Professional Documents

Culture Documents

Bhavya Forge & Fittings Catalogue PDF

Bhavya Forge & Fittings Catalogue PDF

Uploaded by

Niraj Pandey0 ratings0% found this document useful (0 votes)

83 views8 pagesOriginal Title

bhavya forge & Fittings Catalogue.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

83 views8 pagesBhavya Forge & Fittings Catalogue PDF

Bhavya Forge & Fittings Catalogue PDF

Uploaded by

Niraj PandeyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

& Fittings (India)

An ISO 9001: 2015 Certified Co.

it &

& Bhavya Forge

& Fittings (India)

An 180 8001: 2015 Certified Co.

To become a truly Global Payer

ath worldwide fulfilment capability

Burtweld Fittings, LR Bends

‘Spools / Fabricated pipes, Forged Fittings,

Flanges, Customised fittings

Integrated Solutions & Exhaustive Range

Of Products For The Piping Industry

We are a young offshoot from an established company with decade old experience in trading and manufacturing of various

industrial products especially fittings. We have in-depth knowledge and state of the art facility for manufacturing buttweld

fittings, forged fittings, two half fittings, longradius bends (3D to any RADIUS or Customized) and fabricated pipes and Spools

(Our manufacturing facilities include well equipped manufacturing and testing machineries, to manufacture world class

fittings.we offer these products in various sizes and materials like Stainless steel, Carbon steel, Alloy steel, Duplex, Super

duplexand Nickel Alloys.

We are also specializedin manufacturing customized fittings as per customer's drawing or requirement. with such experience

‘and expertise, we are a complete piping solution company offering reliable indian origin piping supplies for various stockiest

‘and traders across the world, hard-to-find items, hard-to-find materials, on demand supply capability makes us stand apart

fromthe me too manufacturers,

\We have our own in-house quality management personnel and testing professionals to ensure that you get best quality

products with best of services.

Quality is our mission, the quality policyis our main toolinachievingiit.

Utmost satisfaction of client's expectation,

Innovative, Costand time effective services.

Consistent and continuous qualityimprovement.

fulfllments of defined quality objective targets.

Develop the organization asan international for excellence.

Continuous evaluation of market o explore challenging areas of operation

‘The group is determined to improve productivity and focus continuously on innovation and upgradation of its products and

people

Email :-sales@bhavyaforge.com Website : www.bhavyaforge.com

& Bhavya Forge

& Fittings (India)

‘An 150 S008: 2085 Ceti Co

State Of The Art Manufacturing That Is At Par

With The Best In Industry.

We have all the latest machines and technology to manufacture high quality butt-weld pipe fittings, forged steel flanges, elbow

pipe fittings, coupling weldolets, sockelets, nippolets, thredolets, flanges, socket weld threaded and dimension tolerances.

(Our production facilities employ best suitable technologies & processes to ensure production of high performance zero-defect

products and components. From design and development to implementation, from testing to packaging, each and every stage of

‘our production process is conducted using cutting edge machinery & trained personnel. Our manufacturing facilities are divided

into two units for smooth functioning

‘Our manufacturing process is well documented and is divided into various departments supervised by experienced industry

‘experts. We use only quality raw materials that are procured from only established and reliable vendors. We have adopted rigorous

‘quality control practices and procedures to ensure the production of only quality products matching industry standards and

parameters.

jines available in our production facility includes

List of Machineries : Testing Equipment's

1) Mandrel Machine with LPG Furnace 1) PM Machine

2} Hydraulic Presses 2) Spectro Analyzer

3) CNC Machine 3) Ulta sonic Testing Machine

4) Lathe Machine 4) Digital Hardness Tester

5) Heat Treatment Furnaces 5) X-Ray Film Viewer

6) Ol Fired Furnace 6) Universal Tensile Testing

7) Plasma Cutting Machine 7) Dye Penetrant Test kit

8) Dies & Tools

9) Cold Forming Press For Elbows.

Quality That Inspires Customer Confidence

(Our design and manufacturing is supported by advance technology

Which enable us to meet net ony the requirements of Internationally

accepted manufacturing & Quality standards but alsotocope up with

growing demand forspecalfttings that meets safety

‘Our Quality Assurance System is documented in an approved Quality

‘Assurance Manual and covers all production processes. Severe control

‘of dimensions and of mechanical properties starting from the raw

material and following right through all production through all

production steps to laboratory tests on the finished product is exercised

inorder to maintain the high quality level of Bhavya Forge products.

Email -sales@bhavyaforge.com Website : www.bhavyaforge.com

b Bhavya Forge

Buttweld Fittings That

Fits Every Need

Reunion

CSTs ee Ao ere)

Stainless Steel & Duplex Steel Fittings

er Upto 16” NB / Welded Upto 48”

Schedule BRYA BC Ine)

Stainless Steel : ASTM A 403 WP - TP 304/3041/304H/316/316L/ 316H / 316Ti /

309 / 310 /317L/ 321 / 347/904L

Dire cre CUE SEI RES CSP EYE PEI)

Alloy Steel, Carbon Steel & LTCS Fittings

Size Ae AN noe

eee SURO OCU BEUBLUBC EEC

Alloy Steel: ASTM A234 WPB - WPS, WP9, WP11, WP12, WP22,WP91

Ror CO ES UET UE EES Er ECU em

Diet cee ORE CICM EES S Cera

re cn aL

ize an

eared SU)

(TN LeU CO Meroe Le Reet

eel rosie rosiit

ivi) en eecom eC ee)

en) rents com cee NEC)

reeled Sem Ceram}

Saad aloe tea oe eA ee cu Teed

* Concentric & Eccentric ) Coupling / Stubend /U bend / End Cap / Laterals.

b Bhavya Forge

& Fittings (India)

‘an $0 9001: 2015 Certified Co

Forged Fittings That Can

Withstand High Pressure

Stainless Steel & duplex Steel forged Fittings

Standard _: ANSI B16.11, MSS SP -97, BS 3799)

Size 2 6°NB to 3” NB, ( Socket-weld & Threaded )

Class +: 3000#, 6000#, 9000#

Stainless Steel : ASTM A TP 304/304L/304H/316/316L/ 316H / 316Ti / 309/310

13171/321/347/904L

Duplex Steel: ASTM A815- UNS 31803, $32750, $32760, $32205

Alloy Steel, Carbon Steel & LTCS Forged Fittings

Size 1 'NB to 3” NB, ( Socketweld & Threaded )

Class + 3000#, 6000#, 90008

Alloy Steel: ASTM A 182-F5, F9, F11, F12, F22 & FO

Carbon Steel: ASTM A106 Gr. A/8/C

Low temp. CS : A350 Lf2

Copper & Nickel Alloys Fittings

size 28"NB to 3” NB, ANSI B 16.11

Schedule: 105/40S/80s

CuproNickel _: C70600(90:10), C71500 (70:30), €71640

Nickel UNS NO2200, NO2201

Monel : UNS NO4400, NOS50O, Alloy 20

Inconel : UNS NO6600, NO6601, NO6625, NO8800, NO8810

Hastelloy —_: UNS N10276, NO6022, N10665, NO6455

Types: Elbow (45Deg., 90 Deg.) /Tee / Union / Cross / Swage Nipple /

Email -sales@bhavyaforge.com Website - www.bhavyaforge.com

b Bhavya Forge

SOS CoE ceo cu Ca

er Pacer a Oe

ee cee CeCe

Stainless Steel : ASTM A TP 304/3041/304H/316/316L/ 316H / 316TI / 309/310 /317L/

321/347/904L

DO ee ee Ce SLCHI ZId

‘ings

Alloy Steel, Carbon Steel & LTCS Flanges Fittings

Size aN See EC

cre Ee eee s

ec OLE ae oe R area eo

Carbon Steel : ASTM A 105 ASTM A 694 F42, F46, F52, F60, F65, F70

Pe REELED

een cn eed

cr an Cea OSE)

fore Se eee Eid

CuproNickel_ : €70600(90:10), €71500 (70:30), C71640

Bic) Ueno torry

IEC) Ueno cnet)

ren) TSN sseon somo ems)

Cn ED EOLA Seo

Sen Ce CER CEN}

ay Weldneck / Socketweld / Slip on / Blind / SORF / Screwed / Threaded /

Pea iene see Pe ul

Flange / Reinforced Nozzle Flanges

ee Cy ee aa

EOI ee

Products That Complete

Our Total Piping Package

Pipes / Tubes

Stainless Steel Seamless & ERW Tubes for Boilers, Super Heaters, Heat

Exchangers and Condensers as per ASTMA 213, A249, A271 & A 688 Gr,

‘TP304, 30413105, 310H, 316, 316L, 316H, 316LN, 317,317L, 321,

321H, 347, 347H, etc

Stainless Steel ERW Large Diameter Pipes as per ASTM A 358 and A 409

Gr. TP 304, 304L, 304H, 304LN, 308, 3095, 309H, 3105, 310H, 316, 316L,

316H, 316LN, 31671, 317,371, 321, 321H, 347, 347H, 348, 348H etc

Alloy Steel Seamless Pipes & Tubes for High Temperature/Pressure

servicesas per ASTMA335 Gr. P1, P2, P5, P9, P11, P12, P22, P91; ASTM A

213 Gr. 12,75, T11, 112 & T22 with IBR Test Certificate,

Carbon Steel Seamless Pipes as per ASTM A 106 Gr.8, AS3 Gr. B, API

SLGr.A, B, X42, X46, X52, X56 & X60 with IBR Test Certificate,

LTCS Pipes : As per ASTM A333Gr.3 & Gr6with IBRTC,

Carbon Steel ERW & Seamless Boller Tubes as per 8S 3059 Part | Gr. 320,

{853059 Part Il Gr 360, 440 & 620 with IBR Test Certificate

High Nickel Alloys : Nickel 200, Inconel. monel, hastelloy, Alloy 20, SMO 254

Drip Rivg : 4" to 24” 150# to 25008

Grade: A182, F304, 321, 316, Duplex Incoloy ete.

Pipe Spools in

b Bhavya Forge

& Fittings (India)

‘An $0 9001: 2015 Certified Co.

Fasteners

Stainless Steel & duplex Steel fasteners

Stainless Steel: A193 68 - BBA/ A193 B8-BEMA / A193

BT /BBTA/ A193 BBC-BECA/A193 B6-B6X

DuplexSteel _:AlsI-UNSS31803, $3205

Alloy Steel, Carbon Steel Fasteners

AlloySteel_: EN-8/EN-SD/EN-9/EN-15/EN-16/EN-

18/EN-24/EN-25/EN- 31/EN-36B/EN-418/EN-42/EN-

4SA/EN-47/A193/ 87-87M

CarbonSteel :4.6,8.8,10.9,129

Thermowell

Flanges size : 4” to.”

Pressure ratings : 150 class, 300 class, 600 class,

900 class, 1500 class material

Well Flange: $5304, 316, 304L, 316L, 310, 321, 446

Inconel 600* or Eqvi., Inconel 800* or Equi. Nickel,

Monel* or Eqvi. Titanium, Hastelloy ‘8’, ‘C’* or

Equivalent.

Hastelloy / Monel / Inconel & other Grades LIKE CuNi 90/10-70/30Spools

Email -sales@bhavyaforge.com

Website

www.bhavyaforge.com

Creer Dean}

Doerr tes Coe

aod Be.

SUGAR INOUSTRIES eee)

TE Es ogee

Coan eT

rene at) Deere aie Tce

& Fittings (India)

An ISO 9001: 2015 Certified Co.

Unit No.38, Parmar Techno Centre, Phase Il, Pelhar Village, Near vasai Phata,

western Exp.Highway N.H.8, Vasai (E), Dist.Palghar-401208.

Customer Care Admin office: +918421148807 / Sales & Marketing Executive: +918421148834

Email :-sales@bhavyaforge.com Website : www.bhavyaforge.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- IR SAMPLE (Blank)Document5 pagesIR SAMPLE (Blank)Niraj PandeyNo ratings yet

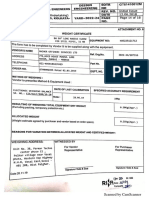

- Weight CertificateDocument27 pagesWeight CertificateNiraj PandeyNo ratings yet

- Exhibitors ListDocument7 pagesExhibitors ListNiraj PandeyNo ratings yet

- FittingsDocument15 pagesFittingsNiraj PandeyNo ratings yet

- 2.1 Test CertificateDocument1 page2.1 Test CertificateNiraj PandeyNo ratings yet

- 1 Gasket-DrawingsDocument4 pages1 Gasket-DrawingsNiraj PandeyNo ratings yet

- Colour Code Chart PDFDocument1 pageColour Code Chart PDFNiraj Pandey100% (2)

- Customer Complaint FormDocument1 pageCustomer Complaint FormNiraj PandeyNo ratings yet

- Bhavya Forge & Fittings (India) .: Dimension Report-As Per Asme B16.9: 2013Document10 pagesBhavya Forge & Fittings (India) .: Dimension Report-As Per Asme B16.9: 2013Niraj PandeyNo ratings yet

- MIDHANI Vendor Registration FormDocument7 pagesMIDHANI Vendor Registration FormNiraj PandeyNo ratings yet