Professional Documents

Culture Documents

Lesson Learnt

Uploaded by

sanjeet giri0 ratings0% found this document useful (0 votes)

27 views2 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views2 pagesLesson Learnt

Uploaded by

sanjeet giriCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

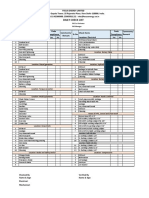

OSLO (SK#P3): LESSON LEARNT Date: 17 feb 2020

Incident:- Tong die fall into the well

Cause:- Due to worn & broken of Tong die holding bolt.

During Latching, the Makeup tong die fall into the well due to worn out and

broken of die holding bolt.

Lesson learnt:- 1) Maintain Checklist and do visual inspection in every tour by the

drilling team(AD/DM/FM), in front of PE and according to the condition PE and

Rig incharge/Manager will take necessary action as required.

2)Planning to use Tong die RETAINING PIN instead of Nut bolt

Location: Tong Slips and Elevetors Yes No Remarks

1 Break out Tong wire condition

2 Make up Tong wire condition

3 Back up lines in good condition

4 Lines to be included in lifting equipment register

5 Tong dies sharp and secured, and do we have spare dies

6 Tong hanging lines in good condition

7 Counter weights move freely

8 Load cell working and calibrated

9 Condition of tong die retainer pin with cottor

10 Latch spring OK

11 Dies sharp and secured

12 Tong pull & snub line condition

13 Do NDT of makeup and break up tong after every well.

Checked By Verified By

Name &

Name & Sign

Sign

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Resume - Resume AltmashDocument1 pageResume - Resume Altmashsanjeet giriNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Abhishek Sharma: B.TECH (Mechanical Engineering) +91-8005888188 Pitliya Bhawan, Amet, Rajsamand, Rajasthan Pin-313332Document2 pagesAbhishek Sharma: B.TECH (Mechanical Engineering) +91-8005888188 Pitliya Bhawan, Amet, Rajsamand, Rajasthan Pin-313332sanjeet giriNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Directional Well Planning OverviewDocument26 pagesDirectional Well Planning Overviewsanjeet giri100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Resume - Resume AltmashDocument1 pageResume - Resume Altmashsanjeet giriNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Asif Hussain: Qualification Board/University Year Percentage/CGPADocument2 pagesAsif Hussain: Qualification Board/University Year Percentage/CGPAsanjeet giriNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Shubham Sharma Career ObjectivesDocument2 pagesShubham Sharma Career Objectivessanjeet giriNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Field Applications of PHPA Muds: A.G. Kadaster, G .... Guild, Hanni, D.D. SchmidtDocument9 pagesField Applications of PHPA Muds: A.G. Kadaster, G .... Guild, Hanni, D.D. SchmidtDiana TorresNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Open Hole Wireline LoggingDocument32 pagesOpen Hole Wireline Loggingsanjeet giriNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- BOP Connection ChecksheetDocument1 pageBOP Connection Checksheetsanjeet giriNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Category Wise Wells For DeepningDocument6 pagesCategory Wise Wells For Deepningsanjeet giriNo ratings yet

- 8 1/2'' Phase Stablizer Detail With Deviation: S.no Well in Depth (M) Deviation in Out Depth (M) Deviation Out StatusDocument1 page8 1/2'' Phase Stablizer Detail With Deviation: S.no Well in Depth (M) Deviation in Out Depth (M) Deviation Out Statussanjeet giriNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 2 - Bit Program ADocument5 pages2 - Bit Program Asanjeet giriNo ratings yet

- Key PointsDocument3 pagesKey Pointssanjeet giriNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Servicing After Every ShiftingDocument3 pagesServicing After Every Shiftingsanjeet giriNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Hole Preparation Prior To Casing LoweringDocument1 pageHole Preparation Prior To Casing Loweringsanjeet giriNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- New Microsoft Office Excel WorksheetDocument4 pagesNew Microsoft Office Excel Worksheetsanjeet giriNo ratings yet

- Mock Drill PlanDocument2 pagesMock Drill Plansanjeet giriNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Daily Check ListDocument1 pageDaily Check Listsanjeet giriNo ratings yet

- Nipple Up-Down BopDocument6 pagesNipple Up-Down Bopsanjeet giri100% (2)

- Question PaperDocument1 pageQuestion Papersanjeet giriNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Phase Wise Checklist and Running Procedures For 9-58 CasingsDocument2 pagesPhase Wise Checklist and Running Procedures For 9-58 Casingssanjeet giriNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Phase Wise Checklist and Running Procedures For 4-12 Casings PDFDocument2 pagesPhase Wise Checklist and Running Procedures For 4-12 Casings PDFsanjeet giriNo ratings yet

- Commen Drilling Practice For All PhaseDocument2 pagesCommen Drilling Practice For All Phasesanjeet giriNo ratings yet

- Mud WeightDocument3 pagesMud Weightsanjeet giriNo ratings yet

- Funnel ViscocityDocument1 pageFunnel Viscocitysanjeet giriNo ratings yet

- SOP (Drilling)Document8 pagesSOP (Drilling)sanjeet giriNo ratings yet

- Hole CleaningDocument1 pageHole Cleaningsanjeet giriNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Mud Engineer TrainingDocument8 pagesMud Engineer Trainingsanjeet giri100% (1)

- SOP (Drilling)Document8 pagesSOP (Drilling)sanjeet giriNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)