Professional Documents

Culture Documents

N50 nitrile rubber data sheet

Uploaded by

Aisha Jan0 ratings0% found this document useful (0 votes)

13 views1 pageOriginal Title

ES-TSF0026-N50

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageN50 nitrile rubber data sheet

Uploaded by

Aisha JanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

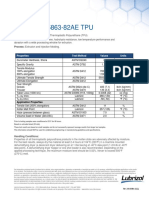

ES-TSF0026

Data Sheet: N50

MATERIAL: NITRILE 50 SHORE

COLOUR: BLACK

GENERAL SERVICE TEMPERATURE RANGE: -35°C to 110°C

SPECIFICATION: ASTMD2000M2BG507B14EF11EF21EO14EO34

PHYSICAL PROPERTIES TEST METHOD REQUIREMENT TEST RESULT

HARDNESS SHORE A ASTM D2240 50+/-5 48

TENSILE STRENGTH, psi ASTM D412 TS≥ 1015 1618

ELONGATION % ASTM D412 E≥ 350 711

B14 COMPRESSION SET

22 hrs @ 100°C % ASTM D395 CS≤ 25 18.7

EF 11 FLUID RESISTANCE, A.OIL, 70 hrs @ 23°C

HARDNESS CHANGE, POINTS ASTM D471 +/-10 +1

TENSILE STRENGTH CHANGE % ASTM D471 -25 -12.55

ELONGATION CHANGE % ASTM D471 -25 -8.86

VOLUME CHANGE % ASTM D471 -5/+10 +0.54

EF21 FLUID RESISTANCE, B.OIL, 70 hrs @ 23°C

HARDNESS CHANGE, POINTS ASTM D471 0/-30 -9

TENSILE STRENGTH CHANGE % ASTM D471 -60 -52.04

ELONGATION CHANGE % ASTM D471 -60 -41.49

VOLUME CHANGE % ASTM D471 0/-40 +12.90

EO14 FLUID RESISTANCE, No.1.OIL, 70 hrs @ 100°C

HARDNESS CHANGE, POINTS ASTM D471 -5/+10 +13

TENSILE STRENGTH CHANGE % ASTM D471 -25 +5.19

ELONGATION CHANGE % ASTM D471 -45 -14.91

VOLUME CHANGE % ASTM D471 -10/+5 -15.90

EO34 FLUID RESISTANCE, No.3.OIL, 70 hrs @ 100°C

HARDNESS CHANGE, POINTS ASTM D471 -10/+5 +7

TENSILE STRENGTH CHANGE % ASTM D471 -45 +14.28

ELONGATION CHANGE % ASTM D471 -45 -26.16

VOLUME CHANGE % ASTM D471 0/+25 -5.57

GLASS TRANSITION TEMPERATURE (TG), °C -35.58

The above test results are based on test slabs / buttons. The results from the actual parts may be different.

Issue Date: 08.05.2013

Unit 2 & 2A Solingen House, T: +44 (0) 1670 840529

Remscheid Way F: +44 (0) 1670 840644

Jubilee Industrial Estate, Ashington E: sales@easternseals.co.uk

Northumberland, NE63 8UJ, UK W: www.easternseals.co.uk

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Es Tsi0244 FFKM8727Document1 pageEs Tsi0244 FFKM8727Suresh KumarNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Es Tsi0259 FFKM8753Document1 pageEs Tsi0259 FFKM8753Suresh KumarNo ratings yet

- ES8067-TS0231-V575-FKM75 Bisphenol Cured - ApprovedDocument2 pagesES8067-TS0231-V575-FKM75 Bisphenol Cured - ApprovedBogdan CăpățînăNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- FKM75 Data Sheet High-Performance Fluorocarbon ElastomerDocument1 pageFKM75 Data Sheet High-Performance Fluorocarbon Elastomerpitrer123No ratings yet

- Es Tsf0010 Aflas70Document1 pageEs Tsf0010 Aflas70Arun JaffersonNo ratings yet

- V75 GF - Viton 75 Type GF Material Data SheetDocument1 pageV75 GF - Viton 75 Type GF Material Data Sheetseeralan_1986No ratings yet

- EPDM Data Sheet - Victaulic CouplingDocument1 pageEPDM Data Sheet - Victaulic CouplingSuresh KumarNo ratings yet

- FFKM 3152 Data SheetDocument1 pageFFKM 3152 Data SheetParth ShahNo ratings yet

- V75mso Viton CompoundDocument1 pageV75mso Viton CompoundRuben HernandezNo ratings yet

- E300 70 Technical ReportDocument1 pageE300 70 Technical ReportDavid Lay IINo ratings yet

- Data Sheet: V GR: Material: Viton 60 Shore - Genuine Dupont PolymerDocument1 pageData Sheet: V GR: Material: Viton 60 Shore - Genuine Dupont PolymerBharat KumarNo ratings yet

- Viton Material - Dopont PDFDocument1 pageViton Material - Dopont PDFKamlesh DalavadiNo ratings yet

- Test Report ConformanceDocument2 pagesTest Report ConformancePriyadarshini KrishnaswamyNo ratings yet

- Mykin Inc Rn00390 Nitrile Compound: General PropertiesDocument1 pageMykin Inc Rn00390 Nitrile Compound: General PropertiesmatteoNo ratings yet

- Toparts Pte LTD: Laboratory ReportDocument1 pageToparts Pte LTD: Laboratory ReportkmulyadiNo ratings yet

- XringDocument2 pagesXringJoão Pedro Marin De GodoiNo ratings yet

- Datasheet V7500AA Viton 75 - Toparts - ApprovedDocument1 pageDatasheet V7500AA Viton 75 - Toparts - ApprovedBogdan CăpățînăNo ratings yet

- Mykin Inc: General PropertiesDocument2 pagesMykin Inc: General PropertiesTrường ĐàoNo ratings yet

- EPDM 70 Specifications PDFDocument1 pageEPDM 70 Specifications PDFfirebolt_hari2006No ratings yet

- Viton-O-Rings-CommercialDocument1 pageViton-O-Rings-CommercialErhanNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- N7047BDocument1 pageN7047B蔡JoNo ratings yet

- MS Black Nitrile Hi Tear 80 Shore Specs 6 22 18Document1 pageMS Black Nitrile Hi Tear 80 Shore Specs 6 22 18Juan UchuyaNo ratings yet

- SN70 Compound Data SheetDocument4 pagesSN70 Compound Data SheetManoj MakholiyaNo ratings yet

- Request Quote 70 Duro NBRDocument2 pagesRequest Quote 70 Duro NBRAlaa SaadNo ratings yet

- Request A Quote: O-Ring Compound HNBR70 Data SheetDocument2 pagesRequest A Quote: O-Ring Compound HNBR70 Data SheetDadangNo ratings yet

- Marco Material Datasheet N1000 PDFDocument2 pagesMarco Material Datasheet N1000 PDFAlaa SaadNo ratings yet

- 70-Duro BunaDocument2 pages70-Duro BunaChang MikeNo ratings yet

- O-Ring Compound Data SheetDocument3 pagesO-Ring Compound Data SheetScarlet BlancoNo ratings yet

- Viton Compound Properties for High Temperature ResistanceDocument1 pageViton Compound Properties for High Temperature ResistanceiswantmachooNo ratings yet

- Cellulose Acetate ButyrateDocument2 pagesCellulose Acetate Butyratenagbocca100% (1)

- 80 NBR 878Document2 pages80 NBR 878adhityaNo ratings yet

- Trirex 3020HF: Polycarbonate ResinDocument5 pagesTrirex 3020HF: Polycarbonate ResinAlbert FortunatoNo ratings yet

- Physical Properties of PVC CPVC PipeDocument1 pagePhysical Properties of PVC CPVC PipeBimal DeyNo ratings yet

- Request Quote for NBR O-Ring MaterialDocument2 pagesRequest Quote for NBR O-Ring MaterialChang MikeNo ratings yet

- Hyvolt IibrochureDocument1 pageHyvolt Iibrochuresamuel cruz menddozaNo ratings yet

- Fluorocarbon Rubber Laboratory Report ResultsDocument1 pageFluorocarbon Rubber Laboratory Report Resultsleidy0529No ratings yet

- Marco Material Datasheet B1105 PDFDocument2 pagesMarco Material Datasheet B1105 PDFAlaa SaadNo ratings yet

- PT Shriya Artha Global - enDocument7 pagesPT Shriya Artha Global - enAryo DanudoroNo ratings yet

- Penetration Bitumen 50-70 CoaDocument1 pagePenetration Bitumen 50-70 CoaU.s. Ezhil ArivudainambiNo ratings yet

- Parker Compound NL153-70 - Material ReportDocument2 pagesParker Compound NL153-70 - Material ReportWMC_PMNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- ETFE Vs ECTFE PDFDocument2 pagesETFE Vs ECTFE PDFpinkNo ratings yet

- Marco Material Datasheet M1005 PDFDocument2 pagesMarco Material Datasheet M1005 PDFRose VillaNo ratings yet

- Marco Material Datasheet V1000Document2 pagesMarco Material Datasheet V1000FinNo ratings yet

- Certificate of Analysis: S-Oil Total Lubricants Co., LTDDocument1 pageCertificate of Analysis: S-Oil Total Lubricants Co., LTDNguyễn Hữu Thiện NhtNo ratings yet

- Megolon S540 PDFDocument2 pagesMegolon S540 PDFMuhammad Shabbir AwanNo ratings yet

- EPDM SpecsDocument1 pageEPDM SpecsRosendo GarcíaNo ratings yet

- Bitumen SpecsDocument5 pagesBitumen SpecsUsman RanaNo ratings yet

- BT 8602Document2 pagesBT 8602Shagun SharmaNo ratings yet

- Material Report: Compound Data SheetDocument2 pagesMaterial Report: Compound Data SheetDouglas GonçalvesNo ratings yet

- PVC Pipe SpecificationsDocument3 pagesPVC Pipe Specificationsguritnoid4775No ratings yet

- Marco Material Datasheet B1001Document2 pagesMarco Material Datasheet B1001flasher_for_nokiaNo ratings yet

- PCN Notification for Fairchild Product Manufacturing ChangeDocument6 pagesPCN Notification for Fairchild Product Manufacturing ChangeFrank CoelhoNo ratings yet

- PBT Data SheetDocument2 pagesPBT Data Sheetabhishek chaudharyNo ratings yet

- NEOPRENE_ RUBBERDocument1 pageNEOPRENE_ RUBBERAnandNo ratings yet

- Medina Side Book Reading Level 1Document70 pagesMedina Side Book Reading Level 1wedanurdayat100% (1)

- Madina Book 1 Arabic Text DR V Abdurrahim PDFDocument120 pagesMadina Book 1 Arabic Text DR V Abdurrahim PDFAisha JanNo ratings yet

- Madina Book 1 Arabic Text DR V Abdurrahim PDFDocument120 pagesMadina Book 1 Arabic Text DR V Abdurrahim PDFAisha JanNo ratings yet

- Madina Book 2 English Key PDFDocument110 pagesMadina Book 2 English Key PDFAisha JanNo ratings yet

- Filler Image RefDocument61 pagesFiller Image RefAisha JanNo ratings yet

- Potential Questions For Class Test 2016Document17 pagesPotential Questions For Class Test 2016Aisha JanNo ratings yet

- Madina Arabic Blank Verb Conjugation SheetDocument1 pageMadina Arabic Blank Verb Conjugation SheetAisha JanNo ratings yet

- Hu2018 Article StudyOnSealingCapacityOfPackinDocument9 pagesHu2018 Article StudyOnSealingCapacityOfPackinAisha JanNo ratings yet

- The road to climate hell: Why we fail to act despite good intentionsDocument7 pagesThe road to climate hell: Why we fail to act despite good intentionsAisha JanNo ratings yet

- Theoreticalbackground PDFDocument25 pagesTheoreticalbackground PDFAisha JanNo ratings yet

- Theoreticalbackground PDFDocument25 pagesTheoreticalbackground PDFAisha JanNo ratings yet

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- How to Build a Tiny Portable House: With Plans and InstructionsFrom EverandHow to Build a Tiny Portable House: With Plans and InstructionsRating: 4 out of 5 stars4/5 (1)

- Building Construction and DrawingFrom EverandBuilding Construction and DrawingRating: 2.5 out of 5 stars2.5/5 (3)

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Markup & Profit: A Contractor's Guide, RevisitedFrom EverandMarkup & Profit: A Contractor's Guide, RevisitedRating: 5 out of 5 stars5/5 (11)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet