Professional Documents

Culture Documents

Milk10 - Culturi Starter

Uploaded by

roxanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Milk10 - Culturi Starter

Uploaded by

roxanaCopyright:

Available Formats

Chapter 10

Cultures and starter

manufacture

Bacteria cultures, known as starters, are used in the manufacture of yog-

hurt, kefir and other cultured milk products as well as in buttermaking

and cheesemaking. The starter is added to the product and allowed to

grow there under controlled conditions. In the course of the resulting

fermentation, the bacteria produce substances which give the cultured

product its characteristic properties such as acidity (pH), flavour, aroma

and consistency. The drop in pH, which takes place when the bacteria

ferment lactose to lactic acid, has a preservative effect on the product,

while at the same time the nutritional value and digestibility are improved.

Dairy Processing Handbook/chapter 10 233

Cultured dairy products have different charac-

teristics, and different starter cultures are

therefore used in their manufacture. Starter

cultures can be classified according to their

preferred growth temperatures:

• Mesophilic bacteria - optimal growth

temperatures of 20 to 30C

• Thermophilic bacteria - optimal growth

temperatures of 40 to 45C

The cultures may be of:

Single-strain type (containing only one

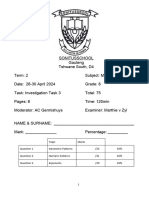

Fig. 10.1 Bacteria in yoghurt: Lactobacillus strain of bacteria);

bulgaricus, left, and Streptococcus thermophilus. • Multiple-strain type (a mixture of several strains, each with its own

specific effect).

Mesophilic bacteria cultures can be further divided into O, L , D and

LD cultures. Table 10.1, reproduced from the Bulletin of the IDF

(263/1991), lists the new and old names of various cultures. The old

names are used in this chapter.

Table 10.1

New and old names of various starters and their uses

Type Old Name New name Product

Mesophillic

O Streptococcus cremoris Lactococcus lactis ssp. cremoris Cheddar cheese

Streptococcus lactis Lactococcus lactis ssp. lactis Feta cheese

Cottage cheese

Quarg

L* Streptococcus cremoris Lactococcus lactis ssp. cremoris Continental cheese

(with eyes)

Streptococcus lactis Lactococcus lactis ssp. lactis

Leuconostoc citrovorum Leuconostoc mesenteroides ssp. cremoris Lactic butter

Leuconostoc lactis Leuconostoc lactis Feta cheese

D** Streptococcus cremoris Lactococcus lactis ssp. cremoris Lactic butter

Streptococcus lactis Lactococcus lactis ssp. lactis

Streptococcus diacetylactis Cit+ Lactococci***

LD Streptococcus cremoris Lactococcus lactis ssp. cremoris Continental cheese

(with eyes)

Streptococcus lactis Lactococcus lactis ssp. lactis Mould ripened cheese

Streptococcus diacetylactis Cit+ Lactococci*** Cultured buttermilk

Leuconostoc citrovorum Leuconostoc mesenteroides ssp. cremoris Lactic butter

Leuconostoc lactis Leuconostoc lactis

Thermophillic

Streptococcus thermophilus Streptococcus salivarius ssp. thermophilus Yoghurt

Lactobacillus bulgaricus Lactobacillus delbrueckii ssp. bulgaricus Mozzarella cheese

Streptococcus thermophilus Streptococcus salivarius ssp. thermophilus Emmental cheese

Lactobacillus helveticus Lactobacillus helveticus Grana cheese

Lactobacillus lactis Lactobacillus delbrueckii ssp. lactis

* L = Leuconostoc ** D = diacetylactis

*** Cit+ = Abbreviation for citrate which is metabolised to flavour and aroma compounds

234 Dairy Processing Handbook/chapter 10

Some Str. diacetylactis bacteria are such powerful acidifiers that they can

be used alone as acidifying cultures, but they are used primarily together

with Str. cremoris/lactis. It is not however possible to use a pure Leuc. citro-

vorum culture, because growth of Leuc. citrovorum in milk is conditional

upon the availability of nutrients produced by Str. lactis or Str. cremoris.

Leuc. citrovorum grows very slowly in milk in the absence of acid-producing

bacteria, and cannot produce aroma substances in such conditions.

Such bacterial characteristics as optimum growth temperature and salt

tolerance are very important in the composition of a culture. The purpose of

the component strains is to produce the desired result in symbiosis, not to

compete with each other. Their characteristics must therefore be comple-

mentary in these respects. Table 10.2 lists essential data for some impor-

tant culture bacteria.

Characteristics of some important culture bacteria

Bacterium Optimum Max salt Acid Citric

(old name) growth tolerance formation, acid

temp, C for growth, % ferment. ferment.

%

I Streptococci

Str. lactis about 30 4 – 6.5 0.8 – 1.0 –

Str. cremoris 25 – 30 4 0.8 – 1.0 –

Str. diacetylactis about 30 4 – 6.5 0.8 – 1.0 +

Str. thermophilus 40 – 45 2 0.8 – 1.0 –

Leuc. citrovorum 20 – 25 – small +

II Lactobacilli

Lb. helveticus 40 – 45 2 2.5 – 3.0 –

Lb. lactis 40 – 45 2 1.5 – 2.0 –

Lb. bulgaricus 40 – 50 2 1.5 – 2.0 –

Lb. acidophilus 35 – 40 – 1.5 – 2.0 –

Dairies normally buy ready-mixed starters – commercial cultures – from

special laboratories. These laboratories put much effort into research and

development to compose special cultures for a given product, e.g. butter,

cheese and a great number of cultured milk products. Thus the dairies can

obtain cultures with selected properties for specific product characteristics

such as texture, flavour and viscosity.

The dairies can buy the commercial cultures in various forms:

• Liquid, for propagation of mother culture (nowadays fairly rare).

• Deep-frozen, concentrated cultures for propagation of bulk starter.

• Freeze-dried, concentrated cultures in powder form, for propagation of

bulk starter.

• Deep-frozen, superconcentrated cultures in readily soluble form, for

direct inoculation of the product.

Stages of propagation

In recent years concentrated cultures have generally been used for direct

manufacture of a bulk starter, see figure 10.2, as well as for direct use in

production. Future handling of cultures will most probably be based on

specially designed, concentrated cultures that can be used direct in pro-

duction without any further propagation at the dairy.

There are however many dairies that still propagate their own bulk start-

ers in successive stages via a mother culture, as shown in figure 10.3; the

technique will therefore be described here.

Dairy Processing Handbook/chapter 10 235

The process may involve two or more stages. Cultures in various stages

of propagation are known by the following names:

• Commercial culture, master culture – the original culture that the dairy

buys from the laboratory.

• Mother culture – the culture prepared from master culture at the dairy.

The mother culture is prepared daily and is, as the name indicates, the

origin of all cultures made at the dairy.

• Intermediate culture – an intermediate step in the manufacture of large

volumes of bulk starter.

• Bulk starter – the starter used in production.

Process technology

Starter manufacture is one of the most important and also one of the most

difficult processes in the dairy. Production failures can result in heavy finan-

cial loss, as modern dairies process large quantities of milk.

Very careful attention must therefore be paid to the manufacturing tech-

Fig. 10.2 Bulk starter manufactured nology and choice of process equipment. Starter production demands the

from freeze-dried or frozen commercial very highest standard of hygiene. The risk of airborne infection by yeasts,

cultures. mould fungi and bacteriophages must be reduced to an absolute minimum.

Mother cultures should be prepared in a separate room supplied with fil-

tered air at a pressure slightly above normal atmospheric pressure. The

cleaning system for the equipment must also be carefully designed to pre-

vent detergent and sterilant residues from coming into contact with the

cultures and spoiling them.

Manufacture of intermediate culture and bulk starter can take place close

to the point of production, or in the same room where the mother culture is

prepared. Each transfer of culture to the next stage of manufacture should

preferably take place under aseptic conditions.

Stages in the process

The process, presented in figure 10.4, is essentially the same for production

of mother culture, intermediate culture and bulk starter. It comprises the

following stages:

• heat treatment of the medium

• cooling to inoculation temperature

• inoculation

• incubation

1 2 3 4 • cooling of the finished culture

• storage of the culture

Fig. 10.3 Steps in the manufacture of

starters.

1 Commercial culture

2 Mother culture reconstituted

3 Intermediate culture

4 Bulk starter

Cooling

Incubation

Cooling

Fig. 10.4 Block diagram of starter Storage

manufacture.

236 Dairy Processing Handbook/chapter 10

Skimmilk is the medium most frequently used for starter production, but

reconstituted skimmilk with 9 – 12% dry matter (DM), made from top-grade

skimmilk powder, is another alternative.

The basic reason for using fresh or reconstituted skimmilk is that anoma-

lies in the flavour of the culture are much more readily apparent. Fresh milk

from selected farmers is also used in some dairies.

A medium with constant composition, such as reconstituted antibiotic-

free skimmilk, is more reliable than ordinary skimmilk.

The medium can also be modified by addition of growth factors such as

Mn2+ (Manganese), example: 0.2 mg MnSO4 per l culture, which is sup-

posed to promote growth of Leuc. citrovorum. Phage-inhibiting media (PIM)

offer an alternative for production of single-strain or multi-strain starters.

These media contain phosphates, citrates or other chelating agents which

make Ca2+ (Calcium) insoluble. The reason for doing this is that most phag-

es require Ca2+ for proliferation. Removing Ca2+ from the medium protects

the lactic acid bacteria from being infected and thus avoids failure of starter

activity. Skimmilk powders with PIM are available on certain markets.

Heat treatment of the medium

The first step in starter manufacture is heat treatment of the medium. It is

heated to 90 – 95C and held at that temperature for 30 to 45 minutes. This

heat treatment improves the properties of the medium through

• destruction of bacteriophages

• elimination of inhibitory substances

• some decomposition of protein

• expulsion of dissolved oxygen

• destruction of original living micro-organisms

Cooling to inoculation temperature

After heat treatment the medium is cooled to inoculation temperature,

which differs according to the type of bacteria culture used. It is important

that the temperatures recommended by the producer of the commercial

culture, or empirically determined optimum temperatures, are maintained.

In propagation of multi-strain cultures, even small deviations from the

proper incubation temperature may favour growth of one strain at the ex-

pense of the other(s), resulting in failure to obtain the desired typical charac-

teristics of the end product. Figure 10.6 demonstrates what happens when

typical yoghurt bacteria are incubated at a progressive temperature range.

Typical inoculation temperature ranges are 20 – 30C for mesophilic

types of bacteria and 42 – 45C for thermophilic types.

Acidity

Inoculation SH

50

For inoculation, a determined quantity of bacteria culture is transferred to

the heat-treated medium after the temperature has been adjusted to the 40

correct level. To prevent any deviations in the culture it is most important

that the starter dosage, the propagation temperature and the time are kept 30

constant throughout all stages — mother culture, intermediate culture and

bulk starter. 20

The amount of starter used can also affect the relative proportions of

different bacteria which produce lactic acid and aroma substances. Varia- 10

tions in the amount of starter can consequently cause variations in the

product. Each manufacturer must therefore determine which practical con-

0 4 8 12 16 20 24

ditions suit his particular production process best. Figure 10.5 illustrates Incubation time,

how the amount of starter used for inoculation affects the acidifying process hours

in a culture. The curves represent dosages of 0.5% and 2.5% respectively. Fig. 10.5 Acid development curves for

The inoculation temperature is 21C in both cases. inoculation with 0.5% and 2.5% of a

mesophilic culture. Incubation tempera-

ture 21C.

Incubation

As soon as inoculation has taken place and the starter has been mixed into

the medium, the bacteria begin to multiply – incubation begins. The incuba-

tion time is determined by the types of bacteria in the culture, the inocula-

tion dosage, etc., and can vary from 3 to 20 hours. It is most important that

Dairy Processing Handbook/chapter 10 237

the temperature is carefully

controlled and that no con-

taminants are allowed to

come into contact with the

culture.

During incubation the

bacteria multiply rapidly

40 41 42 43 44 and

45 ferment lactose to lactic

Incubation temperature C acid. A culture containing

Lactobacillus aroma-producing bacteria

Streptococcus will also produce aroma substances such as diacetyl, acetic and propionic

Fig. 10.6 Effect of incubation tempera- acids, ketones and aldehydes of various kinds, alcohols, esters and fatty

ture on relative counts of cocci and acids as well as carbon dioxide.

bacilli at constant dosage and incubation The importance of a correct incubation temperature is illustrated in the

time. graph in figure 10.6, which refers to a yoghurt culture. The culture contains

two strains of bacteria, Str. thermophilus and Lb. bulgaricus, which coexist

in symbiosis and together produce the desired characteristics of the yog-

hurt, such as pH, flavour, aroma and consistency. Most yoghurt has a ratio

of cocci to bacilli between 1:1 and 2:1. The bacilli must never be allowed to

gain the upper hand, as the flavour will then be too acid.

An example of growth of Str. thermophilus and Lb.bulgarius with result-

ing aroma formation is demonstrated in figure 10.7.

Acetaldehyde Bacteria In this context it may be mentioned that acetaldehyde is

pH ppm Log CFU/g

recognised (Pette and Lolkema, 1950 c; Schultz and Hingst,

7 9,5

1954) as the principal flavour component in the flavour of

9 yoghurt. A principal role in acetaldehyde production is attri-

buted to Lb. bulgaricus, although various strains of this spe-

6 8,5

cies show considerable differences. In the associated growth

8 of Str. thermophilus and Lb. bulgaricus, the rate of acetalde-

5 7,5

hyde production is considerably increased compared to the

single Lb. bulgaricus species (Bottazzi & al., 1973). Thus the

7 symbiotic relationships between these species favourably

4 6,5 influence production of acetaldehyde in the manufacture of

yoghurt. During production of yoghurt, formation of acetalde-

6

hyde does not become evident until a certain level of acidifi-

3 5,5 cation, pH 5.0, has been reached. It attains a maximum at

0 1 2 3 4 5 6

Incubation time, pH 4.2 and stabilises at pH 4.0 (A.Y. Tamime & R.K. Robin-

hours

ST LB pH Acetaldehyde son, Yoghurt - science and technology).

The optimum aroma and flavour of yoghurt are usually

Fig. 10.7 Growth of Str. thermophilus obtained with an acetaldehyde content ranging between 23.0 and 41 ppm

and Lb. bulgaricus with resulting aroma

and a pH value of between 4.40 and 4.00.

development, at 2.5% inoculation.

The curves are derived from information received from Chr

One of the factors affecting the ratio of cocci to bacilli is the incubation

Hansen A/S. temperature. At 40C the ratio is about 4:1, while at 45C it is about 1:2

(see fig. 10.6 ). The optimum temperature for inoculation (and incubation) in

yoghurt manufacture is thus 43C to achieve a cocci-to-bacilli ratio of 1:1,

with a rate of inoculum of 2.5 – 3% and an incubation time of 2.5 – 3 hours.

Number of lactic-acid

producing bacteria During the incubation period it is essential that the person responsible for

production regularly checks acidity development and otherwise follows the

Cooling routines found to give optimal results.

starts

Careful handling of all starter cultures is a very important aspect of the

processing of cultured milk products; this task should therefore always be

Cooled

given to skilled personnel.

Cooling the culture

Cooling is started at an empirically determined acidity to stop bacterial

growth and thus to preserve the activity of the culture at a high level. Figure

10.8 demonstrates the course of events for an ordinary lactic-acid-forming

10 16 20 30 40

Incubation time, culture inoculated with 1% mother culture at 20C.

Fig. 10.8 hours Cooling to 10 – 12C is often practised when the culture is going to be

Growth of lactic-acid produc-

ing bacteria with and without cooling at used within the next 6 hours. If the culture needs to be stored for an ex-

the end of incubation. tended period, more than 6 hours, it is advisable to cool it to about 5C.

238 Dairy Processing Handbook/chapter 10

In large-scale production, or production during more than one shift, it is

more convenient to prepare starters at regular intervals of, say, 4 hours. This

means that active cultures are available at all times, making it easier to fol-

low the prescribed processing schedule and to assure consistently high

quality in the end products.

Preservation of starters

A great deal of research work has been done to find the best way to treat

starters in order to preserve their activity during storage. One method is

freezing. The lower the temperature, the better the cultures keep. Freezing

with liquid nitrogen to –160C and storage at that temperature preserve

cultures very well.

Modern forms of starter cultures – concentrated, deep-frozen or freeze-

dried (lyophilised) – can be stored for a considerable time provided that the

manufacturers’ recommendations are followed.

Table 10.3 shows the recommendations issued by Chr Hansen A/S of

Copenhagen, Denmark.

It should be noted that deep-frozen cultures require lower storage tem-

perature than lyophilised cultures. The former, moreover, are supplied in

insulated polystyrene boxes packed with dry ice; time in transit should not

exceed 12 hours. The latter, on the other hand, can be transported at tem-

peratures up to some 20C for up to 10 days without shortening the stated

shelf life, provided that they are stored at the recommended temperature

after arrival at the buyer’s premises.

Storage conditions and shelf lives of some concentrated

cultures. (Chr Hansen A/S, Denmark)

Type of culture Storage Shelf life, months

1. Freeze-dried DVS Freezer below –18C minimum 12

2. Deep-frozen DVS Freezer below –45C minimum 12

3. Freeze-dried REDI-SET Freezer below –18C minimum 12

4. Deep-frozen REDI-SET Freezer below –45C minimum 12

5. DRI-VAC Refrigator below +5C minimum 12

Freeze-dried, superconcentrated culture (for direct inoculation of

product)

Deep-frozen

Freeze-dried, concentrated culture (for preparation of bulk starter)

Deep-fozen, concentrated culture (for preparation of bulk starter)

Freeze-dried culture in powder form (for preparation of mother culture)

Manufacture of cultures under

aseptic conditions

Since the new generation of concentrated, frozen and lyophilised cultures

was introduced, there is no longer so much demand for the specific equip-

ment for aseptic production of cultures in dairies. However, this does not

mean that the need for hygiene in starter propagation can be neglected.

The recommendations given by the suppliers of the new types of starter

should be carefully followed to obtain optimal results.

Where traditional starter preparation is still required, the procedure can

be accomplished as outlined below.

A typical system for production under aseptic conditions of a bulk starter

via an intermediate culture, also produced under aseptic conditions, is illus-

Dairy Processing Handbook/chapter 10 239

trated in figures 10.10 and 10.11. The following conditions apply:

1 The mother culture is traditionally prepared in 100 ml bottles provided

with a cap containing a membrane.

2 The bottle is filled with skimmilk, autoclaved, and then cooled to the

appropriate inoculation temperature.

3 The master culture is injected into the bottle for mother culture with a

sterilised syringe inserted through the membrane.

4 Following a suitable period of incubation and subsequent cooling, the

mother culture is inoculated into the milk, usually skimmilk, used for the

intermediate culture; the milk is first heated to a minimum of 95C for 30 –

45 minutes and then cooled to adequate incubation temperature. Heating

and cooling are done in a specially designed incubator.

5 After an appropriate incubation period and cooling to about 10 – 12C,

the intermediate culture is transferred by displacement with filtered air

Fig. 10.9 Incubator with four intermedi- through a tube to the bulk starter tank.

ate containers and four compartments 6 Before being inoculated the milk, often skimmilk, is heated by circulation

for mother culture flasks. The tempera- of heating medium and coolant through the tank jacket. Air supplied to and

ture of the heating water bath is accu- evacuated from the the tank passes through a sterile HEPA (High Effiency

rately controlled from the panel. (Labora- Particle Air) filter.

torium Wiesby, Germany.)

Bulk starter tanks

The normal practice is to use two tanks in rotation for manufacture of bulk

starter. One contains ready-made starter for use in the day’s production,

while the starter for the following day is being prepared in the other one.

The tanks should be of aseptic design, i.e. hermetically sealed and triple

jacketed. They should also be capable of withstanding negative pressures

up to 30 kPa (0.3 bar) and positive pressures up to 100 kPa (1 bar). The

agitators should be double-sealed and powered by two-speed motors. In

addition, they should be fitted with HEPA filters (4) to exclude airborne infec-

tion from the air that is drawn in when the tank is cooled after cleaning and

when the heated medium is cooled to incubation temperature.

The bulk starter tank can be equipped with a stationary integrated pH

meter (7) designed to withstand the great temperature differences that oc-

cur during cleaning and heat treatment of the medium.

Fig 10.10 Aseptic transfer of mother

culture to intermediate culture container.

1 Sterile filter

2 Aseptic needle

3 Mother culture flask

4 Intermediate culture container

Fig. 10.11 Aseptic transfer of interme-

diate culture to bulk starter tank.

1. Incubator

2. Intermediate culture container

3. Bulk starter tank

4. HEPA filter

5. Air valve

6. Steam filter

7. pH measurement unit

Milk/culture

Air

Steam

240 Dairy Processing Handbook/chapter 10

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- State of Stealth FINAL 121317Document41 pagesState of Stealth FINAL 121317Muhammad Afzaal100% (2)

- The Better Momentum IndicatorDocument9 pagesThe Better Momentum IndicatorcoachbiznesuNo ratings yet

- Batching Plant ReportDocument89 pagesBatching Plant ReportShahzad Tabassum0% (3)

- Din332 PDFDocument4 pagesDin332 PDFmateo100% (2)

- Quiz 2 Principles of DesignDocument4 pagesQuiz 2 Principles of DesignJovito Reyes0% (1)

- CSCI101 - Lab08 - Functions Zewail CityDocument4 pagesCSCI101 - Lab08 - Functions Zewail CityMahmoud Ahmed 202201238No ratings yet

- Group 3 Aia ReportDocument26 pagesGroup 3 Aia ReportNAVAS E VNo ratings yet

- January 2005 6677 Mechanics M1: Mark SchemeDocument7 pagesJanuary 2005 6677 Mechanics M1: Mark SchemeWael TareqNo ratings yet

- Amotec 12864Q DisplayDocument17 pagesAmotec 12864Q DisplayEdgarNo ratings yet

- ER2 Manual 125kg 5t - 04Document144 pagesER2 Manual 125kg 5t - 04Muhammed ShamseerNo ratings yet

- NUMBERS 2 Percentage ChangeDocument2 pagesNUMBERS 2 Percentage ChangeDinangaNo ratings yet

- KIN LONG Shower Screen CatalogueDocument58 pagesKIN LONG Shower Screen CatalogueFaiz ZentNo ratings yet

- Cramers Rule 3 by 3 Notes PDFDocument4 pagesCramers Rule 3 by 3 Notes PDFIsabella LagboNo ratings yet

- Country Item Name Litre Quart Pint Nip 700 ML IndiaDocument17 pagesCountry Item Name Litre Quart Pint Nip 700 ML Indiajhol421No ratings yet

- Unit 2 SignalsDocument3 pagesUnit 2 SignalsDigitallogicdlNo ratings yet

- SEC - Connection Guidelines - v3 - CleanDocument54 pagesSEC - Connection Guidelines - v3 - CleanFurqan HamidNo ratings yet

- Case How Innovation Drives Research and DevelopmentDocument4 pagesCase How Innovation Drives Research and DevelopmentMohit KumarNo ratings yet

- Customer Service Skills For Success 6th Edition Lucas Test Bank 1Document36 pagesCustomer Service Skills For Success 6th Edition Lucas Test Bank 1yolandarichardsqiyrfwmazc100% (23)

- [Download pdf] Mastering Microsoft Fabric Saasification Of Analytics 1St Edition Debananda Ghosh online ebook all chapter pdfDocument42 pages[Download pdf] Mastering Microsoft Fabric Saasification Of Analytics 1St Edition Debananda Ghosh online ebook all chapter pdflinda.coles284100% (11)

- Un EinsteinDocument22 pagesUn Einsteinapi-26005027No ratings yet

- Bastidas Et Al, 2010Document8 pagesBastidas Et Al, 2010Panji Satria N.No ratings yet

- Investigation Gr. 8Document6 pagesInvestigation Gr. 8Marthie van zylNo ratings yet

- Chapter 34 - The Influence of Monetary and Fiscal Policy On Aggregate Demand (Compatibility Mode) PDFDocument19 pagesChapter 34 - The Influence of Monetary and Fiscal Policy On Aggregate Demand (Compatibility Mode) PDFthanhvu78No ratings yet

- RS68-120 MLN ManuelDocument28 pagesRS68-120 MLN ManuelUmar MajeedNo ratings yet

- Acer Iconia Tab W500 Pegatron EAB00 SchematicsDocument60 pagesAcer Iconia Tab W500 Pegatron EAB00 SchematicsIIIkwarkaNo ratings yet

- BB 3002Document2 pagesBB 3002Leslie TaylorNo ratings yet

- Animal 1414Document6 pagesAnimal 1414trialink minsanNo ratings yet

- Meat PieDocument13 pagesMeat Piecrispitty100% (1)

- Design and Modeling of Zvs Resonantsepic Converter For High FrequencyapplicationsDocument8 pagesDesign and Modeling of Zvs Resonantsepic Converter For High FrequencyapplicationsMohamed WarkzizNo ratings yet

- 8000series Tech Datasheet 2018Document3 pages8000series Tech Datasheet 2018lucky414No ratings yet

![[Download pdf] Mastering Microsoft Fabric Saasification Of Analytics 1St Edition Debananda Ghosh online ebook all chapter pdf](https://imgv2-1-f.scribdassets.com/img/document/732592422/149x198/f876884e8e/1716289284?v=1)