents—Unless otherwise stated, all chemi-

cals shall be of reagent grade,

62 The preparation of the solutions listed below is. de

setibed in Annex Al. Pre-mixed 0.04728 N iodine solution and

(0.0394 1V sodium thiosulfate may be purchased from commer

cial sources It is recommended that the normality of pre-mixed

solutions be verified before use

63 Iodine Solution, e(1,) = 0.02364 movida? (0.04728 N),

containing 57.0 g potassium iodide KI per dm’,

64 Potassium Todate Solution, e({KIO;) = 0.00637 mol/

dm (0.0394 1) containing 45.0 g potassium iodide per dim’

6.5 Potassium. Dichromate Solution, e(K,Ctz0,) =

0.006567 mol/em* (0.0394 N), containing 1.932 g potassium

“The sole sure of suply of the appara known to teenie this te

is Brinknuna ttc ne, One Catiagne Ra, PO Bo 1019, Westbury. NY

11500-0207, The sol cus of spy of fer spose er part #17598 K

Sen Minis wt ct ek ote) howto the emai ath ane Stns

Stim Noth Americ Ine 131 Headend Biv, Egewoed, NY 11717. you ate

sate of leutvesnplisr plese provide the dformation to ASTM Interna

tional Headquarters Your comment wl recive crf eenseraion aa meeting

ofthe spose tshca commie! which you nay en

dichromate (certified/Araceable primary standard) per dun’

(Warning—Potassium dichromate is carcinogenic.)

6.6 Sodium Thiosulfate Solution, e(Na;8;0,) = 0.0394 moll

«dm (0.0394 N), containing 5 em? n-amyl alcohol per dm’.

6.7 Sulfuric Acid, 10%

6.8 Soluble Starch Solution, 1 %, containing 0.02 g salicylic

‘acid per dm’,

69 Deionized Water:

7. Standardization of Solutions

7A Sodium Thiosulfaie, 0.0394 N (0.00008)

71 Use potassiuin dichromate solution as follows:

7.11.1 Measure approximately 20 em’ of 10 % potassium

iodide (see A1.4) solution into a small graduated cylinder and

transfer to a 250 em? iodine flask with a ground glass stopper.

7.1.1.2 Measure approximately 20.cm’ of 10 % sulfuric acid

solution (ee A1.5) into a small graduated eylinder and add to

the KI solution in the iodine flask. The mixture should remain,

colorless.

Nore If ay

7.1.1.3 Using a 20 em? pipet, transfer 20 em? of standard

0.0394 N potassium dichromate solution (see A1.8) into the

250 em? iodine flask, replace stopper, swirl, and place in the

dark for 15 min

7.1.14 Titrate the contents of the iodine flask against the

new sodium thiosulfate solution following 7.1.3 or 7.1.4

7.1.2 Use potassium iodatefiodide solution as follows:

7.1.21 Pipet exactly 20 em? of 0.0394 NV potassium iodatef

iodide solution into 2 250-em* iodine flask

7.1.2.2 Measure approximately 5 ent’ of 10% sulfur wid

into a small graduated cylinder and add to the iodateliodide

solution

7.1.2.3 Cap immediately and mix thoroughly

7.1.2.4 Titrate the contents of the iodine flask against the

new sodium thiosulfate solution following 7.1.3 or 7.1.4

7.13 Digital Bure

7.13.1 Switch the digital buret to fill mode, fill the reservoir

\with unstandardized sodium thiosulfate solution, smd flush the

inlet and delivery tubes.

7.1.3.2. Change to the titrate mode and zero the counter.

7.13.3 Add sodium thiosulfate until the contents of the

iodine flask are a pale yellowish (potassium iodate) or pale

yellowish-ereen (potassium dichromate). Wash the buret tip

id the walls of the flask with water.

7.13.4 Add 5 drops of starch solution to the flask

7.13.5 Continue adding sodium thiosulfate dropwise until

the blue or bluc-violet color almost disappears.

7.1.3.6 Wash the tip and walls of the flask with water, then

advance the counter in 0,01-cm® increments. Continue this

sequence until the endpoint is reached, indicated by a colorless

um iodate) or sea-green (potassium dichromate) solu-

low color should develop, discard this KI solution,

value and repeat from 7.1.1 oF

7.1.2 for a duplicate determination,

7.1.3.8 Calculate the normality of the sodium thiosulfate

solution as in 7.1.5 and proceed as in 7.1.6. Ifthe titration is

ily b1510 - 16a

made to standardize the iodine solution as described in 7.2

calculate the normality of the iodine solution as in 7.2.1.2 and

proceed as in 7.2.1.3,

714 Glass Burets

7.1.4.1 Using a conventional glass buret, fill the buret with

tunstandardized sodiumsthiosulfate solution and flush 2 to

3m’ through the tip.

7.14.2 Adjust to the mark and titrate to a pale yellowish

(potassium iodate) or pale yellowish-green (potassium dichto-

mate).

7.14.3 Wash the buret tip and the walls of the flask with

water,

7.144 Add 5 drops of starch solution to the iodine flask,

7.1.45 Continue adding sodium thiosulfate dropwise until

the endpoint is reached, indicated by a colorless (potassium

jodate) or sea-green (potassium dichromate) solution.

7.1.4.6 Record the titration value to the nearest 0.025 em*

‘and repeat from 7.1.1 oF 7.1.2 for a duplicate determination,

Nore 2—To achive maximum performance trom a glass burst, it

necessary to use small naniier and fo read 10 the nearest 0.035 cm

7.1.4.7 Calculate the normality of the sodium thiosulfate

solution as in 7.1.5 and proceed as in 7.1.6. Ifthe titration is

made to standardize the iodine solution as described in 7.2

calculate the normality of the iodine solution as in 7.2.1.2 and

proceed as in 7.2.1.3.

7.1.5 Caleulate the normality of the sodium thiosulfate

solutions as follows:

= 20 0.0394)/7 a

where:

N= normality, and

T= tivation volume, em’

7.1.6 IEW is not equal to 0.0394, adjust the sofution in the

following manner: ifthe solution is too strong, add water (2.5,

‘em* water per dm” sodium thiosulfate solution for each 0.0001

1 over 0.0394); if the solution is too weak, add solid sodium

thiosulfate (0.025 g solid sodium thiosulfate per dm’ sodium

thiosulfate solution for each 0.0001 N under 0.0394).

7.2 Iodine Solution 0.04728 N (+0.00003)—This solution

‘may be standardized apainst the secondary standard sodium-

thiosulfate solution (see AI,3) standardized as in 7.1,

7.2.1 Use sodium thiosulfate solution as follows:

7.2.1.1 Pipet exactly 20 em’ of iodine solution into a

250-cm’ iodine flask and cap. Continue as in 7.1.3 of 7.1.4.

7.2.1.2 Calculate the normality of the iodine solution as

follows:

N= (00394) 7720 2

where:

7.2.1.3 If Nis not equal to 0.04728 N, adjust solution in the

following manner: ifthe solution is tg0 concentrated, add water

(2.1 cm* water per dm’ iodine solution for each 0.0001 N over

0.04728); if the solution is too diluted, add iodine (12.7 mg

iodine per dm’ iodine solution for each 0.0001 N under

312

0.04728). (This iodine may be more conveniently dispensed

from a concentrated solution.)

8. Normalization Using SRB HT Iodine Standards

8.1 When a laboratory cannot obtain target values for all

three SRB HT Iodine Standards within established x-chart

tolerances, the user should review recommendations found in

Guide D4821. Ifany one of the three SRB HT Iodine Standarcls

is still outside acceptable tolerances, the method described in

8.2 ~ 8.5 should be used to normalize all test results,

8.2 Test the three SRB HIT Iodine Standards four times each,

8.3 Perform a regression analysis using the target value of

the SRB HT Iodine Standards (y value) and the individual

‘measured value (x value)

8.4 Normalize the values ofall subsequent test results using

this regression equation:

Normalized value = (measured value Xslope)+y ~ intercept (3)

8.5 Alternatively, a table of numbers may be generated

based on the regression equation to find the correspondence

between a measured value and a normalized value,

8.6 Reevaluate the need for normalization whenever re-

Placement apparatus or new lots of iotine or sodium thiosulfate

solutions, or both, are put into use,

9. Sampling

9.1 Samples shall be taken

D179 and D190,

accordance with Practices

nk lodine Determination

10.1 Method A—Blank fodine Determination:

10.1.1 Make a blank iodine determination by pipeting 20

em? or dispensing 25 cin’ of 0.04728 iodine solution into a

125-cm1' Erlenmeyer flask and titrating with 0.0394 NV sodium

thiosulfate as in 11,10.1, 11.1022, of 11.10.3

10.1.2 4 25-cm® blank must be multiplied by 0.8 for use in

the formula of 13.1

10.1.3 Make a duplicate blank determination and use the

average of the two in the calculations.

Nore 3A duplicate blank determination need be run oaly once each

slay, unless new solutions are introduced during the day.

10.14 Tf both solutions are within acceptable limits, the

blank will measure 24.00 + 0,09 em* If not, the normalities of

‘one or both solutions should be rechecked. If, after the recheck

of solutions, normalities are still outside the acceptable limits

refer to 7.2.1.3 to adjust iodine solution. See Table 1 for blank.

tolerance components.

10.1.5 The blank tolerance for a 20 cm* volume of iodine

solution is defined as the sum of (1) titration volume deviation

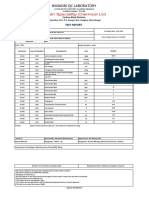

TABLE 1 Blank Tolerance Components

Blank "A Satuion 8. Dapencor Bane

olune cr? __Devaons én _Tokvanos on __Toeranes en

20.00 2005 a

te seg 08

fy 01510 - 16a

{or acceptable variation in both iodine and sodium thiosulfate

solution concentrations, and (2) dispenser tolerance for Class A.

20 mL. pipet.

10.1.6 The solution deviation is based on the maximum

variation in solution concentrations defined in 7.1 and 7.2.

‘Tolerances for Class A volumetric pipets are from Specification

E969.

10.2 Method B—Blank lodine Determination:

10.2.1 Make a blank iodine determination by placing. a

rmagnetic str bar into an empty beaker and place the beaker

xo the automated sample processor.

10.2.2 Initiate the automatic sample processor ancl ti

apparatus.

10.2.3 Dispense an appropriate volume of 0.04728 iodine

solution into the beaker. Treat the blank in the same manner

the sample, refer to Section 12.

ation

[Nome 4—For different size beakers, ensure sti har covers the bottom

sofice of beaker for good mixing

10.2.4 Measures should be taken to ensure adequate purging

of the entire system prior to delivering the final aliquot for

titration (see Note 5)

Nae 5—An example of adequate purging of the system i achieved by

double rinsing with the curent blank solution followed witha distilled

‘water rinse, This can be done inthe following manner: (1) ill he dosing

device, which is equipped with a disposable filter, with an aliquot of the

blank solution from the beaker, dispense the entire volume into ttmation

‘vessel and pump ot nto the waste container: (2) repeat previous

‘ore time and il the dasing device with the final aliquot of Blank solution

(this algo should fave an excess amex that will be used 4o fish the

ir bubbles, possibly formed daring the two previous seps—the volume

of aliquot usc for tation ean vay Goponding on user's preference

20 em has been found satisfactory) (3) dispense 4 sinall potion of the

han solution into the reaction vessel, ensure that apopsie amount of

the solution is left for ittation in the desing device; and (4) clean he

reaction (tration) vessel by rinsing with distilled water and pumping out

waste repotiively

10.2.5 Dispense a final aliquot of the blank solution into the

reaction vessel for titration and wash the walls of the vessel

stirrer, and redox-electrode with distilled water to ensure that

any splashed iodine is washed into the mixture,

10.2.6 Automatically trate the iodine solution with 0.0304

NV sodium thiosulfate

10.2.7 Make duplicate blank determinations. The average of

‘wo determinations is to be used in calculations,

10.2.8 Blank measurements may be macle daily, especially

where small solution lois are prepared within a. lab

Alternatively, blanks may be measured once per solution lot or

other prescribed frequency, for large solution lots which are

Purchased, and where adequate measures are used to monitor

testing such as the daily use of x-charting HT or INR standards,

[Nore 6-—For daily banks, 2 duplicate blank determination need be rn

‘only once each day, unless new solutions are intodced during the da.

Nore 7—When the pswticulate filer is changed adequate measures

should be taken to saturate the fer with iodine solution, An example of

smadequate measure found be satisfactory includes running & isa

Of five bias. The fourth and fifth blank are then averaged forthe final

blank value sind use the average ofthe two ithe caeuations. 1 the fier

hus nat heen changed use the average of the fist and second blanks for

‘aletations

10.2.9 Blank tolerances are sound in Table 2 for different

volumes of iodine solution. A blank tolerance is defined as the

sum of (/) titration volume deviation for acceptable vatiation

in both iodine and sodium thiosulfate solution concentrations,

and (2) dispenser tolerance for a piston-operated volumetrie

apparatus,

10.2.10 A blank tolerance can be calculated from the linear

‘equation as follows:

Y= 0.00564-+0.0059 i)

where:

Y= tolerance +, and

x = aliguot volume, mL.

10.2.11 Blank tolerances for Method B are also found in

Fig. 1. The function for solution deviation only and solution

deviation plus dispenser tolerance are included for reference

10.2.12 The solution deviation is based on the maximum,

variation in solution concentrations defined in 7.1 and 7.2,

Tolerances for piston-operated volumetric apparatus are from

ISO/EN/DIN 8655-3,

LI. Sample Preparation and Iodine Number

Determination—Method A

ILL Dry an adequate sample of carbon black for 1h, in a

uravity-convection oven set at 125°C, in an open container of

Suitable dimensions, so that the depth of the black is no more

than 10 mm. Coo! to room temperature in a desiccator before

11.2 Weigh mass of the dried sample into a glass vial as

shown by the following table. All masses must be to the neatest

0.001 g in case of iodine aumbers from 0 40 520.9 and

nearest 0.0001 g in case of iodine numbers from 521.0 and

above.

logino Number Sample Mase(g) ao ks Sampo Mass

o108 0500 ot

1310-2000 6250 10031

281.0-8008 ora 204

521.0 and above 00825 4001

11.3 Use the sample mass determined by the expected

iodine number. If the result falls either above or below the

range shown for that sample size, retest using the sample mass

specified in 11.2 for the range into which it has fallen,

Nort 8—Unagitated, unpelisted carbon black may be densfid, if

desire, before drying, pros to weighing

11.4 The sample mass table given in [1.2 pertains to the 25,

em? jodine solution as given in 1.5. Ditierent volumes of

iodine solution and of sample masses are permissible only if

the iodine solution to sample mass ratio is kept the same as that

given by the table in 11.2. The sample mass must be kept (0

1.000 g maximum. Should the sample mass and corresponding

TABLE 2 Blank Tolerances

7 Solon 8 Dspensor ‘ane

lune en® Deviations ex® __Toisares en? _Toleanes en!

2000 0.004 20.004 218

000 300% 30.007 20053

00 20019 20.024 20083

eo 30.008, 30.007 29000

My o1810 - 16a

Blank Tolerance Based on Solution and Piston- |

Operated Dispenser Tolerances

Tolerance

10

2 2

‘Alguot Volume, mt

Linear (Solution & Dispense)

volume of iodine solution be increased, then a glass vial with

4 volume that is at least two times the amount of iodine

solution used for the test should be used in order to preserve the

cfficiency of the shaking,

ILS Pipet (or dispense from a calibrated repetitive dis-

penser) 25 cm’ of 0.04728 WV 1, solution into the glass vial

containing the sample and cap immediately.

nNé Vial in the miecinanical shaker and shake tor

J min at a minimum of 240 sirokes/min.

11.7 Centrifuge immediately for | min for pelleted black

sand 3 min for foose black,

Noms 9—Make sure carbon black is separate sufficiently from the

iodine solution to obtain a sufficient quantity of carbon black fre iodine

‘olution tobe dirated. Increase the eeirfugation speed in net to ebin

an adequate separation, if requite

1.8 Decant immediately. If more than one sample is being

sstalyzed, the solution should be decanted into small flasks or

clean, dry vials and capped immediately.

LL Pipet 20 cm’ of solution into a 250-cm* Erlenmeyer

Hlask and titrate with standardized 0.0394 N sodium thiosulfate

solution using either the digital or glass buret as described in

U0,

11.10 Titration of lodine Solution:

N.10.1 Using a Digital Buret:

11,10.L.1 Switch t0 the fill mode, fll the buret reservoir

vith solution, and flush the inlet and delivery tubes,

11.10.1.2 Change to the titrate mode, zero the counter, and

inthe tip with tissue,

11.10.1.3 Add sodium thiosulfate until the solution is pale

ellow. Wash the buret tip and walls of the flask with water,

11.10.14 Add 5 drops of starch solution,

11.10.1.5 Continue adding sodium thiosulfate dropwise un-

| the blue or blue-violet color almost disappears,

I

at

—tinese(solation)

FIG. 1 Blank Tolerances for Method 8 as a Function of Aliquot Volume

11,10.1.6 Wash the tip and walls of the flask with water and

then advance the counter in 0.01-cm increments, Continue this

Sequence until the endpoint is reached as indicated by 1

colorless solution

1.10.1.7 Record the butet reading to the nearest 0.01 em?

1140.2 Using a Conventional Glass Bure

11,10.2.1 Remove any adherent drop on the tip of the buret

by gently toughing the drop with the wall ofa elean flask, The

flask may be used several times by toughing a clean pat ofthe

wall to remove further drops prior to titration. Add sodium

thiosulfate until the solution is pale yellow: Wash the baret tip

and walls ofthe flask with water.

11,10.2.2 Add 5 drops of starch solution.

11.10.2.3 Continue adding sodium thiosulfate dropwise tin-

tl the endpoint is reached as indicated by a colorless solution,

1.10.24 Record the titration volume 1 the nearest 0.025

1103. Using an Auto-tivator:

11.10.3.1 Two redox equivalence point titration methods

should be programmed into the autoitraor:

(2A method to store two blank determinations. as an

sverage blank value, and

(2) method to analyze samples for iodine number.

Note 10—Follow the recommendations of the manufacturer when

Setting the parameters. For good repeatability of te test. spcil care

should be taken when defining the criteria for the detection of the

equivalence point

11.10.3.2 Pipet 20 cm* of test solution into an appropriate

sample container, place the container on the auto-ttrator, and

‘wash the walls of the container, stirrer, and redox electrode

with distilled water,

11.103,3 Run titration method using standardized 0.0304.

sodium thiosulfate solution,

fly p1510 - 16a

11.10.34 Method should report equivalence point volume

to at least 0.01 em’,

12, Sample Preparation and Iodine Number

Determination—Method B

12.1 Dry an adequate sample of carbon black for a mini-

mumof 1 h, in a gravity-convection oven set at 125°C, in an

‘pen container of suitable dimensions, so that the depth of the

black is no more than 10 mm, Cool to room temperature in a

desiccator before use

12.2 Weigh a mass of the dried sample into an appropriate

beaker as shown by the following table. AI masses must be t0

the nearest 0.001 g, and the sample mass must be kept to 1.000

ig maximum, This sample mass table pertains to 50 em° of

jodine solution,

fodine Naver Sample Mace (g) Rao I Sampla Kass

o-1908 ‘000, ‘307

1310-2908 0500 100

pao-s208 250 200

F210 and above 125 00

123 Different volumes of iodine solution and sample

masses are permissible as Tong as the appropriate ratio of

iodine to sample mass is maintained as indicated in 12.2. A

sample mass table for 25 em? of iodine solution is shown

below. The sample mass must be kept to 0.5 g maximum.

Iodine Numbor——-Sarpla Mase (ato: Sample Mass

o-tane 0500. ‘on

0-200 280 100

2510-5209 0125 200.1

521. ad above aces 00:1

124 Use the sample mass determined by the expected

iodine number. If the result falls either above or below the

own for that sample lest using the sample mass

specified in 12.2 or 12.3 for the range into which it has fallen.

Non: H1—Ungiated, unpelited carbon back may be densified, it

ese, before drying, prior to weighing

12,5. Two redox equivalence point titration methods should

bbe programmed into the aufomatic sample processor and

titration apparatus; (7) a method to store two blank determina-

tions as an average blank value as described in 10.2; (2) a

method to analyze samples for iodine number using caleula-

tions found in Section 13,

[Now 12—Users may choose to ate diferent volumes of bank end

‘sample aliqats frosting: als is possible hat equipment frconalty

tng tle Follow th commendations ofthe manufietrer when sting

parameters frsining ines les, strttop volumes for tiation,

For good repeatbiity of the test apecil care should e taken when

‘fining the eter for he deteton ofthe equivalence point, Endpoint

crtron set 25 and EP recogiton st to “greatest” Have been found

sutficen

126 Carefully place a magnetic str bar inthe beaker with

the dried sample and place the beaker into the automated

imple processor. Take adequate precautions to prevent any’

loss of sample from the beaker.

12.7 Initiate the automatic sample processor and titration

apparatus

128 Dispense 50 em? or appropriate volume of 0.04728 N

1, solution into the beaker containing the sample and stir bar

Using a calibrated repetitive dispenser (losing device)

ais

12.9 Stir the sample for 3.0 min then turn off the stir motor.

12.10 Allow the slurry to settle for a minimum of 30s.

Longer settling time may be needed for non-pelleted carbon

black. Settling times may vary due to additional time caused by

the sample processor waiting for previous titrations to c

plete in the reaction vessel

12.11 Take adequate steps to completely purge the dosing

system and reaction vessel. An example cleaning procedure is

found in Note 5

12.12 Dispense a final aliquot of iodine solution into the

reaction vessel for titration using a calibrated repetitive dis-

penser (dosing system) which includes a disposable 5 pm filter

to remove particulates of carbon black. Wash the walls of the

reaction vessel, stirrer, and redoxelectrode with distilled water

12.13 Automatically titrate the iodine solution using 0.0394

1N sodium thiosutfste.

Note 13—A disposable filter's useful life has been reported at

approximately 50 samples, bat may’ vary with sample

form, Whenever the filer i changed alivays insure adequate

taken to saturate the fillers desribed in Nowe 7.

12.14 Report the equivalence point volume to at least 0.01

cm? and calculate iodine number to 0.1 mele.

12.15 Since Method B may give slightly different results

than Method A, the SRB HT or INR’ standards. should be

analyzed with each lot of both iodine and sodium thiosulfate

solutions. If the measured results of the three HT or INR

Standards are not within stated xchart tolerances, a normaliza-

tion using either HTT or INR standards (as described in Section

88) should be applied to all test results.

13. Calculation

13.1 Calculate the iodine adsorption number fo the nearest

0.1 gikg as follows:

1=((a 6)

sya] x(vIW) x % 12691

where:

1 iodine adsorption number, grams of iodine/

kilograms of carbon black expressed as 2

B ‘em? of sodium thiosulfate required for the blank,

5 ‘em of sodium thiosulfate required forthe sample,

v calibrated volume of the 25-cm’ iodine pipet or

dispenser,

w grams of earbon black sample,

Nx normality of the iodine solution, meqiem*, and

126.91 = equivalent mass of iodine mg/mea,

Using the units shown above results in units of milligrams of

iodinefgrams of carbon black, which is equivalent to grams of

iodinefkilograms of carbon black.

14, Report

14,1 Report the following information:

14.1.1 Proper identification of the sample,

14.1.2 Sample mass, and

14.1.3 Result obtained from an individual determination,

reported (0 the nearest 0.1 g/kg.

e

fly o1510 - 162

15, Precision and Bias

15.1 These precision statements have been prepared in

accordance with Practice D483, Refer to this practice for

ferminology and other statistical details.

15.2 An Interlaboratory precision program (ITP) informa-

tion was conducted as detailed in Table 3, Both repeatability

‘and reproducibility represent short-term (daily) testing condi.

tions. The testing was performed using two operators in each

laboratory performing the test once on each of two days (total

Of four tests) A test result is the value obiained from a single

determination. Acceptable dilierence values were not mea

sured. The between operator component of variation is in-

‘luded in the calculated values for rand R.

15.3 ‘The precision results in this precision and bias section

sive an estimate of the precision of this test method with the

‘materials used in the particular interlaboratory program de_

scribed in 15.2. The precision parameters should not be used!

for acceptance or rejection testing of any group of materials

‘without documentation that they are applicable to those par-

‘icular materials and the specific testing protocols of the test

method, Any appropriate value may be used from Table 4.

154 A type | interlaboratory precision program was con-

ducted, Both repeatability and reproducibility represent short

‘erm (daily) testing conditions. The testing was performed

using Iwo operators in each laboratory performing the test once

‘on each material on each of two days (total of four tests). The

umber of participating laboratories is Listed in Table 3,

15.5 The results of the precision calculations for this test are

given in Table 4. The materials are arranged in ascending

“mean level” order

15.6 Repeatability—The pooled relative repeatability, (1), of

this test method has been established as 1.6 %. Any other value

in Table 4 may be used as an estimate of repeatability, as

appropriate. The difference between two single test results (or

determinations) found on identical test material under the

repeatability conditions prescribed for this test will exceed the

repeatability on an average of not more than once in 20 cases

in the normal and correet operation of the method. Two single

st results that differ by more than the appropriate value from

‘Toble 4 must be suspected of being from different populations

and some appropriate action taken.

TABLE 4 Precision Paramtars for D151, lodine Number etn. |

ods A & B (Type 1 Precision)"

Bg

area eee eee ea a

SR882 488057 te 4a 179 dao

sae-8c jet 088 192 1a att op

S588 185 088 191 4a as gay

REA ms 099 im 13 eas 3a 34

eee ar aa 20 a2 tgs Soe ka

soar so 032 om 25 sr ter ae

snoae Se 08 os 25 Geo In ae

S680 217 02 cso 37 oss tee HH

average eat

Proce Valine os 1) 8 tae a ae

The prefered prociion vaues ae show F bod it

Non: 14—Appropriate action may be an investigation of the test

‘method procedure or apparatus far Faulty aperation or the declaration of

Sgniican difference in the two materials, simples, an a0 fork, whieh

cnerate the 60 tet tess

15.7 ReproducibiliyThe pooled relative reproducibility,

(2), of this test has been established as 4.4 6, Any other value

Table 4 may be used as an estimate of reproducibility, as

appropriate. The difference between two single and indepen.

‘dent test results found by two operators working. under the

prescribed reproducibility conditions in different laboratories

‘on identical test material will exceed the reproducibility on an

average of not more than once in 20 cases in the norinal and

correct operation of the method. Two single test results

produced in different laboratories that differ by more than the

‘appropriat= value from Table 4 must be suspected of being

foun different populations and some appropriate investigative

or technica/eommercial action taken,

15.8 Bias—In test method terminology, bias is the difference

between an average test value and the reference (true) test

roperty value, Reference values do not exist for this test

method since the value or level of the test property is

exclusively defined by the test method. Bias, therefore, cannot

be determined,

16. Keywords

16.1 carbon black; iodine adsorption number

TABLE 9 SRBS ITP Information

Troe ol abe (aL)

SAB Mat! rade Produser “oot Period Bisia

‘SRBGA nas ‘coineniar arch 2000 31 (2

sRB-0n2 N26 Contrast Maren 2013, Ting)

‘sho rae ‘abet tune 2000 es (127)

srB-ene Nia abet Marchi 2014 29 3)

‘SRGAC HS Tes ‘coisan September 2010 (28)

‘sa. 80 Us careass ‘Cabe aren 2000 67 (122)

‘SAB.AE Noo Oren Sepeemor 2008 57 (00)

SABA eas Oren ‘Maren 2010 ein)

SRB AF? 633 Oran arch 2018 (122)

R696" N00 cancat> Last half 1866 Ws

lp 01510 ~ 162

Al.2.5 Add approximately 200 em? of deionized water from

{he graduated cylinder into the volumetric flask. Carefully

Swirl to wash remaining 1, solution off the walls of the flask

Carefully transfer this entire wash into the 20 dm jug,

Continue washing until no color remains in the flask ot on the

funnel, using water from the graduated cylinder. Add any

remaining water that is left in the graduated cylinder to the

20-dm jug.

A1.26 A total of 18 dm’ of water needs to be added to the

20dm* jug. Repeat Al.2.2 until all the water is added,

including water used for rinsing the volumetric flask from the

4, solution, To ensure the accurate volume of water is added to

the jug, itis important to use the graduated eylinder and to keep

track of the number of transfers. Use the graduated marks on

the jug only as a reference point to ensure the correct number

of transfers was made. Do not rely on the graduated marke

alone to measure the volume, as these marks are not accurate

‘enough to be used in this procedure.

A127 Add a large clean str bar into the jug. Close the jug

ensuring that the stopper or cover is resistant to iodine (for

example, Teflon or polypropylene),

AL28 Cover the outside of the volumetric flask with

aluminum foil to prevent ambient light from decomposing the

‘iodine, Stir at medium speed for atleast 2 h. Sometimes it can

be difficult to initiate the stirring, The stirring can be started

‘manually by using a clean long Teflon or glass rod

Nove A1.3-—Do not rinse residual Ly solution off the rod im the jug!

1.2.9 Let the jug stand overnight, Stir for 30 min. Store in

1 cool dark place.

Ai.3 Sodium Thiosultate, 0.0394 .N

ALI Add about 4 dm? of water 10 a 20-dm? lass jug

(calibrated for 16 dm’) that has been placed on

stirrer:

4 magnetic

Nowe Al4—Calibraion of the 20-dn? ju

‘measuring 2m? increments from a sraated

carefully 28 possible in order to minimize the

tations

A13.2 Weigh 1565 of sodium thiosulfate (Nay 8,0,

5H;0) and wash through the filling funnel into the jug

AL33 Add 80 em? of n-amyl alcohol to the jug.

A344 Stir until the crystals are dissolved,

AI3.S Add water to the 16-dm? matk

A136

2h.

ALT Age for Ito 2 days, then stir for 0.5 h before using.

either by weight or by

ier, should be dane as

imber of standardization

Place the jug on the magnetic stirrer and stir for I to

AL Potassium Iodide (KI), 10 % Solution

Al-4.1 Weigh approximately 10 g of potassium iodide into

small stoppered flask or bottle

1.4.2 Fill a graduated cylinder with 90 cm? of water and

‘ansfer to the small stoppered flask or bottle,

A143 Mix thoroughly until dissolved

3i8

Nort A1 Sts possible forthe KI solution tobe oxidized and release

‘dine. Discard the KI soltion if any yellow color is oheerval

ALS Sulfuric Acid, 10 % Solution

A1S.1 Fill a graduated cylinder with 90 om? of deionized

water and transfer to a 250-cm* Erlenmeyer flask.

A1.S.2 Measure about 7 cm’ of concentrated sulfuric acid

into a small graduated cylinder or beaker,

ALS.3. Very carefully pour the acid into the 250-cm* flask

of water and swirl gently to mix. Rinse the graduate with

diluted acid trom the 250-em* flask

ALS. Allow the acid to cool to ambient temperature before

using

16 Soluble Starch, 1% Solution

A161 Into a 100-em* beaker weigh about 1 g of soluble

starch and 0.002 g of salicylic acid.

A1.6.2 Add enough water to make

with a stirring rod.

ALG3 Add about 100 em? of w;

and bring to a boil on a hotplate

ALG Add the starch paste to the water, stir,

to boil for 2 to 3 min

A165 Allow the starch solution to cool. Add 2 t

and stir to dissolve,

thin paste while stvving,

ater 10 a 250-cm* beaker

continue

0 3g KI

ALT Potassium Todate/lodide Solution,

Standard)

AL7.1 Dry am adequate quantity of analytical grade po

sium iodate for 1 h in an oven set at a temperature of 125°C.

Allow to cool to ambient temperature in a desiccator,

1.7.2 Dissolve 45 g of potassium iodide in about 200 cm"

of water contained in a 1000.cm* volumetric flask

AL7.3. Weigh 1.4054 g of the freshly dried potassium iodate

‘and add to the iodide solution in the 1000-cm? flask

ALT4 Make up to the mark and cap the flask

0.0394 N (Primary

0.0394 N (Primary

ALS Potassium Dichromate Solution,

Standard)

Nowe Al.6--Potassum dichromate is avslable as certified oxidime-

tre primary standard‘ a finely divided granular foen All procastces

should be used (0 ensure the accuracy ofthe prepared solute

AL8.1 Dry an adequate quantity of potassium dichromate

for Lh in an oven set at 125°C. Allow to cool to ambient

temperature in a desiccator.

A182 Weigh 0.9660 g of the dried potassium dichromate

(KsCr,0,), then using a standard-taper joint funnel, add this to

44 500-cm* volumette flask:

AL8.3 Add about 200 em? of water to the volumetric flask.

A184 Stopper and shake the flask until all erystals are

dissolved,

AL8.5 Add water to the mark and shake wel

A186 Stopper the flask and age for 30 min prior to use

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Special Sample OF 14-2020Document1 pageSpecial Sample OF 14-2020PLASTIC LAB CBDNo ratings yet

- RCT - 1963CB Dispersion On Mechanical Properties of RubberDocument2 pagesRCT - 1963CB Dispersion On Mechanical Properties of RubberPLASTIC LAB CBDNo ratings yet

- Brochure High Performance Carbon Blacks For Automotive Weather Stripping Asia RegionDocument12 pagesBrochure High Performance Carbon Blacks For Automotive Weather Stripping Asia RegionPLASTIC LAB CBDNo ratings yet

- MRG - D R.sirDocument30 pagesMRG - D R.sirPLASTIC LAB CBDNo ratings yet

- Effect of New Generation Blacks On Rubber VulcanizatesDocument12 pagesEffect of New Generation Blacks On Rubber VulcanizatesPLASTIC LAB CBDNo ratings yet

- Spheron 6000ADocument2 pagesSpheron 6000APLASTIC LAB CBDNo ratings yet

- SpheronDocument1 pageSpheronPLASTIC LAB CBDNo ratings yet

- Fundamentals of Carbon BlackDocument6 pagesFundamentals of Carbon BlackPLASTIC LAB CBDNo ratings yet

- FTIR SpectrosDocument11 pagesFTIR SpectrosPLASTIC LAB CBDNo ratings yet

- Certain Types of Carbon Black Used in TiresDocument2 pagesCertain Types of Carbon Black Used in TiresPLASTIC LAB CBDNo ratings yet

- Insights On DispersionDocument3 pagesInsights On DispersionPLASTIC LAB CBDNo ratings yet

- Application of Industrial Black 24112017Document65 pagesApplication of Industrial Black 24112017PLASTIC LAB CBDNo ratings yet

- Rubbercon PresentationDocument35 pagesRubbercon PresentationPLASTIC LAB CBDNo ratings yet