Professional Documents

Culture Documents

NDzym05 MasterMead PDF

Uploaded by

Cristian IfránOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NDzym05 MasterMead PDF

Uploaded by

Cristian IfránCopyright:

Available Formats

by Ken Schramm

MASTERING M AD E

O p ti m iz i n g H o n ey F er m e nt a ti o n

T he challenge of making mead is

achieving the perfect honey fermenta-

tion—clean, with zero or absolutely mini-

Yeast requires

mal off flavors. It optimizes the character nutrients to grow,

of a spectacular honey, yielding aromatics to metabolize sugar

and flavor reflecting its finest properties.

into ethanol and

Simply, it comes down to a series of steps: to stay healthy in

pitching a vigorous, healthy yeast popula-

tion, low lag times, effortless and robust

the process.

yeast reproduction, successful competi-

tion or K-factor activity, and a steady, the FAN content of musts from four pre-

healthy ferment to completion. ferred meadmaking honeys. I bought

Florida Tupelo and Orange Blossom from

Reference texts for wine production, brew- my local farmers market, and Clover

ing, and yeast performance and technolo- (Kroger) and Buckwheat (Private Selection)

gy for the beer and wine industries num- from my local grocery. I contacted Dr. Ben

ber in the dozens, but at present there are Gavitt at the Cornell University/New York

none for mead. But we can begin to piece State Agricultural Extension Service Wine

together a plan for moving mead fermen- Lab and arranged to have the musts ana-

tations to quality levels reserved for the lyzed as well as a sample of pure cherry fermentation. He indicated that while

finest wines and most consistent beers. juice and a finished bottle of mead. there may be variances in FAN levels due

to testing regimens, the numbers are accu-

Yeast requires nutrients to grow, to metab- The Procedure rately representative of FAN levels in

olize sugar into ethanol and to stay To approximate a standard gravity mead mead musts.

healthy in the process. Everything gets must, I measured 100 milliliters of honey

into or out of the yeast cell through the into a sanitized Pyrex vessel, and diluted Results

cell wall, and the plasma membrane is the that to 400 milliliters with steam distilled The Florida Tupelo must had an OG of

barrier that can disrupt fermentation or water. I dissolved the mixture by stirring 1.110, and contained 10 parts per mil-

damage the cell. Membrane health is crit- with a sanitized spoon, and transferred lion FAN. The sterility check showed >1

ical to maintaining healthy functions from 100 milliliters of the mixture to a sterile x 10 6 yeast/100 milliliter, typical of

start to finish. Keep that bugger fat and vial. I used the remainder of the liquid to Saccharomyces, but most importantly, 0

happy, and life (and your mead) is good. measure and record the specific gravity of Viable Bacteria/100 milliliter. That

Fail to meet the membrane’s needs, and all of the samples. The samples were finding indicated that the practice of

everything deteriorates in a hurry. shipped via FedEx to NYSAES Lab. preparing traditional mead musts with-

out heat or the use of sulfites may be

Photo courtesy of the National Honey Board

Growth nutrients include carbon, nitro- Analyses capable of producing a good medium for

gen, phosphate and sulfate. Carbon is Sample 1, the Tupelo, received a FAN clean fermentations.

available from the sugars in the medium. analysis along with a sterility check. The

Nitrogen and phosphate are problematic other must samples received only FAN Sample 2, the Florida Orange Blossom,

in mead musts. analysis. The finished mead received had an OG of 1.110, with 5 ppm FAN.

residual sugar analysis, ETOH, sterility The must from Pure Clover (Sample 3)

While it has been accepted that mead check and a microbial analysis. also registered an OG of 1.110 and 14

musts are low in free amino nitrogen ppm FAN. Sample 4, the Buckwheat, had

(FAN), I have been curious to know exact- Gavitt reported that all samples arrived in an OG of 1.106 and 21 ppm FAN, rein-

ly “How low is low?” I set out to determine good condition, and showed no signs of forcing the widely held belief that darker

www.beertown.org November/December 2005 ZYMURGY 21

musts contain more nutrients. Still, 21 Obviously, the amount of FAN in these and glutamic and aspartic acids. While the

ppm is a long way from the 300 ppm most musts is well below what is needed for a variety of amino acids is largely positive,

winemakers seek from a wine must des- healthy fermentation. The actual FAN their concentration in a must dilution is

tined for more than 12-percent alcohol. compounds in the honeys I had analyzed perilously low. Interestingly, the most

prevalent amino acid in honey, proline,

Target Nitrogen Levels cannot be assimilated by yeast.

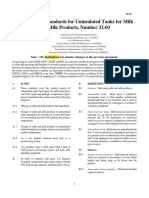

Brix range of must S. G. Target YANC* Level

Vitamins and Minerals

21 1.087 200 ppm

As the yeast population makes the transition

23 1.096 250 ppm

from growth to fermentation, its needs

25 1.106 300 ppm

27 1.115 350 ppm

change to include the sugar that it will gath-

REFERENCE: Bisson and Butzke

er from the must, and vitamins and miner-

SG Conversions: USDA Tables

als to conducts its metabolism. The most

*YANC is Yeast Available (assimilable) Nitrogen Content, which combines all available nitrogen from

critical of the vitamins is biotin, but the yeast

both organic (amino acids) and inorganic (ammonia or urea) sources. needs thiamine, niacin, pantothenate, and

the minerals magnesium, calcium, man-

ganese, potassium, zinc, iron and copper.

Sample 5 was pasteurized cherry juice were not determined, but there is some Many of these micronutrients are utilized in

from Swanson’s Juice Mill in Bear Lake, information on amino acids in honey from the process of transamination, in which

Mich. Its OG was 1.047, and it contained Dr. Jonathon White’s “Composition of amino acids are broken down and then

262 ppm FAN, above the level of 200 Honey,” published in “Honey, A reassembled by the cell to build the lipid

ppm commercial winemakers would con- Comprehensive Survey,” edited by Eva layers in the plasma membrane. Nitrogen is

sider adequate for a lower gravity must. Crane, Britain’s master authority on honey. also a metabolic need. During the fermenta-

That said, most meadmakers would not tion, nitrogen is used in transporters that

use more than 1 and perhaps 2 gallons of White documents a number of important move sugars across the plasma membrane

juice in 5 gallons of must, and that dilu- amino acids in honey, including com- against the concentration gradient.

tion would leave the available nitrogen pounds with high yeast uptake levels such

levels below the optimal range. as lysine, methionine, isoleucine, leucine, “Biotin takes part in all major biochemical

reactions that involve protein synthesis, in

nucleic acid synthesis, in carbohydrate metab-

olism, and in the synthesis of fatty acids. Its

deficiency is clearly shown by poor growth

and damaged plasma membranes.” (Yeast

Technology, Reed and Nagodawithana).

Reed and Nagodawithana document biotin

levels in average beer wort of .56µg/100 ml.

Levels in undiluted honey are quoted by

Kitzes, et al, at .066µg/100g, which would

represent one-quarter to one-third of the lev-

els found in a honey must. Thiamine (vita-

min B1) is used by yeast in amino acid syn-

thesis. It is also needed in the sugar-to-pyru-

vate-to-ethanol pathway. The same two

sources note levels in wort of 60 µg/100 ml,

and levels in honey of ~5/6 µg/100 g. Honey

musts will likely be low in pantothenate, key

to the production of serine and methion-

ine—amino acids used in the plasma mem-

brane. Pantothenate deficiency causes yeast

to produce high levels of H2S and its charac-

teristic rotten egg smell. Lastly, riboflavin,

another key vitamin, is present in wort at 33-

46 µg/100 ml and in ~5/6 µg/100 g of honey.

Minerals important for growth and metab-

olism in a healthy yeast population include

22 ZYMURGY November/December 2005 www.beertown.org

calcium, magnesium, potassium, phospho- quality, requiring less aging to reach hol per cell during the growth phase

rus and zinc, which are present in honey in drinkable maturity. than it does in the stationary phase. So

minor to absolutely negligible quantities. there is an advantage to keeping the

The exception may be potassium. Lallemand recommends rehydration of the yeast growing as long as possible. There

yeast in water supplemented with the is also an advantage to adding the DAP

Minerals are also a large part of the buffer- organic nutrient Go-Ferm. The yeast mem- in as many increments as possible. This

ing capacity of must. Clayton Cone notes branes are devoid of a number of micronu- keeps the yeast growing as long as pos-

that potassium levels above 300 ppm are trients needed to develop the yeast biomass sible and also keeps a fresh supply of N

critical to maintenance of pH levels. required for high gravity musts and the available for the yeast to metabolize

Haydak, et al, reported levels from 100 subsequent stress of higher alcohol levels and build up its protein content.” The

ppm in light honeys (not enough) to over later in the fermentation. yeast will also continue to absorb and

4700 ppm in darker honeys (more than utilize oxygen in the growth phase. For

enough). The average of 205 ppm for light Cone stresses the importance of keep- winemakers, the practice of pumping

honeys, however, would predict a substan- ing the yeast in the growth phase. over would get that oxygen into the

tial shortfall when diluted with water at “Yeast produce 33 times as much alco- fermenting must.

ratios of 3:1 or 4:1. When potassium levels

drop below 300 ppm, pH levels in the cell

can drop below 2.7, and metabolic activity

will virtually cease. Especially in the case of

traditional and show meads, early monitor-

ing of the pH is a wise preventative meas-

ure. Bisson also comments on the need to

establish potassium levels early, as well as

the strong possibility that potassium plays a

role in strengthening the plasma mem-

brane’s resistance to ethanol toxicity.

As the fermentation progresses, environ-

mental and metabolic stress on the plasma

membrane increases. Several key func-

tions rely heavily on good membrane

health, including:

1.Transport of a declining supply of sugar

from the medium into the cell.

2.Transport of ethanol and CO2 through

the membrane out of the cell.

3.Maintaining resistance to ethanol

absorption into the cell through the

membrane against an increasingly hos-

tile concentration gradient.

4.Absorption of ongoing metabolic nutri-

tional needs and survival factors.

Thus it is important to build healthy cell

wall mass during lag and growth phases,

and to maintain it during the entirety of

the stationary phase.

Fermentation Protocols

I have been utilizing staggered addi-

tions of a combination of 1 gram

diammonium phosphate (DAP) and 0.5

gram Fermaid K (Lallemand’s micronu-

trient blend) at pitch and at 24-hour

intervals for three days. Fermentation

times have been reduced, and the

resulting meads have been of very high

www.beertown.org November/December 2005 ZYMURGY 23

The goals are to prolong the growth phase 1. Rehydration at 104º F with Go-Ferm or equates to 3.0 lbs/1,000 gallons.

as much as possible without overfeeding other organic rehydration nutrient at a 2. Addition of 3 grams (approximately

the yeast, to provide a source of micronu- rate of 1.25 grams nutrient per gram of 0.75 teaspoon) Fermaid K, plus 4

trients and to supplement potassium lev- yeast. In all cases, addition of nutrients grams (1 teaspoon) DAP per 5 gallons

els, in particular the lighter-colored hon- by weight will be more accurate than by of must with a vigorous aeration at the

eys with lower mineral levels. For tradi- volume. Volumes are included for the end of the lag phase (six to 12 hours, at

tional 5-gallon mead fermentations with a convenience of those without the bene- the start of obvious fermentation activi-

gravity above 1.120, the keys are: fit of gram measurement devices. This ty). This equates to 21 ounces Fermaid

K plus 28 ounces DAP per 1,000 gal-

lons. For gravities above 1.125,

increase these amounts by an addition-

al 25 percent.

3. Addition of 1 gram (0.25 teaspoon)

DAP, plus 1 gram (0.125 teaspoon)

Fermaid K with a vigorous aeration at

12-hour intervals until 50 percent sugar

depletion or five days, whichever

occurs first (7 ounces DAP plus 3.5

ounces Fermaid K per 1,000 gallons).

4. Supplementing the potassium levels to

a minimum of 300 ppm with a potassi-

um source. Food grade potassium

hydroxide is an option for commercial

meadmakers, but its handling and use

would be problematic on smaller scales.

For home meadmakers, potassium

bitartrate or potassium phosphate are

viable options.

Role of pH in Better Detail

Drs. Roger Morse and Keith Steinkraus

established many years ago that low pH in

a fermenting mead must can lead to a

slowdown in fermentative activity and a

prolonged and unhealthy fermentation.

Bisson explains the phenomenon in her

text on fermentation for her course at UC-

Davis. Movement of amino acids across

the cell membrane (by transporters, or

trans-permeases) is coupled to proton

movement into the cell. Those protons

must then be transported out of the cell

by ATPase pumps (at the expense of one

ATP > ADP hydrolysis per transport).

When the pH drops, additional protons

enter the cell due to passive proton flux. If

the number of protons inside the cell wall

exceeds the capacity of the ATPase pumps

in the membrane to evacuate them, amino

acid uptake slows and fermentative activ-

ity is reduced.

Bisson also notes that fermentations that

falter and stick can be extremely difficult

to restart, making the maintenance of an

appropriate pH all the more important.

24 ZYMURGY November/December 2005 www.beertown.org

No-Heat Methods, Melomels extraneous plant matter. Data aside, this spoons). When the must is fermenting vigor-

and Metheglins, and mead was very tasty, and was well received ously (two to three days), add the fruit or

Microorganisms by different audiences at several tastings. pressed fruit juice and the remainder of the

In The Compleat Meadmaker, I make the honey. This will create a healthy yeast popu-

case for preparing mead musts without the Fruit and spices will add organisms that lation to compete with any bacteria or wild

use of any heat or must sanitation process- compete with your yeast population, not yeast present on the fruit. Continue with

es beyond the requisite rigorous adherence only for food, but also for nutrition. The staggered additions of DAP at 1 gram or 0.25

to equipment sanitation. Although tradi- growth needs of bacteria and wild yeast teaspoon every 12 hours, plus 0.5 gram

tional mead musts may be largely devoid of strains are in most cases almost identical to Fermaid K (0.125 teaspoon) until 50 percent

competitive microflora, the application of those of your chosen/pitched yeast strain— sugar depletion. These numbers can be

that method to melomels and metheglins nitrogen, oxygen and B-vitamins. If the com- scaled to commercial volumes.

creates a window of opportunity for any peting microflora are at phases that allow

organisms that come to the must through them to consume and utilize the available It is important to note that microflora may

fruits or spices. That fruit can bring a load must nutrients, they will have a huge advan- be present and capable of activity beyond

of microflora is obvious; less obvious is the tage in their war to dominate the environ- the point at which the yeast ceases fermen-

fact that the environs in which spices are ment and compromise your fermentation. tation. Especially in musts that may finish

harvested—and the processes by which with considerable residual sugar because

they are prepared for market—are rife with My initial conclusion from this data was that the yeast has reached ethanol tolerance, or

poor sanitary practice and opportunity for the use of sulfites might be preferred to min- those that finish with low alcohol levels

exposure and contamination. imize bacterial contamination. On further (below 10 percent), or both, it is critically

thought, however, the recommended proce- important that the amounts of nutrient

The threat from microflora on fruit dure is to prepare and initiate fermentation used do not exceed that which will be con-

appears to be backed up by the analysis of in a smaller honey must. For a 5-gallon batch sumed by the yeast during growth and fer-

the finished raspberry mead I sent to the of a fresh fruit melomel, start with 2.5 gallons mentation. Excess nutrient at that point

Cornell lab. of water and 8 pounds of honey. Rehydrate will simply serve to nourish organisms that

yeast with Go-Ferm or equivalent and water may harm your mead.

Sample 6: Raspberry Mead at 104º F. Aerate the must thoroughly and

15.0 lb (6.8 kg) Michigan raspberries pitch. When the must has moved through Ken Schramm is author of The Compleat

15.0 lb (6.8 kg) Raspberry Blossom the lag, add 3 grams Fermaid K (1.5 tea- Meadmaker.

Honey

0.5 tsp DAP

0.25 tsp Fermaid K at pitch, 24, 48 and

72 hours.

Original Gravity: Unknown

Final Gravity: 1.002 (corrected to 1.009

post lab)

Analysis Data:

ETOH: 14.1%

Residual sugar: 3.7% (w/v)

Glucose: 25.6 g/l

Fructose: 11.9 g/l

Viable yeast/100 ml: 5

Viable bacteria/100 ml: >1 x 106

Comments: “Yeast typical of Saccharomyces

strains. Bacteria are long rods forming

short chains (Lactobaccillus).”

The bacterial population in this sample is

considerable. Several possible sources of

contamination include process, equipment

(racking cane, bottles, cork, which receive

the same sanitation practices as the “clean”

sample) and the lead suspect, fruit.

Possibilities are airborne and bird- or insect-

carried bacteria and yeast, bug parts or

www.beertown.org November/December 2005 ZYMURGY 25

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CEP - WKT Manual - PDFDocument108 pagesCEP - WKT Manual - PDFHemal Shah100% (1)

- Pharmacokinetic ConceptsDocument28 pagesPharmacokinetic ConceptsAmy Yuen100% (1)

- A564A564M-13 Standard Specification For Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocument8 pagesA564A564M-13 Standard Specification For Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapestjt4779No ratings yet

- EN 206-1 Guide AF 070824Document20 pagesEN 206-1 Guide AF 070824nolanjcNo ratings yet

- Power Wave R500: Operator's ManualDocument42 pagesPower Wave R500: Operator's ManualJohan ZraghozNo ratings yet

- Atlasga18 37vsdmanual 2 PDFDocument128 pagesAtlasga18 37vsdmanual 2 PDFJoseph Ilagan100% (1)

- 05 Expiremental Approach - Affecting Retention TimeDocument28 pages05 Expiremental Approach - Affecting Retention Timejonida88No ratings yet

- Moringa Presentation For Cattle FoodDocument27 pagesMoringa Presentation For Cattle FoodStefan KatzNo ratings yet

- Radioactive Decay - WiDocument118 pagesRadioactive Decay - WiAditya Prakash100% (1)

- 3-A Sanitary Standards For Uninsulated Tanks For Milk and Milk Products, Number 32-03Document10 pages3-A Sanitary Standards For Uninsulated Tanks For Milk and Milk Products, Number 32-03CHRISTIAN ZAVALANo ratings yet

- Urea - Kirk Othmer PDFDocument15 pagesUrea - Kirk Othmer PDFusman_hafeez86No ratings yet

- BE Chemical EngineeringDocument102 pagesBE Chemical EngineeringVaibhav PardeshiNo ratings yet

- Thermo-Mechanical Processing of Elgiloy:: Experimental ProcedureDocument14 pagesThermo-Mechanical Processing of Elgiloy:: Experimental ProcedureJavierBadilloSanJuanNo ratings yet

- B.sc. II Biotechnology Entire Sem - III & IVDocument29 pagesB.sc. II Biotechnology Entire Sem - III & IVGayatriNo ratings yet

- Argumentative EssayDocument2 pagesArgumentative EssayDianna BerishaNo ratings yet

- Effect of MgCl2 Addition On The Sintering Behavior of MgAl2O4 Spinel and Formation of Nano-ParticlesDocument12 pagesEffect of MgCl2 Addition On The Sintering Behavior of MgAl2O4 Spinel and Formation of Nano-ParticlesJarek PlaszczycaNo ratings yet

- Magneto-Convective Non-Newtonian Nanofluid With Momentum and Temperature Dependent Slip Flow From A Permeable Stretching Sheet With Porous Medium and Chemical ReactionDocument18 pagesMagneto-Convective Non-Newtonian Nanofluid With Momentum and Temperature Dependent Slip Flow From A Permeable Stretching Sheet With Porous Medium and Chemical ReactionIOSRjournalNo ratings yet

- Peek Optima Data SheetDocument2 pagesPeek Optima Data SheetBakkiya RajNo ratings yet

- Charcoal Consumption Reduction Through AlternativesDocument29 pagesCharcoal Consumption Reduction Through AlternativesAhmedNo ratings yet

- Assignment 2 - HazopDocument3 pagesAssignment 2 - HazopRaymond ChiaNo ratings yet

- Foam Concrete Benefits and Applications - Cheap Patio IdeasDocument2 pagesFoam Concrete Benefits and Applications - Cheap Patio IdeasKhalid AlameerNo ratings yet

- Research Paper On Bottom AshDocument8 pagesResearch Paper On Bottom Ashaflbtrnpf100% (1)

- Pmo WHSDocument31 pagesPmo WHSKOKO KUSUMAYANTONo ratings yet

- Al-Fasi Et Al.2015 PDFDocument8 pagesAl-Fasi Et Al.2015 PDFUmroh NuryantoNo ratings yet

- TD Puas-620-2k WBDocument3 pagesTD Puas-620-2k WBRizki PutriNo ratings yet

- SPL Konfort 7xx Full en Rev01Document8 pagesSPL Konfort 7xx Full en Rev01kallatisNo ratings yet

- Food Chemistry: A B C C C A D e A ADocument9 pagesFood Chemistry: A B C C C A D e A APat Antolo100% (1)

- Part L EQUIPMENT 430 - Erstl - L - Egstl - L-CV - 2013Document63 pagesPart L EQUIPMENT 430 - Erstl - L - Egstl - L-CV - 2013Dave DumontNo ratings yet

- Alcohol Gel (Aristoflex AVC) ProcedimientoDocument1 pageAlcohol Gel (Aristoflex AVC) ProcedimientoJanssen GomezNo ratings yet

- Azo DyeDocument21 pagesAzo DyeFazal rahimNo ratings yet