Professional Documents

Culture Documents

Flange Lug Design

Flange Lug Design

Uploaded by

sushil0 ratings0% found this document useful (0 votes)

26 views11 pagesFLANGE LUG DESIGN

Original Title

FLANGE LUG DESIGN

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFLANGE LUG DESIGN

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views11 pagesFlange Lug Design

Flange Lug Design

Uploaded by

sushilFLANGE LUG DESIGN

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

420 Pressure Vessel Dasign Manual

PROCEDURE 7-7

DESIGN OF FLANGE LUGS

Trarsporaion an Becton of Pressure Vessels 421

Tobie 79

[boa capa | po —

venas es ‘ s | “ ©

100 ' 5 a I 3 14 2 | 2a 38 a

200 6 T 4 18 16 » 40

400 8 5 | 5 20 6 | | nd

0 3 3 A a 2 s 'e

[ro 7 2 7 = = 2 = *

teble 710

peaae

[ious] Am = [ewee| ee to]

oss [owe | one | 8 | Dame am |

lows} vom [aww ee 2

ors | owe [ae | ase aww

‘oersa | oor de = zee 8a 50 we

[re ome} oa sp se] 7 ee

nasa | ome om | 7686s

8 7 as =

115-8 es woo) 786 |

tee [er vse wo ee pet waa

tase [ ews zo ve

Tobie 741

wens

[exo aa

a [= en

_ = oe

eas ae

[oom as ae

422 Pressure Vessel Design Manual

‘Top Flange Lug

Side Flange Lug

ay

PLaP sina

Pra P owe

ren Pe

Moa ryB

My = Pritt J)

Ms = Pre

My =X, coven Ny

Mat

uM

eM,

Xi = Bi covey,

yy 7B sine

TA 078A,

BOR. < Fy a0 ist

Transporation and Erection of Pressure Vessels 423

Design Process

1} Determine lols

2. Cheek of lug

4. Shear al pin hate

b. Bending of Ing

© Bearing at pi B

3. Cheek of hime ple

4. Cheek of seal lange

5. cheek of fa

6. Cheek of lea! lol at nozzle ro esa ne shel jonetion,

Step [ Betevnmine ads

Detenonime lols Py ana Py

Decermane uniform losik s

Using. aul, solve for worst case ae

Deteroine wens

op 2 Check of Ine,

44 Shear at pin bale

2 ave gu

© Arve anata

eet)

huge to M

Section mntadas %

# Beng stro, ag, 0

Mw

“

Becaring at pan ole

© Bearing required at pin hele

hy

A,

Fy

8 Bearings avait,

A

Dat,

ve grins bt sales

weed; Hoe sarin a

ined ka, Py

ine healing misneat in hig, ML

4,

TTD) mee

ry

Pe aw

Bending monet, MM

Mosl

424

Pressure Vessel Design Manual

Bolt Loads for Rectangular Lugs

Design of Full Circular Base Plate for Lug

Ha full exculur plates sed in low of a rtangala pate

the following evahation may he used,

fo

Unit load on Bott erate,

we a

© Hage distance from point of Toad, ty,

# Bending ste, 0,

om

© Cheek bulline same as rectonarle

‘Transportation and Erection of Pressure Vessels 425

Design of Lug Base Plate Unfors load

From Bt J. Roark, Formate for Sires and Strain, Merve v%

HiIl tsk Co, le Eton, Table HIE, Case 34 weg

8 Eivl reaction. By

K

‘TL TT . Ls -

- - | eh bovis! 30 cae

wae SE aw aan

BA Mone wd My

. MMF BT,

™ I | Thickness required ty

)

“i Sa sk

426 Pressure Vessel Dasign Manual

Check of Bolts

Case I: Bolts on Centerline Case 2: Bolts Straddle Centerline

Teanspomiation and Erection af Pressure Vessels 427

Sample Problem: Top Flange Lug

& 2

aes

|

| -

Given Bok see = 41/48 UNC

Ay 83in2

Ls =n

78862

L: = 0 ‘

ban ty =392kips

bash Hobs

F, holting = 75 ksi mm

© = ain

hug = 36st

A=20n

flange = bbs)

y= 93in

F046) = 1%

. yobs

fy = 94496) = 21.6bs J

Fi, = 06644) = 25.76 ks

Wy = 10h Results

= 5tin

Pp may 58T hips @ @= 1

P= 1200 kips @ #90

Thips @ 0=410

Ths |

. as [sn | an) mo) sa ss | os | wm | oe

7 amo ee | veer] em | ae] er | er 108) ato

os vine [tee | seo 7 ee a ec a

Coast) sie) sty) oss) we) aw | ase ina

Lowa) sis) ws) tee | as) ee | es ss | nae

T. bots (10) 6.94 698 683 647 585 5.08 a3 308 wT

Tots) 79) see | sey) as | ame ae | oat) far

Shep 7 Goch tos

Case 1: N= (10) Bolts: “Case 2 Bolts.

tee 7a] as

com) | ats) ae com | owes ors

t o 78S 3.52 10.33, 16.44

% ae z 7a

, 0} mes | wre as) sao) ats | Be aa

we. oes | teen ten) aaae | asi prota

F ope) ee ce)

fF wom | tan hs | aa |e

10 Check Lug

4. Shear at pin hal

© Aw rgnaced, A

A, = (4h) (Dh) = B16) (9-6) = 9048

Fh Boning of hag dee to My

© Masivnr women, ME

My = Pye = 587(16) = 8592 = K

© Seetion mun, Z

AY 628)

© Beading steoss, tag. 0

My _ S592)

ay Fig 7 MO st

Thickness veguived, t

M

Tat

se

4 =

STH)

© Reasmg at pin ole

ng rane at

© Bearing avai

Ay — Daf) 8-8 = 45

20 Check Lug Base Place

f# Porn toad w

‘Transportation and Erection of Pressure Vessels 428

f# Buul rack

= 634.5ips

# Bly: moment M

WA POUK Gib AIAY 5a

aap LB. B b

“coc th ssi eam

= SM in ps

et

went at midspan M

Moe ME Rit 2 . ]

4

My = 8040 6 17.240 — A891 — Shin. haps

Sects moddadus. 7

UEC) 16 am)

ye) _ 8

= 440in

6 6

Banding sires,

© Mlowable b

ugatrows Fi

= 0.66, = 0.66436) = 28.

30 Check of Vessel Flange

etn

load,

Bending moment My

Mus who =

1.8) — 68.25 naps

490 Pressure Vasse! Design Manval

Top Flange Lugs—Alternate Construction

— tp Blanes Tage Alternate Cs -

50-Ton Capacity 400-Ton Capacity

26.a- aye toe bet

\ Oo

200-Ton Capacity 600-Ton Capacity

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Summery of Changes ASME DIV 1Document8 pagesSummery of Changes ASME DIV 1sushilNo ratings yet

- Bins and Elevated TanksDocument10 pagesBins and Elevated TankssushilNo ratings yet

- Chapter 3 Design Methodology: 3.1 IntroductionDocument10 pagesChapter 3 Design Methodology: 3.1 Introductionsushil100% (2)

- Wind Desgin As Per Ubc-97Document2 pagesWind Desgin As Per Ubc-97sushilNo ratings yet

- Design of TrunionDocument3 pagesDesign of TrunionsushilNo ratings yet

- Davits DesignDocument5 pagesDavits DesignsushilNo ratings yet

- Hydraulic Cylinder Side LoadDocument8 pagesHydraulic Cylinder Side LoadsushilNo ratings yet

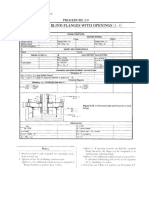

- Blind Flanges With OpeningsDocument1 pageBlind Flanges With OpeningssushilNo ratings yet

- Design of Vessels With Refractory LiningsDocument7 pagesDesign of Vessels With Refractory LiningssushilNo ratings yet