100% found this document useful (2 votes)

7K views6 pagesMachine Setup Sheet

The document provides machine setup instructions for turning a part on a CNC turning machine. It includes information about the raw material, clamping device, tools to be used, operation plan with speeds and feeds, and sample G-code program. The setup sheet provides all the details needed to machine the part on the CNC turning center.

Uploaded by

Haris SetiawanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

7K views6 pagesMachine Setup Sheet

The document provides machine setup instructions for turning a part on a CNC turning machine. It includes information about the raw material, clamping device, tools to be used, operation plan with speeds and feeds, and sample G-code program. The setup sheet provides all the details needed to machine the part on the CNC turning center.

Uploaded by

Haris SetiawanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Machine Setup Sheet

- Tool Setup Sheet

- Operation Plan

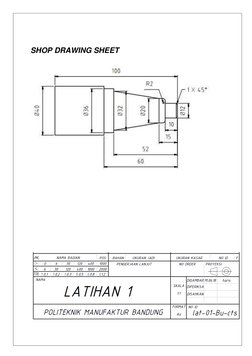

- Shop Drawing Sheet

- Program Sheet

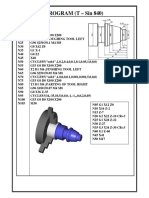

- Program Code