Professional Documents

Culture Documents

Nitoproof 30 PDF

Nitoproof 30 PDF

Uploaded by

Dean Hadi WardanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitoproof 30 PDF

Nitoproof 30 PDF

Uploaded by

Dean Hadi WardanaCopyright:

Available Formats

Nitoproof 30* constructive solutions

(Formerly Nitoproof 30HL)

Multi-purpose, rubberised, bitumen emulsion

Uses Properties

Provides a highly effective waterproof membrane, with cost Form : Dark brown liquid

and labour saving supplementary benefits. It can be used in Specific gravity : 1.00

a wide range of applications : Solids content : Approx. 60 %

Rubber content : Approx. 10 %

! Damp proof membrane in ‘sandwich construction’.

Drying time : 30 mins at 25°C

! Dual purpose waterproofer and curing compound. Overcoating time : 1 hour @ 25°C

! General purpose waterproofer for walls and floors.

Instructions for use

! Highly effective vapour seal.

Surface preparation

! Effective as an adhesive/bonding agent for cork panels,

All surfaces must be clean, dry and free from dirt, dust, oil and

insulation boards, expanded polystyrene etc.

grease.

Advantages Application

! Cost saving, material which can be used as a waterproofer Nitoproof 30 should be applied by brush or squeegee to

and curing compound in a single application. prepared surfaces. Stir well before use, replace lid when not

in use. Soak up any spillage with sand or sawdust and wash

! Labour saving, single component material which is also

down immediately.

water based, and therefore non-toxic.

Damp proof membrane and vertical vapour barrier

! Environmentally friendly, non-flammable, asbestos free

and can be used in confined spaces. Apply Nitoproof 30 at the rate of 1m² per litre, to give a minimum

dry film thickness of 600 microns, as per CP102:1973.

! Excellent service life - resistant to chloride and sulphate

ions. For vertical applications, ensure that there is no material sag.

This can be best achieved by multiple coat applications at a

! Versatile - highly extensible.

maximum rate of 200 microns per coat. For multiple coat

application, the second coat should be applied at right angles

Standards compliance

to the first. All applications should be continued up verticals to

Nitoproof 30 complies with the concrete curing requirements the existing damp proof course. Ensure that the membrane

of ASTM C309, when applied at the rate of 4m2 per litre. is not punctured or damaged during subsequent applications.

Where the surface is to receive a render or plaster finish, a

Description

keyed surface should be formed by ‘gritting’ the second coat

Nitoproof 30 is a rubber reinforced, bitumen emulsion. It is with clean, dry sand. Allow a minimum of 48 hours drying

supplied as a single component liquid, dark brown in colour, period before applying a plaster, render or floor screed.

which dries to form a black, flexible coating.

Flooring adhesive

Nitoproof 30 is available in drums and may be applied directly

Nitoproof 30 is a very effective waterproof adhesive for laying

to the substrate by brush or squeegee.

wood blocks, cork, asphalt and asbestos tiles. The surface

should be clean, dry and smooth. Nitoproof 30 should be

Specification

applied to the floor screed using a notched trowel, and then

Where shown on the contract documents, below ground left to become tacky after which the tiles should be pressed

surfaces shall be protected with Nitoproof 30, a rubberised firmly into place.

bitumen emulsion, applied at the rate of 1 m2 per litre giving

Any contamination of the tile’s upper surface should be

a total dry film thickness of minimum 600 microns.

cleaned immediately using a cloth - refer to any special

recommendations made by the tile manufacturer.

Nitoproof 30*

Nitoproof 30*

Adhesive for insulation Estimating

Nitoproof 30 is suitable for bonding insulation materials such Supply

as polystyrene, fibreboard and cork slabs to walls and floors. Nitoproof 30 : 20 and 200 litre drums

The two surfaces to be bonded must be clean, level and free Theoretical coverage

from all points of contact. Nitoproof 30 should be applied to

(actual coverage rates will depend upon substrate porosity)

both surfaces and left to become tacky (colour begins to

darken). The two surfaces should then be pressed firmly and

General use : 1m² per litre to give 600

evenly together.

microns dft

Repairs Curing compound : 4m2 per litre per coat

to give 150 micron dft

Any damaged areas can be readily overcoated to restore the

membrane continuity - provided the surface is properly

Storage

prepared.

Nitoproof 30 will have a minimum shelf life of 12 months if

Cleaning

stored in normal warehouse conditions at less than 40°C.

Nitoproof 30 can be removed using only clean water, whilst

still damp. If left to dry, then Fosroc Solvent 102* must be Precautions

used.

Fire

Limitations Fosroc Solvent 102 is flammable. Ensure adequate

! Nitoproof 30 is not a structural adhesive, therefore ventilation, do not use near a naked flame and do not smoke

mechanical fixing should be used where appropriate. during use.

! Application should not commence below 6°C or above Flash point

45°C. Fosroc Solvent 102 : 33°C

! Avoid application during windy atmospheric conditions.

Health and safety

Application during such periods might cause cracking.

! For application in harsh climatic conditions, ‘Nitoproof Some people are sensitive to resins and solvents, so gloves

600’ is recommended. and barrier creams (e.g. Kerodex Antisolvent) should be used

when handling these products. Remove any contamination

from the skin with soap and water, or resin removing creams

(e.g. Kerocleanse Standard Grade Skin Cleaner) followed by

washing with soap and water. Do not use solvent.

The use of goggles is also recommended, but should

accidental eye contamination occur, wash thoroughly with

plenty of clean water and seek medical treatment immediately.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard

Conditions for the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s

responsibility to obtain the recent version. Refer to www.fosroc.com.

Head Office

Al Gurg Fosroc telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

LLC Regional offices

Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

Post Box 657, Dubai Bahrain, YBA Kanoo telephone: 17735454 fax: 17732828 email: bahrain@fosroc.com

United Arab Emirates Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

www.fosroc.com

Qatar, Tadmur telephone: 4500607 fax: 4500543 email: qatar@fosroc.com

UAE/0237/07/G

You might also like

- HSE PLAN Generic RA PDFDocument5 pagesHSE PLAN Generic RA PDFテレブリコ ジェファーソン100% (1)

- Air Cooler Cleaner (Acc) Is A Liquid Blend of Highly Active CleaningDocument5 pagesAir Cooler Cleaner (Acc) Is A Liquid Blend of Highly Active CleaningAbdul AnisNo ratings yet

- APPLIED PHYSICS Bonding in Solids by CHARIS ISRAEL ANCHADocument17 pagesAPPLIED PHYSICS Bonding in Solids by CHARIS ISRAEL ANCHACharis Israel Ancha100% (1)

- Pipe RoutingDocument4 pagesPipe RoutingJaykumarNo ratings yet

- Pharmacy Critical CareDocument136 pagesPharmacy Critical CareTohShengPoo100% (1)

- HemodialysisDocument22 pagesHemodialysisAlyssa Agravante100% (3)

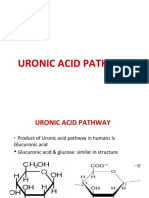

- 12 Uronic Acid PathwayDocument21 pages12 Uronic Acid PathwayAnand VeerananNo ratings yet

- Determining Decarburization and Carburization F2328Document2 pagesDetermining Decarburization and Carburization F2328Ali MohsinNo ratings yet

- Nitoproof 30Document2 pagesNitoproof 30Balasubramanian Ananth0% (1)

- Nitoproof 230 PDFDocument2 pagesNitoproof 230 PDFmilanbrasinaNo ratings yet

- Nitoproof 100 PDFDocument2 pagesNitoproof 100 PDFmilanbrasinaNo ratings yet

- Nitoproof 110 PDFDocument2 pagesNitoproof 110 PDFmilanbrasinaNo ratings yet

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Nitofill Ur63Document3 pagesNitofill Ur63Balasubramanian AnanthNo ratings yet

- Nitocote EN901Document4 pagesNitocote EN901kalidindivenkatarajuNo ratings yet

- Nitoproof 120 PDFDocument2 pagesNitoproof 120 PDFmilanbrasinaNo ratings yet

- Nitofill UR63 : Flexible Polyurethane Injection Resin SystemDocument4 pagesNitofill UR63 : Flexible Polyurethane Injection Resin SystemmilanbrasinaNo ratings yet

- Nitoproof 600Document4 pagesNitoproof 600sandeepuaeNo ratings yet

- Nitofill WS60Document3 pagesNitofill WS60Balasubramanian AnanthNo ratings yet

- Nitoproof 600 PDFDocument4 pagesNitoproof 600 PDFmilanbrasinaNo ratings yet

- Nitoproof 110Document2 pagesNitoproof 110Jude Peter Benjamin100% (1)

- Nitocote cm210Document4 pagesNitocote cm210Venkata RaoNo ratings yet

- Nitoproof 600Document4 pagesNitoproof 600Venkata RaoNo ratings yet

- Nitofill Ur63Document4 pagesNitofill Ur63pravi3434No ratings yet

- Nitoproof 10 PDFDocument2 pagesNitoproof 10 PDFmilanbrasinaNo ratings yet

- Nitoflor FC150Document4 pagesNitoflor FC150Mohammad Abu Al-ToyourNo ratings yet

- Nitofill WS60 : Crack Injection Resin For Stopping Water FlowDocument4 pagesNitofill WS60 : Crack Injection Resin For Stopping Water FlowmilanbrasinaNo ratings yet

- Nitomortar ElDocument4 pagesNitomortar ElBalasubramanian AnanthNo ratings yet

- (PDS) Nitoproof 30Document4 pages(PDS) Nitoproof 30ari_prasNo ratings yet

- Nitocote EN901Document4 pagesNitocote EN901ArieIndrawanNo ratings yet

- Brush BondDocument4 pagesBrush BondVenkata RaoNo ratings yet

- Nitoproof 600Document4 pagesNitoproof 600Balasubramanian AnanthNo ratings yet

- 1 DT 2.8 Preparation FillercoatDocument4 pages1 DT 2.8 Preparation Fillercoatyoxan25808No ratings yet

- Nitomortar FCDocument2 pagesNitomortar FCManish SonowaneNo ratings yet

- Nitoflor Eu50Document4 pagesNitoflor Eu50Venkata RaoNo ratings yet

- Brushbond: Acrylic Polymer Modified Protective and Decorative Coating For Concrete and MasonryDocument3 pagesBrushbond: Acrylic Polymer Modified Protective and Decorative Coating For Concrete and MasonryTori SmallNo ratings yet

- Dulux Trade Ecosure Plaster PrimerDocument5 pagesDulux Trade Ecosure Plaster PrimerEl Bekkari MohamedNo ratings yet

- Nitomortar MHDocument4 pagesNitomortar MHmilanbrasinaNo ratings yet

- Nitoseal 125Document2 pagesNitoseal 125Hantu TuahNo ratings yet

- (PDS) Conbextra EP300Document4 pages(PDS) Conbextra EP300Faizal HaziziNo ratings yet

- Brushbond PDFDocument4 pagesBrushbond PDFpravi3434No ratings yet

- Fosroc Nitocote PE135: Constructive SolutionsDocument2 pagesFosroc Nitocote PE135: Constructive SolutionsRaed Naim KhammashNo ratings yet

- Nitoseal 290Document4 pagesNitoseal 290shanon33No ratings yet

- Nitocote PE135Document2 pagesNitocote PE135Dejan MicicNo ratings yet

- Conbextra EP300Document4 pagesConbextra EP300Venkata Raju KalidindiNo ratings yet

- Nitoproof 100Document2 pagesNitoproof 100Balasubramanian AnanthNo ratings yet

- Concure DPM PDFDocument2 pagesConcure DPM PDFmilanbrasinaNo ratings yet

- Nitocote Ep410Document4 pagesNitocote Ep410pravi3434No ratings yet

- Nitoseal PU 280 PDFDocument2 pagesNitoseal PU 280 PDFhelloitskalaiNo ratings yet

- Nitocote Ep403Document4 pagesNitocote Ep403pravi3434No ratings yet

- Nitocote Et402Document4 pagesNitocote Et402Venkata Rao100% (1)

- Nitomortar ELDocument4 pagesNitomortar ELmilanbrasinaNo ratings yet

- Nitofill WS60: Uses PropertiesDocument4 pagesNitofill WS60: Uses PropertiesVenkata RaoNo ratings yet

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- 1 DT 6.4 Speciality HichemepoxyenamelDocument5 pages1 DT 6.4 Speciality Hichemepoxyenamelyoxan25808No ratings yet

- Nitoseal 130Document2 pagesNitoseal 130Venkata RaoNo ratings yet

- Nitocote HT120Document4 pagesNitocote HT120Venkata Raju KalidindiNo ratings yet

- Nitoproof 30 PDFDocument2 pagesNitoproof 30 PDFEndraNo ratings yet

- Conbextra EP10Document2 pagesConbextra EP10MuhammedHafis100% (1)

- Nitofix : Constructive SolutionsDocument2 pagesNitofix : Constructive SolutionsmilanbrasinaNo ratings yet

- FOSROC Nitoproof 30 SubmittalDocument21 pagesFOSROC Nitoproof 30 Submittallensa jijiNo ratings yet

- Nitocote EPW100: Water Dispersed Epoxy Coating and SealerDocument2 pagesNitocote EPW100: Water Dispersed Epoxy Coating and SealerVenkata Raju KalidindiNo ratings yet

- Brushbond (1) FosrocDocument4 pagesBrushbond (1) FosrocVedachalam ManiNo ratings yet

- Fosroc Dekguard PU: Constructive SolutionsDocument4 pagesFosroc Dekguard PU: Constructive SolutionsganmosesNo ratings yet

- Nitoflor FC150Document4 pagesNitoflor FC150Venkata Raju KalidindiNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- s1gb KFRDocument4 pagess1gb KFRMehdi BouzariNo ratings yet

- SDS Calcium CarbonateDocument5 pagesSDS Calcium CarbonatesyahimiNo ratings yet

- Fibre Reinforced Concrete New Design PerspectivesDocument21 pagesFibre Reinforced Concrete New Design PerspectivesHendrik TaupanNo ratings yet

- C1Document1 pageC1BenePicarNo ratings yet

- Cerium Oxide and Its Nanocomposites Structure, Synthesis, and WastewaterDocument15 pagesCerium Oxide and Its Nanocomposites Structure, Synthesis, and Wastewaterstarr1No ratings yet

- Battery MaintDocument84 pagesBattery MaintPrateek MathurNo ratings yet

- Paper Class 2021AL Tute 34 A3 DsDocument4 pagesPaper Class 2021AL Tute 34 A3 DsBlueNo ratings yet

- Rust Prevention For Parts in Shipment PDFDocument2 pagesRust Prevention For Parts in Shipment PDFAnonymous alQXB11EgQNo ratings yet

- PS 70690 IC Eluent Suppressors PS70690 enDocument19 pagesPS 70690 IC Eluent Suppressors PS70690 enMondommeg SohanemNo ratings yet

- Acoustic Insulation MaterialsDocument11 pagesAcoustic Insulation Materialskesavaganesan58No ratings yet

- DNA As A Genetic MaterialDocument4 pagesDNA As A Genetic MaterialPronali BorahNo ratings yet

- Simplified Focus Area Notes Ii CorrDocument8 pagesSimplified Focus Area Notes Ii Corrwargod RAMZNo ratings yet

- Gauge Blocks: Product Catalogue Ver 1.0Document5 pagesGauge Blocks: Product Catalogue Ver 1.0Juliana chenNo ratings yet

- Emissivity - WikipediaDocument12 pagesEmissivity - WikipediaOmer TokhNo ratings yet

- BioChem Part 3-4Document98 pagesBioChem Part 3-4Mavill Joy CarreonNo ratings yet

- GujCET Chemistry 2010Document5 pagesGujCET Chemistry 2010nayan159100% (1)

- Worship Mudzana Project ProposalDocument2 pagesWorship Mudzana Project Proposaltapiwa guy nyamukapaNo ratings yet

- Final Lect 6 English.Document63 pagesFinal Lect 6 English.xaaabbb_550464353No ratings yet

- Spectrometrie de MasaDocument13 pagesSpectrometrie de MasaLara LarukNo ratings yet

- Challenges and Opportunities in Lactic Acid Bioprocess Design PDFDocument21 pagesChallenges and Opportunities in Lactic Acid Bioprocess Design PDFRafael RubioNo ratings yet

- Chapter 1 Biochem (Carbo)Document30 pagesChapter 1 Biochem (Carbo)harminder singhNo ratings yet