Professional Documents

Culture Documents

Categorizing The Process of Pull and Push Strategy by Dell

Uploaded by

manan akramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Categorizing The Process of Pull and Push Strategy by Dell

Uploaded by

manan akramCopyright:

Available Formats

Categorizing the process of pull and push strategy by dell:

Here is an example of dell .what the ordering process may look like for a company offering a

customized finished good through a push-pull process.

The core product stays fixed and is made from a fixed materials list. It’s the main body of

the product and they can safely assume it is sitting on the shelf in the company’s warehouse. The

end product is considered to be in a semi-finished state waiting for customers to place orders for

their chosen options.

So, in this case, the core product “body” is waiting to be finished with the customer-specific

options. The list of options that follow (Option 1, 2, 3 and 4) allow the customer to choose a

customised solution with minimal delivery times. For the sake of simplicity, they kept the

options fairly straightforward. However, it’s not uncommon for companies to have a long list of

options.

However, the company has all these options ready the moment the customer places the order

because they have a demand history to call upon. In this case, the company has manufactured

most of the finished good and is simply waiting for customers to place orders. When those

customers order, they get the options they want and immediate delivery.

Basically in this process dell use both strategy once they made a core product body is known as

push and customization on the base of customer demand in there system is known as pull

strategy

Boundary line or step of process.

Benefits gain by dell :

Minimal inventory on shelf and responsiveness to customer order is also high and direct end user

support that dell gain as a competitive benefits by using both push and pull. One of the pivotal

rules of Dell’s strategy is that it relies upon maintaining minimal inventory counts of components

and consumables. Inventory obsolescence is avoided at all costs and steps are constantly taken to

reduce the costs of outdated and antiquated inventory. The order fulfillment portion of the

strategy allows Dell to provide a custom-made finished good, one where customers decide upon

options that are controlled by the computer manufacturer itself.There are several inherent

advantages to providing custom-made products directly to end-users. First, the company

eliminates the need to sell through wholesalers and retailers, thereby reducing their markup and

eliminating the middlemen in the value chain. Second, providing finished goods directly to end-

users allows the computer manufacturer to employ a direct sales model, one that it can use to

push other products and services to its customer base. Dell employs a strong direct end-user

customer service support system. Customers are able to deal directly with the company's service

technicians and customer support center. While Dell is a large enterprise, it doesn’t appear as

such in the eyes of its customer base. In essence, it isn’t viewed as a large, faceless corporation.

Eliminating those aforementioned retailers allows Dell to have more control over its product

offering, and more control over the type of customer service its customer base receives.

You might also like

- DellDocument7 pagesDellurpaNo ratings yet

- Ch08 - InventoryDocument112 pagesCh08 - InventoryAdam Yans JrNo ratings yet

- Inventory ControlDocument41 pagesInventory ControlantoniobhNo ratings yet

- Accounting For Management - Unit IVDocument87 pagesAccounting For Management - Unit IVSELVARAJ SNNo ratings yet

- CH 1-5 OMDocument71 pagesCH 1-5 OMAbu DadiNo ratings yet

- Operation Management Notes 130126072649 Phpapp02 PDFDocument30 pagesOperation Management Notes 130126072649 Phpapp02 PDFBalu ANo ratings yet

- Unit 2 L2 Network DesignDocument23 pagesUnit 2 L2 Network DesignJUILI dharmadhikariNo ratings yet

- UniliverDocument38 pagesUniliversalmanahmedkhi1No ratings yet

- Operations Management Crocs Shoes Case StudyDocument19 pagesOperations Management Crocs Shoes Case StudyTHIMMAIAH B CNo ratings yet

- Case Study AcmDocument23 pagesCase Study AcmYouichiHirumaNo ratings yet

- ManualDocument41 pagesManualTuan Bình0% (2)

- PCM Module 5 Notes-FinalDocument8 pagesPCM Module 5 Notes-FinalRevathiKumariNo ratings yet

- A Presentation On Dell Inventory ControlDocument10 pagesA Presentation On Dell Inventory Controlalamazfar100% (1)

- IKEADocument7 pagesIKEAnarmin mammadliNo ratings yet

- Enterprise SystemsDocument11 pagesEnterprise SystemsumairaleyNo ratings yet

- Tesco GSCMDocument6 pagesTesco GSCMadmbad2No ratings yet

- Strategic Service Management A Complete Guide - 2020 EditionFrom EverandStrategic Service Management A Complete Guide - 2020 EditionNo ratings yet

- International School of Management and EconomicsDocument14 pagesInternational School of Management and EconomicsAnh Su Dieu MinhNo ratings yet

- Logistics OutsourcingDocument10 pagesLogistics OutsourcingAbhirup Ubale100% (1)

- Everything You Need to Know About 3PL ServicesDocument6 pagesEverything You Need to Know About 3PL ServicesAbhishek7705No ratings yet

- Cross Docking A Complete Guide - 2020 EditionFrom EverandCross Docking A Complete Guide - 2020 EditionRating: 1 out of 5 stars1/5 (1)

- Warehouse ManagementDocument10 pagesWarehouse ManagementAkshat JainNo ratings yet

- Inventory ControlDocument26 pagesInventory ControlhajarawNo ratings yet

- Lecture 8 Warehouse ManagementDocument22 pagesLecture 8 Warehouse ManagementChudhry Waqas UddinNo ratings yet

- Distribution Network DesignDocument17 pagesDistribution Network DesignHusnain Kasbati100% (1)

- Decision PhasesDocument2 pagesDecision Phasesdaddyaziz800% (1)

- Spare Parts Inventory Management 1Document2 pagesSpare Parts Inventory Management 1stanleyNo ratings yet

- FordDocument11 pagesFordAbhimanyu BhardwajNo ratings yet

- Discussion 1 PmoDocument1 pageDiscussion 1 PmoKashyap ChintuNo ratings yet

- Home Work Chapter 1 To 12Document50 pagesHome Work Chapter 1 To 12Haha JohnNgNo ratings yet

- Cadbury Case StudyDocument3 pagesCadbury Case Studyashish4485No ratings yet

- Inventory Model LSCMDocument30 pagesInventory Model LSCMRajit Kumar Krishna100% (1)

- What Is Supply Chain ManagementDocument6 pagesWhat Is Supply Chain ManagementHusain ShiyajiNo ratings yet

- Ilm LG SCMDocument4 pagesIlm LG SCMUtsav SoniNo ratings yet

- Supply Chain Management Questions and AnswersDocument6 pagesSupply Chain Management Questions and AnswersCanute McinnisNo ratings yet

- Infosys Supply ChainDocument11 pagesInfosys Supply ChainAmit BharNo ratings yet

- Unit 1 - Introduction To Inventory ManagementDocument17 pagesUnit 1 - Introduction To Inventory ManagementNguyễn Thành NamNo ratings yet

- Nestle - Market Penetration - Manifested Marketing BlogDocument7 pagesNestle - Market Penetration - Manifested Marketing BlogAdam DanialNo ratings yet

- Factors That Affected Apple Stock PriceDocument8 pagesFactors That Affected Apple Stock PriceSuk Yee Suk YeeNo ratings yet

- Working of Domestic RefrigiratorDocument15 pagesWorking of Domestic Refrigiratorspursh67% (3)

- Case Elco MandiriDocument5 pagesCase Elco MandiriNindy DaristaNo ratings yet

- SOlectron Cor1Document2 pagesSOlectron Cor1pintu_brownyNo ratings yet

- Inventory PoliciesDocument29 pagesInventory PoliciesLea VenturozoNo ratings yet

- Logistics NotesDocument28 pagesLogistics NotesadnanbmsNo ratings yet

- SCM - Chapter 01Document68 pagesSCM - Chapter 01Talha6775No ratings yet

- Dell's Strategic Management Accounting TechniquesDocument7 pagesDell's Strategic Management Accounting TechniquesJune SueNo ratings yet

- Reckitt Benkiser (Case Study) For SCMDocument13 pagesReckitt Benkiser (Case Study) For SCMDiptiman GuhaNo ratings yet

- MUDA (7 Waste)Document3 pagesMUDA (7 Waste)Shamshair Ali100% (1)

- Strategy Practice Assignment Dell RecommendationDocument3 pagesStrategy Practice Assignment Dell Recommendationwchaitan0% (1)

- Asian Paints & Nirula's: Operations Management AssignmentDocument7 pagesAsian Paints & Nirula's: Operations Management AssignmentApoorv SrivastavaNo ratings yet

- Chapter 01Document17 pagesChapter 01Trang Bùi HàNo ratings yet

- Productivity and Reliability-Based Maintenance Management, Second EditionFrom EverandProductivity and Reliability-Based Maintenance Management, Second EditionNo ratings yet

- Inventory Management System A Complete Guide - 2019 EditionFrom EverandInventory Management System A Complete Guide - 2019 EditionNo ratings yet

- Project Quality Management A Complete Guide - 2019 EditionFrom EverandProject Quality Management A Complete Guide - 2019 EditionNo ratings yet

- Warehouse Management System A Complete Guide - 2019 EditionFrom EverandWarehouse Management System A Complete Guide - 2019 EditionNo ratings yet

- Value Chain Management Capability A Complete Guide - 2020 EditionFrom EverandValue Chain Management Capability A Complete Guide - 2020 EditionNo ratings yet

- Assignment Self ImageDocument2 pagesAssignment Self ImageRachelJosefNo ratings yet

- Market SegmentationDocument30 pagesMarket Segmentationnuplin.zain100% (9)

- The Importance of Product Safety To ConsumersDocument7 pagesThe Importance of Product Safety To ConsumersDeeviya KrishnanNo ratings yet

- Identify The Letter of The Choice That Best Completes The Statement or Answers The QuestionDocument2 pagesIdentify The Letter of The Choice That Best Completes The Statement or Answers The Questionmonalisha mishraNo ratings yet

- Eco 201Document2 pagesEco 201Prottasha AsifNo ratings yet

- Journal of International Consumer MarketingDocument5 pagesJournal of International Consumer MarketingGeorgeNo ratings yet

- Personality and Consumer Behavior Chapter 5 Key ConceptsDocument2 pagesPersonality and Consumer Behavior Chapter 5 Key ConceptsKarishma Chokshi100% (1)

- Business Model Canvas For 'The Vanity Fur' - Pet Care StartupDocument2 pagesBusiness Model Canvas For 'The Vanity Fur' - Pet Care StartupVedant KarnatakNo ratings yet

- FINTECHDocument3 pagesFINTECHNurul AqilahNo ratings yet

- DEMAND Group 3Document6 pagesDEMAND Group 3Cindy BartolayNo ratings yet

- Marketing Concepts and Customer ValueDocument8 pagesMarketing Concepts and Customer Valuehajra ubaidNo ratings yet

- Microeconomics SPRING 2020 Elasticity: Elastic?Document4 pagesMicroeconomics SPRING 2020 Elasticity: Elastic?Nayeli Ramirez100% (1)

- Elasticity and Its Applications: © 2002 by Nelson, A Division of Thomson Canada LimitedDocument46 pagesElasticity and Its Applications: © 2002 by Nelson, A Division of Thomson Canada LimitedShahrat Farsim ChowdhuryNo ratings yet

- Challenges Facing The Lending Company and Possible SolutionDocument2 pagesChallenges Facing The Lending Company and Possible SolutionRuel LonggakitNo ratings yet

- Brand Revitalization & Reinforcement (4488)Document34 pagesBrand Revitalization & Reinforcement (4488)Jayadtiya Singh jasolNo ratings yet

- Wa0004Document6 pagesWa0004Muhammad UsamaNo ratings yet

- 178.200 06-4Document34 pages178.200 06-4api-3860979No ratings yet

- QuestionnaireDocument5 pagesQuestionnaireRahi Digital services Rohan KirpekarNo ratings yet

- GP News Paper Edition 10Document14 pagesGP News Paper Edition 10creative caiiroNo ratings yet

- Mercedes Vs Toyota Brand Architecture Report: Comparing Luxury & ValueDocument3 pagesMercedes Vs Toyota Brand Architecture Report: Comparing Luxury & ValueMotivational ExpeditiousNo ratings yet

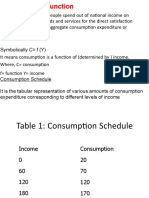

- Consumption Is An Increasing Function of IncomeDocument18 pagesConsumption Is An Increasing Function of IncomeRajesh Lamba100% (1)

- Lecture Notes - ElasticityDocument5 pagesLecture Notes - ElasticityRizwan KhanNo ratings yet

- Identification of The Target Market 1Document16 pagesIdentification of The Target Market 1NezukoNo ratings yet

- Market Research On Lotus ElectronicDocument11 pagesMarket Research On Lotus ElectronicSuryan ShrivastavaNo ratings yet

- Uber Case StudyDocument2 pagesUber Case Studyapi-501556428100% (1)

- Case StudyDocument3 pagesCase StudyarisuNo ratings yet

- What Is Push and Pull Marketing - Passion Digital®Document2 pagesWhat Is Push and Pull Marketing - Passion Digital®Veera ManickamNo ratings yet

- Indifference Curves and Budget LinesDocument9 pagesIndifference Curves and Budget LinesRanaNo ratings yet

- Consumer BehaviorDocument45 pagesConsumer BehaviorSravaniChariNo ratings yet

- Monopolistic Tooth Paste IndustryDocument3 pagesMonopolistic Tooth Paste Industryspbhuvan50% (10)