Professional Documents

Culture Documents

J338

Uploaded by

camelslayer0 ratings0% found this document useful (0 votes)

188 views6 pagesJ338 throttle body 2

Original Title

J338 (2)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJ338 throttle body 2

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

188 views6 pagesJ338

Uploaded by

camelslayerJ338 throttle body 2

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

Volkswagen Workshop Manuals

Li

Polo Mk3

Power unit > Simos injection and ignition system > Mixture preparation system, electronic inj..Gas >

Checking components > Checking throttle valve control part

Checking components

Checking throttle valve control part

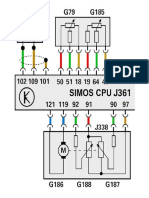

Components of throttle valve control part (338):

Trrte valve drive (G186), angle sender 1 for throttle valve drive (6187) and angle sender 2 for throttle valve drive

Notes:

* Only gold-plated contacts may be used when servicing the throttle valve control part connector contacts.

If the throttle valve control part is replaced, the following must be carried out:

‘¢ Erase leamt values and adapt engine control unit to the throttle valve control part

Special tools, workshop equipment, testers, measuring instruments and au:

ry items required

‘¢ Hand multimeter V.A.G 1526 or multimeter V.A.G 1715

+ Fault reader V.A.G 1551 (or vehicle system tester V.A.G 1552) with cable V.A.G 1551/3

‘+ Adapter set V.A.G 1594

'¢ Test box V.A.G 1598/31

* Current flow diagram.

Check conditions

«© The battery voltage must be at least 11.5 V.

‘* All electrical consumers, e.g. lights and rear window heating must be switched off

« If the vehicle is equipped with an air conditioning system, this must be switched off.

# Coolant temperature must be at least 80 °C, =>display group 04, display zone 3,

Test sequence

— Connect the fault reader V.A.G 1551 (V.A.G 1552). Then switch ignition on and select engine control unit with the

“Address word" 01.

(Connecting fault reader and selecting engine control unit

— Indicated on display:

— Press keys 0 and 8 for the function "Read

measured value block" and confirm entry with Q

key.

— Indicated on display:

— Press keys 0, 6 and 2 for the "Display group

number 62" and confirm entry with Q key.

— Indicated on display:

(1...4 = Display zones)

— Check throttle valve angle sender 1 (187) at

idling speed limit stop in display zone 1

Specification: 0.0...100.0 %

Check throttle valve angle sender 2 (G188) at

idling speed limit stop in display zone 2

Specification: 100.0...0.0 %

— Depress accelerator slowly to full throttle position

and observe angles displayed in display zones 1

and 2:

Page 01-10.)

Rapid data transfer HELP

Select function XXX

Read measured value block

Input display group pumbar XXX

Read measured value black 62 >

1244

The percentage in display zone 1 must rise

evenly.

The tolerance range 0.0...100.0 % is never used

completely.

The percentage in display zone 2 must fall

evenly.

‘The tolerance range 100.0...0.0 % is never used

completely.

Notes:

‘The reason why the display in display zone 1

increases and the display in display zone 2

decreases is because the potentiometers (angle

senders) in the throttle valve control part run in

opposite directions.

* This means that the voltage of one angle sender

moves towards 5 volts. (The more the throttle

valve is opened the higher the voltage;

percentage figure increases).

+ Whilst the voltage of angle sender 2 decreases

from § volts towards 0 volts. (The more the

throttle valve is opened the lower the voltage;

Percentage figure decreases).

Press =skey.

Press keys 0 and 6 for the function "End output"

and confirm entry with the Q key.

— Switch off ignition,

It the displays do not indicate as described

—Remove air cleaner => Page 24-26 , Fig. 2.

—— Pull 6-pin connector off throttle valve control

part -arrow-.

N2a-1064

WS

——+ Measure the resistance on throttle valve control

part between the contacts 3 + 5

Specification: 1.0...5.0 w(at room temperature)

If the specification is not obtained:

— Replace throttle valve control part

=> Page 24-18, item 7.

— Interrogate fault memory, if necessary, repair any

faults and then erase fault memory => Page 01-

20,, interrogating and erasing fault memory.

Erase the leamt values and adapt the engine

control unit again=> Page 24-128

If the specification is obtained:

— Check voltage supply of throttle valve control part

and wiring to control unit => Page 24-47

Check the accelerator pedal position sender. N24-1092

TT

Repair grou

(electronic accelerator

pedal position sender

PC)); Checking accelerator

If the voltage supply and wiring is OK:

—Replace engine control unit

=> Page 24-121

Checking voltage supply and wiring to control unit

——+ Connect multimeter to measure voltage at

connector contacts 2 (positive) + 6 (earth).

— Switch on ignition.

Specification: min, 4.5 V

— Switch off ignition.

=~ Connect multimeter to measure voltage at

connector contact 2 (positive) and earth.

— Switch on ignition.

Specification: min. 4.5 V

— Switch off ignition,

If the specifications are not attained:

M24-0068

‘M24-0069

——+ Connect test box V.A.G 1598/31 to control unit

wiring harness. The engine control unit remains

disconnected.

—— Check wiring for open circuit between test box

and connector referring to current flow diagram:

Contact 1 and test box socket 90

Contact 2 and test box socket 97

Contact 3 and test box socket119

Contact 4 and test box socket 92

Contact 5 and test box socket121

Contact 6 and test box socket 91

Wire resistance: max, 1.5

— Additionally check wires for short to one another,

to vehicle earth and to battery positive.

Specification: =u

If no fault is detected in the wiring:

— Check engine control unit voltage supply => Page

24-17

Power unit > Simos injection and ignition system > Mixture preparation system, electronic inj

Checking components > Checking throttle valve control part

‘M24-0048

jas >

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ECU J361 J338 Throttle Pinouts For Polo 9N1Document1 pageECU J361 J338 Throttle Pinouts For Polo 9N1camelslayerNo ratings yet

- Polo MK3 Fault CodesDocument22 pagesPolo MK3 Fault CodescamelslayerNo ratings yet

- SSP 263 - Polo Model Year 2002Document60 pagesSSP 263 - Polo Model Year 2002camelslayer100% (1)

- J 338Document3 pagesJ 338camelslayerNo ratings yet

- Bennett - Turning Frogs Into InterculturalistsDocument10 pagesBennett - Turning Frogs Into InterculturalistscamelslayerNo ratings yet

- 6 Levels (Handout)Document2 pages6 Levels (Handout)camelslayerNo ratings yet

- Culture - Onion (Slide)Document1 pageCulture - Onion (Slide)camelslayerNo ratings yet

- Continuums - Hofstede NotesDocument2 pagesContinuums - Hofstede NotescamelslayerNo ratings yet