Professional Documents

Culture Documents

Ecp 17138011

Uploaded by

SrashmiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ecp 17138011

Uploaded by

SrashmiCopyright:

Available Formats

Numerical Modelling of the Calcination Process in a Cement Kiln

System

Amila Chandra Kahawalage Morten C. Melaaen Lars-André Tokheim

Department of Process, Energy and Environmental Technology, Faculty of Technology, Natural Sciences and Maritime

Sciences, University College of Southeast Norway, 3918, Porsgrunn, Norway

{amila.c.kahawalage, Morten.C.Melaaen, Lars.A.Tokheim}@usn.no

Abstract then sent to the precalciner where typically 85-95% of

the calcination takes place. Calcination is the process of

The calcium carbonate decomposition into calcium

calcium carbonate decomposition into calcium oxide

oxide and carbon dioxide is a key process step in a

(CaO) and carbon dioxide (CO2), typically occurring at

cement kiln. The reaction requires thermal energy input,

a temperature around 850-900°C. As the calcination is

and pulverized coal is the fuel typically used for this

an endothermic reaction (~1.7 MJ/kgCaCO3), fuel is

purpose in the cement industry. Coal can in many cases

combusted in the calciner. In the rotary kiln, the

be replaced by different types of alternative fuels, but

remaining calcination is completed and clinker is

this may impact process conditions, emissions or

formed.

product quality. In this study, CFD simulations were

carried out to investigate the possibility to replace 50 % Numerical modelling is a widely used tool for

of the coal by refuse derived fuel (RDF). The spatial analysis and optimization of industrial process because

distribution of gas and particle temperatures and it reduces time consumption and costs of doing full-

concentrations were calculated, and the simulations scale tests. Computational fluid dynamics (CFD)

indicated that replacement of coal by RDF resulted in a modelling can be used to make numerical 3D

reduction of fuel burnout, lower gas temperatures and a simulations of different processes, for example the

lower degree of calcination. decarbonation and combustion in the cement kiln

precalciner.

Keywords: precalciner, calcination, refuse derived fuel,

computational fluid dynamics

1 Introduction

Cement is a key building material in construction

industries and its demand is continually going up due to

population growth and development. The energy

required in cement production is supplied by electricity

and thermal energy. In the manufacturing process,

thermal energy is used mainly during the burning

process.

The typical manufacturing process, which is

schematically represented in Figure 1, starts with

mining of limestone (high in calcium carbonate, CaCO3) Figure 1. Principal drawing of the cement

and is followed by crushing, adding of additives such as manufacturing process (Tokheim, 1999)

clay, sand and iron to get the required chemical

composition and grinding of this mixture. The Results from modelling of cement kiln systems have

intermediate product is called 'raw meal'. After been reported in some articles. When coal was co-

homogenization, the raw meal becomes suitable for combusted with meat and bone meal (MBM), the impact

burning in the kiln system. The kiln feed is preheated, of fuel particle size and feeding positions in a rotary kiln

calcined, sintered and cooled in the kiln system, was investigated (Ariyaratne et al., 2015) using a CFD

resulting in a dark grey nodular material called clinker. simulation. This study revealed that although same

The clinker is mixed with some gypsum and other thermal energy was supplied, when introducing MBM

additives and ground to the final product cement. the kiln inlet temperature was reduced due to combined

A precalciner kiln system is the basis for this study. effect of moisture content, ash content and air demand.

It normally consists of a preheater, a precalciner (also (Mikulčić et al., 2014) conducted a numerical study of

known as a calciner), a rotary kiln and a cooler. The kiln co-firing pulverized coal and biomass inside a cement

feed (i.e. the raw meal) is heated in the preheater and calciner and found that when coal was replaced with

biomass, the fuel burnout and the CaCO3 decomposition

DOI: 10.3384/ecp1713883 Proceedings of the 58th SIMS 83

September 25th - 27th, Reykjavik, Iceland

was reduced. Another numerical modeling study reports

a CFD simulation of a calciner with two different case

studies of 100% coal and 100% pet coke (Fidaros et al.,

2007). The use of CFD to predict the precalciner process

behavior was proven by (Kurniawan, 2004).

Energy-wise and product efficiency-wise the

precalciner plays CFD can be used to predict the

precalciner process behavior was an important role in a

cement kiln system as it completes around 85 % of the

calcination. CFD is a well-proven method to investigate

flow, heat transfer and mass transfer phenomena in

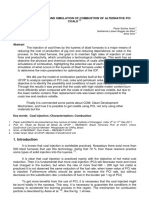

process equipment units. The aim of this study was to Figure 2. CFD Modelling steps of combustion of a

get detailed information about temperatures, calcination solid fuel particle (M=moisture, C=char, V=volatile

degree and fuel burnout in the precalciner system of a compounds, A= ash)

Norwegian cement plant with an annual clinker

production capacity of about 1 Mt. The commercial fuel particle is devolatilized, and finally the char

software ANSYS Fluent was used to conduct the study. fraction, which is very rich in carbon, reacts with O2 and

produces CO and CO2. (In the present study, it was

assumed that only CO2 is produced in this reaction.)

2 Theory When the fuel particle is 100% burnt, i.e. when all the

The gas phase was modelled using the Euler approach, carbon has been oxidized, only ash is left.

and to model the flow of the solid particles, the A single rate devolatilisation model was used for both

Lagrange method was used. For the gas phase, the coal and refuse derived fuel (RDF). Char combustion

equations for conservation of mass, momentum and was modelled with the kinetic/diffusion limited method.

energy (equations 1-4) are used. Devolatilisation was modeled by the single rate

devolatilisation model given in equation 7 and 8. The

∙ (1) rate constants for coal and RDF were taken from

(Badzioch and Hawksley, 1970) and (Wang et al.,

∙ ∙ ̿ (2) 2014), respectively.

1 3

̿ ∙ %$A6 !1 C ,E #!1 CF,E #A6,E . (7)

(3) 1

.! " # . $%&'' ( ∑+ *+ ,+

% G9 H 8 /?

(9)

!------

&'' . #. / (4)

Char combustion was modeled the by

Here, is the mass added to the continuous phase kinetic/diffusion surface rate model. The rate constant

from particles due to fuel devolatilisation, char for coal was used as in (Baum and Street, 1971) and

combustion and raw meal calcination, and / is the (Field, 1969). The rate constant for RDF was taken from

added energy to the continuous phase due to chemical (Wang et al., 2014).

reactions. To model the turbulence, the two equation

N.OP

% 0 turbulence model was used. Particle trajectories $! 3 L M #/ .

JE K9 (10)

were defined by equation 5. 13

123 7! 38 # Q K H 8! /? 3# (11)

1 4! 56 # (5)

3

1 3 4S ?

G6 ER 4 L? (12)

Here, 4 is the drag force on the particle, which for 1 S

spherical particles can be calculated by equation 6.

Particle heat transfer during the initial heating and

9:; => ?& after the devolatization and char combustion is given by

4 < (6)

3 13 @ equation 13.

1

Figure 2 shows how a CFD modelling is sequenced A6 T6 3

*G6 !(U (6 # 06 G6 V!W?@ (6@ # (13)

for combustion of a solid fuel particle. First the fuel 1

particle is heated whereby moisture evaporates. When

the particle reaches the boiling point of water, all free The particle heat transfer during devolatization is

moisture evaporates. After that the volatile part of the given by equation 14.

DOI: 10.3384/ecp1713883 Proceedings of the 58th SIMS 84

September 25th - 27th, Reykjavik, Iceland

It has two tangential inlets to introduce raw meal and

tertiary air. Quarternary air is introduced at the top of the

1 3 1 3

A6 T6 *G6 !(U (6 # *'7 calciner via a separate inlet, and there is also a separate

1 1 inlet at the top for fuel (coal) supplied with conveying

06 G6 V!W?@ (6@ # (14) air. Moreover, there is a separate cooling air inlet.

The ANSYS Fluent CFD software was used to

The particle heat balance during the char combustion model the unit. The computational domain has 489,766

is given by equation 15. elements and is a combination of hexahedral, tetrahedral

and prism elements.

1 3 1 3

A6 T6 *G6 !(U (6 # C/ XY&Z

1 1

06 G6 V!W?@ (6@ # (15) Table 1. Approximate analysis of coal and RDF

Content Coal RDF

The P-1 radiation model was used to implement the (Ariyaratne, (Tokheim,

radiation heat transfer for the gas phase and the particle 2014) 1999)

phase. The gas phase reaction was modelled using a Moisture (%) 1 8.3

finite-rate/eddy-dissipation model. In this study, it was Volatiles (%) 23 71.1

considered that the volatile fraction of coal and RDF Char (%) 62.4 10.3

reacts with O2 and produces CO and H2O. Then CO Ash (%) 13.6 10.3

reacts with O2 and produce CO2. The required kinetic

and eddy-dissipation model data were obtained from

(Kurniawan, 2004). Table 2. Ultimate analysis of coal and RDF

Char was assumed to be 100% carbon (C), which Element (dry Coal RDF

reacts with O2 and produces CO2. It was assumed that and ash-free (Ariyaratne, (Tokheim,

raw meal is pure CaCO3. The CaCO3 decomposition basis) 2009) 1999)

kinetics were according to (Borgwardt, 1985). C (%) 85.3 54.3

H (%) 4.6 8.1

∆ O (%) 6.5 35.8

K[K\ ] → K[\ ] K\ 7 (16)

N (%) 2.0 1.2

1

S (%) 1.6 0.6

`a`bc

%] G=d=ec (17)

1

The approximate and ultimate analyses of coal and RDF

%] GH 8 a /? (18) are shown in Table 1 and Table 2, respectively, and

these values were used as input values in Fluent. The

Mean particle size values of 53, 2500 and 60 µm were

3 Simulation setup used for coal, RDF and raw meal respectively.

Two cases were defined. In Case 1, which can be

Figure 3 shows a 3-D model of the precalciner unit taken as the reference case for comparison purposes,

currently in operation at Norcem cement plant in Brevik. coal was used as the only fuel. In Case 2, a mixture of

Figure 4 shows its front view. 50 % coal and 50 % RDF was used. In both cases the

same fuel energy was supplied. The boundary

conditions and process conditions for the test cases are

given in the Table 3. A slightly higher tertiary air flow

rate was used in Case 2 in order to operate with the same

excess air value in both cases.

Figure 3. 3-D view of precalciner at

Norcem cement plant

DOI: 10.3384/ecp1713883 Proceedings of the 58th SIMS 85

September 25th - 27th, Reykjavik, Iceland

Results and discussion

Figure 4. Front view of the precalciner

(dimensions are in meters)

Table 3. Definition of cases

Figure 5. Particle path along the precalciner

Parameter Case 1 Case 2

Eight planes were created along the precalciner, as

Fuel Energy (MW) 79.5 79.5

shown in Figure 5, to extract data of the gas phase and

Tertiary air (t/h) 94.5 93.0

the particle phase. Gas phase data were calculated as

Quarternary air (t/h) 17.1 17.1

area-weighted averages for each plane.

Raw meal mass flow rate (t/h) 184.3 184.3

Figure 6 (a) and (b) shows the variation of

Coal mass flow rate (t/h) 10.1 5.1

temperature and gas phase composition along the

RDF mass flow rate (t/h) - 7.8

precalciner path length. The connection between path

length and plane position is seen in Figure 5. In both

The composition of tertiary and quarternary air were cases, the oxygen mole fraction is reduced along the

taken as 21 % O2 and 79 % N2. The kiln gas composition path length due to combustion. Carbon dioxide and

was taken as 74.4 % N2, 7.6 % O2, 5.0 % H2O and water are generated proportionally due to combustion.

13.0 % CO2. The tertiary air, quarternary air and raw In both cases, the CO2 generated by the calcination

meal inlet temperatures were all set to 800 ⁰C, which are reaction also increases, and the temperature resulting

quite typical values for the given kiln system. The kiln from fuel combustion is used to heat and calcine the raw

gas inlet temperature was taken as 1050 ⁰C. meal. This can also be seen in Figure 7. At the end of

As the convergence criteria, all variables were kept the path length, the gas, fuel and meal temperatures are

below the residual value of 10-4. The SIMPLE algorithm quite close, ranging from about 860 to 900 °C, which is

was used to to solve the Navier-Stokes equations. The typically what is experienced in the real process.

PRESTO! scheme was used for pressure discretization, There is an increase in gas temperature over the the

and first order discretization schemes were used for initial path length (the first 20 m). However, as the

momentum, turbulent dissipation and turbulent kinetic calcination process escalates, the temperature is

energy. All other parameters were discretized with gradually reduced due to heat transfer from the gas to

second order schemes. the meal.

During the simulation, the progress of the gas phase

temperature and species mole fractions were monitored

at the outlet. When they approached steady state, the

simulation was considered as converged.

DOI: 10.3384/ecp1713883 Proceedings of the 58th SIMS 86

September 25th - 27th, Reykjavik, Iceland

20 1025

975

Mole fraction (%)

Temperature (⁰C)

15

CO₂ (Combustion) Case 1

925

10 O₂ Case 1

875 H₂O Case 1

5

825 CO₂ (Calcination) Case 1

0 775 Gas temperature (⁰C) Case 1

0 10 20 30 40 50

Path length (m)

(a)

20 1025

975 CO₂ (Combustion) Case 2

15

Mole fraction (%)

Temperature (⁰C)

925 CO₂ (Calcination) Case 2

10

O₂ Case 2

875

5 H₂O Case 2

825

Gas temperature (⁰C) Case 2

0 775

0 10 20 30 40 50

Path length (m)

(b)

Figure 6. Variation of gas temperature and mole fraction of CO2 (from calcination + combustion) O2 and

H2O (a) for Case 1 (b) for Case 2

1200

1000

Temperature (⁰C))

800 Coal temperature (⁰C) Case 1

600 Raw meal temperature (⁰C) Case 1

Coal temperature (⁰C) Case 2

400

RDF temperature (⁰C) Case 2

200

Raw meal temperature (⁰C) Case 2

0

0 10 20 30 40 50

Path length (m)

Figure 7. Temperature distribution of coal, raw meal and RDF for Case 1 and Case 2

DOI: 10.3384/ecp1713883 Proceedings of the 58th SIMS 87

September 25th - 27th, Reykjavik, Iceland

100

80

Coal burnout (including moisture

60 evaporation) (%) Case 1

(%)

Calcination degree % Case 1

40 Coal burnout (including moisture

evaporation) (%) Case 2

RDF burnout (including moisture

20 evaporation) (%) Case 2

Calcination degree (%) Case 2

0

0 10 20 30 40 50

Path length (m)

Figure 8. Calcination degree and fuel burnout for Case 1 and Case 2

Figure 8 shows the calcination degree and fuel burnout substitute for coal at Norcem Brevik cement plant" (BIA

for both cases. Although the same energy was supplied project 245690).

in Case 1 and Case 2, the calcination degree is lower in

the latter case. There are two reasons for this. The main

reason is the high moisture content of RDF (see Figure

6), which reduces the particle temperature and gives a Nomenclature

lower burnout of this fuel (see Figure 8).

Gas density (kgm-3)

Hence, less energy is released to support the Gas velocity vector (ms-1)

decarbonation. This happens because in the initial stage, Mass source (kgm-3s-1)

energy is spent on evaporating the moisture. A Static pressure (Nm-2)

consequence of this is that RDF char burning takes place ̿ Stress tenser (Nm-2)

later, i.e. more downstream along the path length. In Acceleration of gravity (ms-2)

addition, since the RDF particles are bigger, it takes External body force (N)

more time to reach complete combustion. Molecular viscosity (kgm-1s-1)

Unit tensor

Conclusion " Total energy (m2s-2)

In this study CFD tool has been applied to get detailed %&'' Effective conductivity (Wm-1K-1)

information about temperatures, calcination degree and ( Gas temperature (K)

fuel burnout in a precalciner system. Even if the fuel *+ The enthalpy formation of species j

energy supply is not changed, replacing part of the coal (Jkg-1)

with RDF reduces the calcination degree in the process,

,+ Diffusion flux of species j (kgm-2s-1)

which can be seen as quality reduction in precalcined

meal. The reason for the reduced calcination degree is ------

&'' Viscous dissipation term

the poorer burnout of the RDF particles caused by / Source of energy (kgm-1s-3)

higher moisture content and larger particles. The 56 Particle velocity vector (ms-1)

method applied in this study can be used to evaluate the 4 Drag force on particle (s-1)

calcination process under different process conditions 6 Particle density (kgm-3)

and to optimize the process when coal is replaced by h6 Particle diameter (m)

other alternative fuels with different characteristics. K4 Drag coefficient

QH Particle Reynold number

Acknowledgement A6 Particle mass (kg)

Financial support from Telemark Fylkeskommune is % Devolatilisation reaction rates constant

greatly acknowledged, as is the support from the C ,E Initial volatile fraction in fuel particle (%)

Norwegian Research Council through the project CF,E Initial moisture fraction in particle (%)

"Optimised and increased use of Refuse Derived Fuel as A6,E Particle initial weight (kg)

DOI: 10.3384/ecp1713883 Proceedings of the 58th SIMS 88

September 25th - 27th, Reykjavik, Iceland

G9 Pre exponential factor for % Mikulčić, H., Berg, E. V., Vujanović, M. & Duić, N. Numerical

"9 Activation energy for % (Jkmol-1) study of co-firing pulverized coal and biomass inside a

cement calciner. Waste Management & Research, 32,

G6 Surface area of particle (m-2) 661-669.2014.doi:10.1177/0734242X14538309

(U Local temperature of continuous phase Tokheim, L. A. The impact of staged combustion on the operation

(K) of a precalciner cement kiln. PhD thesis, Telemark

ER Partial pressure of oxidant (Nm-2) College, Norway. 1999.

JE Diffusion rate coefficient (m-1) Wang, G., Silva, R. B., Azevedo, J. L. T., Martins-Dias, S. &

Costa, M. Evaluation of the combustion behaviour and

Q Universal gas constant (Jkmol-1K-1) ash characteristics of biomass waste derived fuels, pine

T6 Heat capacity of particle (Jkg-1K-1) and coal in a drop tube furnace. Fuel, 117, 809-

* Convection heat transfer coefficient 824.2014.http://dx.doi.org/10.1016/j.fuel.2013.09.080

(Wm-2K-1)

*'7 Latent heat of devolatilisation (Jkg-1)

06 Particle emissivity

V Stefan-Boltzmann constant (5.67 x 10-8

Wm-2K-4)

W? Radiation temperature (K)

C/ Particle absorb energy fraction from char

combustion

XY&Z Heat release by the char combustion

(Jkg-1)

References

Ariyaratne, W. K. H. Alternative fuels in cement kilns –

characterization and experiments Master thesis,

Telemark University College, Norway. 2009.

Ariyaratne, W. K. H. Utilization of Waste-derived Biofuels and

Partly CO2-neutral Fuels in Cement Kilns. PhD thesis,

Telemark University College. 2014.

Ariyaratne, W. K. H., Malagalage, A., Melaaen, M. C. &

Tokheim, L.-A. CFD modelling of meat and bone meal

combustion in a cement rotary kiln – Investigation of

fuel particle size and fuel feeding position impacts.

Chemical Engineering Science, 123, 596-

608.2015.http://dx.doi.org/10.1016/j.ces.2014.10.048

Badzioch, S. & Hawksley, P. G. W. Kinetics of Thermal

Decomposition of Pulverized Coal Particles. Industrial

& Engineering Chemistry Process Design and

Development, 9, 521-530.1970.10.1021/i260036a005

Baum, M. M. & Street, P. J. Predicting the Combustion Behaviour

of Coal Particles. Combustion Science and Technology,

3, 231-243.1971.10.1080/00102207108952290

Borgwardt, R. H. Calcination kinetics and surface area of

dispersed limestone particles. AIChE Journal, 31, 103-

111.1985.10.1002/aic.690310112

Fidaros, D. K., Baxevanou, C. A., Dritselis, C. D. & Vlachos, N.

S. Numerical modelling of flow and transport processes

in a calciner for cement production. Powder

Technology, 171, 81-

95.2007.http://dx.doi.org/10.1016/j.powtec.2006.09.01

1

Field, M. A. Rate of combustion of size-graded fractions of char

from a low-rank coal between 1 200°K and 2 000°K.

Combustion and Flame, 13, 237-

252.1969.http://dx.doi.org/10.1016/0010-

2180(69)90002-9

Kurniawan, K. P. Studies of Fundamental Process Occurring in

Pre-calciners and Cyclone Pre-heater Tower Using

CFD. PhD thesis, University of Wales. 2004.

DOI: 10.3384/ecp1713883 Proceedings of the 58th SIMS 89

September 25th - 27th, Reykjavik, Iceland

You might also like

- Bermudez2011 PulverizedCoalDocument14 pagesBermudez2011 PulverizedCoalKhadeeja NicyNo ratings yet

- Experimental Investigation of The Carbonation Reactor in A - 2020 - Fuel ProcesDocument9 pagesExperimental Investigation of The Carbonation Reactor in A - 2020 - Fuel ProcesFood CatNo ratings yet

- Nikoo - 2008 - Simulation of Biomass Gasification in Fluidized Bed Reactor Using ASPEN PLUSDocument10 pagesNikoo - 2008 - Simulation of Biomass Gasification in Fluidized Bed Reactor Using ASPEN PLUSolajumokeshonubiNo ratings yet

- Catalytic Coal Gasification For Methane Production: A ReviewDocument11 pagesCatalytic Coal Gasification For Methane Production: A ReviewEmilio Jose Carrillo CardenasNo ratings yet

- Marco Balsamo, Francesco Di Natale, Alessandro Erto, Amedeo Lancia, Fabio Montagnaro, Luciano SantoroDocument5 pagesMarco Balsamo, Francesco Di Natale, Alessandro Erto, Amedeo Lancia, Fabio Montagnaro, Luciano Santorojanyperez82No ratings yet

- Hayati Nasution 2021 IOP Conf. Ser. Mater. Sci. Eng. 1143 012050Document9 pagesHayati Nasution 2021 IOP Conf. Ser. Mater. Sci. Eng. 1143 0120502233608No ratings yet

- Tn287-TN287 Modeling Coal Gasification With CFD and The Discrete Phase MethodDocument9 pagesTn287-TN287 Modeling Coal Gasification With CFD and The Discrete Phase MethodNenuko CrossNo ratings yet

- Reactivity of CaoDocument5 pagesReactivity of CaoAlberto Moreno GomezNo ratings yet

- Monitoring and Modelling Gas Side Fouling Biomass BoilerDocument7 pagesMonitoring and Modelling Gas Side Fouling Biomass BoilermsoyoralNo ratings yet

- Yeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Document8 pagesYeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Mohammed AsherNo ratings yet

- Validation of Coal Combustion Model by Using Experimental Data of Utility BoilersDocument8 pagesValidation of Coal Combustion Model by Using Experimental Data of Utility BoilersKhadeeja NicyNo ratings yet

- Representation of Coal and Coal Derivatives in Process ModellingDocument16 pagesRepresentation of Coal and Coal Derivatives in Process ModellingPrateek PatelNo ratings yet

- Controlling LOI From Coal Reburning in A Coal-Fired Boiler: Hou-Peng Wan, Chyh-Sen Yang, B.R. Adams, S.L. ChenDocument7 pagesControlling LOI From Coal Reburning in A Coal-Fired Boiler: Hou-Peng Wan, Chyh-Sen Yang, B.R. Adams, S.L. ChenJayanath Nuwan SameeraNo ratings yet

- Coal To Methanol p2Document8 pagesCoal To Methanol p2moeeezNo ratings yet

- Modelling Coal Gasification With CFD and Discrete Phase MethodDocument5 pagesModelling Coal Gasification With CFD and Discrete Phase Methodmohammadjm2008No ratings yet

- Art. 2 AdelantoDocument14 pagesArt. 2 AdelantoYuliiana HernandezNo ratings yet

- 1 s2.0 S0360319918336413 MainDocument10 pages1 s2.0 S0360319918336413 Mainpattanapon.kNo ratings yet

- 1 s2.0 S0196890421000704 MainDocument13 pages1 s2.0 S0196890421000704 MainHHeNo ratings yet

- Enhancement of Catalytic Performance of Porous Membrane Reactor With Ni Catalyst For Combined Steam and Carbon Dioxide Reforming of Methane ReactionDocument6 pagesEnhancement of Catalytic Performance of Porous Membrane Reactor With Ni Catalyst For Combined Steam and Carbon Dioxide Reforming of Methane ReactionWassachol SumarasinghaNo ratings yet

- CFD Analisys CoalDocument6 pagesCFD Analisys CoalOscar DorantesNo ratings yet

- Computers and Chemical EngineeringDocument16 pagesComputers and Chemical EngineeringJoseph NguyenNo ratings yet

- Modelling of Combustion and Calcination in A CemenDocument7 pagesModelling of Combustion and Calcination in A CemengldiasNo ratings yet

- Firing Estonian Oil Shale in CFB Boilers - Ash Balance and Behaviour of Carbonate MineralsDocument10 pagesFiring Estonian Oil Shale in CFB Boilers - Ash Balance and Behaviour of Carbonate Mineralssalkan_rahmanovic810No ratings yet

- Articulo 04Document9 pagesArticulo 04Alexis GoicocheaNo ratings yet

- A Real-Time Mathematical Model For The Two-DimensionalDocument11 pagesA Real-Time Mathematical Model For The Two-DimensionalMatheus Brandão TheodoroNo ratings yet

- Paper Cement PDFDocument8 pagesPaper Cement PDFAnonymous N3LpAXNo ratings yet

- Eulerian - Eulerian CFD Model On Fluidized Bed Gasifier Using Coffee Husks As FuelDocument12 pagesEulerian - Eulerian CFD Model On Fluidized Bed Gasifier Using Coffee Husks As FuelKee BekiNo ratings yet

- Daofeng 1-S2.0-S0255270117302271-MainDocument10 pagesDaofeng 1-S2.0-S0255270117302271-MainnadiaNo ratings yet

- 3D Computational Fluid Dynamics Study of A Drying Pro 2016 Applied Thermal EDocument12 pages3D Computational Fluid Dynamics Study of A Drying Pro 2016 Applied Thermal EPeter YekNo ratings yet

- SENTA ITS 2018 - Rizqiana Yogi CahyaningtyasDocument5 pagesSENTA ITS 2018 - Rizqiana Yogi CahyaningtyasRizqiana Yogi CahyaningtyasNo ratings yet

- Evaluation of Coal-Based Dimethyl Ether Produc-Tion System Using Life Cycle Assessment in South KoreaDocument5 pagesEvaluation of Coal-Based Dimethyl Ether Produc-Tion System Using Life Cycle Assessment in South KoreaAndroid PCNo ratings yet

- Determining Ga and Ge Affinity in Lignite Using Sequential Extraction and Sink-Float MethodsDocument71 pagesDetermining Ga and Ge Affinity in Lignite Using Sequential Extraction and Sink-Float MethodsalyaxandrNo ratings yet

- A Comparative Analysis of Methanol Production Routes: Synthesis Gas Versus CO2 HydrogenationDocument10 pagesA Comparative Analysis of Methanol Production Routes: Synthesis Gas Versus CO2 HydrogenationMohanad El-HarbawiNo ratings yet

- Z. Gao, R.M. Wagner, C.S. Sluder, C.S. Daw, J.B. Green JR.: SciencedirectDocument12 pagesZ. Gao, R.M. Wagner, C.S. Sluder, C.S. Daw, J.B. Green JR.: SciencedirectAngel FajmNo ratings yet

- Paper Accepted For Publication at Chemical Engineering Research and DesignDocument56 pagesPaper Accepted For Publication at Chemical Engineering Research and Designjhay thegreatNo ratings yet

- 28-3-62-Kinetic Study of Dry Reforming of Methane Over Ni-Ce - Al2O3 Catalyst With DeactivationDocument11 pages28-3-62-Kinetic Study of Dry Reforming of Methane Over Ni-Ce - Al2O3 Catalyst With DeactivationWassachol SumarasinghaNo ratings yet

- Prediction of Ash Slagging Propensity in A Pulverized Coal Combustion FurnaceDocument8 pagesPrediction of Ash Slagging Propensity in A Pulverized Coal Combustion FurnaceaalfanNo ratings yet

- Collected Works About CFD Applications in Chemical EngineeringDocument125 pagesCollected Works About CFD Applications in Chemical EngineeringAlon DavidyNo ratings yet

- 144-Article Text-284-1-10-20220502Document16 pages144-Article Text-284-1-10-20220502Marco HernandezNo ratings yet

- Artigo Do TrabalhoDocument8 pagesArtigo Do TrabalhoRafaelTeixeiraNo ratings yet

- Burner ModellingDocument7 pagesBurner Modellingkhurram482No ratings yet

- CaCO3decomposition For Calcium Looping Applications Kineticmodeling in A Fixed Bed ReactorDocument14 pagesCaCO3decomposition For Calcium Looping Applications Kineticmodeling in A Fixed Bed ReactorBahnmiNo ratings yet

- Effect of Operating Parameters On Coal GasificationDocument13 pagesEffect of Operating Parameters On Coal GasificationViet TruongnhuNo ratings yet

- Simulation and Experimental Results of PSA Process For Production of Hydrogen Used in Fuel CellsDocument18 pagesSimulation and Experimental Results of PSA Process For Production of Hydrogen Used in Fuel Cellswww.beatricechongNo ratings yet

- India Kharagpur PCI - 2011Document12 pagesIndia Kharagpur PCI - 2011Carlos Frederico Campos de AssisNo ratings yet

- Evaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresDocument5 pagesEvaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresjulianapohlmannufrgsNo ratings yet

- Degradation Behavior of Coke Reacting With H2O and CO2 at High TemperatureDocument6 pagesDegradation Behavior of Coke Reacting With H2O and CO2 at High TemperatureSaumit PalNo ratings yet

- CFD Modeling of Coal Pyrolysis in Externally Heated Fixed-Bed Reactor - Qian2018Document10 pagesCFD Modeling of Coal Pyrolysis in Externally Heated Fixed-Bed Reactor - Qian2018Afifatul JannahNo ratings yet

- Palandri, 1993 (J. Anal. Appl. Pyrolysis)Document12 pagesPalandri, 1993 (J. Anal. Appl. Pyrolysis)Alberto Moreno GomezNo ratings yet

- Coal Carbonization: Current and Future ApplicationsDocument9 pagesCoal Carbonization: Current and Future ApplicationsVenkata Krishnan RamanujamNo ratings yet

- Journal of Natural Gas Science and Engineering: Yuefa Wang, Zhongxi Chao, Hugo A. JakobsenDocument9 pagesJournal of Natural Gas Science and Engineering: Yuefa Wang, Zhongxi Chao, Hugo A. JakobsenDaniel Z JucaNo ratings yet

- Upaper24 HQTangDocument17 pagesUpaper24 HQTangSuharman ArmanNo ratings yet

- Production of Hydrogen by Thermal Methane Splitting in A Nozzle-Type Laboratory-Scale Solar ReactDocument11 pagesProduction of Hydrogen by Thermal Methane Splitting in A Nozzle-Type Laboratory-Scale Solar ReactMohammed AlShammasiNo ratings yet

- Study of Seven-Lump Kinetic Model in The Fluid Catalytic Cracking UnitDocument6 pagesStudy of Seven-Lump Kinetic Model in The Fluid Catalytic Cracking UnitShaik RuksanaNo ratings yet

- Articulo Base para ReaccionesDocument11 pagesArticulo Base para ReaccionesValentina Hernandez LopezNo ratings yet

- Simulation of heat transfer and pyrolysis reactions in industrial cracking furnacesDocument15 pagesSimulation of heat transfer and pyrolysis reactions in industrial cracking furnacesTalles CaioNo ratings yet

- Azargohar 2005Document7 pagesAzargohar 2005gueabdelkaderNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsFrom EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsNo ratings yet

- ANSYS PharmaDocument39 pagesANSYS PharmaSrashmiNo ratings yet

- Hydrosystem ArticleDocument2 pagesHydrosystem ArticleSrashmiNo ratings yet

- Ansys Advantage 01 15 PDFDocument56 pagesAnsys Advantage 01 15 PDFSrashmiNo ratings yet

- Miller Axel ANSYS 2013 DetroitDocument26 pagesMiller Axel ANSYS 2013 DetroitSrashmiNo ratings yet

- Ansys Advantage 01 15 PDFDocument56 pagesAnsys Advantage 01 15 PDFSrashmiNo ratings yet

- AA V4 I2 Drilling Into The Heart of Direct ModelingDocument2 pagesAA V4 I2 Drilling Into The Heart of Direct ModelingSrashmiNo ratings yet

- The Right Mix AA V9 I1Document4 pagesThe Right Mix AA V9 I1SrashmiNo ratings yet

- In Vivo in Vitro in Silico AA V9 I1Document5 pagesIn Vivo in Vitro in Silico AA V9 I1SrashmiNo ratings yet

- Overview Leapansysforpharmamixing 170427033834Document16 pagesOverview Leapansysforpharmamixing 170427033834SrashmiNo ratings yet

- Piping ArticleDocument3 pagesPiping ArticleSrashmiNo ratings yet

- BlastDocument2 pagesBlasthosseinnetNo ratings yet

- AMCSEErosioncasestudyby Computational Fluid DynamicsDocument13 pagesAMCSEErosioncasestudyby Computational Fluid DynamicsSrashmiNo ratings yet

- A New Spin On CementDocument2 pagesA New Spin On CementEderlan DiasNo ratings yet

- CFD Duct OptimizationDocument5 pagesCFD Duct OptimizationfaheemqcNo ratings yet

- ANSYS Solutions Spring04Document44 pagesANSYS Solutions Spring04SrashmiNo ratings yet

- Manuscript SandeshDocument10 pagesManuscript SandeshSrashmiNo ratings yet

- Ansys Maxghwell Brochure 14.0Document8 pagesAnsys Maxghwell Brochure 14.0Bahadır AkbalNo ratings yet

- 14.nanoscale Density Functional Theory PDFDocument33 pages14.nanoscale Density Functional Theory PDFSrashmiNo ratings yet

- Try Pass for Free Piping Flow Analysis SoftwareDocument2 pagesTry Pass for Free Piping Flow Analysis SoftwareSrashmi100% (1)

- PASS - EQUIP Vessels Summary SheetDocument2 pagesPASS - EQUIP Vessels Summary SheetSrashmiNo ratings yet

- PASS START-PROF DatasheetDocument2 pagesPASS START-PROF DatasheetSrashmiNo ratings yet

- PASS EQUIP DatasheetDocument2 pagesPASS EQUIP DatasheetSrashmiNo ratings yet

- 14.nanoscale Density Functional Theory PDFDocument33 pages14.nanoscale Density Functional Theory PDFSrashmiNo ratings yet

- PASS - EQUIP-Nozzle Summary SheetDocument2 pagesPASS - EQUIP-Nozzle Summary SheetSrashmiNo ratings yet

- Fatigue, Durability and Fracture Mechanics: Registration FormDocument1 pageFatigue, Durability and Fracture Mechanics: Registration FormSrashmiNo ratings yet

- Resume - Srivalli MS - Mechanical Engineer - 2016-Sep-16Document3 pagesResume - Srivalli MS - Mechanical Engineer - 2016-Sep-16SrashmiNo ratings yet

- Flownex Simulation Environment ModulesDocument4 pagesFlownex Simulation Environment ModulesSrashmiNo ratings yet

- Turbine-Brochure FNXDocument4 pagesTurbine-Brochure FNXSrashmiNo ratings yet

- Classroom Material:: Heat Transfer Fluid Mechanics ThermodynamicsDocument4 pagesClassroom Material:: Heat Transfer Fluid Mechanics ThermodynamicsSrashmiNo ratings yet