Professional Documents

Culture Documents

4130 Data Sheet

Uploaded by

carlottiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4130 Data Sheet

Uploaded by

carlottiCopyright:

Available Formats

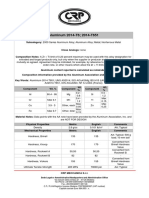

AISI 4130 Steel, normalized at 870°C (1600°F)

Subcategory: AISI 4000 Series Steel; Ferrous Metal; Low Alloy Steel; Medium Carbon Steel; Metal

Key Words: alloy steels, UNS G41300, AMS 6350, AMS 6356, AMS 6360, AMS 6361, AMS 6372, AMS 6370, AMS

6371, AMS 6373, ASTM A322, ASTM A331, ASTM A505, ASTM A513, ASTM A519, ASTM A646, JIS SCM 2, JIS

SCCrM 1, SS14 2225 (Sweden), B.S. CDS 110 (UK), medium carbon steels, chromium-molybdenum, chrome-moly,

MIL SPEC MIL-S-16974, SAE J404, SAE J412, SAE J770, DIN 1.7218, AFNOR 25 CD 4 (France), MIL-S-6758 (flat

and round bar), MIS-S-18729 ANN and NORM (sheet and plate), QQS-624 (round bar)

Component Wt. %

C 0.28 - 0.33

Cr 0.8 - 1.1

Fe 97.3 - 98.22

Mn 0.4 - 0.6

Mo 0.15 - 0.25

P Max 0.035

S Max 0.04

Si 0.15 - 0.35

Physical Properties Metric English Comments

Density 7.85 g/cc 0.284 lb/in³

Mechanical Properties

Hardness, Brinell 197 197

Hardness, Knoop 219 219

Converted from Brinell hardness.

Hardness, Rockwell B 92 92

Converted from Brinell hardness.

Hardness, Rockwell C 13 13

Converted from Brinell hardness. Value below normal HRC range, for

comparison purposes only.

Hardness, Vickers 207 207

Converted from Brinell hardness.

Tensile Strength, Ultimate 670 MPa 97200 psi

Tensile Strength, Yield 435 MPa 63100 psi

Elongation at Break 25.5 % 25.5 %

in 50 mm

Reduction of Area 60 % 60 %

Modulus of Elasticity 205 GPa 29700 ksi

Typical for steel

Bulk Modulus 140 GPa 20300 ksi

Typical for steel

Poisson's Ratio 0.29 0.29

Calculated

Izod Impact 87 J 64.2 ft-lb

Machinability 70 % 70 %

annealed and cold drawn. Based on 100% machinability for AISI 1212

steel.

Shear Modulus 80 GPa 11600 ksi

Typical for steel

Electrical Properties

Electrical Resistivity 2.23e‐005 ohm‐cm 2.23e-005 ohm-cm

specimen hardened and tempered; 20°C (68°F)

Electrical Resistivity at Elevated Temperature 0.0001103 ohm‐cm 0.0001103 ohm-cm

specimen hardened and tempered; 800°C (1470°F)

Electrical Resistivity at Elevated Temperature 0.0001171 ohm‐cm 0.0001171 ohm-cm

specimen hardened and tempered; 1000°C (1830°F)

Electrical Resistivity at Elevated Temperature 0.0001222 ohm‐cm 0.0001222 ohm-cm

specimen hardened and tempered; 1200°C (2192°F)

Electrical Resistivity at Elevated Temperature 2.71e‐005 ohm‐cm 2.71e-005 ohm-cm

specimen hardened and tempered; 100°C (212°F)

Electrical Resistivity at Elevated Temperature 3.42e‐005 ohm‐cm 3.42e-005 ohm-cm

specimen hardened and tempered; 200°C (390°F)

Electrical Resistivity at Elevated Temperature 5.29e‐005 ohm‐cm 5.29e-005 ohm-cm

specimen hardened and tempered; 400°C (750°F)

Electrical Resistivity at Elevated Temperature 7.86e‐005 ohm‐cm 7.86e-005 ohm-cm

specimen hardened and tempered; 600°C (1110°F)

Thermal Properties

Specific Heat Capacity 0.477 J/g‐°C 0.114 BTU/lb-°F

50-100°C

Specific Heat Capacity at Elevated Temperature 0.523 J/g‐°C 0.125 BTU/lb-°F

150-200°C

Specific Heat Capacity at Elevated Temperature 0.837 J/g‐°C 0.2 BTU/lb-°F

750-800°C

Thermal Conductivity 42.7 W/m‐K 296 BTU-in/hr-ft²-°F

100°C

Thermal Conductivity at Elevated Temperature 30.1 W/m‐K 209 BTU-in/hr-ft²-°F

1200°C

Thermal Conductivity at Elevated Temperature 40.7 W/m‐K 282 BTU-in/hr-ft²-°F

300°C

References for this datasheet: http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=m4130r

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistant format. Users requiring more precise

data for scientific or engineering calculations can click on the property value to see the original value as well as raw conversions to equivalent units. We advise that you only use the original

value or one of its raw conversions in your calculations to minimize rounding error. We also ask that you refer to MatWeb's disclaimer and terms of use regarding this information. MatWeb

data and tools provided by MatWeb, LLC.

You might also like

- Cold Drawn PDFDocument1 pageCold Drawn PDFAna Emily PrentissNo ratings yet

- Matweb:, The Online Materials Database Aluminum 6201-T6Document2 pagesMatweb:, The Online Materials Database Aluminum 6201-T6Raj PrasanthNo ratings yet

- AISI 8720 SteelDocument1 pageAISI 8720 SteelSIVASUTECH ENTERPRISESNo ratings yet

- AISI 1050 Steel, As RolledDocument2 pagesAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoNo ratings yet

- Aluminium 7075 t6 7075 t651 PDFDocument3 pagesAluminium 7075 t6 7075 t651 PDFmenosoftNo ratings yet

- MaterialData 6937Document1 pageMaterialData 6937Cristobal Gutierrez CarrascoNo ratings yet

- Carbon Steel Fact SheetDocument2 pagesCarbon Steel Fact Sheettshepo hlakudiNo ratings yet

- Aluminum 7075-T6 7075-T651: Matweb, The Online Materials DatabaseDocument1 pageAluminum 7075-T6 7075-T651: Matweb, The Online Materials DatabaseYohanes BayuNo ratings yet

- ChithirangaDocument34 pagesChithirangaP.ArunadeviNo ratings yet

- AISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) TemperDocument1 pageAISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) Temperapurv bhartiNo ratings yet

- Technical Datasheet: Typical Applications Key Features: Aerospace Carbon Steel TubeDocument1 pageTechnical Datasheet: Typical Applications Key Features: Aerospace Carbon Steel TubeGuntur Aji SubiaktoNo ratings yet

- MaterialData 7754Document2 pagesMaterialData 7754Joko TriwardonoNo ratings yet

- Aluminium 7075 SpecDocument2 pagesAluminium 7075 Specadam.el.polaco7881No ratings yet

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDocument2 pagesAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionALEX MURPHYNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFanne smithNo ratings yet

- Aluminum 6351-T6 6351-T651Document2 pagesAluminum 6351-T6 6351-T651Mathi Engineers And Builders Private LimitedNo ratings yet

- Aluminium 2014 t6 2014 t651 PDFDocument3 pagesAluminium 2014 t6 2014 t651 PDFAbhishek AnandNo ratings yet

- AISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessDocument2 pagesAISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessdavmedclNo ratings yet

- Task Report of ARB Blade (Fikan Mubarok R)Document9 pagesTask Report of ARB Blade (Fikan Mubarok R)fikan mubarokNo ratings yet

- Aisi 5160 Alloy Steel (Uns g51600)Document4 pagesAisi 5160 Alloy Steel (Uns g51600)Rizki RiantoniNo ratings yet

- Aluminum6061DataSheet PDFDocument2 pagesAluminum6061DataSheet PDFhardik033No ratings yet

- Sae 5160 VBDocument2 pagesSae 5160 VBBarron ValentinNo ratings yet

- AISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDocument2 pagesAISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDiegoAlvarezHuguezNo ratings yet

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDocument3 pagesAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionGrimmo1979No ratings yet

- S 45 CDocument1 pageS 45 CFahmi IrmanshahNo ratings yet

- MaterialData AISI-SAE101Document2 pagesMaterialData AISI-SAE101Ian KellyNo ratings yet

- Mechanical Prop of 1065Document2 pagesMechanical Prop of 1065Laine ReyesNo ratings yet

- AISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1PrasadNo ratings yet

- AISI 4140 Chrome Molybdenum High Tensile Steel: Topics CoveredDocument6 pagesAISI 4140 Chrome Molybdenum High Tensile Steel: Topics CoveredCristina NicheNo ratings yet

- 14 CR MoDocument6 pages14 CR Mozd55h2754kNo ratings yet

- Mil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322Document2 pagesMil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322FlavioNo ratings yet

- AluminiumHE15 PropertiesDocument3 pagesAluminiumHE15 PropertiesPrashanthNo ratings yet

- Aisi 5140Document2 pagesAisi 5140rumabiswas853No ratings yet

- Din 1Document1 pageDin 1ttpatelNo ratings yet

- 6061 T6 MaterialDocument2 pages6061 T6 Materialtravis8zimmermannNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFYogesh ChaudhariNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFFebrian JhaNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFHardikNo ratings yet

- Mild Steel PDFDocument3 pagesMild Steel PDFHardikNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFbbbNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFMayand DuaNo ratings yet

- Aisi 4340 Alloy Steel (Uns g43400)Document4 pagesAisi 4340 Alloy Steel (Uns g43400)JourdyPradityaNo ratings yet

- Aisi 4340 Alloy Steel (Uns g43400)Document4 pagesAisi 4340 Alloy Steel (Uns g43400)LamhotFernandoSihombingNo ratings yet

- Aluminum 7175 T736Document3 pagesAluminum 7175 T736TylerLALA100% (1)

- SNI 4658-2008-Pelek Kategori LDocument2 pagesSNI 4658-2008-Pelek Kategori LDimazNugraha100% (1)

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)UmerNo ratings yet

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)prasadjoshi781429No ratings yet

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- EN71000 From ReinferdenDocument2 pagesEN71000 From ReinferdenJason WuNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- AISI 4130 Alloy Steel (UNS G41300) 1Document4 pagesAISI 4130 Alloy Steel (UNS G41300) 1shubham soni100% (1)

- (Discontinued ) : ASTM A202 Low Alloy Steel, Grade BDocument1 page(Discontinued ) : ASTM A202 Low Alloy Steel, Grade BDhanyajaNo ratings yet

- 2024-T3 ASM Material Data Sheet PDFDocument2 pages2024-T3 ASM Material Data Sheet PDFAnonymous mq0U43UsPNo ratings yet

- EP1342656B1Document21 pagesEP1342656B1carlottiNo ratings yet

- Loads Stresses and Deflections in Bicycle FramesDocument12 pagesLoads Stresses and Deflections in Bicycle FramesMuhammad AliNo ratings yet

- Basis For Tubular Joint DesignDocument11 pagesBasis For Tubular Joint Designwinlugue3059No ratings yet

- Welded JointDocument25 pagesWelded JointcarlottiNo ratings yet

- Practical-Small-Scale Explosive Seam WeldingDocument18 pagesPractical-Small-Scale Explosive Seam WeldingcarlottiNo ratings yet