Professional Documents

Culture Documents

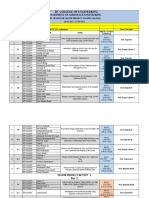

Safety Shell HTO S2 Tech Data Sheet Summary

Uploaded by

frana hadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Shell HTO S2 Tech Data Sheet Summary

Uploaded by

frana hadiCopyright:

Available Formats

SAFETY DATA FIRE FIGHTING

Specific hazards arising from Chemicals: Hazardous combustion products

may include: A complex mixture of airborne solid and liquid particulates and

gases (smoke). Carbon monoxide. Unidentified organic and inorganic

compounds. Suitable Extinguishing Media: Foam, water spray or fog. Dry

SHELL Heat Transfer

chemical powder, carbon dioxide, sand or earth may be used for small fires

Oil S2

only. Unsuitable Extinguishing Media: Do not use water in a jet. Protective

Equipment & Precautions for Fire Fighters: Proper protective equipment

including breathing apparatus must be worn when approaching a fire in a

confined space.

EXTINGUISHING MEDIA: Use water fog, foam, dry chemical or carbon

Texatherm Heat dioxide (CO2) to extinguish flames. PROTECTION OF FIRE FIGHTERS: Fire

Transfer Oil 32 Fighting Instructions: This material will burn although it is not easily ignited.

See Section 7 for proper handling and storage. For fires involving this

material, do not enter any enclosed or confined fire space without proper

protective equipment, including self-contained breathing apparatus.

Combustion Products: Highly dependent on combustion conditions. A

Texatherm Heat complex mixture of airborne solids, liquids, and gases including carbon

Transfer Oil 46 monoxide, carbon dioxide, and unidentified organic compounds will be

evolved when this material undergoes combustion.

Fire Fighting Instructions: Evacuate area. Prevent run-off from fire control or

dilution from entering streams, sewers or drinking water supply. Fire-fighters

should use standard protective equipment and in enclosed spaces, self-

Mobiltherm 605 contained breathing apparatus (SCBA). Use water spray to cool fire exposed

surfaces and to protect personnel. Hazardous Combustion Products:

Aldehydes, Incomplete combustion products, Oxides of carbon, Smoke,

Fume, Sulphur oxides.

In case of fire, use foam, dry chemical or carbon dioxide extinguisher or spray.

Do not use water jet. During use heat transfer oils may be thermally

degraded leading to the formation of volatile hydrocarbons with flash points

considerably lower than the original product. It is therefore essential that the

system is not drained while hot unless an inert gas system is used to displace

flammable gaseous residues.Adequate ventilation is essential during draining

operations as hot oil will fume. The temperature at which spent product is

drained is a compromise between the need to have the oil sufficiently hot to

facilitate drainage, the need to avoid fuming and the dangers of fire from

degraded oil with a low flash point. It is recommended therefore that spent oil

is drained at a temperature of less than 100°C. During system filling and

BP Transcal N venting, care should be taken to ensure that hot oil is not pumped through the

expansion tank. A failure to prevent this could, under certain conditions, lead

to the creation of a flammable atmosphere in the expansion tank. As the

expansion tank is being filled it is essential that the gases and vapours formed

should be free to vent to an open atmosphere where they can quickly

disperse. Oil soaked lagging may spontaneously ignite and should be

replaced by fresh lagging as soon as possible. Product contaminated rags,

paper or material used to absorb spillages, represent a fire hazard, and should

not be allowed to accumulate. Dispose of safely immediately after use. In a

fire or if heated, a pressure increase will occur and the container may burst.

You might also like

- Applications For GreasesDocument33 pagesApplications For Greasesfrana hadi100% (1)

- Applications For Heat Transfer SystemsDocument12 pagesApplications For Heat Transfer Systemsfrana hadiNo ratings yet

- Applications For Refrigeration OilsDocument59 pagesApplications For Refrigeration Oilsfrana hadiNo ratings yet

- Compressor Handbook Sec 6 ArielDocument32 pagesCompressor Handbook Sec 6 Arielfrana hadiNo ratings yet

- CRM & PPPL - Oil & Grease Firts Filling ListDocument2 pagesCRM & PPPL - Oil & Grease Firts Filling Listfrana hadiNo ratings yet

- Total LubeDocument5 pagesTotal Lubefrana hadi100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Review1 ScheduleDocument3 pagesReview1 Schedulejayasuryam.ae18No ratings yet

- 15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsDocument42 pages15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsShashank SinglaNo ratings yet

- Tplink Eap110 Qig EngDocument20 pagesTplink Eap110 Qig EngMaciejNo ratings yet

- Lec 33 - Householder MethodDocument11 pagesLec 33 - Householder MethodMudit SinhaNo ratings yet

- Activity # 1 (DRRR)Document2 pagesActivity # 1 (DRRR)Juliana Xyrelle FutalanNo ratings yet

- Manual s10 PDFDocument402 pagesManual s10 PDFLibros18No ratings yet

- Carriage RequirementsDocument63 pagesCarriage RequirementsFred GrosfilerNo ratings yet

- IEC ShipsDocument6 pagesIEC ShipsdimitaringNo ratings yet

- Huawei R4815N1 DatasheetDocument2 pagesHuawei R4815N1 DatasheetBysNo ratings yet

- SHCDocument81 pagesSHCEng Mostafa ElsayedNo ratings yet

- Turn Around Coordinator Job DescriptionDocument2 pagesTurn Around Coordinator Job DescriptionMikeNo ratings yet

- Playful Homeschool Planner - FULLDocument13 pagesPlayful Homeschool Planner - FULLamandalecuyer88No ratings yet

- Project Scheduling and TrackingDocument47 pagesProject Scheduling and TrackingArun VinodhNo ratings yet

- The Homework Song FunnyDocument5 pagesThe Homework Song Funnyers57e8s100% (1)

- Week 7Document24 pagesWeek 7Priyank PatelNo ratings yet

- Functional DesignDocument17 pagesFunctional DesignRajivSharmaNo ratings yet

- 11-03 TB Value Chains and BPs - WolfDocument3 pages11-03 TB Value Chains and BPs - WolfPrakash PandeyNo ratings yet

- Duavent Drug Study - CunadoDocument3 pagesDuavent Drug Study - CunadoLexa Moreene Cu�adoNo ratings yet

- Technology Management 1Document38 pagesTechnology Management 1Anu NileshNo ratings yet

- Stress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingDocument9 pagesStress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingRory Cristian Cordero RojoNo ratings yet

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- Lesson 6 ComprogDocument25 pagesLesson 6 ComprogmarkvillaplazaNo ratings yet

- E0 UoE Unit 7Document16 pagesE0 UoE Unit 7Patrick GutierrezNo ratings yet

- Modulo EminicDocument13 pagesModulo EminicAndreaNo ratings yet

- Biological Beneficiation of Kaolin: A Review On Iron RemovalDocument8 pagesBiological Beneficiation of Kaolin: A Review On Iron RemovalValentin GnoumouNo ratings yet

- Negotiating Skills Negotiating Skills: To Provide You With The Skills To Plan & Implement Successful NegotiationDocument32 pagesNegotiating Skills Negotiating Skills: To Provide You With The Skills To Plan & Implement Successful NegotiationKanimozhi.SNo ratings yet

- Benevisión N15 Mindray Service ManualDocument123 pagesBenevisión N15 Mindray Service ManualSulay Avila LlanosNo ratings yet

- Article An Incident and Injury Free Culture Changing The Face of Project Operations Terra117 2Document6 pagesArticle An Incident and Injury Free Culture Changing The Face of Project Operations Terra117 2nguyenthanhtuan_ecoNo ratings yet

- Decision Making and The Role of Manageme PDFDocument20 pagesDecision Making and The Role of Manageme PDFRaadmaan RadNo ratings yet

- The JHipster Mini Book 2Document129 pagesThe JHipster Mini Book 2tyulist100% (1)