Professional Documents

Culture Documents

Surge Drum - 11E-01 PDF

Surge Drum - 11E-01 PDF

Uploaded by

onkarrathee0 ratings0% found this document useful (0 votes)

10 views2 pagesOriginal Title

Surge drum -11E-01.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesSurge Drum - 11E-01 PDF

Surge Drum - 11E-01 PDF

Uploaded by

onkarratheeCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

Phillips.

Pru)

CO ee er Led

SURGE DRUMS

BULLETIN SD-11E-01

Engineering Dai

Although this bulletin is concerned mainly with surge drum

design, TABLE 1 applies to all vessels that involve the separa-

tion of liquid from vapor, Horizontal separators require spe-

cial consideration, For a vertical desuperheater it is recom

‘mended that the ratings in the 30 PSI (+17°F) column be re-

duced by 20%

Pern

‘The surge drum on a flooded evaporator performs various

important functions. They are

‘(To separate the liquid out of the gas returning from the

evaporator, allowing the gas to pass to the compressor through

‘the suction line, and returning the liquid to the evaporator for

re-circulation,

(2)To absorb such surges in the evaporator as may occur

due to variation of load during operation. The coil circuits

For Ammonia (R717)

3)To absorb the violent liquid surging that occurs when

the suction line ofa flooded evaporator is opened quickly The

immediate drop in pressure on the liquid lying in the evapora-

tor that accurs when the suction line is opened ereates a tre-

menclous amount of vapor. Practically the entire change of liq-

uid leftin the evaporator at shut-down is suddenly thrown up

into the surge drum,

‘The minimum cross sectional flow area of a surge drum

needed to allow satisfactory liquid separation velocities is de~

pendent upon both the refrigeration load and the suction pres-

sure. To attain the correct separation velocity for vertical surge

‘drums under various load and pressure conditions, the selec-

tion can be made from TABLE

“The surge drum volume in many flooded systems is gov-

cerned principally by volume of liquid that may be in the coil

at the moment of shut-down, Generally the following volumes

of surge drums are recommended for vatious types of work:

will carry am amount of liquid in them in somewhat inverse

mpi od ah ys rel pear amucaron [MMVSURGIR SORTER

load becomes heavier and duty i greater, more gas is formed ARCOURSURTS ERO a

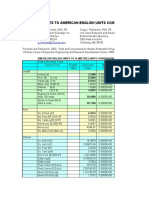

TABLE 1

MAXIMUM TONS IN VERTICAL SURGE DRUMS -- AMMONIA

Sere

‘The separation space in a horizontal surge drum is de-

creased as the liquid level rises. This factor requires careful

consideration when designing the horizontal surge drum,

‘To insure liquid separation under all operating conditions,

the flow area must be adequate when the liquid level is at

its highest point in the drum, This condition will be just,

after maximum volume of liquid has surged from the evapo-

rator,

When a horizontal drum is required on an installation

A discussion of surge drums cannot be complete without

‘mention of proper sizing of the liquid leg. Liquid velocities must

be slowed down enough that oil may be allowed to settle out im

the space below the liquid coil inlet to the evaporator This helps

‘keep the evaporator oil free and insures good heat transfer. Oil

‘must be periodically drained, When an integral oil pot some-

‘what larger than the liquid drop leg is built as part of the liquid

leg at the bottom, the liquid leg tons may be doubled. TABLE 3

gives a good selection of liquid leg sizes for various tonnages.

whe no pres expen i cn aud eto TABLE 3

Fullinformatonwouldbe required suchasefigeran load, Liquio LEGS

fhction pesre Spe of col se and length ot pipe oF MAXIMUM TONS ~- AMMONIA

Cait, numberof outdets for the gas, and any other factors isn)] Tons | [ips n)| TONS

34 1 3 30

1 2 aaa |_45

00d operation ofa flooded sys ;

temis the size of the gas return(s) from the evaporator back uate 2 a so

to the surge drum, Since the gas return is also carrying q- az | 6 5 |_105

uid droplets entrained with the gas, the effect could be an

increase in the pressure drop that penalizes the compressor. a au eI BO)

TABLE? gives the recommended maximum tons that should 2a _|_18 8 | 330

be retumed through extacheavy pipe to 2" IPS, and stan-

dard weight 2 12° IPS and up. When liguid level in the TABLE 4 indicates nominal ammonia suction line capacities

drum is ator below the gas outlet ofthe evaporator, the gas at approximately I psi pressure drop per 100 of equivalent

retum should be made at leat one pipe size larger. Tine, and is shown (or convenience

TABLE 2 TABLE 4

GAS RETURNS SUCTION LINE

FROM EVAPORATOR TO SURGE DRUM MAXIMUM TONS ~ AMMONIA

MAXIMUM TONS -- AMMONIA TRON T sor vac [a psic|s psie | 20 rsic | 20 Psic as rate

“oe |-2ee| re | sor | ir | sor

|IPS_GAS| 10" VAC | 0 PSIG | 5 PSIG | 20 PSIG} 45 PSIG SIZE

RETURN] “a2°F | 2eer | -i7er | 53°F | aor | a [ae « [a [| 1 | 20

sa |e [03 [12 | 22 | 208 | aa

aa | 28 | 33 | as | oe | oe

1 [+26 [sea] 22 [40 | so | 75

1 | se | 66 | 77 | 14 | 14

via | 252 [ase[ aa [20 | 10 | 150

ad oe) aE 22) ae AZ 3.77 | 4.86 4 | 14.8 15, 24.6

17 22 2.5 34 45 2 7.10 | 9.30 | 124 | 222 28 42

2 44 5.2 64 8.2 10.7 242 14 | 14,60] 19.1 | 35.5 45 65

24a | 68 | 6 | 10 | 135 | 175 2 | 19 [zea0] a1 | se | 75 | 108

3 [ats [us | 7 | 2s | 30 a [ose | 48 [ee [te [180 | 00

saa | 172 | 218 | 26 | 34 | as s | «4 | es | 17 | 208 | 260 | 205

4 [24 [31 [36 | 48 [6s © [toa [134 [475 | 308 | 298 | 00

s | a | se | es | es | 115 a | 10 | 230 | sts | s4o | oes | 1040

ca | TTS 40 | 280 | 280 | 490 | 50 | 1100 | 1680

sae aa ane Paes Tae 12 | 400 | 535 | 700 | 1225 | 1580 | 2400

14 [565 | 730 | 260 | 1680 | at70 | 3200

Remit to:

Pee

PO Box 5998

ee

cy

ne

Doe EROS

ea CK Z oes

eel LLL 200)

cre}

TA 7)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Frick CompressorDocument66 pagesFrick Compressoronkarrathee75% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Si (Metric) Units To American English Units Conversion TableDocument9 pagesSi (Metric) Units To American English Units Conversion TableonkarratheeNo ratings yet

- Universal Unit Conversions Template: Engineering Solutions On-Line Presents TheDocument25 pagesUniversal Unit Conversions Template: Engineering Solutions On-Line Presents TheonkarratheeNo ratings yet

- BE Spec Flash EconomizerDocument4 pagesBE Spec Flash Economizeronkarrathee100% (1)

- Guidance For Treatment of Covid-19 in Adults and Children: Patient PopulationDocument7 pagesGuidance For Treatment of Covid-19 in Adults and Children: Patient PopulationonkarratheeNo ratings yet

- Refrig Plant Ice Silo REFRI KAN 06 06 2015Document321 pagesRefrig Plant Ice Silo REFRI KAN 06 06 2015onkarratheeNo ratings yet

- Cooling & Dehumidification Coil PDFDocument30 pagesCooling & Dehumidification Coil PDFonkarratheeNo ratings yet